Professional Documents

Culture Documents

Acmv

Uploaded by

Hafiz AbdullahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acmv

Uploaded by

Hafiz AbdullahCopyright:

Available Formats

Chiller

T&C Forms Air Conditioning System

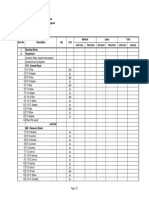

JKR/CKM/T & C :______________________ CAWANGAN KEJURUTERAAN MEKANIKAL JABATAN KERJA RAYA

CHILLER TESTING AND COMMISSIONING PROCEDURE

CHILLER Information (a) Chiller No. (b) Make (c) Model (d) Type of Refrigerant (e) Serial No. (f) Motor Type (g) Motor Starter (h) Refrigerant Capacity (i) Rated Electrical Load

COMPRESSOR Serial No 1 2 Make Model Capacity

KW Rating Actual

R.P.M

Volt R

Amp Y B

Capacity

O/L

P.F

Compressor 1 Setting Actual Low side pressure High side pressure Oil pressure

Compressor 2 Setting Actual

Page 1 of 8

Chiller

T&C Forms Air Conditioning System

COOLER Actual Water inlet temperature Water inlet pressure Air flowrate Air on condenser Air off condenser Acceptable Water outlet temperature Water outlet pressure _____0F db _____0F db _____0F wb _____0F wb Actual Acceptable

KW Rating Actual Actual

R.P.M

Volt R

Amp Y

O/L B

P.F

1- Start Amp 2- Start Amp

Check (a) Proper water thru cooler (b) Proper air flow thru condenser

Satisfactory N/A Yes No

Page 2 of 8

Chiller

T&C Forms Air Conditioning System

OPERATION Chiller 1 Time Ambient Temp Oil pressure (psi) Suction pressure (psi) Chilled water temp (degree F) Compressor current % full load Chiller 2 Time Ambient Temp Oil pressure (psi) Suction pressure (psi) Chilled water temp (degree F) Compressor current

System 1 System 2 System 1 System 2 LWT RWT System 1 System 2

System 1 System 2 System 1 System 2 LWT RWT System 1 System 2

Chiller 3 Time Ambient Temp Oil pressure (psi) Suction pressure (psi) Chilled water temp (degree F) Compressor current

System 1 System 2 System 1 System 2 LWT RWT System 1 System 2

Page 3 of 8

Chiller

T&C Forms Air Conditioning System

OPERATION DATA Item 1 2 3 4 5 6 7 8 9 10 11 12 13 Description Chilled water inlet temp. Chilled water outlet temp. Condenser water inlet temp. Condenser water outlet temp. Chilled water inlet pressure Chilled water outlet pressure Starting current ( Amps ) Running current ( Amps ) Overload setting Low oil pressure cut out setting High discharge temperature safety cut out setting Low water temperature safety cut out setting High pressure cut out setting Data

0 0

Result Pass Fail

Remark

C C 0 C 0 C

Page 4 of 8

Chiller

T&C Forms Air Conditioning System

OPERATION SEQUENCING TEST 1. Single chiller operation

Start up sequences Step Equipment Cut-in 1 2 3 4 5 6 7 8

Load Condition

Remark

Start down sequences Step Equipment Cut-out 1 2 3 4 5 6 7 8

Load Condition

Remark

Page 5 of 8

Chiller

T&C Forms Air Conditioning System

2.

Two chiller operation

Start up sequences Step Equipment Cut-in 1 2 3 4 5 6 7 8 9 10

Load Condition

Remark

Start down sequences Step Equipment Cut-out 1 2 3 4 5 6 7 8

Load Condition

Remark

Page 6 of 8

Chiller

T&C Forms Air Conditioning System

Water Balancing Test AHU No. / Balancing valve No. Model No. Balancing Valve Size (mm) Pressure Difference (PSI) In Out Water Flow Rate (L/s) Designed Measured No. of Turns

Remarks

Note : Drawing indicating balancing valve no. to be attached

Page 7 of 8

Chiller

T&C Forms Air Conditioning System

Checked By Contractor:

Witness By JKR Representative:

Sign:.. Name: Date:

Sign : Name: Date:..

Page 8 of 8

You might also like

- Operation and Maintenance Manual of Air Conditioning System in Klinik Tawau, Klinik Kesihatan Jenis 2Document21 pagesOperation and Maintenance Manual of Air Conditioning System in Klinik Tawau, Klinik Kesihatan Jenis 2LeslieYewMinYunNo ratings yet

- MEP Testing and Commissioning ManagementDocument6 pagesMEP Testing and Commissioning ManagementJon TyackeNo ratings yet

- Fiber Optics Design GuideDocument0 pagesFiber Optics Design GuideHafiz Abdullah100% (1)

- Doha Petroleum Construction Co. LTD Inspection & Test Plan: 1 Material ReceivingDocument1 pageDoha Petroleum Construction Co. LTD Inspection & Test Plan: 1 Material ReceivingmeeNo ratings yet

- SOP For Handling of Rejected Raw MaterialDocument6 pagesSOP For Handling of Rejected Raw Materialanoushia alviNo ratings yet

- From The Desk of Mark Hamilton A Prime-Literature Neothink Nugget For Neothink Members-OnlyDocument8 pagesFrom The Desk of Mark Hamilton A Prime-Literature Neothink Nugget For Neothink Members-Onlyphilosophe662511No ratings yet

- Table Monitoring Progress Finsihing & MEPDocument267 pagesTable Monitoring Progress Finsihing & MEPShahrulNizamNo ratings yet

- Air TestDocument13 pagesAir TestNur Fatin AzarinaNo ratings yet

- MEP Snag List TawarDocument13 pagesMEP Snag List Tawarmohammad100% (1)

- Water Hammer With Column Separation A Historical ReviewDocument37 pagesWater Hammer With Column Separation A Historical Reviewanoop102No ratings yet

- Creative Industries Journal: Volume: 1 - Issue: 1Document86 pagesCreative Industries Journal: Volume: 1 - Issue: 1Intellect BooksNo ratings yet

- BOQ Format - Electrical PDFDocument7 pagesBOQ Format - Electrical PDFKurama Basket100% (1)

- Estimation Engineer - Scope and FutureDocument19 pagesEstimation Engineer - Scope and FutureBehram Ciodia100% (1)

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksmeeNo ratings yet

- Method Stament For Street Pole LightDocument16 pagesMethod Stament For Street Pole Lightمقاول تكييف كهرباء وصحيNo ratings yet

- Check List Distribution BoardDocument1 pageCheck List Distribution BoardAldeline SungahidNo ratings yet

- SUPER Final ImportDocument41 pagesSUPER Final ImportronaldNo ratings yet

- 00-Material Submission FormDocument4 pages00-Material Submission FormHafiz AbdullahNo ratings yet

- Sample Clinic Policy StatementsDocument26 pagesSample Clinic Policy StatementsSuhardy Datuk Mohd NoorNo ratings yet

- Sample Clinic Policy StatementsDocument26 pagesSample Clinic Policy StatementsSuhardy Datuk Mohd NoorNo ratings yet

- 05-EL - FTR - Insulation & Continuity TestDocument3 pages05-EL - FTR - Insulation & Continuity Testben sullivanNo ratings yet

- Section 7 - Schedule of Technical Data Offer Acsu2Document6 pagesSection 7 - Schedule of Technical Data Offer Acsu2Mohd Aliff Mohd YunosNo ratings yet

- RhinoGold 4.0 - Level 1 - Tutorial 014P - Half Channel RingDocument2 pagesRhinoGold 4.0 - Level 1 - Tutorial 014P - Half Channel RingJulio mendoza100% (2)

- VCP Pipe Installation: Method Statement ForDocument11 pagesVCP Pipe Installation: Method Statement ForBELLANo ratings yet

- Boq IDocument7 pagesBoq IAmolNo ratings yet

- Product Sheet: 970 Smartradar AtiDocument4 pagesProduct Sheet: 970 Smartradar AtiJohn HowardNo ratings yet

- Method Statement For Installation of Electric Water Heater - Method Statement HQDocument5 pagesMethod Statement For Installation of Electric Water Heater - Method Statement HQGwenn AsprerNo ratings yet

- European Chains & Hotels Report 2019Document77 pagesEuropean Chains & Hotels Report 2019Tatiana100% (1)

- 6090 Uv Printer Operation Manual - BlackDocument26 pages6090 Uv Printer Operation Manual - BlackSonia NaickerNo ratings yet

- Submittal Sheet: From: CCDocument2 pagesSubmittal Sheet: From: CCCaberte JohnnyNo ratings yet

- Piawai Jambatan BombaDocument5 pagesPiawai Jambatan BombaKeen LoongNo ratings yet

- Form B - BlankDocument3 pagesForm B - BlankKazehaya AliNo ratings yet

- Gas Turbine Inlet Air Cooling System: Bob OmidvarDocument41 pagesGas Turbine Inlet Air Cooling System: Bob OmidvarKangjin ChoNo ratings yet

- Method Statement CoringDocument3 pagesMethod Statement CoringMirza Farouq BegNo ratings yet

- Ve Lift GL 2014Document27 pagesVe Lift GL 2014Lee TaiNo ratings yet

- Garispanduan Arkitek Dan Jurutera PDFDocument117 pagesGarispanduan Arkitek Dan Jurutera PDFJoe QuekNo ratings yet

- Account Opening Form For NRIDocument12 pagesAccount Opening Form For NRISanjay Jay SanjayNo ratings yet

- Internal Approval of Method StatementsDocument12 pagesInternal Approval of Method Statementsmidhun muraliNo ratings yet

- Need Statement M& eDocument27 pagesNeed Statement M& eApai MfarNo ratings yet

- Colour Coding To Pipelines (Ground Colour and Colour Bands)Document4 pagesColour Coding To Pipelines (Ground Colour and Colour Bands)Naizil Kareem100% (1)

- Air Cond Maintenance Unit RatesDocument4 pagesAir Cond Maintenance Unit RatesBenjamin Ling0% (1)

- JKR C 1 S: Oka Concrete Industries Sdn. BHDDocument1 pageJKR C 1 S: Oka Concrete Industries Sdn. BHDGnabBangNo ratings yet

- Evaluations of VendorsDocument4 pagesEvaluations of VendorsWael_Barakat_3179No ratings yet

- Rates 02032015Document5 pagesRates 02032015qoci5koNo ratings yet

- Fat - MSB Pmu JinjangDocument6 pagesFat - MSB Pmu JinjangFirdaus Muhammad100% (1)

- M&E Provision For Retail - REV 4Document18 pagesM&E Provision For Retail - REV 4Chun SeongNo ratings yet

- MitsubishiDocument8 pagesMitsubishiRaheem_ka67% (3)

- Material Submittal - Checklist PDFDocument1 pageMaterial Submittal - Checklist PDFDanish AhamadNo ratings yet

- Electrical Engineer (Professional) CLASSIC TemplateDocument1 pageElectrical Engineer (Professional) CLASSIC TemplateNguyen LongNo ratings yet

- Building WorksDocument44 pagesBuilding Worksafiq91No ratings yet

- Pqp-Part 3Document9 pagesPqp-Part 3jparsbNo ratings yet

- Endorsement by - JKR Standard Sanitary FittingsDocument9 pagesEndorsement by - JKR Standard Sanitary FittingsYoke ShuNo ratings yet

- Mycesmm - Class D.revision VersionDocument8 pagesMycesmm - Class D.revision VersionerickyfmNo ratings yet

- Testing and Commissioning of Emergency Light SystemDocument1 pageTesting and Commissioning of Emergency Light SystemUmair BaBerNo ratings yet

- Method Statement Submission: For: LPG System Work Installation, Testing & CommissioningDocument5 pagesMethod Statement Submission: For: LPG System Work Installation, Testing & CommissioningMd ShahinNo ratings yet

- Project Name: Dubai Petroleum Panel Ref: LPC System Shop Owner: Fed From: SMDB-6-601 Consultants: EXPDocument6 pagesProject Name: Dubai Petroleum Panel Ref: LPC System Shop Owner: Fed From: SMDB-6-601 Consultants: EXPjimmy_barredoNo ratings yet

- Ms 03 Fit Out WorksDocument18 pagesMs 03 Fit Out WorksHichem ZerradNo ratings yet

- User Manual - Online Wiring Certificates-Rev3Document12 pagesUser Manual - Online Wiring Certificates-Rev3Tony Ras Mwangi100% (1)

- Guideline On Indoor Air Quality Service For Hospital Support ServiceDocument53 pagesGuideline On Indoor Air Quality Service For Hospital Support ServiceLee Jing YangNo ratings yet

- 002 R2. Material Submittal For SheduleDocument1 page002 R2. Material Submittal For SheduleJoe PsNo ratings yet

- Basic Building Services Mech Design GuideDocument1 pageBasic Building Services Mech Design GuidemitasyahuNo ratings yet

- Design MethodologyDocument7 pagesDesign MethodologyBenjamin YusuphNo ratings yet

- Quotation For Chiller MaintenanceDocument3 pagesQuotation For Chiller MaintenanceabianshbaralNo ratings yet

- CP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01Document6 pagesCP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01tarekNo ratings yet

- 12.ACMV (Painting & Labelling) - PDFDocument3 pages12.ACMV (Painting & Labelling) - PDFIswadi Bin ZulkarnainNo ratings yet

- ESE-Testing & Commissioning For Fireman Intercom SystemDocument2 pagesESE-Testing & Commissioning For Fireman Intercom SystemalifNo ratings yet

- Arabian Construction Company: Projected Cash FlowDocument8 pagesArabian Construction Company: Projected Cash FlowJule LobresNo ratings yet

- Method Statement For Installation of Hvac SystemDocument7 pagesMethod Statement For Installation of Hvac SystemAhsan ShoaibNo ratings yet

- Telekom ManholeDocument3 pagesTelekom ManholeYusof0% (1)

- Method Statement For Mackintosh Probe TestDocument1 pageMethod Statement For Mackintosh Probe TestNurLiyana RasmiNo ratings yet

- 2021-01-11 Sample BEM Letter - Active ECP InvolvementDocument1 page2021-01-11 Sample BEM Letter - Active ECP InvolvementmohdkamalhaziqNo ratings yet

- Video Intercom Solution and Cabling SpecificationsDocument20 pagesVideo Intercom Solution and Cabling SpecificationsSaid GedeonNo ratings yet

- QCDD Handing Over IndexDocument2 pagesQCDD Handing Over IndexMohammed Javid HassanNo ratings yet

- Water Cooled Package (WCPS) Start-Up FormDocument3 pagesWater Cooled Package (WCPS) Start-Up FormAhmed SofaNo ratings yet

- 560 Cdef 1 DB 152Document1 page560 Cdef 1 DB 152Hafiz AbdullahNo ratings yet

- 01-Load Schedule PDFDocument8 pages01-Load Schedule PDFHafiz AbdullahNo ratings yet

- Contractor ParticularsDocument7 pagesContractor ParticularsHafiz AbdullahNo ratings yet

- PO-01 (Tower Access Road)Document4 pagesPO-01 (Tower Access Road)Hafiz AbdullahNo ratings yet

- Rfpforppavoli PDFDocument25 pagesRfpforppavoli PDFHafiz AbdullahNo ratings yet

- Meeting at Trenergy 9.11.2018Document1 pageMeeting at Trenergy 9.11.2018Hafiz AbdullahNo ratings yet

- 01 External ElectricalDocument6 pages01 External ElectricalHafiz AbdullahNo ratings yet

- This Is Sample - For Preview Only Package 5 - Sample: Treated Water Pumping MainDocument3 pagesThis Is Sample - For Preview Only Package 5 - Sample: Treated Water Pumping MainHafiz AbdullahNo ratings yet

- Meeting at Trenergy 9.11.2018Document1 pageMeeting at Trenergy 9.11.2018Hafiz AbdullahNo ratings yet

- Sample - Tender Analysis On Major Items Comparison PDFDocument3 pagesSample - Tender Analysis On Major Items Comparison PDFHafiz AbdullahNo ratings yet

- Sample PDFDocument3 pagesSample PDFHafiz AbdullahNo ratings yet

- FIHDocument12 pagesFIHHafiz AbdullahNo ratings yet

- Project: KUSTEM: 6 X 300mm sq./4c XLPE/SWA/PVC (Cu.) Laid U/G. A) Calculation Base On Percentage (%)Document1 pageProject: KUSTEM: 6 X 300mm sq./4c XLPE/SWA/PVC (Cu.) Laid U/G. A) Calculation Base On Percentage (%)Hafiz AbdullahNo ratings yet

- Cable QuotationDocument7 pagesCable QuotationHafiz AbdullahNo ratings yet

- JKR Acmv Ahu PDFDocument4 pagesJKR Acmv Ahu PDFHafiz Abdullah50% (2)

- Senarai Lampiran SPP Bil.3 Tahun 2008Document5 pagesSenarai Lampiran SPP Bil.3 Tahun 2008Razaleeno HarunNo ratings yet

- Inspection Form For LV Panel Installation, Cable Termination and Power On ChecklistDocument1 pageInspection Form For LV Panel Installation, Cable Termination and Power On ChecklistHafiz AbdullahNo ratings yet

- Cisco Core SwtichDocument12 pagesCisco Core SwtichHafiz AbdullahNo ratings yet

- Nikkostirling 2009 CatalogDocument12 pagesNikkostirling 2009 Catalogalp berkerNo ratings yet

- Practices For Lesson 3: CollectionsDocument4 pagesPractices For Lesson 3: CollectionsManu K BhagavathNo ratings yet

- CCNA 1 v60 Study Material Chapter 9 Transport LayerDocument9 pagesCCNA 1 v60 Study Material Chapter 9 Transport LayerRazaqNo ratings yet

- Information For New CustomersDocument1 pageInformation For New CustomersOctavian P TodirasNo ratings yet

- Degassed Cation Conductivity MeasurementDocument11 pagesDegassed Cation Conductivity MeasurementPhạm Nhật MinhNo ratings yet

- Man Pa-4000Document18 pagesMan Pa-4000JOEY76BYNo ratings yet

- Labtech 20121120 - SS HIRE Bro C 2Document24 pagesLabtech 20121120 - SS HIRE Bro C 2Carlos PereaNo ratings yet

- Multibio BrochureDocument1 pageMultibio Brochuree-ComfortUSANo ratings yet

- Pass Transistor LogicDocument36 pagesPass Transistor LogicMuneza NaeemNo ratings yet

- GrabBee HD ManualDocument9 pagesGrabBee HD ManualAndrea Lissette Perez FuentesNo ratings yet

- Classification of Pumps and TurbinesDocument12 pagesClassification of Pumps and TurbinesKarim SayedNo ratings yet

- Apollo15 Colossus3 CMC Data CardsDocument18 pagesApollo15 Colossus3 CMC Data CardsPablo De LeonNo ratings yet

- Non Destructive Testing Tech EnglishDocument1 pageNon Destructive Testing Tech Englishvictor hugoNo ratings yet

- K Sera Sera CaseDocument12 pagesK Sera Sera CaseAditya SinghNo ratings yet

- Astm f1554Document3 pagesAstm f1554ingsabrinaNo ratings yet

- Ind Mkt. Caselet 1Document6 pagesInd Mkt. Caselet 1harshalNo ratings yet

- Cobra-5: Power Brush SystemDocument12 pagesCobra-5: Power Brush SystemJuan Carlos CarrilloNo ratings yet

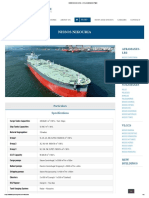

- NISSOS NIKOURIA - KYKLADES MARITIME - SpecsDocument2 pagesNISSOS NIKOURIA - KYKLADES MARITIME - SpecsEkvazis TarsachNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- How To Get A Non-Professional Driver's License in The Philippines 2014Document7 pagesHow To Get A Non-Professional Driver's License in The Philippines 2014rkris88No ratings yet