Professional Documents

Culture Documents

1110 0003 W en - WW

Uploaded by

hitm357Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1110 0003 W en - WW

Uploaded by

hitm357Copyright:

Available Formats

Technical Documentation

DOC-1110-0003

Introduction

Liquid caustic soda must be stored and disposed of in compliance with relevant laws and regulations. Handling of liquid caustic soda should be accompanied by collective protective measures (clearly signalled showers and eye baths in the vicinity). Please consult our safety data sheet.

Storage tank capacity

The tank capacity should be adequate to carry a sufficiently large stock and be able to receive the total amount of volume from the road tanker. If the consumption of liquid caustic soda is less than 50 tonnes per month, the ideal storage capacity should be at least 1,5 x the volume of the road tanker. This should be suitably adapted if the consumption of liquid caustic soda is higher than 50 tonnes per month.

Storage tank labelling

The storage tank should be labelled with the product name, the safety symbol, the tank identification as well as with the orange ADR plate. Liquid caustic soda

Tank #

Example: tank label

Storage tank materials

Liquid caustic soda is a corrosive product. Liquid caustic soda is currently stored in steel, nickel, nickel alloys or certain types of plastic materials. The choice is determined by temperature, concentration, tank location, safety issues, and the end use. Stainless steel Austenitic stainless steel AISI 304L is suitable for AISI 304/316/316L are also adequate, but to a lesser extent. temperatures upto 70 C.

Low carbon steel Unlined soft steel with a corrosion allowance is suitable if the iron content in the end product is not important, and the storage temperature is not higher than 45 C. Stress relaxation is recommended. A carbon content between 0,18 and 0,25% is the best compromise between ductility/weldability and stress cracking resistance. Stress cracking or caustic embrittlement in unlined soft steel could occur if the liquid temperature is higher than 45 C.

Solvay Chemicals International SA Rue de Ransbeek 310 B - 1120 Brussels Brussels, RPM 0406804736 +32 2 264 21 11 www.solvaychemicals.com DOC-1110-0003-W-EN (WW) Issue 3 - June 2009

1/4

LIQUID CAUSTIC SODA

LIQUID CAUSTIC SODA - STORAGE

Technical Documentation

Lined steel Lined soft steel with a corrosion allowance is suitable if the iron content in the end product is important or the temperature of the liquid is higher than 45 C. Vinyl ester, epoxy or ebonite are suitable liners. The condition of the liner should be checked according to supplier specification. Plastics Plastic tanks might be used if the supplier specifications are strictly followed. The maximum allowed pressure and vent line must be checked if compressed air is used during unloading. GFRP with a PP lining or a PVC lining are suitable to a maximum temperature of 60 C. GFRP makes the construction more rigid, whereas the lining provides resistance to corrosion. The condition of the liner should be checked according to supplier specification. Spiral wound extruded HDPE to a maximum temperature of 45 C or PP to a maximum temperature of 60 C are adequate for small storage tanks.

Storage tank equipment

The tank must be fitted with the following: - filling line of at least DN 50, with a clearly labelled coupling point at a maximum of one meter above ground level, - vent line of at least DN 100 on top of the storage tank, - overflow line of at least DN 100, directed towards the ground and inside the bund, - manhole, - tank fluid level measurement device, - high-level alarm, to avoid overflow and in the case of unloading with pump to switch it off, - low-level alarm, to avoid cavitation and to switch off the transfer pump to the end-use. - discharge line. If there is a risk of solidification due to the product freezing at low temperatures, a temperature controller should be installed. Note: The size of vent and overflow lines should be larger or equal in size to the filling line.

Bund

The storage tank must be placed on an adequate reinforced concrete foundation to support the tank and must be placed in a bund, containment dyke or be double walled. Liquid caustic soda corrodes concrete. Epoxy paint coating gives good corrosion protection. At least potentially exposed surfaces i.e. pump base/foundation, etc. should be protected. Rainwater collected inside the bund may contain liquid caustic soda. Connecting the bund area to the sewer system is not recommended. A valve between the bund and a sewer system is not sufficient to protect the sewer system from possible contamination of liquid caustic soda i.e. valve may be left open by mistake. The safest way of emptying the bund is to use a manually operated pump. Pipes should be passed over the bund walls and not through them. It is essential that the bund and bund wall is sealed liquid-tight from the top to the bottom. Caution: Storage tanks of products which are not compatible with liquid caustic soda (e.g., hydrochloric acid) should not be placed in the same bund.

Solvay Chemicals International SA Rue de Ransbeek 310 B - 1120 Brussels Brussels, RPM 0406804736 +32 2 264 21 11 www.solvaychemicals.com DOC-1110-0003-W-EN (WW) Issue 3 - June 2009

2/4

LIQUID CAUSTIC SODA

LIQUID CAUSTIC SODA - STORAGE

Technical Documentation

Pipes, valves and pumps

Pipes Stainless steel pipes are suitable for transporting liquid caustic soda up to 70 C. Carbon steel pipes are adequate if the iron content of the product is not important. Plastic pipes e.g. GFRP with PP or PVC lining are adequate Please be aware that the pressure resistance of the pipe decreases rapidly when temperature increases. Plastic pipes should be supported over their whole length. Supplier specifications should be followed. Valves Stainless steel valves are recommended for liquid caustic soda use. Pumps Stainless steel or cast iron with double mechanical seal centrifugal pumps are suitable for liquid caustic soda transfer. Issues with shaft tightening are avoided by using magnetic driven pumps. Membrane pumps are suitable for a consistent delivery dose of liquid caustic soda: Their EPDM-membrane should be provided with PTFE-lining, and their housing should be made of PVC, PP or stainless steel. Gaskets Gaskets made of modified PTFE or carbon with a nickel inlay should be used.

Heating and thermal insulation

Tanks and pipelines should be insulated and/or fitted with a heating system if the product is stored outside or in an unheated building. The freezing temperature depends of the product concentration. (e.g., liquid caustic soda 50% freezes at 12 C). In order to minimise corrosion and reduce stress-fracture risks in unlined soft steel tanks, the storage temperature must not exceed 45 C. Electrical tracing is the simplest method of heating. Warm water circulation is also adequate. Steam circulation could be acceptable but, in this case, nickel heaters are compulsory and supervision is required in order to avoid local overheating and the accelaration of the corrosion rate. An external heating system is recommended.

EPDM: GFRP: HDPE: PP: PTFE: PVC:

Ethylene Propylene DiMonomer Glass Fibre Reinforced Polyester High-Density PolyEthylene PolyPropylene PolyTetraFluoroEthylene PolyVinyl Chloride

Solvay Chemicals International SA Rue de Ransbeek 310 B - 1120 Brussels Brussels, RPM 0406804736 +32 2 264 21 11 www.solvaychemicals.com DOC-1110-0003-W-EN (WW) Issue 3 - June 2009

3/4

LIQUID CAUSTIC SODA

LIQUID CAUSTIC SODA - STORAGE

Technical Documentation

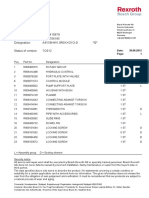

Example: Storage tank bottom unloading with compressed air

Example: Storage tank bottom unloading with pump

1 2 3 3 4 5 6 7 8 8

Flexible hose Flushing water Unloading pump Transfer pump (to the end-use) Pressure gauge Filling line Overflow line Level measurement High level alarm Low level alarm

9 10 11 12 13 14 15 16 17

Vent line Drain valve Bund To end use To waste treatment Thermometer Heat exchanger Thermal insulation Collection sump

__________________________________________________________________________________________________________ To our present knowledge, the information contained herein is accurate as of the date of this document. However, we do not make any warranty, express or implied, or accept any liability in connection with this information or its use. This information is for use by technically skilled persons at their own discretion and risk and does not relate to the use of this product in combination with any other substance or any other process. This is not a license under any patent or other proprietary right. The user alone must finally determine suitability of any information or material for any contemplated use, the manner of use in compliance with relevant legislations and whether any patents are infringed. We reserve our right to make additions, deletions, or modifications to the information at any time without prior notification.

Solvay Chemicals International SA Rue de Ransbeek 310 B - 1120 Brussels Brussels, RPM 0406804736 +32 2 264 21 11 www.solvaychemicals.com DOC-1110-0003-W-EN (WW) Issue 3 - June 2009

4/4

LIQUID CAUSTIC SODA

LIQUID CAUSTIC SODA - STORAGE

You might also like

- Advanced Ms Excel ManualDocument51 pagesAdvanced Ms Excel ManualMohamed Hussain100% (4)

- CI 2013 CatalogDocument15 pagesCI 2013 Cataloghitm357No ratings yet

- Pip Stf05521Document16 pagesPip Stf05521joelgir32100% (5)

- PIP Process Industry Practices. 'Piping' Piping Support DetailsDocument167 pagesPIP Process Industry Practices. 'Piping' Piping Support DetailsLynn Bishop100% (5)

- Oxychem Caustic Soda HandbookDocument44 pagesOxychem Caustic Soda HandbookManoj PanchalNo ratings yet

- Sodium HydroxideDocument16 pagesSodium Hydroxidehitm357No ratings yet

- Chris Brooks - Storage Tanks Inspection, Maintenance and FailureDocument43 pagesChris Brooks - Storage Tanks Inspection, Maintenance and FailureAnderson ReyesNo ratings yet

- Caustic Soda ManualDocument63 pagesCaustic Soda ManualFarhan Zafar Khan100% (1)

- Cathodic ProtectionDocument61 pagesCathodic Protectionnavinchopra1986100% (2)

- Cathodic Protection For Storage Tanks and Buried PipingDocument62 pagesCathodic Protection For Storage Tanks and Buried PipingBalakumar100% (1)

- Electrical Engineering Cathodic ProtectionDocument319 pagesElectrical Engineering Cathodic ProtectionGiovanni LerasNo ratings yet

- Airmaster User ManualDocument333 pagesAirmaster User Manualhitm357No ratings yet

- BCSA Allocation of Design Responsibilities in Constructional Steelwork - Orange Book FINALDocument18 pagesBCSA Allocation of Design Responsibilities in Constructional Steelwork - Orange Book FINALDifa LiuNo ratings yet

- SteelDoc 05 2007Document67 pagesSteelDoc 05 2007hitm357No ratings yet

- Ab-094 Welding Examiner SyllabusDocument8 pagesAb-094 Welding Examiner Syllabushitm357No ratings yet

- Catalog CombinedDocument64 pagesCatalog Combinedflanker_13No ratings yet

- Ab-59 Ice SyllabusDocument44 pagesAb-59 Ice Syllabushitm357No ratings yet

- CSWIP 3-2-2010 WIS10 Senior Welding InspectionDocument318 pagesCSWIP 3-2-2010 WIS10 Senior Welding Inspectionhitm357No ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- Piping Design ManualDocument155 pagesPiping Design Manualnick10686100% (1)

- Beginner - Guide PLC ControllerDocument255 pagesBeginner - Guide PLC ControllerLuís Ki-llahNo ratings yet

- Comprehensive Inspection FormDocument17 pagesComprehensive Inspection FormbaworsNo ratings yet

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- 2 & 3 Phase SeperatorsDocument7 pages2 & 3 Phase Seperatorshitm357No ratings yet

- Ogc Reg 220 74 ExemptionDocument1 pageOgc Reg 220 74 Exemptionhitm357No ratings yet

- Pfi-Es-3 (2000) PDFDocument4 pagesPfi-Es-3 (2000) PDFBarnum Pebble Darrel100% (1)

- 2 3Phase-Separators PDFDocument8 pages2 3Phase-Separators PDFReza RhiNo ratings yet

- Ogc Reg 151 71 OgcrDocument167 pagesOgc Reg 151 71 Ogcrhitm357No ratings yet

- Ogc Reg 045 2001 OrphanDocument6 pagesOgc Reg 045 2001 Orphanhitm357No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Operating Instructions - Flowfit CYA27Document68 pagesOperating Instructions - Flowfit CYA27brunotrdNo ratings yet

- Combi WRDocument93 pagesCombi WREdinson FlorianoNo ratings yet

- Weishaupt WG20Document8 pagesWeishaupt WG20batazivoNo ratings yet

- Burners and Torches: National Handtorch Type 3A BlowpipeDocument14 pagesBurners and Torches: National Handtorch Type 3A Blowpipefrenzy personNo ratings yet

- Brass Gate Valve PN16: Technical CatalogueDocument10 pagesBrass Gate Valve PN16: Technical Cataloguekikokiko KarimNo ratings yet

- Volumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmDocument19 pagesVolumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmGreen FarmersNo ratings yet

- R 001 PDFDocument152 pagesR 001 PDFleekiangyenNo ratings yet

- Catalogo Carton Clamp Serie DDocument4 pagesCatalogo Carton Clamp Serie DPipe BonillaNo ratings yet

- Diesel Inspection Testing FormDocument6 pagesDiesel Inspection Testing Form5463RNo ratings yet

- LCS BrochureDocument8 pagesLCS BrochureemmanolanNo ratings yet

- Olympus GIF 180 Gastrointestinal Videoscope - Instructions PDFDocument110 pagesOlympus GIF 180 Gastrointestinal Videoscope - Instructions PDFFatima HammoudNo ratings yet

- Gas Pressure RegulatorDocument12 pagesGas Pressure RegulatorSarah DeanNo ratings yet

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudylguardiaNo ratings yet

- 6 44 0006 Rev6Document415 pages6 44 0006 Rev6karunaNo ratings yet

- Engine Build Alternator Model: FD3-1.4A1 EG160-8NDocument1 pageEngine Build Alternator Model: FD3-1.4A1 EG160-8NSutan PauloNo ratings yet

- Sunstrand Hydro Service ManualDocument69 pagesSunstrand Hydro Service ManualKevins Small Engine and Tractor Service100% (8)

- VFT Catalogue 2010Document91 pagesVFT Catalogue 2010sanjeevvangeNo ratings yet

- Salon Tipi 3 Faz ServisDocument79 pagesSalon Tipi 3 Faz ServisaydintarakNo ratings yet

- Fassi F45A.22 PDFDocument80 pagesFassi F45A.22 PDFSaulius KlimkeviciusNo ratings yet

- Catalog Mechatronics Compact SystemDocument17 pagesCatalog Mechatronics Compact SystemPirlo QuangNo ratings yet

- Ignition StartingDocument42 pagesIgnition StartingTarik Benzineb100% (5)

- Insul.: Pipe Outside Diameter 139,7 MM AND WALLDocument1 pageInsul.: Pipe Outside Diameter 139,7 MM AND WALLI Made Gumi SetiawanNo ratings yet

- 1001 Service Manual Tier IIIDocument162 pages1001 Service Manual Tier IIIAlberto100% (1)

- Viega G3 INT K 2013Document26 pagesViega G3 INT K 2013ricochetoNo ratings yet

- Is 2347.2006Document20 pagesIs 2347.2006Sunil Devdutt ThakoreNo ratings yet

- A4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Document25 pagesA4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Alonso TabordaNo ratings yet

- Case Cx350 Crawler Excavator Shop ManualDocument20 pagesCase Cx350 Crawler Excavator Shop Manualpatrick100% (54)

- StanadyneDocument4 pagesStanadynemurillo_rodriguez8382No ratings yet

- Breaker 6720280 enUS SM 06-12 PDFDocument260 pagesBreaker 6720280 enUS SM 06-12 PDFHenry HuayhuaNo ratings yet