Professional Documents

Culture Documents

Reliability Assesment of Jacket Structure

Uploaded by

nazeer_mohdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reliability Assesment of Jacket Structure

Uploaded by

nazeer_mohdCopyright:

Available Formats

Petroleum & Coal ISSN 1337-7027 Available online at www.vurup.

sk/petroleum-coal Petroleum & Coal 53 (4) 291-301, 2011

RELIABILITY ASSESSMENT OF OFFSHORE JACKET STRUCTURES IN NIGER DELTA

M.A. Salau1, D.E. Esezobor2, M. F. Omotoso1 Department of Civil & Environmental Engineering, University of Lagos, Akoka, Yaba Lagos State, Nigeria, mattfunso@yahoo.com 2 Department of Metallurgical & Materials Engineering University of Lagos, Akoka, Yaba Lagos State, Nigeria

Received July 26, 2011, Accepted October 15, 2011

1

Abstract Jacket platform is essential for continuous crude oil production in Nigerian offshore oil and gas fields. However, the structures are constantly exposed not only to hostile environment and operational conditions but as well as seawater that consists of salty and oxygenated water with high pH level that accelerates corrosion process. This phenomenon leads structural members to reduction in thickness with time. The application of the available computer software used for offshore structural assessment, simply give data about the structural member strength with no information regarding structural system reliability. In this paper, a time-variant formulation technique for the accurate estimation of corroded jacket structural system reliability is derived and presented by utilizing series and parallel reliability theories. The results of the study established that the reliability of a jacket structures is the product of bracings and legs reliabilities and this value decreases with platform age.

Keywords: Jacket Structures; Corrosion; Reliability Assessment; Niger Delta.

1. Introduction Offshore jacket platforms are commonly adopted structures for oil and gas production in Nigerian shallow and intermediate water depths (water depth less than 300 m). A large numbers of these existing structures are operating beyond design life due to high cost of replacement. Consequently, there is a growing need to closely monitor the operational integrity of the platforms to prevent unexpected failures. The safety of this offshore platform creates strong reasons to develop effective methods for the reliability assessment of jacket structures in Nigerian territorial waters. The major causes of engineering steel structural failure in marine environment are accredited to components corrosion damage and related hazards with negative impact on personnel safety and production loss. The investigation on damaged offshore structures installed in the North Sea for about 50 years ago demonstrates that fatigue and corrosion accounted for about 40.4% of the structural damages [1]. Steel components with limited assess and poor performance of Cathodic Protection (CP) systems are noted for excessive losses to corrosion that often lead to cost intensive repairs and replacement, particularly jacket structures [2]. The safety of an offshore platform is generally assumed to be achieved by appropriate design, according to the established standards and procedures. However, there is a general recognition that assessment method for existing structures is quite different from new design process [3]. The compliance with existing rules and regulations may grant jacket structures safety during design stage, however this may not be appropriate for jacket assessment, most especially when the structure is corroded and ageing [4] Structural inspection and assessment, accompanied by repair or replacement can be means of preventing corrosion failure in members and joints. In this case, the amount of inspection is critical and based on the inspection planning by the facilities operators. Inspection planning relies on probabilistic analysis or Risk-Based Inspection (RBI). Recently, the Classification Societies have suggested conducting inspections of offshore jacket platforms at regular intervals during the structures operating life, which may provide

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

292

vital information for monitoring platform conditions [5]. The probability of structural failure could therefore be determined with the use of outcome of this inspection data. However, applications of proper structural design, inspection, and maintenance with effective corrosion mitigation measures are viewed as a way of preventing offshore structural failures. Studies [6-7] have proved that enduring reliability appeared possible for offshore platform provided the structure has sufficient strength. The system reliability of intact structures that free from corrosion dent is usually presumed to be 100%. This value decreases as the structural member thickness reduces with the jacket age. A ratio known as reliability factor is proposed in this paper for establishing a relationship between intact and corroded structures and determining reliability reduction rates. A schematic diagram of an offshore jacket platform is showed in figure 1.

Topside FACILITIES

MWL

Jacket Structures

Mudline

Figure 1 Schematic of Offshore Jacket Platform 2. Methodology 2.1 Theoretical background 2.1.1 Structural reliability method One of the aims of applying structural reliability methods in offshore design guidelines is to identify the members that are truly critical and establish if additional member can improve structural system reliability [8]. Reliability assessment for a jacket structural system may be complex due to the structure several bracings. However, with sufficient knowledge of reliability theory it is possible to establish jacket structural system reliability. The series or chain reliability system requires only a member to fail before the entire system fails. Platform legs demonstrate series reliability system when failure of a leg in a 4-legged jacket structures rendered the whole platform unsuitable for operation. However, higher reliability of each leg improves the system. Parallel system reliability (active parallel or stand-by parallel) can be applicable to structural bracings that support external loads as a group. When any bracing member fails, the load shed by the failed member will be supported by the other intact members in the group. Corroded and failed jacket bracing member is a classical example of this scenario. Jacket bracing arrangements illustrate parallel reliability system since damage of a bracing member does not result to the platform failure. Increase in number of bracing improves the system reliability. However, correlation between the bracings member reduces this benefit. The time-variant reliability and corresponding reliability factor as a function of time with due consideration to corrosion rate is described below. Here, the time-variant reliability is defined by Equation (1).

R (t ) = 1 Pf (t )

(1)

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

293

Where R(t) and Pf(t) represent member reliability and probability of failure respectively Equation (2) can be written in term of member initial thickness and time variant corrosion wastage, as shown in Equation (2) and (3).

R(t ) = T Pf (t )

(2) (3)

R (t ) = 1

t T

Where, T represents initial member thickness and t thickness loss due to corrosion. 2.1.2 Series Reliability Model The system reliability estimation as illustrated in Figure (2) can be represented in Equation (4) [7].

R(s)(t ) = R( pA ).R( pB ).R( pC ).R( pD )

(4)

where RA, RB, RC and RD represent the reliability of components A, B, C, and D, QA, QB, QC, and QD represents the probability of failure of A, B, C, and D. The success of the system (S) can be represented in terms of Boolean logic in equation (5):

S = A BC D

The reliability or probability of success of the systems is:

(5) (6) (7)

RS = RA . RB . RC . RD

For n components in series, it is written as:

R S = R1 . R 2 . R 3 . R 4 R n

The characteristics of series systems are that the greater the number of the components, the lower the system reliability while the least reliable component in the system will determine the overall reliability of the system. 2.1.3 Parallel reliability Parallel reliability system is designed with redundant components. This is often done when reliability of a system may be low as time goes on due to material degradation [9] as it is applicable to jacket bracing structural members sited in a corrosive environment. However, parallel systems may either be Active or Stand-by Parallel system. For Active Parallel System, the whole components are active at all times. For a Standby Parallel System, some of the components will be standing-by in a ready state to act in place of failed ones. Figure 3 shows active parallel systems, where component A and B are active at all times. The system is believed to be operating at all times under one of the following conditions: (1) A and B is both operating, (2) Item A is operating and B has failed, (3) Item B is operating and A has failed. But when both A and B fail, then the system is considered a failure.

INPUT OUTPUT

PA

PB

PC

PD

Figure 2 Schematic of Four Pipes Series Reliability Diagram

A

INPUT INPUT

B

Figure 3 Diagram of an Active Parallel System The calculation for the reliability of active parallel reliability system is expressed in Eq. (8).

R (s ) = R (a ) + R (b ) R (a ). R (b )

(8)

where: R(s) is the reliability of the system, R(a) and R(b) are the reliabilities of the system components.

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

294

For the Standby parallel, the system is fully redundant. Any one of A or B or combination A and B in working condition will make the system success. All components must fail for the system to fail. The failure of Stand-by Parallel can be represented in Boolean Logic as:

F = A B

The probability of the system failure is given by either:

(9) (10)

PS = P A .PB

RS = 1

{(1

R A )( . 1 RB

)}

(11)

2.1.4 Jacket Group Bracing Reliability (Active Parallel) The reliability estimation for group bracing A for a jacket structures is illustrated in Figure 4 whose bracing member arrangement is in active parallel mode and can be represented by Equation (9).

RA =1[(P a +P b +P c +P d. P a.P b.P c.P d )]

(12)

where: RA is reliability of bracing group A and Pa, Pb, Pc, Pd are the failure probabilities of each bracing members or member thickness corrosion loss. The reliability of other bracing groups B, C, D, E, and F will be also estimated according to the formula in Equation (12).

L4

L1 L3

L2

MWL

(+) 4.0

d a

Group A: Consist of all the diagonal bracings between Level (+) 4.0m and (-) 7.0m

EL (-) 7.0 Group B: Consist of all the horizontal bracings in Level (-) 7.0m

Group C: Consist of all the diagonal & vertical bracings between Level (-) 7.0m and (-) 18.3m

EL (-) 18.3 Group D: Consist of all the horizontal bracings in Level (-) 18.3m

Group E: Consist of all the diagonal & vertical bracings between Level (-) 18.3m and (-) 32.0m

B A

EL (-) 32.0 Group F: Consist of all the horizontal bracings in Level (-) 32.0m

1 2

Figure 4 Jacket Structure Diagram showing Bracing Member Groups and Support Legs

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

295

Bracing Member Groups in Parallel Reliability Mode

. RA

RB

RC

Jacket Platform Legs in Series Reliability Mode

Input RD

R1

R2

R3

R4

Out put

RE

RF

Figure 5 Jacket Structural Reliability Schematic Diagram 2.1.5 Complete Jacket Bracing Reliability (Stand by Parallel) The individual bracing group reliability A, B, C, D, E, and F is represented as:

R A , R B , R C , , R D , , R E , R F .The reliability for the complete bracing group is parallel in

manner and is represented mathematically in equations (13) and (14).

RSG = 1 {(1 RA )( . 1 RB )(1 RC )(1 RD )(1 RF )}

(13) (14)

R SG = 1 PA . PB . PC . PE . PF

where:

P A . P B . PC . P E . P F

is the failure probability of individual group bracings

2.1.6 Jacket Legs Reliability For a fixed offshore jacket platform, the pile head is assumed to be located at mudline. The legs system reliability is defined as a product of individual leg reliability since every jacket legs is essential for the successful operation of platform. Accordingly, for a four legged jacket platform the system reliability RSL is shown in equation 15.

R SL = R 1 . R 2 . R 3 . R 4

2.1.7 Jacket System Reliability

(15)

where:R1, R2, R3,R4, is the correspondent reliability for each jacket platforms four legs. Jacket platform structure consists of legs and bracings at different levels, along the structure length. The jacket system reliability could be obtained by applying network reduction techniques. The network reduction illustrated in Figure 5 is the most appropriate one for a four legged jacket structures with six bracing groups. RA, RB, RC, RD, RE and RF represent individual bracing groups that are arranged in parallel and R1, R2, R3 and R4 represent the four jacket legs that are arranged in series. Based on Equation (16), the structural system reliability of a jacket structures due to corrosion loss is the product of jacket bracings reliability and reliability of jacket platform legs.

R JS = R SL . R SG

(16)

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

296

However, to make use of assessment method narrated in the above sections, certain field works need to be carried out. The existing jacket structural member thicknesses proposed for assessment are required with the differences between member original thickness and existing thickness. The reliability calculations for the jacket structures in this case study using excel software and following the method narrated above is presented in Table 2, 3, 4 and 5 respectively. 2.2 Field Analysis The offshore jacket platform that was surveyed was installed in 1985 on 4-leg fixed steel jacket structures in a water depth of 32m. Ultrasonic Test, (UT) illustrated in Figure 6, was employed to conduct the surveillance on the jacket structural members to determine the extent of corrosion loss and flaws. The UT test was performed on three sports along each member length. The point with minimum thickness was adopted as current thickness for the member. Figure 7 shows the jacket structures elevations, plans, and sections at different levels, while Table 1 gives the values for the jacket member thickness.

Figure 6 Detection and Reflection of Ultrasonic Beam Table 3 Complete Jacket Bracing Reliability (Stand by parallel Systems) Group A B C D E F Reliability = RSG ID RA RB RC RD RE RF Reliability (R) 0,9396 0,7717 0,9475 0,5879 0,4102 0,6158 1 - PA.PB.PC.PD PE.PF Failure Probability P = (1 - R) 0,06036 0,22834 0,05249 0,41214 0,58985 0,38421 0,999932430

Table 4 Jacket Legs Reliability (Series Systems) Group Support L ID L01, (PL1) L02, (PL2) L03, (PL3) L04, (PL4) Reliability (RSJ) 3. Results and discussion With reference to jacket members corrosion loss data got in 2008 and shown in Table 1, the jacket structural reliability systems was established using excel software. The Corrosion Loss = tp (%) 7,080 6,361 4,976 4,309 Failure Probability (P = tp/100) 0,0708 0,06361 0,04976 0,04309 Reliability (1 - P) 0,9292 0,93639 0,95024 0,95691 0,7912

PL1.PL2. PL3.PL4

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

297

reliability of the group bracings was estimated and presented in Table 2. The complete bracing member reliability and jacket legs reliability were also established in Table 3 and 4 respectively. The overall reliability of the jacket structural systems and reliability factor were also estimated and presented in Table-5. The data gathered during the platform survey includes anodes percentage utilization. The survey revealed that anodes located in the splash zone are depleted faster than the one placed in the other tidal zones along the jacket length. A jacket structural member was flooded due to pitting corrosion in the joint welds. The entire jacket was found to be covered with uniform rusting. The member corrosion losses range from 0% to 17% compared with members as built thickness. The rate of corrosion is found to be higher in the splash zone than any other tidal zones due to accelerated corrosion process in the area. In this paper, the failure mode of jacket structures was interpreted as either series or parallel systems and depends on member arrangement and correlation. The bracing members are in parallel systems failure mode and majority of bracings yield for failure before the structure collapse mode is wholly developed. The failure mode of a jacket platform legs is associated with series system and if any one of the legs develop failures mode the whole platform is considered to has failed and recommended for abandonment. The reliability assessment method developed in this study is most appropriate since the technique eliminate the rigorous exercises associated using 3D computer software for existing platform assessment due to member corrosion losses. The method is a handy tool to monitor structural safety with regards to structural member thickness corrosion loss and it can be accomplished with pocket calculator or Microsoft excel-software. Reliability Factor (FR) is proposed in the study to establish jacket structures safety as the platform is ageing. 3.1 Reliability Factor The reliability of a newly installed jacket is 1 or 100%, since the structural members are corrosion free. A factor (RF) is hereby established between an intact and corroded jacket structural system reliability to determining the rate of structural system reliability decreases. The proposed factor can be represented mathematically as:

RF =

1 Rn

(17)

Rn Jacket structural system reliability Accordingly, jacket reliability prediction for the year 2008 is estimated and presented in Table 5. The factor is essential to determine jacket safety during the operating lifecycle as the factor shows jacket reliability reduction rates. The value is suggested to be 1.0 to 1.25 since load factor of safety is about 1.25 depending on the load under consideration. However, this factor may be fixed by individual operator of the platforms based on her best engineering practice. Table 5 System Reliability & Reliability Factor Estimation S/N 1 2 3 4 5 Period Duration Support Legs (RSL) Jacket Bracing (RSG) Reliability (RSJ) Reliability Factor (RF) 1985 0 yrs 1 1 (1.0 x1.0) =1.0 (1.0/1.0) =1.0 2008 23 yrs 0.9995 0.8578 (0.9995 x 0.8578) = 0.8577 (1.0/0.8577) = 1.166

4. Conclusions Time-variant formulation for reliability assessment of an existing offshore jacket structures was derived and presented taken into account structural component damage due to corrosion loss. Application of series and parallel reliability theories was applied for the estimation of jacket structural system reliability, with regards to member corrosion wastage. The technique was proposed for offshore jacket structural assessment procedures. The advantage of this assessment method over manual structural member capacity check and 3D computer model due to corrosion loss includes provision of structural reliability values for individual member and as well as for the whole jacket structural system. This

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

298

accomplishment is important for the straightforward assessment of existing offshore platforms particularly, when the structure life extension is anticipated. References [1] [2] Sharp J.V.,: (1992), Ageing offshore structures: a review of recent UK research, Offshore Mechanics and Arctic Engineering, OMAE 1992, V. III-B, Material Engineering, p.p. 391-398 C. Guedes Soares and Garbatov: (1998), Reliability Assessment of Maintained Ship Hulls with Correlated Corroded Elements, Unit for Marine Technology and Engineering, Instituto Superior Tecnico, Universidade Tecnica de Lisboa Paris 1096, Portugal, Marine Structures p.p.629-653. Moan, T.: (2005). Reliability-based Management of Inspection Maintenance and Repair of Offshore Structures, Journal of Structures and Infrastructure Engineering, Vol. 1, No 1, pp 33 62, Taylor & Francis Publication. Gerhard Ersdal: (2005). Assessment of Existing Offshore Structures for Life Extension, PhD Thesis University of Stavanger Norway 16 p. API RP-2A WSD (2000). Recommended Practice for Planning, design and constructing fixed offshore platforms Working Stress Design, API Recommended practice 2A-WSD Twenty-first edition. BOMEL :(2003), ageing structures and life extension Review of UK work in various industries, HSE Proposal number: P241. Restricted Commercial Report Issued by Bomel Consortium Ledger House, Maidenhead, Berkshire, SL6 2NR, UK. Nicholas Summerville: (2004) Basic Reliability An introduction to Reliability Engineering (ISBN 1-4184-2418-8) 108 p. Buche.r C.G. and Bourgund. U.: (1990), A Fast and Efficient Response Surface Approach for Structural Reliability Problems, Structural Safety, Vol. 7, p.p. 5. Au S.K. and Beck J.L: (1999), A new adaptive importance sampling scheme for reliability calculation, Structural Safety, Vol. 21, p.p. 135-158.

[3] [4] [5] [6] [7] [8] [9]

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

299

A

A B

+ 4.00

MWL

OMA

+ 4.00 MWL

1DB 9.6 2MB

OMB

+ 4.00

1D1

OM1

MWL

9.4

+ 4.00 MWL

OM2

1D1

EL (-) 7.00

EL (-) 7.00

2MA

EL (-) 7.00

2M1 9.6

9.6 3DB

L01

3D1 L04 9.1

EL (-) 7.00

2M2

3D2 L01 L03 3MB

L04

L03

L01 3MB

L02

9.45

12.7

EL (-) 18.30

4M1

EL (-) 18.30

18.25

4MA

EL (-) 18.30

4MB

18.2

EL (-) 18.30

4M2

18.52

51B 52B 18.5

Tabl

8.10

18.11

11.6

18.6

18.11

5BA 5D4 5CA

11.9 18.6 12.5 53B

EL (-) 32.00

6M1

EL (-) 32.00

6MA

EL (-) 32.00

6MB

EL (-) 32.00

6M2

Row- A Row1 2

Row- B

1 2

Row-1

1

1

12.0

Row-2

2

2

6MB

4MB

9.1

B

2MH 2M1

2MB

B

2MD

4ME

4MB 4MD

B

9.4

4MD 4ME

9.0

Row4M2

6MC

2MG

4M1 4MF 4MC 4MG

4M2 4M1 4MF

6M2

2MF

2ME

6M1

6ME

2M2

4MC

6MD

4MG

2MA

Plan at Level () 7.00

Plan at Level () 18.30

Plan at6MA Level () 18.30

Plan at Level ( ) 32.00

Figure 7 Jacket Platform Elevations and Sections

11

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

300

Table 1 Jacket Member Wall Thickness Corrosion Loss

Member Type and Elevation 1DA 3DA 5DA 5BA 5AA 5CA 1DA 3DA 1DB 3DB 3MB 53B 52B 51B 1D1 3D1 1D2 3D2 5B2 2MB 2MD 2M2 2MH 2ME 2MA 2MF 2M1 2MG 4MD 4ME 4MC 4MG 4M2 4MA 4M1 4MB 4MF 6M2 6MA 6MD 6MC 6ME 6M1 6MB 4MD 4ME 4MC 4MG Horizontal Bracing EL (-) 1.5m Horizontal Bracing EL (-) 1.5m Diagonal Brace EL (-) 4.0m to (-) 7.0m Diagonal Brace EL (-) 7.0m to (-) 18.3m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 4.0m to (-) 7.0m Diagonal Brace EL (-) 7.0m to (-) 18.3m Diagonal Brace EL (-) 7.0m to (-) 18.3m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 4.0m to (-) 7.0m Diagonal Brace EL (-) 7.0m to (-) 18.3m Diagonal Brace EL (-) 4.0m to (-) 7.0m Diagonal Brace EL (-) 18.3m to (-) 32.0m Diagonal Brace EL (-) 18.3m to (-) 32.0m Horizontal Brace EL (-) 7.0m Diagonal Member EL (-) 7.0m Horizontal Brace EL (-) 7.0m Diagonal Brace EL (-) 7.0m Diagonal Brace EL (-) 7.0m Horizontal Brace EL (-) 7.0m Diagonal Brace EL (-) 7.0m Horizontal Brace EL (-) 7.0m Horizontal Brace EL (-) 7.0m Diagonal Brace EL (-) 18.3m Diagonal Brace EL (-) 18.3m Diagonal Brace EL (-) 18.3m Diagonal Brace EL (-) 18.3m Horizontal Brace EL (-) 18.3m Horizontal Brace EL (-) 18.3m Horizontal Brace EL (-) 18.3m Horizontal Brace EL (-) 18.3m Horizontal Brace EL (-) 18.3m Horizontal Brace EL (-) 32.0m Horizontal Brace EL (-) 32.0m Horizontal Brace EL (-) 32.0m Horizontal Brace EL (-) 32.0m Horizontal Brace EL (-) 32.0m Horizontal Brace EL (-) 32.0m Horizontal Brace EL (-) 32.0m Jacket Leg 1 Jacket Leg 2 Jacket Leg 3 Jacket Leg 4 Thickness (mm) 1985 9.525 9.525 9.525 12.7 12.7 12.7 12.7 12.7 9.525 12.7 9.525 12.7 12.7 12.7 9.525 9.525 9.525 9.525 12.7 9.525 9.525 9.525 9.525 9.525 9.525 9.525 9.525 9.271 9.525 9.525 9.525 9.525 9.525 9.525 9.525 9.525 9.271 9.525 12.700 9.525 9.525 9.525 9.525 12.700 19.1 19.1 19.1 19.1 UT Thickness (mm) 2008 9.501 9.45 8.1 10.5 12.40 11.90 12.4 11.9 9.6* 12.7 9.6* 11.6 11.9 12.5 9.4 9.1 9.1 8.9 12.5 9.2 9.3 9.3 9.3 9.2 9.2 9.0 9.3 9.1 9.1 9.0 9.1 8.6 9.1 9.0 8.6 9.1 9.1 8.400 12.300 8.900 9.1 9.0 9.4 12.300 18.11 18.25 18.52 18.65 Thickness Reduction (%)2008 0.262 0.787 14.961 17.323 2.362 6.299 2.36 6.30 0.00 8.66 6.30 1.575 1.31 4.46 4.46 6.56 1.57 3.412 2.36 2.36 2.36 3.41 3.41 5.51 2.36 1.84 4.46 5.512 4.46 9.71 5.512 9.711 4.462 1.844 1.84 11.811 3.150 6.562 4.462 5.512 1.312 3.150 5.18 4.45 3.04 2.36

ID

Jacket Legs

Plan @ (-) 32.0m

Plan @ (-) 18.3m

Plan @ (-) 7.0m

Row 2

R o w 1

Row B

Row A

M.A. Salau, D.E. Esezobor, M. F. Omotoso/Petroleum & Coal 53 (4) 291-301, 2011

301

Table2 Jacket Bracing Group Reliability (Active Parallel Systems)

Group A ID 1DA, (Pa) 1D1, (Pb) 1D2, (Pc) 1DB, (Pd) Reliability (RA) 2MB, (Pa) 2M2, (Pb) 2ME, (Pc) 2MA, (Pd) 53B, (Pe) 2MD, (Pf) 2MG, (Pg) 2M1, (Ph) 2MH, (Pi) Reliability (RB) 3DA, (Pa) 3D1, (Pb) 3D2, (Pc) 3DB, (Pd) 3MB, (Pe) Reliability (RC) 4ME, (Pa) 4M2, (Pb) 4MA, (Pc) 4M1, (Pd) 4MB, (Pe) 4MG, (Pf) 4MF, (Pg) Reliability (RD) 5BA, (Pa) 5AA, (Pb) 5CA, (Pc) 5DA, (Pd) 52B, (Pe) 51B, (Pf) 53B, (Pg) 5B2, (Ph) Reliability(RE) 6M2, (Pa) 6MA, (Pb) 4MD, (Pc) 6MC, (Pd) 6ME, (Pe) 6M1, (Pf) 6MB, (Pg) 4MC, (Ph) Reliability(RF) Corrosion Loss = tp (%) Failure Probability (P = tp/100) 0,00262 0,01312 0,04462 0,000 Pa.Pb.Pc.Pd] Reliability (1 - P) 0,99738 0,98688 0,95538 1,000 0,9396 0,96588 0,97638 0,96588 0,96588 0,94488 0,97638 0,98156 0,97638 0,97638 0,7717 0,99213 0,95538 0,93438

0,262 1,312 4,462 0,000 1- [(Pa + Pb + Pc + Pd)

3,412 0,03412 2,362 0,02362 3,412 0,03412 3,412 0,03412 5,512 0,05512 2,362 0,02362 1,844 0,01844 2,362 0,02362 2,362 0,02362 1 - [(Pa + Pb + Pc + Pd + Pe + Pf + Pg + Ph + Pi) - Pa.Pb.Pc.Pd.Pe.Pf.Pg.Ph.Pi)] 0,787 0,00787 4,462 0,04462 6,562 0,06562 None None 1 [(Pa + Pb + Pc + Pd + Pe) Pa.Pb.Pc.PD.Pe] 5,512 0,05512 4,462 0,04462 5,512 0,05512 9,711 0,09711 4,462 0,04462 9,711 0,09711 1,844 0,01844 1 - [(Pa + Pb + Pc + Pd + Pe + Pf + Pg ) Pa.Pb.Pc.Pd.Pe.Pd.Pf.Pg] 17,323 0,17323 2,362 0,02362 6,229 0,06229 14,961 0,14961 6,299 0,06299 1,575 0,01575 8,661 0,08661 1,575 0,01575 1 - [(Pa + Pb + Pc + Pd + Pe + Pf + Pg +Ph) - Pa.Pb.Pc.Pd.Pe.Pf.Pg.Ph)] 11,811 0,11811 3,150 0,0315 6,562 0,06562 4,462 0,04462 5,512 0,05512 1,312 0,01312 1,150 0,0115 4,462 0,04462 1 - [(Pa + Pb + Pc + Pd + Pe + Pf + Pg +Ph) - Pa.Pb.Pc.Pd.Pe.Pf.Pg.Ph)]

0,9475 0,94488 0,95538 0,94488 0,90289 0,95538 0,90289 0,98156 0,5879 0,82677 0,97638 0,93771 0,85039 0,93701 0,98425 0,91339 0,98425 0,4102 0,88189 0,9685 0,93438 0,95538 0,94488 0,98688 0,9885 0,95538 0,6158

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Root of Islam : AQEEDAH !.. . )Document13 pagesThe Root of Islam : AQEEDAH !.. . )nazeer_mohdNo ratings yet

- Canada Tourist Visa For IndiansDocument3 pagesCanada Tourist Visa For Indiansnazeer_mohdNo ratings yet

- The Root of Islam : AQEEDAH !.. . )Document13 pagesThe Root of Islam : AQEEDAH !.. . )nazeer_mohdNo ratings yet

- What Are The Tawrat, Zabur and Injil?Document19 pagesWhat Are The Tawrat, Zabur and Injil?nazeer_mohdNo ratings yet

- Moving Wheel Loads AnalysisDocument3 pagesMoving Wheel Loads AnalysisAnibal Via EnNo ratings yet

- Tutorial5 SACS PDFDocument19 pagesTutorial5 SACS PDFnazeer_mohdNo ratings yet

- The Concept of SabrDocument1 pageThe Concept of Sabrnazeer_mohdNo ratings yet

- Obeying Your ParentsDocument2 pagesObeying Your Parentsnazeer_mohdNo ratings yet

- SACS Training in MumbaiDocument5 pagesSACS Training in Mumbaioluomo1No ratings yet

- Tutorial #4 KL4120 Offshore Platform Ocean Engineering ITB 2015Document26 pagesTutorial #4 KL4120 Offshore Platform Ocean Engineering ITB 2015Ockto Perdana SinagaNo ratings yet

- Tutorial1 SACS PDFDocument13 pagesTutorial1 SACS PDFnazeer_mohd100% (2)

- Tutorial #2 KL4120 Offshore Platform Ocean Engineering ITB 2015Document13 pagesTutorial #2 KL4120 Offshore Platform Ocean Engineering ITB 2015Ockto Perdana SinagaNo ratings yet

- Manufacturing Data Books: Agip Gas BVDocument1 pageManufacturing Data Books: Agip Gas BVnazeer_mohdNo ratings yet

- Running SACS 5.2 On Windows 7Document1 pageRunning SACS 5.2 On Windows 7nazeer_mohdNo ratings yet

- Process Group: DeliverablesDocument9 pagesProcess Group: Deliverablesnazeer_mohdNo ratings yet

- Instrumentation GroupDocument4 pagesInstrumentation Groupnazeer_mohdNo ratings yet

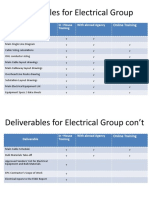

- Deliverables For Electrical GroupDocument5 pagesDeliverables For Electrical Groupnazeer_mohdNo ratings yet

- Basrah Gas E+ps Contract InductionDocument4 pagesBasrah Gas E+ps Contract InductionraghebomNo ratings yet

- ASD (Working Stress) Vs Limit StateDocument1 pageASD (Working Stress) Vs Limit Statenazeer_mohdNo ratings yet

- Deliverables (Rotating) : Deliverable in - House Training With Abroad AgencyDocument10 pagesDeliverables (Rotating) : Deliverable in - House Training With Abroad Agencynazeer_mohdNo ratings yet

- Combined Strap FootingDocument12 pagesCombined Strap FootingBang Joy100% (1)

- Compressors: Training ManualDocument127 pagesCompressors: Training Manualnazeer_mohd100% (8)

- SENIOR PROCESS ENGINEER'S INTERVIEW QUESTIONNAIRE Rev.01Document1 pageSENIOR PROCESS ENGINEER'S INTERVIEW QUESTIONNAIRE Rev.01nazeer_mohdNo ratings yet

- Pipe Support Isolated FootingDocument11 pagesPipe Support Isolated Footingnazeer_mohdNo ratings yet

- Circular Water Tank With Domcal Top and BaseDocument24 pagesCircular Water Tank With Domcal Top and BaseAmit Kumar PaulNo ratings yet

- SENIOR HSE ENGINEER'S INTERVIEW QUESTIONNAIRE Rev01Document3 pagesSENIOR HSE ENGINEER'S INTERVIEW QUESTIONNAIRE Rev01nazeer_mohdNo ratings yet

- Intze Water Tank Based On K. RajuDocument49 pagesIntze Water Tank Based On K. RajuRamachandra SahuNo ratings yet

- Combined Footing For FD PlantDocument13 pagesCombined Footing For FD Plantnazeer_mohdNo ratings yet

- Circular Water Tank With Domcal Top and Flat BaseDocument20 pagesCircular Water Tank With Domcal Top and Flat BaseIrshad Khan100% (2)

- Circular Water Tank (Rigid Joint)Document26 pagesCircular Water Tank (Rigid Joint)nazeer_mohdNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HIRA For Electrical Hand Tools - 12Document1 pageHIRA For Electrical Hand Tools - 12Devendra BrilltechNo ratings yet

- BookingDocument2 pagesBookingAbhishek Kumar ChaturvediNo ratings yet

- Solution Manual For A Friendly Introduction To Numerical Analysis Brian BradieDocument14 pagesSolution Manual For A Friendly Introduction To Numerical Analysis Brian BradieAlma Petrillo100% (43)

- Account Statement From 27 Dec 2017 To 27 Jun 2018Document4 pagesAccount Statement From 27 Dec 2017 To 27 Jun 2018mrcopy xeroxNo ratings yet

- Taguig City University: College of Information and Communication TechnologyDocument9 pagesTaguig City University: College of Information and Communication TechnologyRay SenpaiNo ratings yet

- 12-24VDC Powered Ignition System: N N N N N N NDocument2 pages12-24VDC Powered Ignition System: N N N N N N NLeinner RamirezNo ratings yet

- Crew Body Temp: Arrival ArrivalDocument1 pageCrew Body Temp: Arrival ArrivalАлександр ГриднёвNo ratings yet

- CHAPTER 2 Principles of MarketingDocument41 pagesCHAPTER 2 Principles of MarketingASHIMA THAPANo ratings yet

- Hach Company v. In-SituDocument8 pagesHach Company v. In-SituPatent LitigationNo ratings yet

- DO 31 s2020Document18 pagesDO 31 s2020charles barkleyNo ratings yet

- MODULE-1-EU111 Univeristy and IDocument8 pagesMODULE-1-EU111 Univeristy and IAbzchen YacobNo ratings yet

- 1st Activity in EthicsDocument2 pages1st Activity in EthicsAleiah Jane Valencia AlverioNo ratings yet

- Oxidation Ponds & LagoonsDocument31 pagesOxidation Ponds & LagoonsDevendra Sharma100% (1)

- The Effect of Cross-Cultural Management On The Performance of Multinational Companies in NigeriaDocument13 pagesThe Effect of Cross-Cultural Management On The Performance of Multinational Companies in NigeriaPreethu GowdaNo ratings yet

- OIG ReportDocument43 pagesOIG ReportRohan M100% (1)

- Assessment Form (Indoor)Document14 pagesAssessment Form (Indoor)Mark Tally0% (1)

- Course Outline of Lecturer Economics For Service Commissions TestDocument5 pagesCourse Outline of Lecturer Economics For Service Commissions TestSheraz Ali KhanNo ratings yet

- Incorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)Document9 pagesIncorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)juan diazNo ratings yet

- Electricity at Work - Safe Working Practices HSG85Document27 pagesElectricity at Work - Safe Working Practices HSG85Sivakumar NatarajanNo ratings yet

- BOOK2Document201 pagesBOOK2Chetan Satish PadoleNo ratings yet

- C10G - Hardware Installation GD - 3 - 12 - 2014Document126 pagesC10G - Hardware Installation GD - 3 - 12 - 2014Htt Ếch CốmNo ratings yet

- Company Grasim ProfileDocument48 pagesCompany Grasim ProfileNitu Saini100% (1)

- Shalina Healthcare JD - Business AnalyticsDocument2 pagesShalina Healthcare JD - Business AnalyticsMeow bunNo ratings yet

- GTA TaxonomyDocument12 pagesGTA Taxonomyalvaropiogomez1No ratings yet

- Color Management Handbook Vol2Document28 pagesColor Management Handbook Vol2ianjpr100% (2)

- Moral IssuesDocument34 pagesMoral IssuesDaryll Jade PoscabloNo ratings yet

- Case Study (3 To 5 Months Test Plan) : Test Deliverable Responsibility Completion TimeDocument1 pageCase Study (3 To 5 Months Test Plan) : Test Deliverable Responsibility Completion Timepry_kumNo ratings yet

- Heist Story ScriptDocument3 pagesHeist Story Scriptapi-525637110No ratings yet

- Delta CaseDocument8 pagesDelta CaseSeemaNo ratings yet

- NF en 1317-5 In2Document23 pagesNF en 1317-5 In2ArunNo ratings yet