Professional Documents

Culture Documents

Pehp7046 03

Uploaded by

thailanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pehp7046 03

Uploaded by

thailanCopyright:

Available Formats

Fuel Contamination Control

Contamination Control Enhances Performance

Contamination control is increasingly important for maximizing performance and service life in fuel systems. Some Cat fuel systems exceed pressures of 30,000 psi in order to deliver more horsepower, better fuel economy and fewer emissions. This necessitates tolerances smaller than five microns between parts. These tolerances and injection pressures make fuel systems more vulnerable to wear and abrasion. Injector NozzlesContaminants move quickly in high-pressure systems, causing damage, eroding orifices and resulting in incomplete atomization of fuel and overfueling. This harms performance and fuel economy. Contaminants also result in hard starts and increased emissions. Larger contaminants can actually clog orifices. Injector Plungers and BarrelsAbrasive particles cause wear between an injectors plunger and barrel. Contaminants scuff metal surfaces, causing metal-to-metal contact and eventual injector seizure. Control ValvesContaminants damage valves that control fuel pressures, eroding mating parts of the valves. This excessive wear causes leaks and eventual loss of engine power.

Fuel Contamination Control

Human hair (80 microns) Advanced High Efficiency (4 microns) Standard efficiency (15 microns)

Damages fuel systems (5-10 microns)

Standard 15 Advanced High Micron(c) Typical Efficiency 4 Absolute Engine Micron(c) Part Application Absolute Number Part Number 3126B, 3176 3176B, 3176C 3196, 3304 3304B, 3306 3306B, 3406 3406B, 3406C 1R-1712 3406E, 3408E 1R-0749 3412D, 3412E 3456 (C9, C10, C11, C12, C13, C15) 3508, 3508B 1R-0755 1R-1725 3508C, 3512 (Spin On) (Cartridge)* 3512B, 3516 1R-0756 3516B, 3524B (Cartridge)* 3114, 3116 1R-1740 3208, 3304 1R-0750 3304B, 3306 3306B, 3306C 3114, 3116 None 3126, 3126E 1R-0751 C7, C9 None 3116, 3126 1R-0753 3126B, 3456B None 3456E, C9 1R-0762 C10, C12 3606, 3608 None 3612, 3616 1R-0766 3618 (Cartridge)*

*Gen Sets/Industrial Refer to your Operation and Maintenance Manual to find the correct part number for your application. Most applications require that an Advanced High Efficiency filter be used.

Size of Contamination A particle five microns across can damage fuel systems. A micron is onemillionth of a meter. To give you an idea of how small that is, an average human hair is 80 microns in diameter. Tolerances in Cat fuel injectors are 1/20th the diameter of a human hair. Its easy to understand how even small contaminants can damage todays fuel systems. Sources of Contamination In the FuelContaminants can enter during storage or transportation of fuel. A reliable supplier, filtered dispensing and periodic sampling and testing assures consistent quality. During OperationAirborne particles can be drawn into your fuel tank through the vent tube. A fuel tank vent can ingest dust when it is not properly sealed. ExternalContamination can enter during maintenance and service, even when changing filters. Filtering Contamination The precision components in todays fuel systems require specially designed fuel filters. Cat Advanced High Efficiency Fuel Filters use exclusively designed filtration media to remove more than 98% of particles, four microns in size and larger. Cat Advanced High Efficiency Fuel Filters feature: spiral roving and acrylic beads to maintain pleat stability and spacing to better trap and hold contaminants non-metallic center tube for strength and to prevent metal contamination

Measuring Contamination

Contamination is measured by counting particles and reported by comparing those results to an International Standards Organization (ISO) code. This ISO standard refers to the number of particles in three different size categories contained in a one-milliliter sample. The first number refers to the number of particles that are greater than 4 microns, the second number refers to particles that are greater than 6 microns, and the third number refers to particles that are greater than 14 microns. An ISO level of 18/15/13 would mean that a one-milliliter sample of fuel contains ISO Code 18 or between 1300-2500 particles greater than 4 microns, ISO Code 15 or between 160-320 particles greater than 6 microns, and ISO Code 13 or between 4080 particles greater than 14 microns. If the contamination level is allowed to rise one ISO Code, the amount of particles for that size will double.

Cat filters Other brands of filters

98% efficiency

50% efficiency

= 4 micron particle

CAT DeALeRS defINe WORLdcLASS pROdUcT SUppORT.

We offer you the right parts and service solutions, when and where you need them. The Cat Dealer network of highly trained experts can help you maximize your equipment investment.

PEHP7046-03 www.cat.com 2007 Caterpillar All Rights Reserved Printed in USA CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the POWER EDGE trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

You might also like

- Miniskaff Assembly Instructions PDFDocument2 pagesMiniskaff Assembly Instructions PDFthailanNo ratings yet

- Hyundai spare parts catalog download/TITLEDocument2 pagesHyundai spare parts catalog download/TITLEthailanNo ratings yet

- Miniskaff Assembly Instructions PDFDocument2 pagesMiniskaff Assembly Instructions PDFthailanNo ratings yet

- 40 Foot Container DimensionsDocument3 pages40 Foot Container DimensionsthailanNo ratings yet

- HILUX Electrical Wiring Diagram GuideDocument244 pagesHILUX Electrical Wiring Diagram Guidethailan100% (2)

- Possible Frame IssueDocument10 pagesPossible Frame IssuethailanNo ratings yet

- 2016 Mining Catalogue MASTERDocument79 pages2016 Mining Catalogue MASTERthailanNo ratings yet

- Norma Normaquick Quick ConnectorDocument16 pagesNorma Normaquick Quick ConnectorthailanNo ratings yet

- MV99 - Load Sensing VVDocument46 pagesMV99 - Load Sensing VVthailanNo ratings yet

- Ar Industrial Catalog en 2016 WebDocument120 pagesAr Industrial Catalog en 2016 WebthailanNo ratings yet

- Bul SAE J2044 PDFDocument8 pagesBul SAE J2044 PDFthailanNo ratings yet

- Portable Repair WorkshopsDocument24 pagesPortable Repair WorkshopsthailanNo ratings yet

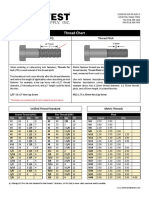

- Unc Unf Metric Thread Chart Northwest FastenerDocument1 pageUnc Unf Metric Thread Chart Northwest FastenerthailanNo ratings yet

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Document52 pagesSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanNo ratings yet

- AMastersGuidetoContainerSecuring2ndEdition 3 PDFDocument50 pagesAMastersGuidetoContainerSecuring2ndEdition 3 PDFthailanNo ratings yet

- 3c EngDocument2 pages3c EngthailanNo ratings yet

- 520L0893 PDFDocument240 pages520L0893 PDFthailanNo ratings yet

- Alemite CatalogDocument177 pagesAlemite CatalogthailanNo ratings yet

- 3 o Ring Guide Issue 7 PDFDocument32 pages3 o Ring Guide Issue 7 PDFthailanNo ratings yet

- Alemite CatalogDocument177 pagesAlemite CatalogthailanNo ratings yet

- NPTDocument6 pagesNPTthailanNo ratings yet

- 38 Alemite Product Catalog PDFDocument277 pages38 Alemite Product Catalog PDFthailanNo ratings yet

- JIS ThreadsDocument7 pagesJIS Threadsthailan0% (1)

- Cummins Heavy Duty Product Guide PDFDocument22 pagesCummins Heavy Duty Product Guide PDFthailanNo ratings yet

- Type of ThreadDocument13 pagesType of ThreadVils ArabadzhievaNo ratings yet

- Ourproductconcept Eng PDFDocument8 pagesOurproductconcept Eng PDFthailan100% (1)

- How To Identify Fluid Ports and ConnectorsDocument24 pagesHow To Identify Fluid Ports and ConnectorsKathryn WorkmanNo ratings yet

- Dseries Eng PDFDocument3 pagesDseries Eng PDFthailanNo ratings yet

- Mounting Flange HZW EngDocument2 pagesMounting Flange HZW EngthailanNo ratings yet

- Mounting Flange HZW EngDocument2 pagesMounting Flange HZW EngthailanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manual of Green Building MaterialsDocument153 pagesManual of Green Building MaterialsKawser HossainNo ratings yet

- Cube Boom: Permenant DeploymentDocument1 pageCube Boom: Permenant Deploymentapi-3703371No ratings yet

- Leather Burnishing & Polishing: Existing ProcedureDocument6 pagesLeather Burnishing & Polishing: Existing ProcedurevinothjohnnashNo ratings yet

- Group ID A 10's mono wheel vehicle designDocument1 pageGroup ID A 10's mono wheel vehicle designChirag N PatelNo ratings yet

- Modification and Development in Air CoolerDocument6 pagesModification and Development in Air CoolerSONUNo ratings yet

- Water for Pharma ValidationDocument14 pagesWater for Pharma ValidationPépé TechopathamNo ratings yet

- Triplex Pump ManualDocument11 pagesTriplex Pump ManualDustin WhiteNo ratings yet

- Find this flexible cable product and technical specification onlineDocument3 pagesFind this flexible cable product and technical specification onlineRicardo Mendes100% (1)

- Cool The Summer - Leaflet - HRDocument48 pagesCool The Summer - Leaflet - HRPeter Ace John IngelNo ratings yet

- Solar Cells - Thin-Film TechnologiesDocument468 pagesSolar Cells - Thin-Film TechnologiesDavid K. HongNo ratings yet

- JP Pdms 014 BoltinDocument10 pagesJP Pdms 014 BoltinKodali Naveen KumarNo ratings yet

- Recovery of Mn2+, Co2+ and Ni2+ From Manganese Nodules by Redox Leaching and Solvent ExtractionDocument7 pagesRecovery of Mn2+, Co2+ and Ni2+ From Manganese Nodules by Redox Leaching and Solvent Extractionpriska monanginNo ratings yet

- 615-LS 42 ManualDocument48 pages615-LS 42 ManualmelisaBNo ratings yet

- Ropaque™ Ultra E: Technical Data Sheet For Europe, Middle East and AfricaDocument3 pagesRopaque™ Ultra E: Technical Data Sheet For Europe, Middle East and AfricahongducxxxNo ratings yet

- Nanoscale Silk PaperDocument9 pagesNanoscale Silk PaperphyskrNo ratings yet

- Mel ZG611Document5 pagesMel ZG611jitendraNo ratings yet

- Lgi Tungsten Tube Bulb Array Reflector Shield / Device For 16 Tube Holders Model - Lgi 16.05.2017ad, 03.45amDocument7 pagesLgi Tungsten Tube Bulb Array Reflector Shield / Device For 16 Tube Holders Model - Lgi 16.05.2017ad, 03.45amPierre Le GrandeNo ratings yet

- Lightweight Self-Consolidating Concrete - Statistical Modelling, Mixture Design and Performance EvaluationDocument417 pagesLightweight Self-Consolidating Concrete - Statistical Modelling, Mixture Design and Performance Evaluationshak543No ratings yet

- AP CRDA Basic Cost Of Materials 2016-2017Document57 pagesAP CRDA Basic Cost Of Materials 2016-2017Hari Krishna AaryanNo ratings yet

- Boiler Feed Water Treatment & BlowdownDocument6 pagesBoiler Feed Water Treatment & BlowdownnurulNo ratings yet

- BTS Ac SystemDocument40 pagesBTS Ac Systemmohsinaliqureshi02No ratings yet

- Reactive Polyglycol EthersDocument2 pagesReactive Polyglycol EthersJayNo ratings yet

- Organic Coated Steel: ArcelorDocument37 pagesOrganic Coated Steel: ArcelordangmiuNo ratings yet

- Uni Interface ZündDocument3 pagesUni Interface Zündmaxime100% (1)

- Sensitization of Weld Overlay 308 PDFDocument12 pagesSensitization of Weld Overlay 308 PDFShoaib AhmedNo ratings yet

- Process for Producing Ammonium Nitrate from Ammonia OxidationDocument20 pagesProcess for Producing Ammonium Nitrate from Ammonia OxidationGracia ManurungNo ratings yet

- Zephyr 20S 62-60519-01 PDFDocument42 pagesZephyr 20S 62-60519-01 PDFAnonymous K53TYtF0% (1)

- Ecoboost 1.0 LDocument11 pagesEcoboost 1.0 Lcarlosve87100% (1)

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresNo ratings yet

- Catalog Thiet Bi Dien Ls Aptomat MCCB Elcb Ls - RemovedDocument5 pagesCatalog Thiet Bi Dien Ls Aptomat MCCB Elcb Ls - RemovedMai Lê Kiều MyNo ratings yet