Professional Documents

Culture Documents

FA Series Force Gauge

Uploaded by

quescikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FA Series Force Gauge

Uploaded by

quescikCopyright:

Available Formats

Torbal FA Internal Load-Cell

Force Gauge

Force Gauge w/ External Load Cell

Instruction Manual:

FA Series Force Gauge

Fulcrum Inc. 100 Delawanna Ave. Suite 502 Clifton, NJ 07014 Tel. (973)473-6900 Fax. (973)777-8302 www.fulcruminc.net www.torbalscales.com

Instruction Manual FA Series Force Gauge

Table of Contents

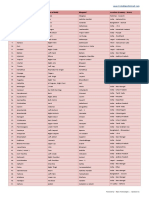

Chapter 1: Cautionary Notes ........................................................................................................................... - 2 1.1 Main Safety Rules ................................................................................................................... - 2 1.2 Rules for Disposing of a Worn Force Gauge ........................................................................ - 2 1.3 Important Handling Cautions and Warnings ...................................................................... - 3 1.4 Safety Rules for Measurements over 1kN (about 100kg) .................................................... - 4 Chapter 2: Specifications ................................................................................................................................. - 5 Chapter 3: Part Descriptions ........................................................................................................................... - 7 Chapter 4: Keys and Display Indicators ....................................................................................................... - 10 Chapter 5: Functions, Descriptions, Definitions .......................................................................................... - 11 Chapter 6: Mounting Force Gauge on a Test Stand .................................................................................... - 12 Chapter 7: Getting Started ............................................................................................................................ - 13 Chapter 8: Users Menu ................................................................................................................................. - 14 Chapter 9: Force Gauge Menu Diagram ...................................................................................................... - 15 Chapter 10: Applications ............................................................................................................................... - 17 10.1 Data Stored .......................................................................................................................... - 17 10.2 Threshold ............................................................................................................................. - 19 Chapter 11: Units ............................................................................................................................................ - 20 Chapter 12: Configuration ............................................................................................................................. - 21 12.1 Measure Speed .................................................................................................................... - 21 12.2 Auto-zeroing ........................................................................................................................ - 21 12.3 Printout ................................................................................................................................ - 22 12.4 Interface and USB Port Configuration ............................................................................. - 23 12.5 LCD Settings........................................................................................................................ - 24 12.6 Language.............................................................................................................................. - 24 12.7 Date and Time ..................................................................................................................... - 25 12.8 Keyboard ............................................................................................................................. - 25 12.9 Auto-OFF ............................................................................................................................. - 25 12.10 Battery ................................................................................................................................ - 26 12.11 Defaults .............................................................................................................................. - 26 Chapter 13: Taking a Measurement ............................................................................................................. - 27 13.1 Push Force ........................................................................................................................... - 27 13.2 Pull Force ............................................................................................................................. - 27 13.3 Type of Measurement Diagrams ....................................................................................... - 28 13.4 Measurement Setup Diagrams........................................................................................... - 29 Chapter 14: Calibration ................................................................................................................................. - 30 Chapter 15: Maintenance, Trouble Shooting, and Repairing Minor Damage ......................................... - 32 15.1 Cleaning the Force Gauge .................................................................................................. - 32 Chapter 16: Additional Attachments ............................................................................................................ - 33 Chapter 17: Warranty .................................................................................................................................... - 33 Chapter 18: Notes ........................................................................................................................................... - 33 -

-1-

Instruction Manual FA Series Force Gauge

Chapter 1: Cautionary Notes

The TORBAL force gauge is an accurate and precise instrument. Always handle the force gauge with care.

1.1 Main Safety Rules

Carefully read the safety instructions below. Make sure to follow all warnings and precautions in order to effectively prevent electrocution or injury and avoid damaging the device.

Repairs and any necessary adjustments should only be conducted by qualified personnel. Do not operate the force gauge when any part of the enclosure has been removed. Do not operate the force gauge in potentially explosive atmospheres. Do not use the force gauge for anything other than its designed purpose. Do not operate the force gauge in areas with an excessively high humidity (95% +) Be sure to only use the specified power source Do not unplug the product while it is in use. Only connect the external load cell wires to the force gauge as intended. Use protective eye wear when measuring the breaking point of objects prone to shattering. In the case of suspected damage to the force gauge, turn off the gauge and do not use it until it is

examined by qualified personnel.

If liquid spills into the gauge, do not continue to use, unplug the device and call technical support.

1.2 Rules for Disposing of a Worn Force Gauge

Disposal of electronic equipment in waste containers is forbidden by law.

Please dispose of electronic equipment in appropriate recycling centers or by returning to the original point of purchase. -2-

Instruction Manual FA Series Force Gauge

1.3 Important Handling Cautions and Warnings

DO NOT let the force gauge fall or drop onto the ground!

DO NOT pass or handle liquids near the force gauge to prevent spillage and liquid damage!

Never use the forge gauge if there is an object or material wedged between the measuring rod and frame! Always line up the measuring rod parallel to the object being measured to prevent the rod from warping and damaging the device!

DO NOT attempt to measure the force of an object that is submerged in a liquid!

-3-

Instruction Manual FA Series Force Gauge

1.4 Safety Rules for Measurements over 1kN (about 100kg)

Warnings: Exceeding the range of the force gauge by more than 20% may cause damage to the sensor and endanger the user. The bearings should always be attached to the external load cell during measurements to prevent damage to the unit and injury to the user. Proper Set-up: Measurements with an external load cell should be done under proper supervision. 1. Attach the bearings into the external load cell by screwing them into the parallel holes on each side.

2. Connect the wire to the force gauge. 3. Put the load cell on a flat surface and turn the force gauge on. 4. Once the device has initialized, connect a load to the bearings to perform a measurement. *Make sure the force gauge meter is secure so it does not fall or get pulled during measurements.

Maintenance, Inspection, and Repairs: All maintenance and repairs on the force gauge and external load cell should only be conducted by trained professionals. * Force gauges with a capacity of 1kN or above are equipped with an external load cell connected by a wire. Bearings are connected to the load cell to prevent excess stress when mounting a load. The meter and load cell are delivered in two separate cases.

-4-

Instruction Manual FA Series Force Gauge

Chapter 2: Specifications

Model FA50 Maximum Capacity Readability (d) Accuracy Measurement Units Maximum Overload Operating Temperature Internal Resolution Process Speed Internal Memory Capacity Interface Assisting Software Display Measurement Options Power Supply Battery Life Measuring Rod Dimensions Weight 50N (~5kg) 0.01N (1g) FA200 200N(~20kg) 0.05N (5g) 0.2% N, kgf, lbf, ozf, kg, lb, oz 20% -10 to 40C 24 bits 10 or 40 measurements per second 8 files x 800 measurements each USB FM (time characteristic, statistical analysis, data archiving) LCD Graphical 61x34mm Peak value measurement, continuous measurement, dynamic measurement (force vs time plot) Lithium polymer batteries set 1000mAh (LP703048P6H type) + supply ~115V 60Hz / 12VDC @ 1.2A ~20h (~45h backlighting off) 11mm (thread M6x9mm) 210x110x40mm (8.4x4.4x1.6in) 700g (1.5lb) FA500 500N(~50kg) 0.1N (10g)

-5-

Instruction Manual FA Series Force Gauge

Model FA1k Maximum Capacity Readability (d) Accuracy Measurement Units Maximum Overload Operating Temperature Internal Resolution Process Speed Internal Memory Capacity Interface Assisting Software Display Measurement Options Power Supply Accumulator Working Time Measuring Rod Dimensions Weight 1kN (~100kg) 0.2N (20g) FA2k 2kN (~200kg) 0.5N (50g) FA5k 5kN (~500kg) 1N (100g) FA10k 10kN (~1t) 2N (200g) 0.2% N, kgf, lbf, ozf, kg, lb, oz 20% -10 to 40C 24 bits 10 or 40 measurements per second 8 files x 800 measurements each USB FM (time characteristic, statistical analysis, data archiving) LCD Graphical 61x34mm Peak value measurement, continuous measurement, dynamic measurement (force vs time plot) Lithium polymer batteries set 1000mAh (LP703048P6H type) + supply ~115V 60Hz / 12VDC @ 12A ~20h (~45h backlighting off) 210x110x40mm (8.4x4.4x1.6in) 460g (1.0lb) + sensor weight FA20k 20kN (~2t) 5N (500g) FA50k 50kN (~5t) 10N (1kg)

-6-

Instruction Manual FA Series Force Gauge

Chapter 3: Part Descriptions

Force Gauge

Force Gauge with External Load Cell

Rear View

The force gauge is equipped with a socket for an external power supply unit as well as a USB port for a computer or printer. The USB port allows for all measurement results to be loaded onto a computer for further analysis and recordings.

-7-

Instruction Manual FA Series Force Gauge

The following attachments are only usable with the Force Gauge with an internal load cell: Attachment Extension Piece Description Used to extend reach of other attachable tips

Hook

Used for measuring pull force or hanging and weighing an object

Chisel Point

Measures edge pressure force

Flathead

Measures surface pressure force

V-Groove

Measures pressure force on an axis or edge

Cone Point

Measures point pressure force

-8-

Instruction Manual FA Series Force Gauge

1 Measuring Rod (Internal load cell only) 2 LCD Screen 3 Keypad 4 Hand Grip 5 Mounting Holes 6 AC Adapter Port 7 USB Port -9-

Instruction Manual FA Series Force Gauge

Chapter 4: Keys and Display Indicators

CONTINOUS MEASUREMENT ACQ

AUT

1.00N

-

ON/OFF UNIT/CLEAR BACKLIGHT ENTER (0) ENTER MENU PEAK MEM PRINT

OFF SLW/FST ACQ AUT

Main Keys Power On and Off (standby) Change units, Cancel selection, or Change a parameter value Turn Illumination On/Off (ECO Mode) Confirm command, Select an option or digit Zero / Tare Navigation Keys Move cursor up or increase the value of selected digit Move cursor down or decrease the value of selected digit Move to the next menu level or display the next option Move to the previous menu level or display the previous option Confirm the entered parameter or select a highlighted option Function Keys Meter function menu Measures the maximum value Save the result to memory (press and hold for save menu) Print results Indicators Indicates that the weighing result has stabilized Appears after turning off the gauge Slow/fast measurement mode (10Hz/40Hz) Device will automatically acquire measurements Automatic zeroing is on Indicates the type of force being applied and the current forces proximity to capacity. NOTE: (capacity is at + and -) Force Gauge with Internal Load Cell: + = push force - = pull force Force Gauge with External Load Cell: + = pull force - = push force

- 10 -

Instruction Manual FA Series Force Gauge

Chapter 5: Functions, Descriptions, Definitions

Peak Measuring allows the user to record peak values for both compression (push) and tension (pull) measurements.

Min/Max Threshold Measuring allows the user to select parameters for their measurement with a buzzer to signal if they exceed the selected parameters.

Data Storing allows the user to save their data either in the RAM of the device or in any of 8 open files of 800 samples each.

Measure Speed allows the user to set the speed at which the force gauge takes measurements. This is useful when trying to be precise with measurements. Offered at 10Hz (slow) and 40Hz (fast).

Internal Calibration is used to calibrate the force gauge with an external calibration mass or by configuring your geographical location parameters.

Statistic Graphing is used to chart the results of a sample of measurements. Results can be viewed in a bar graph or an axis graph.

- 11 -

Instruction Manual FA Series Force Gauge

Chapter 6: Mounting Force Gauge on a Test Stand

One of the unique capabilities of the FA Series force gauge is its ability to be mounted on a test stand. The test stand is dual guiding cylinders with a 3mm pitch lead screw. Attached to the mounting bracket for the scale are electronic calipers. The caliper reads to 8in (200mm). The calipers read in inches or millimeters (push button select). It can be zeroed at any location on the caliper scale. Inches read to .001 and millimeters read to .01. 1. The device has four screw holes on the back of its frame, which align with the mounting holes on the test stand. Use the screws included with the test stand to mount the device to the stand. * When using the test stand, make sure the device is secure, but do not over-tighten the screws as this may damage the unit.

2. Once the force gauge is mounted connect a desired attachment. 3. If desired, other attachments can be connected to the base of the test stand. 4. To measure forces turn the knob on the test stand clockwise to raise the unit up and counterclockwise to lower the unit down. Note: The test stands knob moves the gauge 3mm, up or down, per full turn or rotation. - 12 -

Instruction Manual FA Series Force Gauge

Chapter 7: Getting Started

1. Carefully take the force gauge out of the case. 2. Force Gauges with an external sensor require the bearings to be screwed into the load cell for support. Note: If using the unit on a test stand refer to the chapter: Mounting the Force Gauge on a Test Stand. 3. Select a suitable tip in order to effectively conduct a measurement. (Choose the tip that will best measure the force of the object being tested). 4. Slowly screw the tip onto the measuring rod at the top of the force gauge. 5. If necessary, connect the force gauge to a power outlet by plugging the AC Adapter into the 12V socket at the bottom of the unit. Once the AC adapter is connected to the force gauge, plug the other end into a wall socket. Turning on the Gauge

1. Press the ON/OFF key to turn the device on. Fulcrum, Inc. 100 Delawana Ave. Clifton, NJ 07014 www.fulcruminc.net As the device powers on it initializes itself. Do not move or attempt to use the device during this process. Note: To accelerate the initialization process, press the MENU key. The results from the prior initialization will be used.

ZEROING

FA0017

ZEROING

2. Once the force gauge is turned on and has a suitable tip attached for your measurement, align the device so that it is parallel to the object measured. Note: Before beginning the measurement, tare the force gauge by pressing the 0 key.

______

- 13 -

Instruction Manual FA Series Force Gauge

Chapter 8: Users Menu

The USERs MENU provides access to all of the force gauges functions and capabilities. Knowing how to effectively navigate through the menu will make operating the force gauge fast and simple. USERs MENU 1. 2. 3. 4. 5. 6. Applications Units Configuration Calibration Info Exit To access the USERs MENU press the MENU key. Use the arrow keys to scroll through the options and press ENTER to select one.

* EXIT will always return you to the previous screen.

The USERs MENU includes: 1. Applications Advanced measurement functions. 2. Units Choose the unit of measurement you wish to use. 3. Configuration Allows you to change the operation settings of the force gauge. 4. Calibration Allows you to calibrate the device for weight. 5. Info Contains basic information about the device.

- 14 -

Instruction Manual FA Series Force Gauge

Chapter 9: Force Gauge Menu Diagram

- 15 -

Instruction Manual FA Series Force Gauge

- 16 -

Instruction Manual FA Series Force Gauge

Chapter 10: Applications

The APPLICATIONS menu includes functions that are helpful when conducting force measurements. APPLICATIONS Data stored Threshold values Exit

The APPLICATIONS menu includes: 1. Data Stored This allows you to view statistics from your recently saved measurements as well as choose to either manually or automatically save future measurements. 2. Threshold This option allows you to set parameters (min/max) for your measurements. It also gives you the option of setting up a notification if thresholds are exceeded.

10.1 Data Stored

DATA STORED 1. 2. 3. 4. 5. Stats Mode Record Memory Exit <MANUAL> <AUTO> <R/-> <R/D&T> <RAM> <F01> <F02><F08> The DATA STORED function allows you to choose between manual and automatic data saving as well as view your measurement statistics.

STATS Count: Total: Average: MAX: MIN: St. dev: 100 990g 9.9g 12g 8g 3.78g

To view the statistical analysis of a set of measurements open up the STATS function

In addition to reading the numerical data, the results can be viewed in graph form as either a Histogram (Bar Graph) or a Chart (Graph w/ time axis).

<PRINT><HISTOGRAM><CHART><SAVE> <LOAD> <RESET><DELETE><EXIT>

To load, save, or print the results, navigate to the bottom of the STATS menu and select a function.

- 17 -

Instruction Manual FA Series Force Gauge

SAVE DATA 2009-12-17 10:00 < FILE02 > ... < FILE08 >

When SAVE is chosen for the results, the SAVE DATA screen appears listing all 8 files. The file being used to save the current set of results will be automatically renamed with the date and time of the save. The file can be renamed to a custom title by pushing up and down on the directional keys.

The two types of modes are MANUAL and AUTO. DATA STORED 1. 2. 3. 4. 5. Stats Mode <MANUAL> <AUTO> Number of samples 100 Sampling time 0.1 sec Exit AUTO: Saving will take continuous measurements at the frequency set until the total number of samples is reached. When the gauges Mode is set to automatic the Number of Samples and the frequency of the samples (Sampling Time) will need to be set. Max Samples = 800 Max Rate @40Hz = .025sec Max Rate @10Hz = .1sec

DATA STORED 6. 7. 8. 9. 10. Stats Mode Record Memory Exit <MANUAL> <AUTO> <R/-> <R/D&T> <RAM> <F01> <F02><F08>

MANUAL: When this option is chosen, you must press the memory button on the keypad each time you wish to record a measurement.

When the device is set to manual you must also set the Record and Memory.

Record - When the force gauge is set to Manual, the format that statistics are recorded in must be set. R/R/D&T The results of a set of measurements are recorded. The results of a set of measurements are recorded with the date and time of each sample.

Memory This function allows data to be saved directly to either the Random Access Memory (RAM) of the unit or in one of the devices 8 open files. The RAM is a temporary save, which will not keep the data once the device is turned off. To save the data permanently save it to one of the files (File 01 File 08).

- 18 -

Instruction Manual FA Series Force Gauge

10.2 Threshold

The THRESHOLD option is used to set up parameters when using Min/Max measurements. When the Min/Max values are exceeded, the devices buzzer sounds. To get to this screen go to APPLICATIONS in the Main Menu. 1. To enable the Min/Max notification, change the status from OFF to ON. 2. Set the Min and Max parameters. 3. Set the buzzer type.

THRESHOLD 1. 2. 3. 4. 5. Status: MIN MAX Buzzer Exit <ON> <OFF> 1.000kg 2.000kg <MODE1> <MODE2>

There are 2 options that can be used to signal that the the parameters have been exceeded: - MODE1 short signal upon exceeding MIN, long signal upon exceeding MAX, - MODE2 interrupted signal below MIN, continuous signal above MAX, no signal for OK.

- 19 -

Instruction Manual FA Series Force Gauge

Chapter 11: Units

The UNITS function is used to set a desired unit of measure. Access this function by going to the Main Menu. UNITS Kilogram Pound Ounce Newton Exit

Kilograms force: 1 kgf = 2.205 lbf Pounds force: 1 lbf = 16 ozf Ounces force: 1 ozf = .028 kgf Newton: 1 N = 0.10197 kgf

[lb] [oz] [N]

- Kilograms: 1Kg = 2.205lb - Pounds: 1 lb = 16 oz - Ounces: 1 oz = .028 kg

* Units can also be changed by pressing the Units/Clear key on the keypad.

- 20 -

Instruction Manual FA Series Force Gauge

Chapter 12: Configuration

The Configuration options are used to set up general functions of the force gauge. CONFIGURATION 1. Measure Speed 2. Auto-zeroing 3. Printout 4. Interface 5. LCD settings 6. Language 7. Date and time 8. Auto-OFF 9. Battery 10. Default settings 11. Exit

12.1 Measure Speed

This function allows the speed at which the device takes measurements to be adjusted. The measurement displayed will increase or decrease at a faster or slower rate depending on the speed chosen. The speed allows the user to obtain more or less readings during a measurement. The speed should be chosen based on the object being MEASURE SPEED measured. SLOW / 10 Hz SLOW will allow for slower measurements FAST / 40 Hz Exit FAST will allow for faster measurements

12.2 Auto-zeroing

Auto-zeroing is used to prevent small amounts of force, resulting from unwanted variables, from affecting measurements. This process is achieved when undesired measurements (e.g. vibration, movement, etc.) are picked up by the force gauge, but immediately tared and therefore are not recorded. AUTO-ZEROING 1. Status 2. Range 3. Exit <ON> <OFF> 002 d Auto-zero uses the d setting to select the range up to which the force gauge will not record. The highest the auto-zeroing can be set to is 100 d. This is 100x the smallest amount normally picked up by the force gauge (i.e. 1.00N, 0.100kg, .100lb, 1.00oz). - 21 -

Instruction Manual FA Series Force Gauge

12.3 Printout

The PRINTOUT menu allows you to customize the information that is transmitted to the computer. This information is used for printing and analyzing. The basic software for transmitting information from the force gauge to the computer is TORBAL Communication. To access this function go to CONFIGURATION in the Main Menu. PRINTOUT Heading Date Time ID1> ID2> ID3> Measurement Number Signature Exit Communications Printout Example:

In this menu you can check off the information that you wish to be included on your analysis. ID1, ID2, and ID3 are options that are used for adding custom notes (up to 20 characters). Use the up and down arrow keys to create the text.

- 22 -

Instruction Manual FA Series Force Gauge

12.4 Interface and USB Port Configuration

The Interface menu is designed to allow you to change the format and rates at which information is transmitted to a computer. You must connect the force gauge to the computer using the USB port. To access this function go to CONFIGURATION in the Main Menu. * To connect the force gauge up to a computer it is recommended that TORBAL FM is installed on the computer. With this program the user can view real-time results and measurements from the force gauge. TORBAL FM also allows the user to fully control the force gauge from the computer. The TORBAL FM settings must match those of the force gauge. INTERFACE 1. Baudrate 2. Bits 3. Parity 4. Sending 5. Exit 57600 8-bit none NORMAL The optimal settings from transmitting information to a computer are as follows: -Baudrate (transmission and receiving rate): 4,800, 9,600, 19,200, 38,400, 57,600, 115,200 bps. -Bits (the number of bits which define a character): 7 or 8 bits.

-Parity (refers to the alteration of the process that the bits are sent and received in): none, odd, even. -Sending (the transmission method during measurement): Normal Waits for stable results after pressing PRINT before sending. NO STB Sends results regardless of stable results after pressing PRINT. AUTO STB Automatically sends after the result has stabilized. CONTIN. Sends continuous transmissions (approx. every 0.1s).

Description of the data transmission protocol when working with a computer (LonG): The scales transmit the result as follows (8 bits, 1 stop, no parity, 4,800 bps): ComputerGauge: initiating signal S I CR LF (53 h 49 h 0Dh 0 Ah), GaugeComputer: gauge indication according to the following format (16 bytes) Description of individual bytes: byte 1 - - or space byte 2 - space byte 3-4 - digit or space byte 5-9 - digit, comma or space byte 10 - digit byte 11 - space byte 12 - k, l, c, p or space byte 13 - g, b, t, c or % byte 14 - space byte 15 - CR byte 16 - LF - 23 -

Instruction Manual FA Series Force Gauge

12.5 LCD Settings

This menu allows you to adjust the settings of the display screen. Access this function by going to CONFIGURATION in the Main Menu. SETTINGS 1. Contrast 2. Backlight 3. Direction 4. LCD time 5. Exit <OFF> <ECO> <BAT> <ON> <AUTO> <UP> <DOWN> OFF The Contrast option controls how clear the images on the screen appear. By increasing or decreasing the contrast, you will darken or fade the images, respectively.

The Backlight feature gives you options for when you would prefer the backlight on. ON OFF ECO BAT The backlight is always on. The backlight is always off. The backlight can be turned on by holding the backlight key on the main keyboard. The backlight is turned off after 30 seconds of inactivity to preserve battery life.

The Direction option allows you to control, which direction the screen faces. UP DOWN AUTO The screen is always upright The screen is always upside down. The screen automatically adjusts to the direction the force gauge is being held.

The LCD time option can be set to display the date and time on the top bar on the main screen.

12.6 Language

This menu allows you to choose the language you wish the force gauge to be displayed in. Access this function by going to CONFIGURATION in the Main Menu. LANGUAGE 1. Language 2. Exit <PL><ENG><DE><ESP> There are 4 languages available to choose from: -PL Polish -ENG English -DE German -ESP Spanish

- 24 -

Instruction Manual FA Series Force Gauge

12.7 Date and Time

This menu will allows you to set the date and time. You can also adjust the format of the date. Access this function by going to CONFIGURATION in the Main Menu. DATE AND TIME 1. Time 2. Date 3. PIN 4. Format 5. Exit 10:00:00 2011-01-11 0 <YYYY-MM-DD><MM- DDYYYY> <DD-MM-YYYY>

12.8 Keyboard

This menu allows you to turn sounds on or off when pressing the buttons on the main keyboard. Access this function by going to CONFIGURATION in the Main Menu. KEYBOARD 1. Beep 2. Exit <ON><OFF> <ON><OFF>

12.9 Auto-OFF

This menu allows you to set the force gauge to automatically turn off in order to preserve battery life. Access this function by going to CONFIGURATION in the Main Menu. AUTO-OFF 1. Status 2. Exit <ON><BAT><OFF> -ON The device automatically shuts off after 5 minutes of inactivity. OFF -BAT The device will shut off automatically when the battery is low. -OFF The device will only turn off when the user presses the ON/OFF key.

- 25 -

Instruction Manual FA Series Force Gauge

12.10 Battery

This menu displays the remaining battery life. It also gives you the option of turning off Charging when nonrechargeable batteries are being used (This function only applies to certain models). Access this function by going to CONFIGURATION in the Main Menu. BATTERY 1. Charging 2. Charge level 3. Exit <Off><ON> 80%

* Charging non-rechargeable, alkaline batteries can cause major damage to the force gauge.

12.11 Defaults

This option will restore the original setting that the device was configured under. Access this function by going to CONFIGURATION in the Main Menu. DEFAULTS Restore default settings? NO YES

- 26 -

Instruction Manual FA Series Force Gauge

Chapter 13: Taking a Measurement

The FA Series force gauges are designed for measuring the compressive/tension force in laboratory, manufacturing, and quality control applications. Measurements up to 200N can be performed by holding the force gauge in your hand. For measurements above 200N it is strongly recommended that a double-hand handle is attached to the force gauge (additional equipment). The USB port allows for all measurement results to be loaded onto a computer for further analysis and recordings. After configuring the force gauge, take measurements by using the steps below: 1. Attach a tip suitable for the measurement about to be performed (i.e. pull, push, mass). 2. Turn the device on in the starting position (tare the device if necessary). Note: If the device needs to be mounted to a test stand or has an external load cell, secure the device for measuring. 3. If the intended measurements are to find out the push/pull peak force, the PEAK button should be pressed to initialize the feature (press once for push peak, twice for pull peak). Note: The force gauge with external load cell requires the PEAK button be pushed once for pull force and twice for push force (opposite of the internal force gauge).

13.1 Compressive Force (Push)

1. 2. 3. 4. To measure the push force of an object, angle the device so it is linear to the object. If measuring by hand grasp the device firmly. Push the force gauge forward with the attached tip pressing into the object. Study the measurements being recorded as the force is applied.

13.2 Tension Force (Pull)

1. 2. 3. 4. To measure the pull force of an object, angle the device so it is liner to the object. If measuring by hand grasp the device firmly. Wrap the hook tip around the object and pull the force gauge away from the object. Study the measurements being recorded as the force is applied.

* Do not exceed the gauges maximum capacity by more than 20% All stored data can be viewed in STATS (Applications > Data Stored > Stats). From here you can view the data in a histogram or chart. Stored data can also be saved to a computer for analyzing or printing. * When you are packing the force gauge up, make sure to remove any attachments from the measuring rod to prevent damage. - 27 -

Instruction Manual FA Series Force Gauge

13.3 Type of Measurement Diagrams

- 28 -

Instruction Manual FA Series Force Gauge

13.4 Measurement Setup Diagrams

- 29 -

Instruction Manual FA Series Force Gauge

Chapter 14: Calibration

Calibration is an important step when weighing the mass of an object. This process is used to adjust the force gauge or scale to the actual gravity and barometric conditions of the users current location. It also accounts for any drift due to temperature changes. To get to this function go to the Main Menu. There are multiple methods that can be used to calibrate the gauge:

- Use an object of known weight to correctly adjust the scale.

CALIBRATION 1. 2. 3. 4. 5. 6. 7. 8. Calibration-START Mode Load <5kg> <20kg><10kg><...> Correction g = 9.81416m/s2 Geographical location Factory calibration Exit 1. Position the device upside down with the hook tip attached. The gauge should be secured in the same fashion that you plan to use it to weigh objects in (e.g. locked into a stand, by hand, etc.). 2. Set the Mode to Mass 3. Select the Load weight exactly equal to the weight of the calibration weight that will be used to calibrate. 4. Place the calibration weight on the hook or hook-held platform. 5. Select Calibration START to initiate calibration.

- Input the g-value (gravitational acceleration) of the location where the force gauge is being used.

For this method, the exact g-value must be known and can be typed in using the arrow keys. Note: The g-value of a given location can be found on the internet. (e.g. Wikipedia, a municipality site, etc.)

- Input the Geographical Location of where the force gauge is being used.

If the g-value is not known, the geographical coordinates can be entered. 1. Select Geographic Location 2. Enter the Latitude of the current location 3. Enter the Elevation of the current location By entering these coordinates, the g-value will automatically be updated therefore calibrating the device. Note: The geographical coordinates of a given location can be found through multiple methods including: A GPS, Smart Phone Apps, and the Internet. - 30 -

Instruction Manual FA Series Force Gauge

- Input a Correctional Value

Errors may occur through extensive use and overloading of the force gauge. To account for these errors a correctional value must be entered to adjust the force gauge. Note: In order to perform a Correction an object with a known weight must be obtained. 1. Position the device upside down with the hook tip attached. The gauge should be secured in the same fashion that you plan to use it to weigh objects in (e.g. locked into a stand, by hand, etc.). 2. Place the calibration weight on the hook or hook-held platform. 3. Find the difference between the actual weight and the measured weight of the object. Note: The scale must be set to a unit of weight for this operation. 4. Select Correction and enter the difference. By entering this value the force gauge will automatically be adjusted by calibrating itself.

* Factory calibration can be used to reset the force gauge to its default settings from its original calibration at the manufacturer.

- 31 -

Instruction Manual FA Series Force Gauge

Chapter 15: Maintenance, Trouble Shooting, and Repairing Minor Damage

There are a number of errors caused by the user that will cause the force gauge to not work properly.

1. The force gauge should always be kept clean. If dirt or dust builds up and gets in any of the opening of the force gauge, the software can begin

to malfunction.

2. Make sure no substances get stuck between the measuring rod and the frame of the device.

If anything gets wedged in this area, it can cause the measurements to become inaccurate and can lead to permanent damage of the unit.

* If anything substances do get wedged inside, they should be removed using a tool which does not conduct electricity. 3. Unauthorized personnel should not perform any repairs on the force gauge. If anyone other than a trained technician tries to repair or adjust the force gauge, they can cause permanent damage. Error Indications: Message/fault The message RESETTING is displayed for an extended period of time. AD range exceeded (+/-) The values indicated by the gauge differ significantly from the correct values. Units displayed are different from the selected units. Cause The initializing process is disturbed The initializing process is disturbed The gauge needs to be adjusted. The UNIT/CLEAR key may have been pressed by accident. Recommendation Dont move the force gauge and press T(0) Put the gauge in horizontal position and turn it off and on using the ON/OFF key. Contact a servicing facility to calibrate the gauge. Press the UNIT/CLEAR key several times to display the correct units.

15.1 Cleaning the Force Gauge

The force gauge should be cleaned regularly to prevent dirt and dust from building up. 1. Get a damp cloth 2. Rub the cloth over the frame, key pad, LCD screen, and measuring rod. 3. Dry the force gauge off with a dry cloth. * DO NOT pour liquid directly onto the force gauge. * DO NOT attempt to clean the force gauge with alcohol. * DO NOT wipe in the power socket or the USB port. - 32 -

Instruction Manual FA Series Force Gauge

Chapter 16: Additional Attachments

The FA Series force gauge offers a variety of additional attachments that can be used in the measurement of objects. These attachments are all available for purchase through www.forcemeters.com.

This chrome-plated allen vise clamp is ideal when performing peel testing, or gripping thin material such as film, paper, or foil. The vise is equipped with an adjustable allen screw and interlocking claps which allow for secure sample griping without damage. This chrome-plated manual C-Clamp is designed to secure samples on the testing stand. The clamp also easily attaches to the force gauge and it is ideal for making measurement on wide range of sample shapes and sizes. This attachment should be used when testing samples that need to be gripped over a large surface area. The roller grip attachment is used when measuring tape strength as well as tape adhesives. The grip is ideal for testing any sample that needs to be draped in order to obtain an accurate force measurement.

The two grip handle adapter is especially useful when performing force measurements between 200N and 500N. The handle securely mounts the force gauge meter allowing users a comfortable and firm grip when pulling ir pushing objects that require extensive force. The hook plate allows the TORBAL force gauges to be securely suspended in a hanging position. The kook can be used on all FA models with built-in load-cells. Hanging the force gauge is particularly useful when measuring articles which must be hung on the force meter in order to measure downward pull forces.

- 33 -

Instruction Manual FA Series Force Gauge

Allen Vise Clamp

C-Clamp

Roller Grip

Two-Grip Handle

Hook Plate

- 34 -

Instruction Manual FA Series Force Gauge

Chapter 17: Warranty

PURCHASERS 12-MONTH WARRANTY Warranty is valid only if the attached warranty registration card is completed and returned within 30 days. This product is a precision device made to exacting standards of scientific accuracy. It is guaranteed to have been adjusted and inspected for proper workmanship and performance, and certified for its currently advertised specifications before shipment. Fulcrum Products are warranted against defects in material and workmanship under normal use and service. This warranty is extended only to the first purchaser. This limited warranty will not apply if, upon inspection, it is found that the product was tampered with, misused, overloaded, or abused. mishandled, placed in an improper environment, improperly installed or adjusted, used for a purpose other than that for which it was designed, or repaired by unauthorized personnel. Fulcrums liability under this warranty is limited to furnishing labor and parts necessary to remedy the defect covered by this warranty and restore the product to normal operating condition. Purchasers may be charged a minimum repair fee for in-warranty products returned for repair if those products are determined to be problem free. To make a claim under this limited warranty, obtain an RMA number from Fulcrum and return the product, carefully packed in its original packaging, shipping prepaid, with the RMA number written on the return package.

- 35 -

Instruction Manual FA Series Force Gauge

Torbal FAk External Load-Cell

Chapter 18: Notes

- 36 -

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Hemodynamic Monitoring in ICUDocument111 pagesHemodynamic Monitoring in ICUManjunath Gemini100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Winter Solstice, CGW 2011Document38 pagesWinter Solstice, CGW 2011Lady HekateShadowMoonfire0% (1)

- Basic Resistance Training GP5Document20 pagesBasic Resistance Training GP5matt.tubieron23No ratings yet

- First Periodical Exam Math 8Document2 pagesFirst Periodical Exam Math 8Joanne88% (8)

- The Foods of Italy BookDocument92 pagesThe Foods of Italy BookmanupopNo ratings yet

- Pill Counting - : Counting Prescription Drugs For The First Time (F2)Document8 pagesPill Counting - : Counting Prescription Drugs For The First Time (F2)quescikNo ratings yet

- Instruction Manual SystemDocument72 pagesInstruction Manual SystemquescikNo ratings yet

- DRX 200 300 Instruction ManualDocument50 pagesDRX 200 300 Instruction ManualquescikNo ratings yet

- Analytical Balances Torbal AGZN SeriesDocument50 pagesAnalytical Balances Torbal AGZN SeriesquescikNo ratings yet

- Buku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BDocument8 pagesBuku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BKeni KenizaNo ratings yet

- The Poet of NatureDocument31 pagesThe Poet of NaturejulyNo ratings yet

- 365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusDocument10 pages365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusER Aditya DasNo ratings yet

- Bearing Solutions and Service For Wind TurbinesDocument16 pagesBearing Solutions and Service For Wind TurbinesDrZEIDINo ratings yet

- Architecture of HimalayasDocument3 pagesArchitecture of HimalayasAndrea CaballeroNo ratings yet

- Pearson Correlation ValueDocument7 pagesPearson Correlation ValuemarianaNo ratings yet

- Interactions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CDocument22 pagesInteractions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CTrydawNo ratings yet

- Nfpa 13d 2007 IndexDocument3 pagesNfpa 13d 2007 Indexsaladin1977No ratings yet

- A Study On Risk Assessment in The Construction of High-Rise BuildingsDocument5 pagesA Study On Risk Assessment in The Construction of High-Rise BuildingsMohamedSaidNo ratings yet

- Aljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossDocument3 pagesAljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossT. LimNo ratings yet

- Vertical HabitatDocument6 pagesVertical HabitatAbdul SakurNo ratings yet

- BTS "Whalien 52" Lyrics Romanization, English and Indonesian TranslationDocument11 pagesBTS "Whalien 52" Lyrics Romanization, English and Indonesian TranslationEmaFediFeniNo ratings yet

- MOE XT2-XT4 110... 125V Ac/dcDocument3 pagesMOE XT2-XT4 110... 125V Ac/dcLê Xuân ĐịnhNo ratings yet

- Method Statement of T-Beams PDFDocument14 pagesMethod Statement of T-Beams PDFKAmi KaMranNo ratings yet

- Peethas ListDocument1 pagePeethas ListChetan PrajapatiNo ratings yet

- Robotics Toolbox 9.6 TutorialDocument149 pagesRobotics Toolbox 9.6 TutorialRogério Lopes100% (1)

- IJHIM 6 - Nur Husnina (36 SD 42)Document7 pagesIJHIM 6 - Nur Husnina (36 SD 42)RSU Sayang BundaNo ratings yet

- Iso TR 16922 2013 (E)Document18 pagesIso TR 16922 2013 (E)Freddy Santiago Cabarcas LandinezNo ratings yet

- Corrosion Resistant Steels: Stainless Steel AlloysDocument11 pagesCorrosion Resistant Steels: Stainless Steel AlloysPraveen SamarthiNo ratings yet

- Jason Read, "Real Subsumption"Document32 pagesJason Read, "Real Subsumption"Aren Z. AizuraNo ratings yet

- General Wireless Design Considerations 1 PDFDocument0 pagesGeneral Wireless Design Considerations 1 PDFDurga TejaNo ratings yet

- DSE MC G11 G12 Equations Straight Lines 2023Document6 pagesDSE MC G11 G12 Equations Straight Lines 2023ernestchan501No ratings yet

- Fact Sheeton Canola OilDocument15 pagesFact Sheeton Canola OilMonika ThadeaNo ratings yet

- Strength of Materials: 2. Assume Missing Data, If Any, SuitablyDocument2 pagesStrength of Materials: 2. Assume Missing Data, If Any, SuitablynvnrevNo ratings yet

- Power and Propulsion PDFDocument13 pagesPower and Propulsion PDFahmedalgaloNo ratings yet