Professional Documents

Culture Documents

14 Common Syn0 S

Uploaded by

DanielOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14 Common Syn0 S

Uploaded by

DanielCopyright:

Available Formats

Commissioning Common Functions

Comm_Common page 01

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

DR-SM150

page 02

List of Contents

1.1 Required Software-Tools ........................................................................................ 6

1.2 Drive Firmware ....................................................................................................... 8

1.3 Structure and Content of the CFC ......................................................................... 10

1.4 Getting the PG/PC Installation ready to handle the SM150-project ...................... 12

1.5 Registering Library FBA121 .................................................................................. 14

1.6 Getting the Project ready for the download to the CFC ........................................ 18

1.7 Downloading the Project ........................................................................................ 20

1.9 Exemplary SM150 Application ............................................................................... 22

1.10 Drive Devices, Components and Topology of a typical Project ............................ 24

1.11 Project with three Power Sections in parallel ........................................................ 26

2.1 Checking Cabling and Voltage Supplies ............................................................... 28

2.2 Checking the Communication Network in HW-Config ...................................... 30

2.3 Rebooting the Controllers ...................................................................................... 32

2.4 Checking the Communication Network in NetPro ............................................ 34

2.5 Setting the IP-Address on the PG/PC .................................................................... 36

2.6 Assigning the PG/PC to ETHERNET in NetPro .................................................... 38

2.7 Going Online to D445 and Downloading the Drive Devices ................................. 40

2.8 Defaulting the DC-Master and setting the Node-Address via PMU ...................... 44

2.9 Going Online and Downloading the Project Data via Drive Monitor ..................... 46

2.10 Adapting Parameters to particular Plant Conditions ............................................. 52

2.11 Loading the OP177 ................................................................................................ 56

2.12 General Content and Structure of the DCC-charts ................................................ 66

2.13 Assigning the Code to activate DCC-charts ........................................................ 68

2.14 Clearing faults and alarms on behalf of the DC-Master ........................................ 78

2.15 Clearing faults and alarms (on behalf of the ET200 stations) ............................... 84

2.16 Forcing a control command via ET200 .................................................................. 92

2.18 Adding field messages to the fault monitoring ....................................................... 104

2.19 Selection of the active cooling pump ..................................................................... 108

2.20 Defining properties for the ET200 analog modules ............................................... 112

2.21 Controlling the drives operation via OP177 .......................................................... 114

2.22 Stamping the Power Stack Adapters (PSA) .......................................................... 116

S

I

T

R

A

I

N

1.3 Structure and Content of the CFC ......................................................................... 10

1.4 Getting the PG/PC Installation ready to handle the SM150-project ...................... 12

1.5 Registering Library FBA121 .................................................................................. 14

1.6 Getting the Project ready for the download to the CFC ........................................ 18

1.7 Downloading the Project ........................................................................................ 20

1.9 Exemplary SM150 Application ............................................................................... 22

1.10 Drive Devices, Components and Topology of a typical Project ............................ 24

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 01

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

1.1 Required Software-Tools ........................................................................................ 6

1.2 Drive Firmware .......................................................................................................

1.3 Structure and Content of the CFC ......................................................................... 10

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 03

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

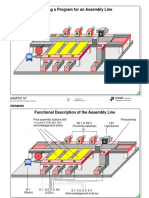

Training Rack

ET200 Motor

ET200 Auxiliaries

Control

Electronics

Synchronous Motor

with Induction Motor

DC-Master

Motor

Module

G120 Load Generator Infeed

OP177

Bus Coupler

DR-SM150

page 04

Preface

This training section covers all essential steps of commissioning a SM150 medium voltage converter as used in

rolling-mill applications.

With the inevitable exception of the medium voltage hardware the SM150 training unit is equipped with the same

components as will be found in typical rolling-mill applications of SM150:

- individually controlled power sections for Active Line Module and Motor Module

- original control electronics (processor boards, option components) including the Power Stack Adapters

- separate ET200 stations for the motor periphery (MOT-ET) and the auxiliaries (HIB-ET)

- DC-Master to provide the excitation current for the synchronous motor

- OP177 for local control of the SM150

The programming within the project used for this training is based on an original site project with very few exceptions;

in consequence all steps of commissioning a SM150 converter with synchronous motor can be carried out on the

training unit in quite the same way as at site.

Naturally, the commissioning of the medium voltage hardware cannot be included in this training.

Apart from the training for which this material is prepared it can well be used as guideline and reference material for

plant commissioning. In this case, however, the particular link of the plant periphery to the drive controllers (via PLC,

TMxx, ) has to be considered and the plant periphery has to be included in the commissioning sequence as well.

Wherever you do any commissioning work, please strictly observe the five safety rules.

- Switch off the power supply on all poles

- Verify the de-energized condition

- Ensure against unauthorized re-energizing (lock-out, tag-out)

- Ground and short circuit the power terminals on all poles

- Cover or fence off adjacent live components

S

I

T

R

A

I

N

This training section covers all essential steps of commissioning a SM150 medium voltage converter as used in

With the inevitable exception of the medium voltage hardware the SM150 training unit is equipped with the same

components as will be found in typical rolling-mill applications of SM150:

- individually controlled power sections for Active Line Module and Motor Module

- original control electronics (processor boards, option components) including the Power Stack Adapters

- separate ET200 stations for the motor periphery (MOT-ET) and the auxiliaries (HIB-ET)

- DC-Master to provide the excitation current for the synchronous motor

- OP177 for local control of the SM150

The programming within the project used for this training is based on an original site project with very few exceptions;

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

This training section covers all essential steps of commissioning a SM150 medium voltage converter as used in

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 03

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Synchronous Motor

with Induction Motor

Comm_Common page 05

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Software Tools and Licenses

Simotion CFC

Active Line Module

and Motor Module

DC-Master OP177

SIMATIC Manager

SIMOTION SCOUT

STARTER integrated

DRIVE ES

DriveMonitor

WinCC flexible

DR-SM150

page 06

1 Preparatory Steps

1.1 Required Software-Tools

To have access to the programming of a SM150-converter as used in rolling-mill applications a number of software-

tools and their respective licenses have to be installed on the PG/PC. At the PG/PC used for the training these tools

and licenses are installed already.

Verify that all the required software-tools are installed and that the respective licenses are available.

S

I

T

R

A

I

N

1.1 Required Software-Tools

To have access to the programming of a SM150-converter as used in rolling-mill applications a number of software-

tools and their respective licenses have to be installed on the PG/PC. At the PG/PC used for the training these tools

and licenses are installed already.

Verify that all the required software-tools are installed and that the respective licenses are available.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

To have access to the programming of a SM150-converter as used in rolling-mill applications a number of software-

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 05

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Comm_Common page 07

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Matching the Software Tool to the Firmware

Content of the Compact Flash Card

Version of the Tool SIMOTION SCOUT

DR-SM150

page 08

1.2 Drive Firmware

As a general rule, the versions of the software-tools have to match the drives firmware. This applies in particular to

the version of SIMOTION SCOUT in relation to the firmware of the SM150.

Create file directory SCOUT: > Temp_Trainee; if it should already exist, delete all its content.

Using Explorer and a card reader, copy the entire content of the Flash Card of SIMOTION D445 to directory

SCOUT:\ Temp_Trainee\D445_CFC.

Execute the routine remove hardware safely (button at the right end of the bottom line) before removing the CFC and

the card reader; put the D445 CFC back into controller D445.

Open tool SCOUT and verify that the version of SIMOTION SCOUT and the firmware of the SM150 are a matching

pair.

S

I

T

R

A

I

N

the version of SIMOTION SCOUT in relation to the firmware of the SM150.

Create file directory SCOUT: > Temp_Trainee; if it should already exist, delete all its content.

Using Explorer and a card reader, copy the entire content of the Flash Card of SIMOTION D445 to directory

SCOUT:\ Temp_Trainee\D445_CFC.

Execute the routine remove hardware safely (button at the right end of the bottom line) before removing the CFC and

the card reader; put the D445 CFC back into controller D445.

Open tool SCOUT and verify that the version of SIMOTION SCOUT and the firmware of the SM150 are a matching

pair.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

s a general rule, the versions of the software-tools have to match the drives firmware. This applies in particular to

the version of SIMOTION SCOUT in relation to the firmware of the SM150.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 07

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Comm_Common page 09

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Hardware Description Data, Ident-Files and User Data

Vector-related ACX-data and Ident-file for the Motor-Module Power Stack (PSA)

Infeed-related ACX-data and Ident-file for the Line-Module Power Stack (PSA) / port X105

V

e

c

t

o

r

-

r

e

l

a

t

e

d

u

s

e

r

d

a

t

a

I

n

f

e

e

d

-

r

e

l

a

t

e

d

u

s

e

r

d

a

t

a

DR-SM150

page 10

1.3 Structure and Content of the CFC

Check the content of the Compact Flash Card to identify the Hardware Description Data, the Ident-files both for the

Infeed and for the Motor Module and the User Data:

A) Hardware Description Data (DESCxxxx.ACX) define converter properties such as power section data (voltage,

current) and the actual value monitoring on the PSA

B) Ident-files (ident_xx.bin) assign the allocation of the PSA to its application as Infeed for SM150, Motor Module

for SM150, Motor Module for GM150 etc.

C) User Data (PSxxxxxx.ACX) contain the parameterization of the individual objects of the drive devices Infeed,

Motor Module and Simotion programming (PSxxxx00.ACX to PSxxxx99.ACX).

In case of parallel Infeeds, the data for the second Infeed (port X104) respectively the third Infeed (port X103) are

located in \Data\14\... respectively in \Data\13\...

Check whether file fba121V23_0_simotion4_1_1.zip is available on C:\Programme\Siemens\Step7\u7umc\data\dcc

(file fba has to be installed on the same drive as SCOUT; SCOUT must be installed on drive C only!).

If this library already exists on your PG/PC, then please delete it to be able to go through the steps required for its

registering (not a normal approach, just for the sake of training).

S

I

T

R

A

I

N

Infeed and for the Motor Module and the User Data:

A) Hardware Description Data (DESCxxxx.ACX) define converter properties such as power section data (voltage,

current) and the actual value monitoring on the PSA

B) Ident-files (ident_xx.bin) assign the allocation of the PSA to its application as Infeed for SM150, Motor Module

for SM150, Motor Module for GM150 etc.

C) User Data (PSxxxxxx.ACX) contain the parameterization of the individual objects of the drive devices Infeed,

Motor Module and Simotion programming (PSxxxx00.ACX to PSxxxx99.ACX).

In case of parallel Infeeds, the data for the second Infeed (port X104) respectively the third Infeed (port X103) are

located in \Data\14\... respectively in \Data\13\...

Check whether file fba121V23_0_simotion4_1_1.zip is available on C:\Programme\Siemens\Step7\u7umc\data\dcc

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

heck the content of the Compact Flash Card to identify the Hardware Description Data, the Ident-files both for the

Infeed and for the Motor Module and the User Data:

A) Hardware Description Data (DESCxxxx.ACX) define converter properties such as power section data (voltage,

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 09

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Vector-related ACX-data and Ident-file for the Motor-Module Power Stack (PSA)

M

A

T

E

R

I

A

L

Comm_Common page 11

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Running the Project on the PG/PC

deletes the old compilation in full

deletes modifications only

left

mouse

click

right mouse click >

open object

DR-SM150

page 12

1.4 Getting the PG/PC Installation ready to handle the SM150-project

As (typically) found in plant commissioning the SM150-project is provided as a zipped file (project archive) for the

training as well. Here it is part of the CFC-content by the name Yas_syn0.zip in file 0_Training.

Open the SIMATIC Manager and delete project Yas_Syn0 if it should already exist (File > Delete > Yas_Syn0 > OK).

Now retrieve project Yas_syn0.zip from file Temp_Trainee > 0_Training into the prompted directory

(SCOUT:\Programme\Siemens\Step7\S7Proj).

Select any one of the three SM150 drive devices you find via Yas_Syn0 > Obermotor G2 (Yask_CX32 / Infeed,

Yask_SINAMICS_Vector / Motor Module, D445_Master / SIMOTION program) and open SCOUT:

- left mouse click (lMC) on the drive device in the navigator-section and

- right mouse click (rMC) on the drive device in the worksheet-section > Open Object

In SCOUT start the routine Save project and REcompile all. You will observe that the compilation output lists a

considerable number of error messages. These error messages indicate that a library required for the compilation of

DCC-charts used in the project is missing. Specifically it is the library FBA121 which contains DCC functions used in

rolling-mill applications.

The project for the SM150 can only be compiled and downloaded if this library is available (registered) on the PG/PC.

S

I

T

R

A

I

N

training as well. Here it is part of the CFC-content by the name Yas_syn0.zip in file 0_Training.

Open the SIMATIC Manager and delete project Yas_Syn0 if it should already exist (File > Delete > Yas_Syn0 > OK).

Now retrieve project Yas_syn0.zip from file Temp_Trainee > 0_Training into the prompted directory

(SCOUT:\Programme\Siemens\Step7\S7Proj).

Select any one of the three SM150 drive devices you find via Yas_Syn0 > Obermotor G2 (Yask_CX32 / Infeed,

Yask_SINAMICS_Vector / Motor Module, D445_Master / SIMOTION program) and open SCOUT:

- left mouse click (lMC) on the drive device in the navigator-section and

- right mouse click (rMC) on the drive device in the worksheet-section > Open Object

In SCOUT start the routine Save project and

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

1.4 Getting the PG/PC Installation ready to handle the SM150-project

As (typically) found in plant commissioning the SM150-project is provided as a zipped file (project archive) for the

training as well. Here it is part of the CFC-content by the name Yas_syn0.zip in file 0_Training.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 11

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

old compilation in full

ons only

Comm_Common page 13

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Registering the DCC-Library FBA121

before

inserting

the

library

Enter

Enter

Enter

after

inserting

the

library

DR-SM150

page 14

1.5 Registering Library FBA121

Exit SCOUT to be able to register library FBA121 (processes u7bt04ax.exe or u7wwbfax.exe must not be running!).

Register the library as follows:

- copy the library fba121V23_0_simotion4_1_1.zip from your source to directory

Programme\Siemens\Step7\u7umc\data\dcc

- call up the DOS-prompt (Start > Programme > Zubehr > Eigabeaufforderung)

- call directory programme\siemens\step7\u7umc\data\dcc

- ask for the content via dir

- request the registry of the library via inst_dcc_lib fba121v23_0_simotion4_1_1

S

I

T

R

A

I

N

- copy the library fba121V23_0_simotion4_1_1.zip from your source to directory

Programme\Siemens\Step7\u7umc\data\dcc

- call up the DOS-prompt (Start > Programme > Zubehr > Eigabeaufforderung)

- call directory programme\siemens\step7\u7umc\data\dcc

- ask for the content via dir

- request the registry of the library via inst_dcc_lib fba121v23_0_simotion4_1_1

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

xit SCOUT to be able to register library FBA121 (processes u7bt04ax.exe or u7wwbfax.exe must not be running!).

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 13

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Comm_Common page 15

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Importing required DCC-Libraries

mark library TPfba121 library is imported

DR-SM150

page 16

After the successful installation close the DOS-prompt and select the library in SCOUT:

- right mouse click (RMC) on D445 > Select technology packages

- in addition to already marked technology packages select fba121_SIMOTION. and dcblib_SIMOTION. > OK

Now update the DCC-libraries in SCOUT > DCC:

- open any of the DCC-charts in D445 > PROGRAMS

- access the import of libraries via Options > Block Types > OK

- mark library TPfba121_SIMOTION, transfer it to Imported libraries ( button >> ), mark library

TPdcblib_SIMOTION, transfer it to Imported libraries and Accept the request of the Import of the two libraries

- ignore the warning messages

- exit the DCC-chart

S

I

T

R

A

I

N

- in addition to already marked technology packages select fba121_SIMOTION. and dcblib_SIMOTION. > OK

Now update the DCC-libraries in SCOUT > DCC:

- open any of the DCC-charts in D445 > PROGRAMS

- access the import of libraries via Options > Block Types > OK

- mark library TPfba121_SIMOTION, transfer it to Imported libraries ( button >> ), mark library

TPdcblib_SIMOTION, transfer it to Imported libraries and Accept the request of the Import of the two libraries

- ignore the warning messages

- exit the DCC-chart

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

After the successful installation close the DOS-prompt and select the library in SCOUT:

- right mouse click (RMC) on D445 > Select technology packages

- in addition to already marked technology packages select fba121_SIMOTION. and dcblib_SIMOTION. > OK

Now update the DCC-libraries in SCOUT > DCC:

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 15

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

library is imported

Comm_Common page 17

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Getting the Project Ready for the Download to the CFC

deletes the old

compilation in full

DR-SM150

page 18

1.6 Getting the Project ready for the download to the CFC

In SCOUT again start the routine Save project and REcompile all. Once finished without errors, initiate the step

Check consistency.

If no consistency errors are signaled, the project (the user directories for the Infeed rsp. the Motor Module and the

Simotion programming) is ready to be downloaded to the CFC either via D445 with the CFC inserted or directly to the

CFC via card-reader.

For either of the two approaches, the CFC has to have a Simotion specific boot section (invisible via card-reader)

and the firmware for Sinamics SM150. At this step of training these preconditions are satisfied.

In the given situation user files for the Infeed and the Motor Module already exist on the CFC; they will subsequently

be overwritten by the download of the project (with no user files on the CFC these files will appear only after having

them loaded to the file system followed by a power-on initialization).

S

I

T

R

A

I

N

If no consistency errors are signaled, the project (the user directories for the Infeed rsp. the Motor Module and the

Simotion programming) is ready to be downloaded to the CFC either via D445 with the CFC inserted or directly to the

CFC via card-reader.

For either of the two approaches, the CFC has to have a Simotion specific boot section (invisible via card-reader)

and the firmware for Sinamics SM150. At this step of training these preconditions are satisfied.

In the given situation user files for the Infeed and the Motor Module already exist on the CFC; they will subsequently

be overwritten by the download of the project (with no user files on the CFC these files will appear only after having

them loaded to the file system followed by a power-on initialization).

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

1.6 Getting the Project ready for the download to the CFC

In SCOUT again start the routine Save project and

If no consistency errors are signaled, the project (the user directories for the Infeed rsp. the Motor Module and the

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 17

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 19

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Downloading the Project to the CFC

only for Simotion technology,

irrelevant for SM150

DR-SM150

page 20

1.7 Downloading the Project

Insert the CFC in the card-reader and connect it to one of the USB-ports of the PG/PC; identify which directory is set

up for the Compact Flash Card.

Directory for SIMOTION_D: . . . . . . .

Download project Yas_Syn0 to the CFC:

- in SCOUT, RMC on D445 > Load to file system > Save normally

- button Select target > select the drive identified for the CFC > OK

- acknowledge the request to overwrite the existing user data

Verify that the ACX-data and the Ident-files are located on the CFC (\ADDON\DATA\...) both for the Infeed and for

the Motor Module; else copy them from a suitable source to their respective location.

l.8 AIIcnfIon socIfIc IuIso Infforns >onIy for InformnfIo l.8 AIIcnfIon socIfIc IuIso Infforns >onIy for InformnfIo l.8 AIIcnfIon socIfIc IuIso Infforns >onIy for InformnfIo l.8 AIIcnfIon socIfIc IuIso Infforns >onIy for InformnfIon< n< n< n<

If fho sysfom orfurbnfIons on fho IIno sIdo nnd/or fho hnrmonIc confonf of fho mofor sIdo hnvo fo bo fronfod In n

nrfIcuInr cusfomor socIfIc wny, socInI uIso nfforns mIghf hnvo fo bo downIondod fo fho CIC onco n usor

dIrocfory Is nvnIInbIo cronfod I.o. ns or l.?.

As n ruIo, fho CIC Is rogrnmmod In fuII nf SIIMIS If nof, nIIcnfIon socIfIc uIso nfforns hnvo fo bo

coIod fo fho dIrocforIos ns foIIows

Vocfor .`!SI!`SIAMICS`ATA`!ITAI`0l3`ICCT`0

Infood .`!SI!`SIAMICS`ATA`l5`!ITAI`040`ICCT`0 lI.o. `l5` for orf Xl05

S

I

T

R

A

I

N

up for the Compact Flash Card.

Directory for SIMOTION_D: . . . . . . .

Download project Yas_Syn0 to the CFC:

- in SCOUT, RMC on D445 > Load to file system > Save normally

- button Select target > select the drive identified for the CFC > OK

- acknowledge the request to overwrite the existing user data

Verify that the ACX-data and the Ident-files are located on the CFC (\ADDON\DATA\...) both for the Infeed and for

the Motor Module; else copy them from a suitable source to their respective location.

l.8 AIIcnfIon socIfIc IuIso Infforns >onIy fo l.8 AIIcnfIon socIfIc IuIso Infforns >onIy fo l.8 AIIcnfIon socIfIc IuIso Infforns >onIy fo

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

nsert the CFC in the card-reader and connect it to one of the USB-ports of the PG/PC; identify which directory is set

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 19

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 21

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Single Line Diagram of a Typical SM150 Rolling Mill Application

DR-SM150

page 22

1.9 Exemplary SM150 Application

The single line diagram above serves as an example for a setup of a SM150 in rolling mill applications :

- Synchronous motor with external DC-excitation and encoder

- DC-excitation provided by a Simoreg DC-Master

- Stator winding fed by Sinamics SM150 (Infeed, Motor Module)

- Signal interface to the field via ET200-S (group Auxiliaries, group Motor)

- Local control via OP177

- Process control via MRG, Basic Automation

- Data link via Profibus and Profinet

The above setup is true for a motor which can be supplied by a single SM150 unit.

For larger power ratings the Infeeds and Motor Modules will be paralleled. Motors of large power ratings mostly

feature two or three groups of stator windings; the number of Infeeds and Motor Modules is then adapted accordingly.

A typical rolling mill stand comprises two motors, an upper motor (Obermotor) and a lower motor (Untermotor). The

above setup will then be found twice, one serving the Obermotor and one serving the Untermotor. An example of

such a project is shown on the next slide.

S

I

T

R

A

I

N

- Synchronous motor with external DC-excitation and encoder

- DC-excitation provided by a Simoreg DC-Master

- Stator winding fed by Sinamics SM150 (Infeed, Motor Module)

- Signal interface to the field via ET200-S (group Auxiliaries, group Motor)

- Local control via OP177

- Process control via MRG, Basic Automation

- Data link via Profibus and Profinet

The above setup is true for a motor which can be supplied by a single SM150 unit.

For larger power ratings the Infeeds and Motor Modules will be paralleled. Motors of large power ratings mostly

feature two or three groups of stator windings; the number of Infeeds and Motor Modules is then adapted accordingly.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

he single line diagram above serves as an example for a setup of a SM150 in rolling mill applications :

- Synchronous motor with external DC-excitation and encoder

- DC-excitation provided by a Simoreg DC-Master

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 21

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Comm_Common page 23

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Drive Devices, Components and Topology of a Typical Project

SINAMICS_Vector_OM_G2

SIMOTION_CX32_OM_G2

HB-A11

HF-A11

HC-A11

HD-A11

HD-A31

HP-A11

HG-A11

HD-A51

DR-SM150

page 24

1.10 Drive Devices, Components and Topology of a typical Project

The control of the Obermotor G2 requires a number of drive devices as shown in the Simatic project:

- Simoreg DC-Master (to provide the DC-excitation for the synchronous motor)

- Simotion CX32 (to control the Infeed of the SM150)

- Sinamics_Vector (to control the Motor Module of the SM150)

- D445_Master (to provide technological control for the individual motor)

Sinamics drive devices consist of a number of components; these are listed separately for the Infeed (CX32) and for

the Motor Module (Sinamics_Vector).

These components are interconnected via Drive-CLiQ; the respective Topology Trees indicate the wiring. (The training

rack is wired identically to a plant application; some additional components are built in but are not connected.)

Verify that the DRIVE-CLiQ wiring as listed in the project topology is set up identically in the SM150 training rack.

Communication networks via Profibus and Profinet are used to link other non-Sinamics components such as OP177,

ET200-S and DC-Master to the overall system (refer to slides in sections to come).

S

I

T

R

A

I

N

- Simoreg DC-Master (to provide the DC-excitation for the synchronous motor)

- Simotion CX32 (to control the Infeed of the SM150)

- Sinamics_Vector (to control the Motor Module of the SM150)

- D445_Master (to provide technological control for the individual motor)

Sinamics drive devices consist of a number of components; these are listed separately for the Infeed (CX32) and for

the Motor Module (Sinamics_Vector).

These components are interconnected via Drive-CLiQ; the respective Topology Trees indicate the wiring. (The training

rack is wired identically to a plant application; some additional components are built in but are not connected.)

Verify that the DRIVE-CLiQ wiring as listed in the project topology is set up identically in the SM150 training rack.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

1.10 Drive Devices, Components and Topology of a t

The control of the Obermotor G2 requires a number of drive devices as shown in the Simatic project:

- Simoreg DC-Master (to provide the DC-excitation for the synchronous motor)

- Simotion CX32 (to control the Infeed of the SM150)

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 23

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 25

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Project with Three Power Sections in Parallel

DR-SM150

page 26

1.11 Project with three Power Sections in parallel

To increase the power rating up to three power sections are paralleled both on the line side (Active Line Modules) and

on the motor side (Motor Modules).

While all three power stack adapters for the motor side power sections are controlled by the D445_SINAMICS

controller, one SIMOTION CX32 controller each is assigned to the three power stack adapters of the line side power

sections.

As a standard, each of the three Infeed power sections has its own Voltage Sensing Module.

S

I

T

R

A

I

N

on the motor side (Motor Modules).

While all three power stack adapters for the motor side power sections are controlled by the D445_SINAMICS

controller, one SIMOTION CX32 controller each is assigned to the three power stack adapters of the line side power

As a standard, each of the three Infeed power sections has its own Voltage Sensing Module.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

1.11 Project with three Power Sections in parallel

o increase the power rating up to three power sections are paralleled both on the line side (Active Line Modules) and

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 25

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Comm_Common page 27

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Voltage Supplies and Signal Check

Motor

Fan Group

Converter

Cooling

ET200-S

Motor

SM150

Cooling Fans

Control

Voltage

DR-SM150

page 28

2 Basic Commissioning

2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for InformnfIon< Ion< Ion< Ion<

IrIor fo cnrryIng ouf fho wIrIng nnd InsuInfIon fosf nII cIrcuIf bronkors nnd fusod swIfch dIsconnocfors hnvo fo bo

oonod sonsIfIvo oquImonf on fho Innf ond of fho cnbIos hns fo bo dIsconnocfod ns woII.

!ofor fo fho cIrcuIf dIngrnms fo IdonfIfy fho voIfngo IovoI for whIch fho cnbIos nro usod fo know whIch voIfngo fo

chooso for fho InsuInfIon fosf l00V, 500V, l000V, 5000V.

Mnko suro fhnf fho cnbIos fo fho Innf food fho oquImonf ns sfnfod In fho cIrcuIf dIngrnms. Thon ono by ono

connocf onch wIro nf fho Iond sIdo fo ground fho monsurod Imodnnco musf bo vory smnII nIfornnfIvoIy you cnn

monsuro fho Imodnnco bofwoon fwo wIros shorfcIrcuIfod nf fho Iond.

ConfInuo by monsurIng fho InsuInfIon Imodnnco of onch wIro ngnInsf ground usIng nn InsuInfIon mofor fho

Imodnnco musf bo In fho fons of Mognohms.

ow suIy fho nuxIIInry voIfngo fo fho busbnrs In fho cnbInofs nnd chock voIfngo IovoI nnd hnso soquonco.

Thon swIfch on ono cIrcuIf bronkor nffor fho ofhor nnd ono by ono chock fho voIfngo IovoI nnd oInrIfy rs. fho

hnso soquonco nf fho Iond. IquImonf whIch cnn bo dnmngod by nn Incorrocf voIfngo IovoI or oInrIfy shouId bo

dIsconnocfod unfII fho corrocf suIy hns boon vorIfIod.

IIonso obsorvo foIIowIng wnrnIngs

!sIng suIfnbIo mofhods, onsuro fhnf no dnngor cnn nrIso for orsonnoI or mnforInI boforo foodIng voIfngo fo

oquImonf In fho Innf.

Ioforo sfnrfIng fho mofor fnns mnko suro fhnf fho mofor If hns boon cIonnod nnd nInfod ofhorwIso fho nIr

fIow mIghf cnrry foroIgn bodIos Info fho mofor nIr gn ossIbIy IondIng fo n dnmngo of fho InsuInfIon onco fho

mofor rofnfos.

on`f nccof nny comromIsos on fhoso oInfs.

IrIor fo cnrryIng ouf fho wIrIng nnd InsuInfIon fosf nII cIrcuIf bronkors nnd fusod swIfch dIsconnocfors hnvo fo bo

oonod sonsIfIvo oquImonf on fho Innf ond of fho cnbIos hns fo bo dIsconnocfod ns woII.

!ofor fo fho cIrcuIf dIngrnms fo IdonfIfy fho voIfngo IovoI for whIch fho cnbIos nro usod fo know whIch voIfngo fo

chooso for fho InsuInfIon fosf l00V, 500V, l000V, 5000V.

Mnko suro fhnf fho cnbIos fo fho Innf food fho oquImonf ns sfnfod In fho cIrcuIf dIngrnms. Thon ono by ono

connocf onch wIro nf fho Iond sIdo fo ground fho monsurod Imodnnco musf bo vory smnII nIfornnfIvoIy you cnn

monsuro fho Imodnnco bofwoon fwo wIros shorfcIrcuIfod nf fho Iond.

ConfInuo by monsurIng fho InsuInfIon Imodnnco of onch wIro ngnInsf ground usIng nn InsuInfIon mofor fho

Imodnnco musf bo In fho fons of Mognohms.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf 2.l ChockIng CnbIIng nnd VoIfngo SuIIos >onIy for Informnf

IrIor fo cnrryIng ouf fho wIrIng nnd InsuInfIon fosf nII cIrcuIf bronkors nnd fusod swIfch dIsconnocfors hnvo fo bo

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 27

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Motor

Fan Group

Comm_Common page 29

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

HW-Configuration of the Project for the Training Rack

64

32

16

8

4

2

1

address-coding

of ET200S;

i.e. address 17

PROFIBUS-addresses are set

- via switches on the ET200S-stations

- via parameter on the DC-Master

- via interface definition on the MoMo

- via DRIVE-CLiQ port on the ALM

DR-SM150

page 30

2.2 Checking the Communication Network in HW-Config

Open the HW-Configuration (i.e. in SCOUT) and compare the communication network of the project to the actual

connection of the PROFIBUS- and ETHERNET-nodes: RMC on D445 > Open HW configuration.

Note down the PROFIBUS-addresses assigned to the nodes:

- HIB-ET200: . . . . . . . . . . - MOT-ET200: . . . . . . . . . . - DC-Master: . . . . . . . . . .

Verify respectively set these addresses via hardware where possible.

S

I

T

R

A

I

N

connection of the PROFIBUS- and ETHERNET-nodes: RMC on D445 > Open HW configuration.

Note down the PROFIBUS-addresses assigned to the nodes:

- HIB-ET200: . . . . . . . . . . - MOT-ET200: . . . . . . . . . . - DC-Master: . . . . . . . . . .

Verify respectively set these addresses via hardware where possible.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.2 Checking the Communication Network in HW-Con

Open the HW-Configuration (i.e. in SCOUT) and compare the communication network of the project to the actual

connection of the PROFIBUS- and ETHERNET-nodes: RMC on D445 > Open HW configuration.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 29

C

O

U

R

S

E

- via DRIVE-CLiQ port on the ALM

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

via switches on the ET200S-stations

- via parameter on the DC-Master

- via interface definition on the MoMo

- via DRIVE-CLiQ port on the ALM

Comm_Common page 31

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Rebooting the Controllers / Connecting the Ethernet Ports

X120

IE1/OP

X130

IE2/NET

An Ethernet port is defined by its IP-address, by a Subnet mask

and (if networked) by the definition of a Standardgateway.

The definition of the Subnet mask depends on the application

class; Subnet mask and IP-address range have to match.

Subnet mask IP-address range class networks / hosts

255.0.0.0 1 to 126 A 126 / 1677721

255.255.0.0 128 to 191 B 16384 / 65534

255.255.255.0 192 to 223 C 2097152 / 254

DR-SM150

page 32

2.3 Rebooting the Controllers

Using the routine Safely Remove Hardware remove the card-reader from the PG/PC and insert the CFC in the D445.

Put all switches on the auxiliaries rack to their lower position and switch on the 24VDC supply to all Simotion and

Sinamics components on the SM150 rack by closing the line-side auxiliary supply breaker Q11 (this reboots the

controllers of the components). Allow approximately 3 minutes for the initialization. If the Drive-CLiQ topology of the

project matches the physical wiring the RUN-LEDs of the Drive-CLiQ components will turn green.

Now also switch on the supply to the auxiliaries rack via its main breaker Q1.

To analyze the nature of fault or alarm messages on the SM150, an online connection with the PG/PC has to be set

up next.

The PG/PC can be connected to the D445 via PROFIBUS or via ETHERNET; presently the ETHERNET connection to

port X130, IE2/NET will be used.

Connect an ETHERNET cable between port IE2/NET of the D445 and an available port of the PG/PC.

S

I

T

R

A

I

N

Put all switches on the auxiliaries rack to their lower position and switch on the 24VDC supply to all Simotion and

Sinamics components on the SM150 rack by closing the line-side auxiliary supply breaker Q11 (this reboots the

controllers of the components). Allow approximately 3 minutes for the initialization. If the Drive-CLiQ topology of the

project matches the physical wiring the RUN-LEDs of the Drive-CLiQ components will turn green.

Now also switch on the supply to the auxiliaries rack via its main breaker Q1.

To analyze the nature of fault or alarm messages on the SM150, an online connection with the PG/PC has to be set

up next.

The PG/PC can be connected to the D445 via PROFIBUS or via ETHERNET; presently the ETHERNET connection to

port X130, IE2/NET will be used.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

sing the routine Safely Remove Hardware remove the card-reader from the PG/PC and insert the CFC in the D445.

Put all switches on the auxiliaries rack to their lower position and switch on the 24VDC supply to all Simotion and

Sinamics components on the SM150 rack by closing the line-side auxiliary supply breaker Q11 (this reboots the

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 31

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

X130 X1 X130

IE2/NET IE2/

Comm_Common page 33

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Communication Network as seen via NetPro

DR-SM150

page 34

2.4 Checking the Communication Network in NetPro

Open the NetPro view (i.e. in SCOUT) and compare the communication network of the project to the actual connection

of the PROFIBUS- and ETHERNET-nodes: Project > Open NetPro.

In addition to the existing hardware NetPro shows a SIMATIC PC Station and a SIMODRIVE 611U. Remove the

SIMODRIVE 611U from the network: (rMC) SIMODRIVE 611U > Delete > Yes > Yes.

Note down the PROFIBUS- and ETHERNET-addresses assigned to the nodes

(via right mouse click on node connection > Object Properties):

- HIB-ET200: . . . . . . . . . . .

- MOT-ET200: . . . . . . . . . . .

- DC-Master: . . . . . . . . . . .

- PG/PC_MPI: . . . . . . . . . . .

- PG/PC_DP: . . . . . . . . . . .

- PG/PC_ETHERNET: . . . . . . . . . . . . . . . . . . . . . . .

- OP177_ETHERNET: . . . . . . . . . . . . . . . . . . . . . . .

- OP177_MPI, DP: . . . . . . . . . . .

- D445_DP1: . . . . . . . . . . .

- D445_DP2/MPI: . . . . . . . . . . .

- D445_IE1/OP: . . . . . . . . . . . . . . . . . . . . . . .

- D445_IE2/NET: . . . . . . . . . . . . . . . . . . . . . . .

- D445_CBE30: . . . . . . . . . . . . . . . . . . . . . . .

of the PROFIBUS- and ETHERNET-nodes: Project > Open NetPro.

In addition to the existing hardware NetPro shows a SIMATIC PC Station and a SIMODRIVE 611U. Remove the

SIMODRIVE 611U from the network: (rMC) SIMODRIVE 611U > Delete > Yes > Yes.

Note down the PROFIBUS- and ETHERNET-addresses assigned to the nodes

(via right mouse click on node connection > Object Properties):

- HIB-ET200:

- MOT-ET200: . . . . . . . . . . .

- DC-Master:

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.4 Checking the Communication Network in NetPro

Open the NetPro view (i.e. in SCOUT) and compare the communication network of the project to the actual connection

of the PROFIBUS- and ETHERNET-nodes: Project > Open NetPro.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 33

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 35

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Setting the IP-Address on the PG/PC

Enter

DR-SM150

page 36

2.5 Setting the IP-Address on the PG/PC

Follow the sequence Start > Einstellungen > Netzwerkverbindungen and doubleclick on LAN-Verbindung; open the

properties menu via button Eigenschaften. Scroll down to Internetprotokoll (TCP/IP), mark it and again continue via

button Eigenschaften.

Now assign the subnet-mask and the IP-address to a setting compatible with the definition of the ETHERNET port

IE2/NET of the D445 :

. . . . . . . . . . . . . . . . . . . . . .

Test the communication by pinging the D445 in the DOS-prompt: ping IP-address.

S

I

T

R

A

I

N

properties menu via button Eigenschaften. Scroll down to Internetprotokoll (TCP/IP), mark it and again continue via

Now assign the subnet-mask and the IP-address to a setting compatible with the definition of the ETHERNET port

IE2/NET of the D445 :

. . . . . . . . . . . . . . . . . . . . . .

Test the communication by pinging the D445 in the DOS-prompt: ping IP-address.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.5 Setting the IP-Address on the PG/PC

ollow the sequence Start > Einstellungen > Netzwerkverbindungen and doubleclick on LAN-Verbindung; open the

properties menu via button Eigenschaften. Scroll down to Internetprotokoll (TCP/IP), mark it and again continue via

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 35

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 37

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Assigning the PG/PC to ETHERNET in NetPro

Network > Save and Compile

DR-SM150

page 38

2.6 Assigning the PG/PC to ETHERNET in NetPro

In NetPro the PG/PC is connected both to an MPI-network and to an ETHERNET-network.

To enable an online connection to the D445, the link to the ETHERNET-network has to be activated:

- right mouse click (RMC) on PG/PC > Object Properties

- acknowledge the change of assignment via button Yes

- in tab Assignment of menu Properties PG/PC, section Configured Interfaces select

Ethernet Service Noteboo

- in section Interface Parameter Assignments select TCP/IP Intel 825666MC Gigab...

(this selection has to match the device name for the LAN-Verbindung selected above)

- define this selection as Assigned via button Assign > OK

- mark the assigned interface, verify that the checkmark next to Active is inserted and terminate the assignment

by pressing button OK

The assigned connection of the PG/PC to the D445 is highlighted in yellow.

Any change of assignment in NetPro will become effective only after NetPro has been Saved and Compiled: Network

> Save and Compile (the warning message points at missing ET200-hardware for the Obermotor which is not used

in the training rack; close the warning message).

Exit program NetPro by Network > Exit

S

I

T

R

A

I

N

To enable an online connection to the D445, the link to the ETHERNET-network has to be activated:

- right mouse click (RMC) on PG/PC > Object Properties

- acknowledge the change of assignment via button Yes

- in tab Assignment of menu Properties PG/PC, section Configured Interfaces select

Ethernet Service Noteboo

- in section Interface Parameter Assignments select TCP/IP

this selection has to match the device name for the LAN-Verbindung selected above)

- define this selection as Assigned via button Assign > OK

- mark the assigned interface, verify that the checkmark next to Active is inserted and terminate the assignment

by pressing button OK

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.6 Assigning the PG/PC to ETHERNET in NetPro

n NetPro the PG/PC is connected both to an MPI-network and to an ETHERNET-network.

To enable an online connection to the D445, the link to the ETHERNET-network has to be activated:

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 37

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Comm_Common page 39

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Going Online to D445 and Downloading the Drive Devices

connect to

target system

download to

target system

DR-SM150

page 40

2.7 Going Online to D445 and Downloading the Drive Devices

Return to SCOUT and request the online mode. The consistency plugs have to indicate the online state for drive

device D445_Master (closed plugs); data inconsistency, however, will be signaled (red-green).

Generate consistency by downloading drive device D445_Master.

You will notice that the download of the D445 is aborted with a fatal error as regards the I/O-definitions.

Open the HW-Configuration to identify the addresses assigned to the still existing nodes

(left mouse click on node address range pops up on bottom):

HIB-ET200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MOT-ET200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC-Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ALM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MoMo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Find out which variables of the I/O-container are not supported by hardware by checking the I/O-variables for

addresses not specified in the HW-Config.:

missing addresses:

variable name address range column position

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to . . . . . . . . . . . . . . . . . . . . . . . to . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to . . . . . . . . . . . . . . . . . . . . . . . to . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . to . . . . . . . . . . . . . . . . . . . . . . . to . . . . . . . . . .

Variables by the name pn_pda are assigned to the SIMATIC PC Stationwhich is not available in hardware but is

still part of the project (refer to NetPro).

Variables by the name pn_drv are assigned to SIMODRIVE 611U which has been removed in NetPro.

In Offline mode delete the 611U-variables (pn_drv) from the I/O-container and activate the function Save and

Compile. You will notice the error message error in source U2COMCBE.

S

I

T

R

A

I

N

device D445_Master (closed plugs); data inconsistency, however, will be signaled (red-green).

Generate consistency by downloading drive device D445_Master.

You will notice that the download of the D445 is aborted with a fatal error as regards the I/O-definitions.

Open the HW-Configuration to identify the addresses assigned to the still existing nodes

(left mouse click on node

IB-ET200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MOT-ET200 . . . . . . . . . . . . . . . . . . . . .

DC-Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ALM . . . . . . . . . . . . . . . . . . . . . . .

MoMo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.7 Going Online to D445 and Downloading the Drive

Return to SCOUT and request the online mode. The consistency plugs have to indicate the online state for drive

device D445_Master (closed plugs); data inconsistency, however, will be signaled (red-green).

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 39

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 41

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Finding the Reference address / module / terminal / bit

address references in I/O-container

any DCC-chart

DR-SM150

page 42

To easily find the blocks of chart U2COMCBE which use the variables pn_drv, open any DCC chart, select menu

Chart Reference Data and open the listing of Cross Reference Chart Elements Address.

Search for one of the variables pn_drv_piw and double click on it; the chart page showing this variable and its wiring

to a DCC-block is opened automatically.

Now delete all 8 inputs to block RCB100 (left Mouse Click on input signal line > Delete Interconnection). Follow the

same approach to delete the chart output to the variables pn_drv_pqw.

Compile the modified chart U2COMCBE: Cart > Compile > Chart as program > Compile individual chart > OK.

Once more Save and Compile the project and check its consistency. If consistency is still not given, follow the above

approach once more to delete the offending links to the variables in question.

Again Save and Compile the project, check its consistency and then download the D445 again. Be sure to have the

function Copy RAM to ROM executed for device D445_Master.

Reboot the drive (power off/on) and continue by downloading the Motor Module and the Infeed. After completion of the

downloads all three drive devices have to indicate data-consistency (green-green). Dont forget to have a Copy RAM

to ROM executed at the end of the download of devices SIMOTION_CX32 and SINAMICS_Vector.

If a drive device changes to disconnected (red-red) in the sequence of downloading, reconnect it as follows:

- mark the drive device in question

- open the function menus via right mouse click

- left mouse click on Connect online

device changes to offline requested (white-white)

- again open the function menus via right mouse click

- left mouse click on Connect online

device changes to online mode (green-green)

Open the Alarm-tab in SCOUT and try to acknowledge all faults. You will notice that fault Excitation group signal fault

(this fault is quite logical as the DC-Master has not yet been commissioned) persists.

S

I

T

R

A

I

N

earch for one of the variables pn_drv_piw and double click on it; the chart page showing this variable and its wiring

to a DCC-block is opened automatically.

Now delete all 8 inputs to block RCB100 (left Mouse Click on input signal line > Delete Interconnection). Follow the

same approach to delete the chart output to the variables pn_drv_pqw.

Compile the modified chart U2COMCBE: Cart > Compile > Chart as program > Compile individual chart > OK.

Once more Save and Compile the project and check its consistency. If consistency is still not given, follow the above

approach once more to delete the offending links to the variables in question.

Again Save and Compile the project, check its consistency and then download the D445 again. Be sure to have the

function Copy RAM to ROM executed for device D445_Master.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

To easily find the blocks of chart U2COMCBE which use the variables pn_drv, open any DCC chart, select menu

Chart Reference Data and open the listing of Cross Reference Chart Elements

earch for one of the variables pn_drv_piw and double click on it; the chart page showing this variable and its wiring

to a DCC-block is opened automatically.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 41

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 43

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Defaulting the DC-Master and Setting the Node-Address via PMU

Increasing / decreasing

- the parameter number

- the index number

- the value

/

Change from parameter level to

value indication and vice versa

Change from parameter level to

index level and vice versa

Change from index level to

value indication and vice versa

P234 17.20

P150 i 001

56.37 i 001

Acknowledging a fault

last

indication

F036

P

P

P

P

P +

Shifting fault or alarm

messages to the background

P +

Recalling fault or alarm

messages from the background

F036

P0623

o11.0

A537

P0623

o11.0

DR-SM150

page 44

2.8 Defaulting the DC-Master and setting the Node-Address via PMU

As a standard, the DC-Master for the SM150 synchronous motor application is pre-commissioned at SIEMENS and

the parameter file provided within the project will require only minor modification at site (i.e. the optimization of the

armature current controller for the synchronous motor excitation).

Start by defaulting the DC-Master to factory settings using its ParaMeterizing Unit (PMU):

- shift eventual fault and alarm messages to the background

- scroll to parameter P051 (access level) and set the value to P051 = 21 (default request; after execution of this

routine an internal offset tuning is carried out automatically (indication P051 = 22) and

- after some seconds delay P051 reads P051 = 40 service level for commissioning)

- scroll to P918 to set the PROFIBUS address as defined in NetPro: P918 = . . . . . . . . .

- scroll to P927 to extend the parameterization authority to SST1 + PMU + PROFIBUS: P927 = 7

Switch the power supply for the DC-Master (F001) off and on again to activate the new PROFIBUS address;

acknowledge eventual fault messages.

Profibus alarm A83 will persist since settings for the Profibus communication still have to be parameterized.

S

I

T

R

A

I

N

the parameter file provided within the project will require only minor modification at site (i.e. the optimization of the

armature current controller for the synchronous motor excitation).

Start by defaulting the DC-Master to factory settings using its

- shift eventual fault and alarm messages to the background

- scroll to parameter P051 (access level) and set the value to P051 = 21 (default request; after execution of this

routine an internal offset tuning is carried out automatically (indication P051 = 22) and

- after some seconds delay P051 reads P051 = 40

scroll to P918 to set the PROFIBUS address as defined in NetPro: P918 = . . . . . . . . .

- scroll to P927 to extend the parameterization authority to SST1 + PMU + PROFIBUS: P927 = 7

Switch the power supply for the DC-Master (F001) off and on again to activate the new PROFIBUS address;

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.8 Defaulting the DC-Master and setting the Node-Address via PMU

As a standard, the DC-Master for the SM150 synchronous motor application is pre-commissioned at SIEMENS and

the parameter file provided within the project will require only minor modification at site (i.e. the optimization of the

armature current controller for the synchronous motor excitation).

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 43

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

i 001

M

A

T

E

R

I

A

L

56.37

M

A

T

E

R

I

A

L

F036

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

P

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

Comm_Common page 45

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Tool Drive Monitor

offline online

RAM

online

EEPROM

tracer

parameter list as used

to open Drive Monitor

complete

parameter list

complete

parameter list

empty

parameter list

upload

download

upload download

left mouse click

right mouse click

online

RAM

online

EEPROM

Copy RAM to ROM

P971 = 1

DR-SM150

page 46

2.9 Going Online and Downloading the Project Data via Drive Monitor

Within the project view of the SIMATIC Manager the DC-Master is listed in addition to the three drive devices.

Navigate to the parameter list (or lists) provided for the DC-Master:

- in the navigator-section successively doubleclick on DC-Master CBP2, SIMOREG DC MASTER and

Parameter

- right mouse click on the parameter list DC_Yas_Trainee_Delta in the worksheet-section > Open Object

The tool for the DC-Master, Drive Monitor, is opened.

Navigate to the parameter list (or lists) provided for the DC-Master:

- in the navigator-section successively doubleclick on DC-Master CBP2, SIMOREG DC MASTER and

- right mouse click on the parameter list DC_Yas_Trainee_Delta in the worksheet-section > Open Object

The tool for the DC-Master, Drive Monitor, is opened.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

2.9 Going Online and Downloading the Project Data

Within the project view of the SIMATIC Manager the DC-Master is listed in addition to the three drive devices.

Navigate to the parameter list (or lists) provided for the DC-Master:

- in the navigator-section successively doubleclick on DC-Master CBP2, SIMOREG DC MASTER and

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 45

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

M

A

T

E

R

I

A

L

upload

M

A

T

E

R

I

A

L

download

M

A

T

E

R

I

A

L

Comm_Common page 47

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Messages: Differing Firmware and Missing Data Base

The FW-release of the DC-Master used

in the project differs from the FW-version

of the Control Unit.

(FW 3.1 cannot be run on CU-HW 2.2)

Unless the very latest release of Drive Monitor

is used, a missing data base has to be added.

DR-SM150

page 48

In Drive Monitor, click on the list of all offline parameters: a list of the parameters defined in project parameter list

DC_Yas_Trainee_Delta opens and indicates the offline values of these parameters.

Request operating mode online EEPROM (to have changes of parameter values saved in non-volatile fashion);

acknowledge an eventual device identification message.

If the message Device Identification pops up, ignore it by pressing the SW-button OK.

ShouId fhIs fnII fo hnon, n rogrnm udnfo sg?0v3l_dos.oxo for rIvo MonIfor hns fo bo InsfnIIod by coyIng

fho fIIo fo fho dIsk drIvo whIch Is usod for SCO!T ofc. nnd by sfnrfIng fho InsfnIInfIon.

S

I

T

R

A

I

N

Request operating mode online EEPROM (to have changes of parameter values saved in non-volatile fashion);

acknowledge an eventual device identification message.

If the message Device Identification pops up, ignore it by pressing the SW-button OK.

ShouId fhIs fnII fo hnon, n rogrnm udnfo sg?0v3

fho fIIo fo fho dIsk drIvo whIch Is usod for SCO!T ofc. nnd by sfnrfIng fho InsfnIInfIon.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

In Drive Monitor, click on the list of all offline parameters: a list of the parameters defined in project parameter list

DC_Yas_Trainee_Delta opens and indicates the offline values of these parameters.

Request operating mode online EEPROM (to have changes of parameter values saved in non-volatile fashion);

acknowledge an eventual device identification message.

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

page 47

C

O

U

R

S

E

C

O

U

R

S

E

C

O

U

R

S

E

M

A

T

E

R

I

A

L

Comm_Common page 49

SITRAIN / METAL ACADEMY

Siemens AG 2011 - all rights reserved

Downloading the Parameter File with Drive Monitor

DR-SM150

page 50

Now download the project file DC_Yas_Trainee_Delta to the EEPROM (the download of a complete file takes

considerably longer than the download of a delta file, which contains only those parameters whose values are other

than default values); close the eventual device identification message with button Download.

If the download is executed with only a very small number n of errors (indicated by [OKxxx: E<0: n>]), call up the

Details with the respective button. Analyze the reason for the error; mostly the errors result from different versions of

the tool Drive Monitor and the Firmware of the DC-Master and can be ignored.

On the DC-Master programming numerous Free Function Blocks are used. These Free Function Blocks have to be

enabled either temporarily (for test operation with a maximum test time of 500 operating hours) or permanently via

PIN-code.