Professional Documents

Culture Documents

Overview: Overview:: Oil Painting Oil Painting

Uploaded by

Sachin PetleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overview: Overview:: Oil Painting Oil Painting

Uploaded by

Sachin PetleCopyright:

Available Formats

Means of production refers to physical, non-human inputs used in productionthe factories, machines, and tools used to produce wealth.

Engineering is cause and technology is the effect. Engineering is a lot of theory. Technology or technologists do more hands on applications. Engineering is the application of scientific and technical knowledge to solve human problems. Engineers use imagination, judgment and reasoning to apply science, technology, mathematics, and practical experience. The result is the design, production, and operation of useful objects or processes Technology refers to all tools and procedures and their interconnections

Overview:

Overview:

Deals with descriptions. Data can be observed but not measured. Colors, textures, smells, tastes, appearance, beauty, etc. Qualitative Quality

Deals with numbers. Data which can be measured. Length, height, area, volume, weight, speed, time, temperature, humidity, sound levels, cost, members, ages, etc. Quantitative Quantity

Example 1: Oil Painting

Example 1: Oil Painting

Qualitative data:

Quantitative data:

blue/green color, gold frame smells old and musty texture shows brush strokes of oil paint peaceful scene of the country masterful brush strokes

picture is 10" by 14" with frame 14" by 18" weighs 8.5 pounds surface area of painting is 140 sq. in. cost $300

Production Technology:

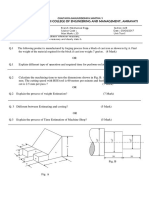

A system for scheduling the manufacture of products and managing stock inventory that aims to optimize costs, minimize inventory and maintain a steady work flow. The modern production technology that might be used by a manufacturing business can identify production blockages and sense capacity constraints, and it does not usually operate at full capacity if sufficient inventory to meet demand already exists. Production technology is the study, development and implementation of sources, and invention of products as well as the improvement in current products. Planning, implementation, and control of industrial production processes to ensure smooth and efficient operation. Production management techniques are used in both manufacturing and service industries. Production management responsibilities include the traditional five M's: men , machines, methods, materials, and money, product, price,promotion,place,pepole, product,plant,process,programme,people Metrology : The science that deals with measurement. A system of measurement. The primary goal of statistical quality control is to maintain and improve processes through techniques such as sampling and process improvement projects, which reduce variations in product. Statistical process control uses control charts to monitor changes in processes, machinery, labor or the environment. Inspections and sampling determine when a process is outside of the control parameters, which can result in a reduction in quality Q. 1)Concept of qaulity ? We have all probably felt that sense of disappointment when something we have purchased does not live up to expectations. It could be a CD that is scratched and does not play properly, a new car with a number of rattles or the customer service department who dont return your call. At the heart of meeting such expectations is the notion of quality. People define quality in many ways. Some think of quality as superiority or excellence, others view it as a lack of manufacturing and service defects, still others think of quality as related to product features or price. A study that asked managers of 86 firms in the eastern United States to define quality produced several dozen different responses including Perfection Consistency Eliminating wastes Speed of delivery Compliance with policies and procedures Providing a good, sable product Doing it right the first time

Pleasing customers Total customer service and satisfaction Reduce the total cost of the Product

The quality movement can trace its roots back to medieval Europe, where craftsmen began organizing into unions called guilds in the late 13th century. Until the early 19th century, manufacturing in the industrialized world tended to follow this craftsmanship model. The factory system, with its emphasis on product inspection, started in Great Britain in the mid-1750s and grew into the Industrial Revolution in the early 1800s. In the early 20th century, manufacturers began to include quality processes in quality practices. After the United States entered World War II, quality became a critical component of the war effort: Bullets manufactured in one state, for example, had to work consistently in rifles made in another. The armed forces initially inspected virtually every unit of product; then to simplify and speed up this process without compromising safety, the military began to use sampling techniques for inspection, aided by the publication of military-specification standards and training courses in Walter Shewharts statistical process control techniques. The birth of total quality in the United States came as a direct response to the quality revolution in Japan following World War II. The Japanese welcomed the input of Americans Joseph M. Juran and W. Edwards Deming and rather than concentrating on inspection, focused on improving all organizational processes through the people who used them .

Definition of Quality Books, Quality Gurus, Definition of Quality Quality Institutes Joseph M Juran Quality is fitness for use

Eugene Lodewick Quality is convenient to think of all matters related to Q of Grant & Richard S manufactured product in terms of these functions of --Leavenworth specification, production and inspection. Philip B Crosby W Edwards Deming Quality is conformance to requirement, it is respect to Humanity. Quality should be aimed at the needs of the consumer present and future. Armand Feigenbaum V Quality is the total product and service characteristics of maintenance

marketing, engineering, manufacturing and

through which the product and service in use will meet the expectation of the customer.

Shigeru Mizuno

Product quality encompasses those characteristics which the product must possess, if it is to be used in the intended manner.

Genechi Teguchi

Quality is the loss (from function variation and harmful effects) a product causes to society after being shipped, other than any losses caused by its intrinsic functions.

ISO 9000

Planned

and

systematic

actions

necessary

to

provide

adequate confidence that a product or service will satisfy given requirements for quality. American National Totality of the features and characteristics of a product that bears on its ability to satisfy the stated or implied needs.

Standards Institute

The Taylor System

Late in the 19th century the United States broke further from European tradition and adopted a new management approach developed by Frederick W. Taylor. Taylors goal was to increase productivity without increasing the number of skilled craftsmen. He achieved this by assigning factory planning to specialized engineers and by using craftsmen and supervisors, who had been displaced by the growth of factories, as inspectors and managers who executed the engineers plans. Taylors approach led to remarkable rises in productivity, but it had significant drawbacks: Workers were once again stripped of their dwindling power, and the new emphasis on productivity had a negative effect on quality. To remedy the quality decline, factory managers created inspection departments to keep defective products from reaching customers. If defective product did reach the customer, it was more common for upper managers to ask the inspector, Why did we let this get out? than to ask the production manager, Why did we make it this way to begin with?

Quality controls, is a process by which entities review the quality of all factors involved in production. Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer. This approach places an emphasis on three aspects

1) Elements such as controls, job management, defined and well managed processes performance and identification of records 2)Competence, such as knowledge, skills, experience, and qualifications 3)Soft elements, such as personnel integrity, confidence, organizational culture, motivation, team spirit, and quality relationships. Customer :- Automotive mirror manufacturer Challenge:-Maintain quality control to keep continuous supply of products to avoid line shutdown Solution:-Anixters technical services teams stringent quality control measures. Results Randomly tested products regardless of source location Standardized fasteners used in production Manufactured parts to specification Benefits Achieved zero parts per million defects Expanded quality offerings/Stand as good quality product Reduced shipping and freight time and costs

Challenge

, Meet or exceed regulatory requirements and release product as quickly as possible.

Solution

, Lab associates implement 5S principles, sorting material and equipment, setting everything in order by storing it in

common and highly visible locations, standardizing labels and driving sustainability with daily, weekly and monthly checklists.

Results

QC labs achieved zero observations following their most recent FDA audit. The inspectors even used the laboratories 5S processes to train their staff in best manufacturing practices. From a customer point of view, testing lead times remains constant at industryleading levels of less than five days, despite a five-fold increase in output for critical drugs. increase the production rate, cost is reduced, testing leadtime reduced. .Sort, Sort in order, shine,standardize,sustiability.

Quality Control Objective : Improved company income,Cost reduction, Interchangability,Optrimum Quality at min price,customers satifications,Quality mindness

Quality Characteristics: Appearance (dimension, chemical, sensory), performance, length of life, dependability, reliability, durability, smell, taste, feel, sound, price.

The cost of carrying out company quality function (meeting the quality needs of the customer) know as cost of quality

Value of Quality: with superior quality the company can earn higher share of market, firmer prices, few returns and complaint from the customers. It is this effect on income which makes quality to have value. Hence makes the return direct or indirect gained by the manufacturers due to mission of quality control. Value of quality composed of: 1) Value inherent in the design 2) Value inherent in the conformance to that design. The value inherent in the design usually called as grade. Grade is the variation in the specification for the same functional use. Difference in grade may involve difference in: Life of the product, appearance, interchangeability, reliability, versatility, ability to take occasional overloads luxury features etc. Quality Specification: A specification is a definition of design. The design remains a concept mind of the designer until the he defines it through verbal description, sample, drawing etc. The quality specification includes,

1) 2) 3) 4) 5) 6)

Specification of tolerance on various parts. Material specification. Process specification. Method of test Criteria for acceptance and rejection Method of use. One Specification may be necessary or separate specification may be necessary to desired quality characteristics in the material, parts products etc.

Need of specification 1) It helps the manufacturing departments to know what exactly is to be produced. 2) The raw material, process, equipments, skill etc. required producing the product of designed quality. 3) To discriminate between defective and non defective products. 4) To decide test standards, inspections and test devices required. 5) To decide what is the exact requirements of the buyers. Once a definition is available any one of the parties in the industries can communicate any other and use the shorthand description to define a complex product. Inspection: means checking of the material, products or components of products at various stages in manufacturing. It includes 1) The interpretation of a specification. 2) Measurements of the product. 1) Receiving Inspection 2) In process Inspection 3) Finished good inspection 4) To maintain customer relationship 5) Gauge Maintains 6) Test Equipments maintains 7) Decision of Salvage.

Inspection means checking the characteristics of a product to ensure that conformity to a set of specifications is met. Sometimes it means checking 100% of a batch of product; sometimes it means checking only some samples (in that latter case, it is exactly the same as "statistical quality control".

Quality control usually means only checking the conformity of products already made. It comprises inspection and other tests such as lab tests. Some people use quality control to designate some more upstream activities that aim at preventing quality issues (usually these activities are called "quality assurance").

Acceptance Function Finished Good Only inspection Special Instrument needed

Prevention Function Data analysis for design of experiments. Several Procedure and methods No special needed

The cost of carrying out company quality function (meeting the quality needs of the customer) know as cost of quality

Value of Quality: with superior quality the company can earn higher share of market, firmer prices, few returns and complaint from the customers. It is this effect on income which makes quality to have value. Hence makes the return direct or indirect gained by the manufacturers due to mission of quality control. Value of quality composed of: 3) Value inherent in the design 4) Value inherent in the conformance to that design. The value inherent in the design usually called as grade. Grade is the variation in the specification for the same functional use. Difference in grade may involve difference in: Life of the product, appearance, interchangeability, reliability, versatility, ability to take occasional overloads luxury features etc. Quality Specification: A specification is a definition of design. The design remains a concept mind of the designer until the he defines it through verbal description, sample, drawing etc. The quality specification includes,

7) 8) 9) 10) 11) 12)

Specification of tolerance on various parts. Material specification. Process specification. Method of test Criteria for acceptance and rejection Method of use. One Specification may be necessary or separate specification may be necessary to desired quality characteristics in the material, parts products etc.

Need of specification 6) It helps the manufacturing departments to know what exactly is to be produced. 7) The raw material, process, equipments, skill etc. required producing the product of designed quality. 8) To discriminate between defective and non defective products. 9) To decide test standards, inspections and test devices required. 10) To decide what is the exact requirements of the buyers. Once a definition is available any one of the parties in the industries can communicate any other and use the shorthand description to define a complex product. Inspection: means checking of the material, products or components of products at various stages in manufacturing. It includes 1) The interpretation of a specification. 2) Measurements of the product. 2) Receiving Inspection 2) In process Inspection 3) Finished good inspection 4) To maintain customer relationship 5) Gauge Maintains 6) Test Equipments maintains 7) Decision of Salvage.

Inspection means checking the characteristics of a product to ensure that conformity to a set of specifications is met. Sometimes it means checking 100% of a batch of product; sometimes it means checking only some samples (in that latter case, it is exactly the same as "statistical quality control".

Quality control usually means only checking the conformity of products already made. It comprises inspection and other tests such as lab tests. Some people use quality control to designate some more upstream activities that aim at preventing quality issues (usually these activities are called "quality assurance").

Acceptance Function Finished Good Only inspection Special Instrument needed

Prevention Function Data analysis for design of experiments. Several Procedure and methods No special needed

Quality assurance (QA) refers to the planned and systematic activities implemented in a quality system so that quality requirements for a product or service will be fulfilled. It is the systematic measurement, comparison with a standard, monitoring of processes and an associated feedback loop that confers error prevention. This can be contrasted with Quality "Control", which is focused on process outputs. Two principles included in QA are: "Fit for purpose", the product should be suitable for the intended purpose; and "Right first time", mistakes should be eliminated. QA includes management of the quality of raw materials, assemblies, products and components, services related to production, and management, production and inspection processes

Assurance Function Special techniques are needed

Inspection planning market quality determination

Collecting data can be easy and fun. But sometimes it can be hard to tell other people about what you have found. Thats why we use statistics. Two kinds of statistics are frequently used to describe data. They are measures of central tendency and dispersion. These are often called descriptive statistics because they can help you describe your data. Mean, median and mode These are all measures of central tendency. They help summarize a bunch of scores with a single number. Suppose you want to describe a bunch of data that you collected to a friend for a particular variable like height of students in your class. One way would be to read each height you recorded to your friend. Your friend would listen to all of the heights and then come to a conclusion about how tall students generally are in your class But this would take too much time. Especially if you are in a class of 200 or 300 students! Another way to communicate with your friend would be to use measures of central tendency like the mean, median and mode. They help you summarize bunches of numbers with one or just a few numbers. They make telling people about your data easy. Range, variance and standard deviation These are all measures of dispersion. These help you to know the spread of scores within a bunch of scores. Are the scores really close together or are they really far apart? For example, if you were describing the heights of students in your class to a friend, they might want to know how much the heights vary. Are all the men about 5 feet 11 inches within a few centimeters or so? Or is there a lot of variation where some men are 5 feet and others are 6 foot 5 inches? Measures of dispersion like the range, variance and standard deviation tell you about the spread of scores in a data set. Like central tendency, they help you summarize a bunch of numbers with one or just a few numbers

An external customer of an organization is a customer who is not directly connected to that organization.[7][8]

An internal customer is a customer who is directly connected to an organization, and is usually (but not necessarily) internal to the organization. Internal customers are usually stakeholders, employees, or shareholders, but the definition also encompasses creditors and external regulators.[9][8]

Strengthened competitive position Adaptability to changing or emerging market conditions and to environmental and other government regulations Higher productivity Enhanced market image Elimination of defects and waste Reduced costs and better cost management Higher profitability Improved customer focus and satisfaction Increased customer loyalty and retention Increased job security Improved employee morale Enhanced shareholder and stakeholder value Improved and innovative processes

In statistics and probability theory, standard deviation (represented by the symbol ) shows how much variation or "dispersion" exists from the average (mean, or expected value). A low standard deviation indicates that the data points tend to be very close to the mean, whereas high standard deviation indicates that the data points are spread out over a large range of values.

the descriptive statistics, the range is the length of the smallest interval which contains all the data. It is calculated by subtracting the smallest observation (sample minimum) from the greatest (sample maximum) and provides an indication of statistical dispersion. It is measured in the same units as the data. Since it only depends on two of the observations, it is a poor and weak measure of dispersion except when the sample size is large. Variance is the sum of the square of the deviation from the arithmetic mean divided by the no. Of observation. ` n` in the other words variance is the square of the sta. deviations.

Standard deviation is a number that tells you approximately how far the values in a data set deviate from the mean (the average).

wo types of process data: 1. Variable: continuous data. Things we can measure. Example includes length, weight, time, temperature, diameter, etc. 2. Attribute: discrete data. Things we count. Examples include number or percent defective items in a lot, number of defects per item etc.

You might also like

- TQM 1st UnitDocument66 pagesTQM 1st Unitraja0% (1)

- QualityDocument12 pagesQualityIsabel MalicdanNo ratings yet

- Unit IV - Stastical Quality ControlDocument34 pagesUnit IV - Stastical Quality ControlSai KethavarapuNo ratings yet

- Introduction to Quality ManagementDocument53 pagesIntroduction to Quality ManagementKarma AkabaneNo ratings yet

- Total Quality Management: R. Nat NatarajanDocument14 pagesTotal Quality Management: R. Nat NatarajanVanessa D'souzaNo ratings yet

- Operation Management ReviewerDocument65 pagesOperation Management ReviewerMariel Anne DulaNo ratings yet

- Unit 1: Fitness For Use Grade Degree of Preference Degree of Excellence Conformity To RequirementsDocument12 pagesUnit 1: Fitness For Use Grade Degree of Preference Degree of Excellence Conformity To RequirementsNivethithaa DhanrajNo ratings yet

- Lecture 2: Quality Management EssentialsDocument46 pagesLecture 2: Quality Management EssentialsWei HuaiNo ratings yet

- Introduction to Quality Management FundamentalsDocument47 pagesIntroduction to Quality Management FundamentalsLovely CabuangNo ratings yet

- TQM Review Lecture 2010Document97 pagesTQM Review Lecture 2010Vicky de ChavezNo ratings yet

- Ôm Ôm Ôm Ôm ÔmDocument8 pagesÔm Ôm Ôm Ôm ÔmMithun BMNo ratings yet

- Quality in The Medieval Guilds of EuropeDocument26 pagesQuality in The Medieval Guilds of EuropeFB MemesNo ratings yet

- Value ChainDocument6 pagesValue ChainSyed NazrulNo ratings yet

- Quality Characteristics and DimensionsDocument17 pagesQuality Characteristics and DimensionsRaulNo ratings yet

- Evolution of Quality ConceptsDocument25 pagesEvolution of Quality ConceptsYiğit IlgazNo ratings yet

- Mata Kuliah QC Iwan PratamDocument75 pagesMata Kuliah QC Iwan PratamIwan PratamaNo ratings yet

- TQM & Om: TQM Customer-Driven Quality ManagementDocument24 pagesTQM & Om: TQM Customer-Driven Quality ManagementsadfiziaNo ratings yet

- Quality AssuranceDocument37 pagesQuality AssuranceUsama AnsariNo ratings yet

- The Conceptsof Quality ControlDocument6 pagesThe Conceptsof Quality ControlCOMRADE GOODLUCK CHUKWUNo ratings yet

- Quality Control FundamentalsDocument19 pagesQuality Control FundamentalsSushant KaseNo ratings yet

- TQM Questions and AnswersDocument19 pagesTQM Questions and AnswersYogeesha HCNo ratings yet

- Quality Control: Concept, Quality GurusDocument59 pagesQuality Control: Concept, Quality GurusPurnajit BhowmikNo ratings yet

- SQL IntroductionDocument46 pagesSQL IntroductionYitages kefelewNo ratings yet

- Lecture 3 - Fundamentals of Quality ManagmentDocument14 pagesLecture 3 - Fundamentals of Quality ManagmentNhật Hạ LêNo ratings yet

- Mukiwa TQM Examination and AnswersDocument8 pagesMukiwa TQM Examination and AnswersMadalitso MukiwaNo ratings yet

- Quality Assurance, or QA For Short, Is The Set of Planned and Systematic ActionsDocument24 pagesQuality Assurance, or QA For Short, Is The Set of Planned and Systematic Actions0921py100% (1)

- Bahan Quality ManagementDocument89 pagesBahan Quality ManagementBambang SugihartoNo ratings yet

- Authors:-: Chandrashekar.H.S & Mahantesh.V.NDocument16 pagesAuthors:-: Chandrashekar.H.S & Mahantesh.V.NMahantesh NadagoudaNo ratings yet

- UMP Faculty of Engineering Quality Control FundamentalsDocument58 pagesUMP Faculty of Engineering Quality Control FundamentalsAswaja313No ratings yet

- Quality AssuranceDocument8 pagesQuality AssuranceElzubair MirghaniNo ratings yet

- TQMDocument150 pagesTQMDanger CatNo ratings yet

- TQMDocument51 pagesTQMTanviSheikhNo ratings yet

- Unit I: Quality ManagementDocument22 pagesUnit I: Quality ManagementMohdazeem KhanNo ratings yet

- L02-Project Quality ManagementDocument44 pagesL02-Project Quality ManagementMUHAMMAD AZEEM KhanNo ratings yet

- Apparel Lecture1!Document10 pagesApparel Lecture1!Md Ahasan HabibNo ratings yet

- Quality ManagementDocument52 pagesQuality ManagementarNo ratings yet

- Lecture Note On Statistical Quality ControlDocument25 pagesLecture Note On Statistical Quality ControlGanesh BabuNo ratings yet

- QualityDocument55 pagesQualityBharath BalasubramanianNo ratings yet

- Quality Control in Apparel ManufacturingDocument160 pagesQuality Control in Apparel ManufacturingAbu AsadNo ratings yet

- 11 Quality Control & AssuranceDocument33 pages11 Quality Control & AssuranceJiten BendleNo ratings yet

- To Study Taguchi'S Stretegy For Design of Experiments.: A Seminar Report ONDocument54 pagesTo Study Taguchi'S Stretegy For Design of Experiments.: A Seminar Report ONashwani kaushikNo ratings yet

- Group 1 Foundation of TQMDocument9 pagesGroup 1 Foundation of TQMSweetMikanNo ratings yet

- Introduction Quality ManuscriptDocument8 pagesIntroduction Quality ManuscriptKristine Mae SampuangNo ratings yet

- Modeling and Control of Manufacturing SystemDocument47 pagesModeling and Control of Manufacturing Systemjanel_tingNo ratings yet

- Productivity and QMDocument78 pagesProductivity and QMDhananjay SharmaNo ratings yet

- CHAPTER 5 - Quality ManagementDocument21 pagesCHAPTER 5 - Quality ManagementJohn TuahNo ratings yet

- Quality Assurance & QUALITY CONTROldocDocument15 pagesQuality Assurance & QUALITY CONTROldocapi-19786321No ratings yet

- Chapter 20Document41 pagesChapter 20Amer RahmahNo ratings yet

- Introduction To QualityDocument36 pagesIntroduction To QualityMarjorieSarsateBlancoNo ratings yet

- PROTON'S TOUGH ATTITUDE ON QUALITY SHOWING RESULTSDocument28 pagesPROTON'S TOUGH ATTITUDE ON QUALITY SHOWING RESULTSWoon HowNo ratings yet

- Quality Assurance: "Quality Engineering" Redirects Here. For The Journal, SeeDocument5 pagesQuality Assurance: "Quality Engineering" Redirects Here. For The Journal, Seeaditya2053No ratings yet

- IE 135 NotesDocument19 pagesIE 135 NotesPaul Rainer De VillaNo ratings yet

- Japan's Post-War Economic Success Through Quality ManagementDocument534 pagesJapan's Post-War Economic Success Through Quality ManagementDaniel Armstrong100% (1)

- Introduction To Quality: Assist. Prof. Dr. Özlem Türker Bayrak A 206-B Ozlemt@cankaya - Edu.trDocument60 pagesIntroduction To Quality: Assist. Prof. Dr. Özlem Türker Bayrak A 206-B Ozlemt@cankaya - Edu.trShubham SharmaNo ratings yet

- Manage Quality ExcellenceDocument8 pagesManage Quality ExcellenceIris CastilloNo ratings yet

- 1 Introduction To Statistical Quality ControlDocument20 pages1 Introduction To Statistical Quality Controljher18No ratings yet

- Introduction to Total Quality Management (TQMDocument29 pagesIntroduction to Total Quality Management (TQMMadhav ShenoyNo ratings yet

- Taguchi on Robust Technology Development: Bringing Quality Engineering UpstreamFrom EverandTaguchi on Robust Technology Development: Bringing Quality Engineering UpstreamRating: 1 out of 5 stars1/5 (1)

- PUT Sample Paper PMDocument2 pagesPUT Sample Paper PMSachin PetleNo ratings yet

- Intro 2 Me ChengDocument25 pagesIntro 2 Me ChengSachin PetleNo ratings yet

- Hosts UmbrellaDocument1 pageHosts UmbrellaFabsor SoralNo ratings yet

- SachinbuoyancyDocument8 pagesSachinbuoyancySachin PetleNo ratings yet

- Aarambh Coaching Classes: Admission FormDocument2 pagesAarambh Coaching Classes: Admission FormSachin PetleNo ratings yet

- Youth Festival Information Broucher 20170001Document21 pagesYouth Festival Information Broucher 20170001Sachin PetleNo ratings yet

- Mechanical From Not Fill UpDocument4 pagesMechanical From Not Fill UpSachin PetleNo ratings yet

- Oriental University, Indore: Application FormDocument2 pagesOriental University, Indore: Application FormSachin PetleNo ratings yet

- 6me04 Theory of Machines IIDocument5 pages6me04 Theory of Machines IISachin PetleNo ratings yet

- Module 8 Ress43Document75 pagesModule 8 Ress43Lohanathan VkNo ratings yet

- Que Paper SBP Imc Unit Test-IDocument1 pageQue Paper SBP Imc Unit Test-ISachin PetleNo ratings yet

- 01 BKB 01 PDocument36 pages01 BKB 01 PSachin PetleNo ratings yet

- Pulsar 200 Parts CatalogueDocument37 pagesPulsar 200 Parts CataloguePersada79% (24)

- Sae Team ChroniclestudentDocument4 pagesSae Team ChroniclestudentSachin PetleNo ratings yet

- G H Raisoni College of Enggeneering & Management Amravati: Subject: Submission of Envelopes Winter-2016 ExaminationDocument2 pagesG H Raisoni College of Enggeneering & Management Amravati: Subject: Submission of Envelopes Winter-2016 ExaminationSachin PetleNo ratings yet

- What Is AnnealingDocument2 pagesWhat Is AnnealingSachin PetleNo ratings yet

- ReceiptDocument1 pageReceiptSachin PetleNo ratings yet

- 06-09-16 Daily Report Sem-VII Sec-B Mechanical Engg W16Document2 pages06-09-16 Daily Report Sem-VII Sec-B Mechanical Engg W16Sachin PetleNo ratings yet

- 2 G H 2 G H 2 G (2 H) 2 G (1+h)Document1 page2 G H 2 G H 2 G (2 H) 2 G (1+h)Sachin PetleNo ratings yet

- Youth Festival TeamDocument2 pagesYouth Festival TeamSachin PetleNo ratings yet

- G H Raisoni College of Engineering and Management, Amravati Department of Civil Engineering Academic Year 2016-17 Class Test - IIDocument1 pageG H Raisoni College of Engineering and Management, Amravati Department of Civil Engineering Academic Year 2016-17 Class Test - IISachin PetleNo ratings yet

- BE Final FormatDocument30 pagesBE Final FormatSachin PetleNo ratings yet

- 1 MarksDocument1 page1 MarksSachin PetleNo ratings yet

- 08-08-16 Daily Report - Mechanical Engg - VII Sem Section A - W16Document2 pages08-08-16 Daily Report - Mechanical Engg - VII Sem Section A - W16Sachin PetleNo ratings yet

- Revised Time Table of S-16 Practical ExamDocument6 pagesRevised Time Table of S-16 Practical ExamSachin PetleNo ratings yet

- G H Raisoni College of Engineering and Management, Amravati: File No.Document1 pageG H Raisoni College of Engineering and Management, Amravati: File No.Sachin PetleNo ratings yet

- Eemmcqsem 3Document4 pagesEemmcqsem 3Sunil PKNo ratings yet

- Not Return Books List 2016Document13 pagesNot Return Books List 2016Sachin PetleNo ratings yet

- Learn 3Ds-MAX Modeling and RenderingDocument3 pagesLearn 3Ds-MAX Modeling and RenderingSachin PetleNo ratings yet

- Customer AnalysisDocument44 pagesCustomer Analysissimply_coool100% (2)

- Name: - Class: Form 4 - Economics Quiz # 2Document2 pagesName: - Class: Form 4 - Economics Quiz # 2Rafena MustaphaNo ratings yet

- Section 1, Seat No.4: Product Box CompanyDocument106 pagesSection 1, Seat No.4: Product Box CompanyKoy'z Vilailuk RadchakidNo ratings yet

- Study Cafe Business Plan by Vijay, Manish and MohitDocument24 pagesStudy Cafe Business Plan by Vijay, Manish and MohitMohit Vats100% (1)

- 103 - Marketing ManagementDocument14 pages103 - Marketing ManagementRiyaz BabwaniNo ratings yet

- ERP Case Study: Lessons from Hershey's Implementation FailureDocument22 pagesERP Case Study: Lessons from Hershey's Implementation FailureVarun Mehrotra100% (2)

- Industrial MKTDocument88 pagesIndustrial MKTpsiholocoNo ratings yet

- Case Study Ent300Document20 pagesCase Study Ent300hyukgotthatsomething50% (2)

- Lecture 6 - Ports of MalaysiaDocument68 pagesLecture 6 - Ports of Malaysiashuting2teoh100% (6)

- Logistics and Supply Chain Integration - 289 PDFDocument289 pagesLogistics and Supply Chain Integration - 289 PDFvupro219100% (4)

- Wipro Consumer Care and Lighting: Fast-Growing FMCG CompanyDocument1 pageWipro Consumer Care and Lighting: Fast-Growing FMCG CompanynishantsingamNo ratings yet

- BPO Whitepaper Business Process Transformation 0512-1Document8 pagesBPO Whitepaper Business Process Transformation 0512-1Ganesh BabuNo ratings yet

- The US Fresh Produce Value Chain The US Fresh Produce Value ChainDocument45 pagesThe US Fresh Produce Value Chain The US Fresh Produce Value ChainBalapekNo ratings yet

- NestleDocument31 pagesNestlekrupamayekarNo ratings yet

- Cultural and Social Influences On The Perception of Beauty: A Case Analysis of The Cosmetics Industry - Kenneth A. Hunt, Jennifer Fate, Bill DoddsDocument10 pagesCultural and Social Influences On The Perception of Beauty: A Case Analysis of The Cosmetics Industry - Kenneth A. Hunt, Jennifer Fate, Bill DoddsZovem Se HristinaNo ratings yet

- New Product Development Process Hindustan UnileverDocument38 pagesNew Product Development Process Hindustan UnileverSiddhant Sagar86% (7)

- Tariffs and Trade BarriersDocument7 pagesTariffs and Trade BarriersVara PrasadNo ratings yet

- Diff: Topic: Why Study Economics? Skill: FactDocument10 pagesDiff: Topic: Why Study Economics? Skill: FactgadgdagadgaNo ratings yet

- Index Number (MBA)Document6 pagesIndex Number (MBA)Veerendranath NaniNo ratings yet

- Distribution Channels and Supply Chain Management ExplainedDocument26 pagesDistribution Channels and Supply Chain Management ExplainedRavimohan RajmohanNo ratings yet

- Comparative Study of Tools of Promotion MixDocument22 pagesComparative Study of Tools of Promotion Mixmonirba4850% (2)

- MarketResearchCareers Announces The Market Research Industry's 2019 Thought Leading SuppliersDocument3 pagesMarketResearchCareers Announces The Market Research Industry's 2019 Thought Leading SuppliersPR.comNo ratings yet

- 2016 Students ch04 - Lovelock - Developing Service Products - 6e - STUDENTDocument36 pages2016 Students ch04 - Lovelock - Developing Service Products - 6e - STUDENTbold onyxNo ratings yet

- Operations Management: Location StrategyDocument21 pagesOperations Management: Location StrategyMarty DelimaNo ratings yet

- Trend Hunter Sample Custom Report Pop Up ShopsDocument76 pagesTrend Hunter Sample Custom Report Pop Up ShopsYeison PalenciaNo ratings yet

- 4.fashion Term, CycleDocument42 pages4.fashion Term, CycleTreesa Chitra Jos100% (4)

- A Level Economics Papers Nov2010 PDFDocument97 pagesA Level Economics Papers Nov2010 PDFLincolnt LeeNo ratings yet

- Logistics in Supply ChainDocument16 pagesLogistics in Supply ChainajaymeshramNo ratings yet

- 6 Choosing Brand ElementsDocument53 pages6 Choosing Brand ElementsFaisal ChishtiNo ratings yet

- Import Substitution: A Strategy for Local Economic DevelopmentDocument13 pagesImport Substitution: A Strategy for Local Economic DevelopmentRhea VermaNo ratings yet