Professional Documents

Culture Documents

Project Case Study: Musheireb Heart of Doha - DCP

Uploaded by

atiqulaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Case Study: Musheireb Heart of Doha - DCP

Uploaded by

atiqulaCopyright:

Available Formats

Musheireb Heart of Doha

People Innovation Passion Project Case Study

Musheireb Heart of Doha - DCP

PROJECT: Musheireb Heart of Doha START DATE: 2010 COMpLETION DATE: 2015 LOCATION: Doha, Qatar INdUsTRY: Infrastructure & Utilities DEVELOpER: Musheireb Properties CONsULTANT/ARCHITECT: Time Qatar/ M. Engineering VALUE: US $ 50 Million

PROJEcT CAsE STUdY

Drake & Scull International PJSC

01

Musheireb Heart of Doha

Project Case Study

Concept & Location

Musheireb, Heart of Doha is a massive 35-hectare site which will transform the architectural centre of Qatars capital city, recreating a way of living that is rooted in Qatari culture. The Musheireb development is being undertaken by Dohaland which is a subsidiary of the Qatar Foundation for education, science and community development lead by Her Highness Sheikha Moza Bint Vasser. The Musheireb project will be a shining example of Qatars progress in the region, and will bridge the gap between the historic Doha of the past, and the leading, global metropolis it is today. The project recreates the highlights of Qatars traditional architecture and urban planning work as well as develops a sustainable and beneficial community of the future. The Musheireb will revitalise the historic core of Doha itself, giving families the opportunity to live in beautiful homes and enjoy the benefits of a strong, well-served local community. The project aims to bring about a complete transformation of the urban landscape of Doha, and will be at the forefront of the massive expansion that Qatar will undertake, in preparation for the Football World Cup in 2022. Salient features of planned development include organic courtyard patterns, townhouses (which will be arranged as fireej clusters, each sharing a communal majilis and courtyard garden), retaining the historic street pattern including the famous Kahraba street and the line of the old Wadi.

Mushreib is designed to comply with leading energy efficiency and sustainability standards, and will maximize the adoption of the latest in sustainable technology, combined with traditional techniques of climatic design such as shading structures, wind catchers and massive construction. High levels of eco performance will be achieved with minimum wastage and low levels of pollution. Given Dohalands focus on sustainability and environment, the District Cooling System is a vital part of the strategy to provide an energy efficient approach to the Musheireb project. The qualitative advantages of the system are perceived in terms of better comfort, better reliability, and maximized convenience. It provides better quality of cooling, maximum cost effectiveness, capital cost elimination, space saving, decrease in sound pollution, and importantly, is environmentally friendly. As Dohalands target is to build the first sustainable downtown regeneration project, they decided to build an energy efficient district cooling system, achieving the highest LEED certification. DSWP was selected to commission, install, and test the district cooling system for the entire project.

Drake & Scull International PJSC

02

Musheireb Heart of Doha

Project Case Study

Scope of Work

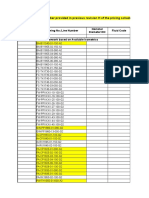

The Musheireb Development area requires a high capacity district cooling network, comprising two centralized district cooling plants, to produce a thermal energy in the form of chilled water and supply the chilled water to the buildings through a piping network. Dohaland commissioned DSWP to design, build, install and operate the district cooling system. There are two district cooling plants, each plant with a cooling capacity of nearly 30,000 TR, provided by electrically driven chillers. The scope of work being undertaken by DSWP includes: Mechanical, electrical and support equipment and systems for two independent central cooling plants. An interconnected sidewide reticulation network located connecting 59 energy transfer stations. Cooling tower make-up and blow down pipelines from PR1 to PR2. Water treatment plant using TSE water for the cooling tower make-up and development irrigation, water feature and toilet flushing for the development energy transfer station (ETS). P/C control panels, instrumentations programming, testing & commissioning. Operation and maintenance of the district cooling system for a period of seven years, with a design life of 25 years for sea shore installation. DSWPs team on site is responsible for the design and engineering development, plant and material selections

procurement, installation, commissioning and performance validation of mechanical and electrical chilled water process plant for the district cooling system. DSWPs scope also covers the design and construction of a chilled water reticulation network including valves and valve chamber details, the design and construction of complete Mechanical Electrical and Plumbing (MEP) building services for the plants, the testing and commissioning of the Plants as well as the operation and maintenance of the district cooling plants for a minimum period of five years.

Challenges

The Heart of Doha DCP project has proved to be a unique learning experience for DSWP, as it encountered and overcame interesting challenges in the initial stages itself. One of the major challenges is creation of an energy efficient district cooling system, which primarily depends on electrically driven chillers. This contradiction was the main aspect of consideration for DSWP throughout the concept design, detailed engineering studies, equipment selection stages, right up to the adoption of construction methodology. Another challenge was to regulate the usage of water during construction for the cooling tower make-up, as part of DSWPs commitment to conscious sustainability. Return Delta T from the building and partial load consumption is another perennial challenge for DCP projects in the Middle East, which DSWP was able to face by leveraging its strong experience in DCP projects, all over the world.

Drake & Scull International PJSC

03

Musheireb Heart of Doha

Project Case Study

DSWP Innovation

From a design perspective, the central chilled water plant consists of MV electrically driven chillers for producing chilled water at 4.5 degree Celsius laid out in a series-counter flow arrangement. The chilled water system consists of primary / secondary pumping arrangement with a separate primary and secondary water pumps. The secondary pumps are driven by a variable frequency drive. The cooling tower make-up water is provided from the TSE water polishing plant. The package control systems had to be included with a control interface to allow monitoring and controlling the system. DSWP is also responsible for undertaking the chemical treatment system for all the internal plant room piping and the reticulation network. To reduce construction time, DSWP decided to move all the equipment to the basement except for the cooling tower which is located at the ground level. These led to efficient space utilization, as well as ease the movement of the teams at work. The challenge of delivering a LEED compliant, energy efficient and sustainable district cooling system spurred DSWP to usher in several innovative methods. One of the major decisions undertaken was to select super efficient Mitsubishi chillers that brought about a significant effect on the system efficiency, as chillers typically consume 70% of the electricity required for any Cooling plant. DSWP also adopted efficient equipments, pumps and applied special internal cooling methods to boost pumping efficiency.

District cooling plants tend to consume a lot of water for the cooling tower make-up. DSWP designed a Reverse Osmosis water treatment plant to treat the TSE water and use the water produced for cooling tower make up. The Reverse Osmosis plant has 90% recovery which is great from a recycling perspective. The plant recycles water from the cooling tower to the Reverse Osmosis plant for re-treatment. The water generated can then be used for irrigation, water release and sewage requirements for the entire development. To eliminate the Delta T problem faced in DCPs, DSWP has pioneered a new control design and philosophy using modern Smart control valves known as Electro-mechanic Flow Metering Control Valves (EFMCV). The new control design has successfully addressed all challenges and has been able to improve design efficiency while ensuring that the end user receives the required supply temperature regardless of the load partial consumption. Apart from this, another area DSWP is focusing on is Acoustic Analysis of the DCPs. The noise generated by district cooling systems proves to be a disruption to the local communities, and one of DSWPs targets was to reduce this element. DSWP employed advanced Acoustic Studies using the latest computer modeling technologies to analyze noise levels and develop noise reduction solutions in the identified areas. The unique combination of DSWPs storied experience, technological strength, design competence and technical knowhow have resulted in brisk progress that is well set to deliver the clients vision for an energy efficient District Cooling Plant that will lie at the Heart of Dohas most prestigious development for years to come.

Drake & Scull International PJSC

04

Musheireb Heart of Doha

Project Case Study

For enquiries and other concerns, please send an email to corporate@drakescull.com

www.drakescull.com

You might also like

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- MHOD District Cooling - Arup 29-09-2011Document52 pagesMHOD District Cooling - Arup 29-09-2011Mrityunjay MallikNo ratings yet

- 01 District Cooling in The Global South Full Presentation China India EgyptDocument78 pages01 District Cooling in The Global South Full Presentation China India EgyptSanjay Bathwar100% (2)

- Paris District Cooling System 305MW Requirements 47% Energy SavingsDocument8 pagesParis District Cooling System 305MW Requirements 47% Energy SavingsarifzakirNo ratings yet

- District Heating and Cooling Systems ExplainedDocument9 pagesDistrict Heating and Cooling Systems Explainedaldeanz89No ratings yet

- District Cooling PresentationDocument14 pagesDistrict Cooling PresentationDina FouadNo ratings yet

- Ashrae Variable Flow Chiller Plant DesignDocument43 pagesAshrae Variable Flow Chiller Plant Designcarmen hernandez100% (1)

- IMPULSE District Cooling SystemDocument41 pagesIMPULSE District Cooling SystemAshique Muhammed T MNo ratings yet

- Market Insight - District Cooling Market in GCCDocument8 pagesMarket Insight - District Cooling Market in GCCAnonymous VovdmoI1y100% (1)

- Guide to District Cooling Benefits and ImplementationDocument14 pagesGuide to District Cooling Benefits and Implementationاحمد الجزار2007No ratings yet

- District Cooling System (DCS)Document14 pagesDistrict Cooling System (DCS)YeungMingKai100% (1)

- District CoolingDocument28 pagesDistrict Coolinggehgeray100% (3)

- 2009 UPC PresentationDocument81 pages2009 UPC PresentationFarhsa Dhom Eemihahs DhomNo ratings yet

- Durrat Island district cooling load estimate based on revised masterplanDocument1 pageDurrat Island district cooling load estimate based on revised masterplanAbraham JyothimonNo ratings yet

- ASHRAE Journal SaveChillerPlantEnergyWithGuideline22 2008 - Feb 2010Document4 pagesASHRAE Journal SaveChillerPlantEnergyWithGuideline22 2008 - Feb 2010WahidHamed100% (3)

- Quick Referencefor Efficient Chiller System Design PDFDocument2 pagesQuick Referencefor Efficient Chiller System Design PDFsrinivasan2081100% (1)

- District CoolingDocument8 pagesDistrict Coolingmsn20091No ratings yet

- Chilled Water OptimizationDocument61 pagesChilled Water Optimizationmuoi2002No ratings yet

- Benefits of District CoolingDocument13 pagesBenefits of District CoolingsyedahmedsabirNo ratings yet

- Ashrae - Understanding Zero Energy BuildingsDocument7 pagesAshrae - Understanding Zero Energy BuildingsVlad GrigoreanNo ratings yet

- York Chillers SOW Chiller 2019 1Document22 pagesYork Chillers SOW Chiller 2019 1Pratikno SajaNo ratings yet

- Energy Sav HVAC SystemDocument16 pagesEnergy Sav HVAC SystemrapidSHVNo ratings yet

- SKM High Efficiency Packaged Air Conditioners PACS-C SeriesDocument30 pagesSKM High Efficiency Packaged Air Conditioners PACS-C SeriesOmair FarooqNo ratings yet

- Area CalculationDocument38 pagesArea CalculationTanveerNo ratings yet

- 01) Chiller Plant Optimisation (KY)Document41 pages01) Chiller Plant Optimisation (KY)Anonymous WCG2HjPybJNo ratings yet

- Supply and distribution systemsDocument44 pagesSupply and distribution systemsmitasyahuNo ratings yet

- Water Cooled Chiller GuideDocument5 pagesWater Cooled Chiller GuideMUHAMMAD TAHANo ratings yet

- System Series - 04 Ice Storage System PDFDocument121 pagesSystem Series - 04 Ice Storage System PDFpal_stephenNo ratings yet

- Energy Savings From Building Energy Management SystemsDocument14 pagesEnergy Savings From Building Energy Management Systemshb_scribNo ratings yet

- R-410A Air-Cooled ChillersDocument84 pagesR-410A Air-Cooled ChillersThe Ka1serNo ratings yet

- Optimizing Design and Control of Chilled Water Plants PDFDocument20 pagesOptimizing Design and Control of Chilled Water Plants PDFMarli MoiseNo ratings yet

- Large Chilled Water SystemDocument314 pagesLarge Chilled Water SystemEsteban Lopez Arboleda100% (3)

- Optimizing HVAC Water Pumping SystemsDocument49 pagesOptimizing HVAC Water Pumping SystemsVasanth KumarNo ratings yet

- Cooling Load CalculationDocument90 pagesCooling Load CalculationmiraqueelaliNo ratings yet

- District Cooling 2010Document29 pagesDistrict Cooling 2010aviruch100% (1)

- Riesenberger J. and J. Koeller (2005) Commercial Laundry FacilitiesDocument30 pagesRiesenberger J. and J. Koeller (2005) Commercial Laundry FacilitiesTilakjiNo ratings yet

- DISTRICT COOLING Design and Water Managementcode 2016Document45 pagesDISTRICT COOLING Design and Water Managementcode 2016waelroustomNo ratings yet

- Course Content: Fundamentals of HVAC ControlsDocument39 pagesCourse Content: Fundamentals of HVAC ControlsMuhammad AfzalNo ratings yet

- Water Treatment in ChillersDocument14 pagesWater Treatment in ChillersabmopalhvacNo ratings yet

- Chilled Water System PresentationDocument119 pagesChilled Water System Presentationceo123456100% (4)

- HVAC Resource Guide For Green Building Design ENV SLB002 enDocument36 pagesHVAC Resource Guide For Green Building Design ENV SLB002 enFarid SedekyNo ratings yet

- Indirect Evaporative Cooling - Past, Present and Future PotentialsDocument28 pagesIndirect Evaporative Cooling - Past, Present and Future PotentialsDavid DonosoNo ratings yet

- ARTICLE Simplified Chiller Sequencing PDFDocument6 pagesARTICLE Simplified Chiller Sequencing PDFVara PrasadNo ratings yet

- Final - District Cooling System Design MENA - July2021Document220 pagesFinal - District Cooling System Design MENA - July2021Mubashir KhanNo ratings yet

- Variable Flow Chiller Plant Design PDFDocument28 pagesVariable Flow Chiller Plant Design PDFLeed ENNo ratings yet

- Chilled Water SystemsDocument16 pagesChilled Water SystemsacmvorgNo ratings yet

- HVAC DesignDocument3 pagesHVAC DesignNatalie BentleyNo ratings yet

- District Cooling Best GuideDocument175 pagesDistrict Cooling Best Guiderama_eas100% (4)

- Understanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDocument13 pagesUnderstanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDavid O. AlmeidaNo ratings yet

- A Fundamental Perspective On Chilled Water SystemsDocument25 pagesA Fundamental Perspective On Chilled Water SystemsAntonio LebrunNo ratings yet

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Taj Kitchen Case StudyDocument4 pagesTaj Kitchen Case StudySandeep GargNo ratings yet

- Gardens by The Bay High Performance Through Design Optimization and IntegrationDocument19 pagesGardens by The Bay High Performance Through Design Optimization and IntegrationAteeque AminbhaviNo ratings yet

- MHT Global Utilities Presentation v2 JKDocument62 pagesMHT Global Utilities Presentation v2 JKJan KamerNo ratings yet

- AED Building Physics PDFDocument48 pagesAED Building Physics PDFaasimalyNo ratings yet

- Tianjin Sdic Project: China's Largest Desalination PlantDocument2 pagesTianjin Sdic Project: China's Largest Desalination PlantAverroesAlhazenNo ratings yet

- Masdar City Abu Dhabi, Uae Siemens Middle East Headquarters (2013) 22800.0 SQM Ar - Sheppard Robson 17724Document37 pagesMasdar City Abu Dhabi, Uae Siemens Middle East Headquarters (2013) 22800.0 SQM Ar - Sheppard Robson 17724Agastya DasariNo ratings yet

- Mechanical Vapour Compression MVC BrochureDocument6 pagesMechanical Vapour Compression MVC BrochureNitin KurupNo ratings yet

- Casestudy16 Gorsline Building Preserve HistoryDocument2 pagesCasestudy16 Gorsline Building Preserve HistorymajortayNo ratings yet

- HBS Tata Hall Case Study Highlights Building's Sustainable and Efficient DesignDocument14 pagesHBS Tata Hall Case Study Highlights Building's Sustainable and Efficient DesignAnil AbduNo ratings yet

- E Me 130 LPG Pressure Storage SpheresDocument24 pagesE Me 130 LPG Pressure Storage SpheresatiqulaNo ratings yet

- M-me-130-Lpg Pressure Storage Vessels and SpheresDocument18 pagesM-me-130-Lpg Pressure Storage Vessels and SpheresatiqulaNo ratings yet

- Monster Industrial ManholeDocument2 pagesMonster Industrial ManholeatiqulaNo ratings yet

- Air Distribution N Outlet SelectionsDocument43 pagesAir Distribution N Outlet SelectionsatiqulaNo ratings yet

- Henry Law Use in Process SimulationDocument7 pagesHenry Law Use in Process SimulationrvicentclasesNo ratings yet

- System Curve MakingDocument1 pageSystem Curve MakingatiqulaNo ratings yet

- Developing System Head Curves For Closed SystemDocument6 pagesDeveloping System Head Curves For Closed SystematiqulaNo ratings yet

- Eelements of Calculation StyleDocument43 pagesEelements of Calculation StyleatiqulaNo ratings yet

- Selecting The Proper Flare System PDFDocument6 pagesSelecting The Proper Flare System PDFjdgh1986100% (1)

- Chiller Plant EfficiencyDocument28 pagesChiller Plant EfficiencyatiqulaNo ratings yet

- 30K Data Sheet North AmericaDocument2 pages30K Data Sheet North AmericaatiqulaNo ratings yet

- NN 100 PackageDocument2 pagesNN 100 Packageprasadblr3462No ratings yet

- Comparison of Clean Agent and Sprinkler System Performance On In-Cabinet FiresDocument44 pagesComparison of Clean Agent and Sprinkler System Performance On In-Cabinet FiresatiqulaNo ratings yet

- GLACIER LAr Tank Design (Deliverable 2.2)Document76 pagesGLACIER LAr Tank Design (Deliverable 2.2)atiqulaNo ratings yet

- Central Chiller PlantDocument2 pagesCentral Chiller PlantatiqulaNo ratings yet

- Blood Pressure.14Document1 pageBlood Pressure.14atiqulaNo ratings yet

- Belimo ActuatorsDocument8 pagesBelimo ActuatorspalindapcNo ratings yet

- Zinc - Scientific Review On Usage, Dosage, Side Effects - ExamineDocument39 pagesZinc - Scientific Review On Usage, Dosage, Side Effects - Examineatiqula0% (1)

- Maca - Scientific Review On Usage, Dosage, Side Effects - ExamineDocument24 pagesMaca - Scientific Review On Usage, Dosage, Side Effects - ExamineatiqulaNo ratings yet

- Hydraulic Balance in A District Cooling System: Technical PaperDocument9 pagesHydraulic Balance in A District Cooling System: Technical PaperatiqulaNo ratings yet

- Rhodiola Rosea - Scientific Review On Usage, Dosage, Side Effects - ExamineDocument35 pagesRhodiola Rosea - Scientific Review On Usage, Dosage, Side Effects - ExamineatiqulaNo ratings yet

- Abb - The Motor GuideDocument118 pagesAbb - The Motor GuideRolando DaclanNo ratings yet

- Blood Glucose - Scientific Review On Usage, Dosage, Side Effects - ExamineDocument9 pagesBlood Glucose - Scientific Review On Usage, Dosage, Side Effects - ExamineatiqulaNo ratings yet

- Miller Compensation PDFDocument7 pagesMiller Compensation PDFatiqulaNo ratings yet

- Control Valve Selection For Optimal Hydronic System PerformanceDocument7 pagesControl Valve Selection For Optimal Hydronic System PerformanceatiqulaNo ratings yet

- Coenzyme Q10 - Scientific Review On Usage, Dosage, Side Effects - ExamineDocument42 pagesCoenzyme Q10 - Scientific Review On Usage, Dosage, Side Effects - Examineatiqula0% (1)

- Irina Tweedie Interview Script PDFDocument10 pagesIrina Tweedie Interview Script PDFatiqulaNo ratings yet

- Hybrid Head AmpDocument1 pageHybrid Head AmpatiqulaNo ratings yet

- 2.lecture On Hydraulic TurbineDocument52 pages2.lecture On Hydraulic TurbineEng Bagaragaza RomualdNo ratings yet

- PIPING IdentificationDocument49 pagesPIPING IdentificationSiji OktoberNo ratings yet

- IFP Matrix by Project Milestones As of July 2019 PDFDocument11 pagesIFP Matrix by Project Milestones As of July 2019 PDFAngelica BalonggaNo ratings yet

- Prezentare CIBSE PT EN806Document56 pagesPrezentare CIBSE PT EN806danateoNo ratings yet

- Humidification / Dehumidification SystemDocument4 pagesHumidification / Dehumidification SystemMatias RolonNo ratings yet

- Kenya Water Design - Manual - 2005 PDFDocument500 pagesKenya Water Design - Manual - 2005 PDFChege KagoNo ratings yet

- Water Conservation Efforts at SchoolDocument66 pagesWater Conservation Efforts at SchoolAlberto CumerlatoNo ratings yet

- Course PDFDocument2 pagesCourse PDFRoanne CadangNo ratings yet

- Hydraulic Design of Sewer PipesDocument34 pagesHydraulic Design of Sewer PipesAkhil Shetty100% (1)

- Water Reticulation Design GuidelinesDocument32 pagesWater Reticulation Design GuidelinesVhuso Mwafuka Maringe50% (2)

- Muse Maya Wave Installazione enDocument24 pagesMuse Maya Wave Installazione enCalin SimionNo ratings yet

- Watershed Management and Rainwater HarvestingDocument9 pagesWatershed Management and Rainwater HarvestingAtharv ShrotriyaNo ratings yet

- Water Refilling Station Engineer's ReportDocument3 pagesWater Refilling Station Engineer's ReportPaw LabadiaNo ratings yet

- OPERATION OF THE BW-300 SERIES & BW 405 THERMOSTATIC SHOWERDocument16 pagesOPERATION OF THE BW-300 SERIES & BW 405 THERMOSTATIC SHOWERvimmakNo ratings yet

- EPA Arsenic FactsheetDocument2 pagesEPA Arsenic FactsheetEric CheahNo ratings yet

- As NZS 2419-1-1994 Fire Hydrant Installations Part 1 System Design Installation and CommissioningDocument66 pagesAs NZS 2419-1-1994 Fire Hydrant Installations Part 1 System Design Installation and CommissioningdavidNo ratings yet

- Pressure-Controlled Pumps CascadeDocument2 pagesPressure-Controlled Pumps Cascadecc_bauNo ratings yet

- Quantity Surveying GuideDocument21 pagesQuantity Surveying GuideShivani KothawadeNo ratings yet

- Catching Water Where It FallsDocument50 pagesCatching Water Where It FallsASHUTOSH SINGHNo ratings yet

- 4985 PDFDocument26 pages4985 PDFgavallapalliNo ratings yet

- DN15-40 Water MetersDocument3 pagesDN15-40 Water MetersRashedNo ratings yet

- Eedm NotesDocument86 pagesEedm NotesManvi Asija100% (1)

- Kerala Govt Clarifies Service Tax Rules for Construction WorksDocument3 pagesKerala Govt Clarifies Service Tax Rules for Construction WorksViswalal ViswanathanNo ratings yet

- IVRCL Profile: EPC, Manufacturing & Engineering LeaderDocument37 pagesIVRCL Profile: EPC, Manufacturing & Engineering LeaderSanjay RoutNo ratings yet

- Biocontamination Control Techniques For Purified Water SystemDocument4 pagesBiocontamination Control Techniques For Purified Water SystemAli KureishiNo ratings yet

- Unit-4 Sewer Appurtenances - Only Introduction (4 Hours) R2Document13 pagesUnit-4 Sewer Appurtenances - Only Introduction (4 Hours) R2Girman RanaNo ratings yet

- Small Earth Dams and DugoutsDocument5 pagesSmall Earth Dams and DugoutsWiwik WidyaNo ratings yet

- Chapter Five SpillwaysDocument85 pagesChapter Five SpillwayssubxaanalahNo ratings yet

- Express Water Magazine - March 2018Document52 pagesExpress Water Magazine - March 2018mayur_259100% (3)

- Water LegislationDocument33 pagesWater LegislationBongi FaithNo ratings yet