Professional Documents

Culture Documents

HS05

Uploaded by

rashidkingCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HS05

Uploaded by

rashidkingCopyright:

Available Formats

45th IEP Convention 12

COMPULSORY SAFETY AND HEALTH COURSE FOR ENGINEERING AND NON ENGINEERING PROGRAM IN UNIVERSITY TUN HUSSEIN ONN (UTHM) MALAYSIA

A.M LEMAN AND ISHAK BABA

a b

FACULTY OF ENGINEERING TECHNOLOGY, UNIVERSITY TUN HUSSEIN ONN MALAYSIA a email: mutalib@uthm.edu.my b email: ishak@uthm.edu.my

ABSTRACT

Education is one of the social mobility to develop the nation. In University, the program that was developed must meet the requirement from the stake holder and as well as industries. The Safety and Health course is University Tun Hussein Onn Malaysia is compulsory and it was offered in second year for the Diploma and First Degree program. The introduction of these courses was taking into account the knowledge given to student as per preparation before this student goes to Industrial Training. The industrial accident and the occupational diseases statistics of Malaysia need to be study and it is evidence why the safety and health issues and problems should be prevented. The course that was developed hopefully will be beneficiaries to all involve parties. The Safety and Health culture towards the total management for Malaysia has been established for Occupational Safety and Health Malaysian Plan 2015. So the future engineers and technologist must be preparing with the knowledge and better understanding for built a better world.

Keywords: Safety and Health, Engineering, Engineering Technology.

45th IEP Convention 12

1. INTRODUCTION

Organization worldwide strives to develop their management system for business functions, ranging from quality and environment to safety, information security and social responsibility. For the latest decade a considerable amount of these efforts has been concentrated on introducing and applying standards such as the ISO 9001 and ISO14001 (Eriksson and Hansson, 2006). Numerous manufacturing and service organization are considering integrating their respective occupational and safety management and audit systems into the International Organization for Standardization (ISO) based audit driven quality management system (ISO 9000) or environmental management system (ISO 14000) models (Dyjack et al, AIHA, 1998). The need for Integrated Management System (IMS) often arises as a result of decisions to implement Environmental Management System (EMS) and occupational safety and health management system in addition to a Quality Management System (QMS). Thus the development of standard from various sources emerged. A good example is the series of the OSHAS 18001: 2007 and OSHAS 18002:2008. The OSHAS 18001 is compatible with ISO 9001:2000 (Quality) and the ISO 14001:1996 (Environmental) management system standards, which can facilitate the integration of quality, and environment OSH management system individual organization (BSI, OHSAS 18001:1999). Malaysia has also introduced the Malaysian standard and the latest is MS ISO 9001: 2008 and MS 1722: 2003. Malaysian Standard also emphasizes on the employer understanding and take the opportunity to improve on the quality aspect. People worldwide face occupational safety and health hazards daily. Over the years, the global occupational hygiene community has worked diligently to develop ways to protect workers, in workplaces of all types and sizes. Standards and guidelines were developed to help the employers and employees to develop their OSH Management system. A standard is an agreed, relatable way of doing something. It is published document that contains a technical specification or other precise criteria designed to be used consistently as a rule, guideline, and definition. Standards help to make life simpler and increase the reliability and the effectiveness of many goods and services. It is created by bringing together the experience and the expertise of all interested parties such as the producers, sellers, buyers, users and the regulators of particular material, product, process or service. Standards are designed for voluntary use. However, laws and regulations may refer to certain standards and make compliance with them compulsory (British Standard, 2009). In this study certain standards were referred based on the Malaysian standard requirements. MS 1722: Part 1: 2005, Occupational Safety and Health Management Systems-Part 1: Requirements was establish to guide the company on safety and health aspect. MS 1722: Part 2: 2003, OSH Managements Systems-Part 2: Guidelines was developed to give the understanding to the company and guidance to employer to build up the Occupational

45th IEP Convention 12

Management System. From the environment aspect, the study also will look at the MS ISO 14001: 2004, Environment Management System (EMS) Requirements with Guidance for use.

2. OSH MALAYSIAN PERSPECTIVE

Occupational safety and health (OSH) management system is one of the ways to push forward the safety and health approach and it is apply to the 10 industrial sectors in Malaysia. The establishments of OSH management system worldwide are the key to sustainable development. This paper were highlighted some of the key factor why OSH management system must put into organization practice. The overviews on OSH Malaysian perspective were mentioned about the history of Malaysian OSH development. OSH Standards and guidelines approach from a various partys involvement and System Model is the guide to implementation of OSH management system from BS OHSAS 18001:2007. The Malaysian standard MS 1722: 2003 has significant impact to the whole management system development. The OSH management system created by organization should be implementing widely. The government was target to reduce the industrial accident and occupational diseases through the OSH Malaysian Plan 2015. The

university involvement through education program is so important to make sure the safety and healthier work environment has become a reality. OSH provides a working environment which is conducive to workers. Reasonable precautionary steps are taken so as to ensure that workers are prevented from injury or health hazard due to work activities being carried out. Occupational safety and health (OSH) was first implemented in Malaysia some 130 years ago towards the end of the 19 century (DOSH 2007). In 1953 initially, the formation of the OSH was managed by Factories and Machineries Department. Its main activities were to ensure machinery safety and also the safety and health of workers in the manufacturing sector. With the rapid growth of technology and the economic development of the country, the department no longer focused solely on the manufacturing sectors, but also other occupational sectors. Hence, the Factories and Machineries Department was upgraded to the Department of Occupational Safety and Health (DOSH) in 1994, where its main focus is to ensure the safety, health and welfare of people at workplace and to protect others from the danger arising from occupational activities. DOSH is the only government agency responsible for administrating, managing and enforcing legislation pertaining to OSH in the country with the vision of making all occupations safe and healthy while enhancing the quality of working life (OSHA, 1994). From the DOSH report, the industrial accident statistic was tabulated in Table 2.1. The data describes the number of

th

industrial accidents occurred by sector from year 2005 to 2009. It shows that the number of industrial accident is quite high especially for manufacturing sector. Table 2.2 presents a total number of investigation cases of occupational diseases and poisoning. For the occupational disease, The Occupational Health Division monitors and analyses the data 3

45th IEP Convention 12

received.

For each case of occupational disease and poisoning that is investigated, the

department advises the industries to take corrective measures to prevent from recurrence. To ensure the safety, health and welfare of workers are taken care; DOSH work towards making sure that the occurrence of industrial accidents in Malaysia is low, by introducing the OSH Master Plan 2015. This plan provides the direction of OSH in the country, and function as a guide for working cohesively with stakeholders and social partner, including government agencies, local authorities, labor unions, employer associations, academic institutions and other nongovernmental organization. Small and Medium Industries (SMI) sector has been identified as the major source of accidents in the manufacturing industry. New strategies had therefore been introduced to reduce the accidents and to increase the level of awareness for the compliance with the Factories and Machinery Act, 1967 and Occupational Safety and Health Act, 1994. So the education is the best situation to deliver the knowledge to the student. Hence, the development of the safety and health culture were being introduced since university. The levels of education are divided to 3 categories which is:

i. ii. iii.

Short Course/ Seminar Diploma Degree

3. THE WAY OF IMPLEMENTATION

In the University of Tun Hussein Onn Malaysia, 48 programs on Diploma level and First Degree level were offered. The nature of the education is divided with two main programs (engineering and non-engineering). Some of the programs include safety as a core courses and the others made it elective courses. In this situation the curriculum development has figure out the important of safety and health as a tool to the occupation and productivity. Through the meeting and discussion, the decision has been made that the Occupation Safety and Health course is compulsory to engineering and non-engineering whether from diploma level or first degree level. At the same time, the university also has conducted a several course and seminar regarding occupational safety and health. From the whole structure of curriculum, occupational safety and health course basically was scheduled in second year. The reason is the student start to run the laboratory testing and some or workshop work need to be done as per request of core subject in the curriculum. The other reason is student must prepare with their knowledge to identify the hazard, assess the risk and minimize the risk before they proceed to the Industrial Training in the 3 year. Table 3 below shows the example of curriculum structure. Table 4 shows a curriculum summary

rd

45th IEP Convention 12

4. DISCUSSION

The implementation of occupational safety and health in education program is one of the method to introduced the occupational safety and health and it also the way to develop safety and health culture for the nation. In the reality, the set target to enhance the capability of diverging the knowledge based on this syllabus.

4.1 Goal

To provide knowledge and skills in occupational safety and health at workplace.

4.2 Learning Outcomes

Upon completion of the course, students should be able to: 1. 2. 3. Design safety and health program to meet the work place requirements. Perform according to the most current acts pertinent to the Occupational Safety and Health. Adopt current technique on reporting of accident/incident according to OSHA 1994, FMA 1967 or DOSH requirements. (A3, PLO8)

4.3 Synopsis

This course introduces students to knowledge and skills in occupational safety and health in workplace. Scope of study includes Health, Safety and Environment Managements: introduction to OSH, OSHA 1994 (Act 514), FMA 1967, EQA 1974, occupational safety and health management system, safety, health and environment culture; Risk Management and Assessment: introduction to risk management, risk assessment techniques, HIRARC; Physical Injury & Controls: introduction to physical injury, construction work, electrical work, mechanical work, chemical work; Health Hazards: introduction to health hazards & hygiene, chemical hazards, physical hazards, biological hazards, hygiene; Accident Investigation & Reporting: introduction, accident investigation, investigations and causes of incident, incident analysis and data collection method From the syllabus, the content are basically have 5 main topics such as: i. ii. iii. iv. v. Health, Safety And Environment Management Risk Management And Assessment

Physical Injury And Controls Health Hazards Accident Investigation And Reporting

Then the expectation that the learner (student) will use the kind of practical as a real training based on the Malaysia legislative (act) and regulation. The implementation of variety technique of teaching and learning approach will help the student do responsible to their self and the surrounding. The OSH standard also will be used as a teaching material while developing the 5

45th IEP Convention 12

practical question. The case study will be adopt to ensure the student has an idea how to solve the matters regarding OSH. The assessment and evaluation based on this criteria: i. ii. Course work : 60 % Final Exam : 40 %

5. CONCLUSION

The occupational safety and health culture must be implemented during formal and non-formal education. The engineering and non-engineering courses need to be justified on what hazard that will be exposed and what kind of risk need to be estimated by the student before they graduate. The Hazard Identification, Risk Assessment and Risk Control (HIRARC) approach as a key element to introduced as a part of Occupational Safety and Health syllabus in the University Tun Hussein Onn Malaysia (UTHM).

45th IEP Convention 12

6. REFERENCES

British Standard (BS) (2009). About Standards. London. United Kingdom. BS EN ISO 14001:2004 (2004). Environmental Management Systems. BS OHSAS 18002:2008. Occupational Health and Safety Management Systems. Clarke, S. (2006). "Safety Climate in an Automobile Manufacturing Plant: the effects of work environment, job communication and safety attitudes on accidents and unsafe behaviour." Personnel Review, 35 413-430. Department of Occupational Safety and Health (2005). Code of Practice on Indoor Air Quality. Ministry of Human Resource of Malaysia.Putrajaya. Department of Occupational Safety and Health (2007). DOSH Annual Report, Human Resources Ministry of Malaysia, Putrajaya. Department of Occupational safety and Health (DOSH) (2008). Annual Report. Putrajaya. Dyjack.D.T, Levine, S.P and Holtshouser, J.L. (1998). Comparison of AIHA ISO 9001-Based Occupational Health and Safety Management System Guidance Document with a Manufacturers Occupational Health and Safety Assessment Instrument. American Industrial Hygiene Association Journal, Volume 59. No 6 p 419-429. Eijkemans G. and Goelzer B. (2004). The practical application in developing countries; Outcomes of the planning meeting in Utrecht, The Netherlands, 13-16 June 2004. GOHNET Newsletter ISSUE No. 7 Summer 2004. World Health Organization. Geneva. Eriksson, H. and Hansson, J. (2006). Integrated management systems theoretical and practical implications, The Asian Journal on Quality, Vol. 7 No. 2, pp. 69-82. Friend M. A and Khon J. P. (2007). Fundemaentals of Occupational safety and Health. Fourth Edition. Government Institute. The Scarecrow Press, Maryland. United States of America . pp 1-7. Goetsch,D.L (2010). The Basic of Occupational Safety.Prentice Hall. Pearson.New Jersey.pp.115 ISO 9001:2000 (2000). Quality Management Systems. ISO 9001:2000 and MS ISO9001:2008.Quality Management Systems. Department of Standard Malaysia. ISO 9001:2008 (2009), Quality Management Systems. Jafari, M., Karimi, A., & Azari, M. (2008). The Role of Exhaust Ventilation Systems in Reducing Occupational Exposure to Organic Solvents in A Paint Manufacturing Factory. Indian Journal Occupational and Environmental Medicine, 12, 82-87. Kim, C. N., Choi, W. H., Choung, S. J., Park, C. -H., & Kim, D. S. (2002). Efficient ventilation of VOC spread in a small-scale painting process. Building and Environment, 37, 1321-1328.

45th IEP Convention 12

Kitumbo H. I. (2009). Accident prevention a safe workplace. African Newsletter on Occupational Health and Safety Volume 19, number 1, April 2009 Finnish Institute of Occupational Health (FIOH). Pp 3. Liu, H., Liang, Y., Bowes, S., Xu, H., Zhou, Y., Armstrong, T. W., et al. (2009). Benzene Exposure in Industries Using or Manufacturing paint in China A Literature Review, 1956-2005. Journal of Occupational and Environmental Hygiene , 6, 659-670. MS 1722: Part 1: 2005, Occupational Safety and Health Management Systems-Part 1: Requirements was establish to guide the company on safety and health aspect. Department of Standard Malaysia. MS 1722: Part 2: 2003, Occupational Safety and Health Managements Systems-Part 2: Guidelines was developing to give the understanding to the company and guidance to employer to build up the Occupational Management System. Department of Standard Malaysia. Occupational Safety and Health Act 1994 and regulations (2006). MDC Publication. Kuala Lumpur. Occupational Safety and Health Master Plan for Malaysia 2015 (2009).Ministry of

HumanResource,Putrajaya. Reese C.D (2009). Occupational health and safety management : a practical approach. Boca Raton, Fla. ; New York, N.Y.: CRC Press, 2009. SMIDEC.Annual report 2007. Kuala Lumpur. Malaysia. Social Security Organization (2007). SOCSO Annual Report 2007, Social Security Organization, Kuala Lumpur. Social Security Organization. (2006). SOCSO Annual Report 2006.Kuala Lumpur. Thebe, A. Pule (2008). Practical Tools and Occupational Health and Safety, African Newsletter on Occupational Health and Safety. 18(2), 23. Tsuyoshi Kawakami (2009). Good OSH practices to Create Healthy and Safe Workplaces. Asian Pacific Newslatter On Occupational Health and Safety. 16. (1), 3. Yamataki, H., Suwazono, Y., Okubo, Y., Miyamoto, T., Uetani, M., Kobayashi, E. and Nogawa, K. (2006). Health status of workers in small and medium -sized companies and compared to large companies in Japan, Journal of Occupational Health, Vol. 48, pp. 166 -74.

45th IEP Convention 12

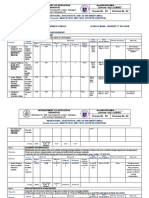

Table 2.1. Industrial Accidents Statistics by sector from 2005-2009

Sector /Year Manufacturing Mining and Quarrying Construction Agriculture and Forestry Utility Transport &

Communication

Year 2005

D 65 3 87 18 2 14 2 3 0 2

196

Year 2006

NPD 2058 107 246 614 177 145 53 27 10 22

3459

Year 2007

NPD 2752 22 365 1014 66 47 13 7 18 44

4348

Year 2008

NPD 2094 5 76 712 51 7 11 11 25 16

3008

Year 2009

NPD 1564 4 55 365 82 18 2 13 2 3

2108

PD 93 4 36 23 20 0 3 1 0 2

182

D 66 2 81 32 5 10 0 0 4 9

209

PD 116 1 25 19 6 1 1 0 2 3

174

D 63 9 95 30 10 2 3 0 4 3

219

PD 133 1 10 14 4 0 1 2 0 3

168

D 76 6 72 42 19 8 0 1 4 2

230

PD 134 0 2 7 12 1 0 1 1 1

159

D 63 3 71 44 23 18 0 0 1 1

224

PD 90 1 6 8 3 0 0 0 0 0

108

NPD 1419 2 38 440 116 21 0 18 0 0

2054

Wholesale and retail Hotel and restaurant Financial & Real Estate Public Services Total

Source: DOSH annual report 2007, 2008 and 2009. Legend: D -Death PD -Permanent Disability NPD -Non-Permanent Disability

45th IEP Convention 12

Table 2.2. Total Number of Investigation Cases of Occupational Diseases and Poisoning from 2005 to 2009

No. 1. 2. 3. 4. 5. 6. 7. 8. Types of Disease Occupational Lung disease (OLD) Occupational Skin Disease (OSD) Occupational Noise Hearing Loss (NIHL) Occupational Muscular Skeletal Disorder (OMD) Disease caused by chemical agent (poisoning) Disease caused by biological agent Occupational Cancer Other and Non- Occupational Disease TOTAL 2005 51 57 190 10 139 0 0 4 451 2006 38 30 106 22 116 3 2 45 362 2007 50 192 120 18 117 1 1 47 546 2008 56 70 169 31 41 2 3 81 453 2009 57 53 427 57 61 3 2 2 669

Table 3. The occupational safety and health course

L 2 2 2 1 1 1 1 2 12 T 2 2 2 2 0 0 0 0 8 P 0 0 0 0 3 2 3 0 8 SLT 4 4 4 3 4 3 4 2 28

MATHEMATICS

CORE/ GENERAL MODULE

PROFESSIONAL DEVELOPMENT MODULE

CODE BWM 12203 BWM 12303 BWM 22403 BWM 22502 BNJ 10802 BPK 20802 BNJ 21102 BNJ 20602

COURSE Mathematics for Engineering Technology I Mathematics for Engineering Technology II Mathematics for Engineering Technology III Statistics for Engineering Technology Computer Programming Entrepreneurship Occupational Safety & Health Management and Professional Ethics TOTAL

C 3 3 3 2 2 2 2 2 19

Legend: C: Credit, L: Lecture, T: Tutorial, P: Practical, SLT: Student Learning Time

10

45th IEP Convention 12

Table 4. Curriculum Summary of Degree in Mechanical Engineering Technology (Plant) with honours (BNL)

Year Semester Code UWB10102 UWA10102/202 UWS 10103 UWB 10*02 UQ* 1***1 BNJ 10302 BWM 12203 BNJ 10102 BNJ 17001 UWA 10302 UWB 10202 UWS 10202 UQ* 1***1 BWM 12303 BNJ 1502 BNJ 10203 BNJ 10602 ENJ 17101 BNJ 10802 BNJ 18001 UWB 20302 BWM 22403 BPK 20802 BNJ 17101 BNJ 20203 BNJ 10403 BNJ 20102 BWM 22502 BNJ 21102 BNJ 20203 BNJ 20403 BNL 20102 BNJ 20502 BNJ 20302 BNJ 27101 BNL 20203 BNJ 20602 BNJ 28001 BDJ 20303 BNJ 30403 BNJ 37001 BNJ 30203 BNJ 30302 BNJ 30102 BNL 30103 BNL 30201 BNL 30303 BNJ 38012 BNJ 49003 BNL 40101 BNL 40202 BNL 40303 BNL 40403 BNL 40503 Courses Academic English Islamic Studies / Moral Studies Malaysian Nationhood and Current Development Foreign Language Co-Curriculum I Creativity and Innovation Mathematics for Engineering Technology I Engineering Drawing Engineering Laboratory I Islam Civilisation and Asian Civilisation Effective Communication Ethnics Relationship Co-Curriculum II Mathematics for Engineering Technology II CAD and Modelling Statics Material Science Engineering Laboratory Computer Programming Mechanical Engineering Practice I Technical Writing Mathematics for Engineering Technology III Entrepreneurship Engineering Laboratory III Fluid Mechanics Solid Mechanics Dynamics Statistics for Engineering Technology Occupational Safety and Health Fluid Mechanics Control Engineering & Instrumentation Fundamentals to Plant Engineering Electrical Power and Machine Mechanics of Machine Engineering Laboratory IV Plant Engineering Design Management and Profesional Ethics Mechanical Engineering Practice II Plant Fabrication Technology Industrial Engineering and Quality Management Engineering Laboratory V Mechanical Engineering Design Electrical Technology & Micro Processing Vibration Thermodynamics Processes Plant Engineering Technology Practice I Piping Engineering Industrial Training Bachelor Degree Project I Plant Engineering Technology Practice II Instrumentation & Process Control Pressure Vessal Design Heat Transfer Process Technology I Credit 2 2 3 2 1 2 3 2 1 2 2 2 1 3 2 3 2 1 2 1 2 3 2 1 3 3 2 2 2 3 3 2 2 2 1 3 2 1 3 3 1 3 2 2 3 1 3 12 3 1 2 3 3 3 Total

I 1

18

II

18

III

18

2 II

18

III

18

II

12

15

11

45th IEP Convention 12

II

BNJ 49105 BNL 40603 BNL 40703 BNL 40803

Bachelor Degree Project II Process Technology II Plant Energy Efficiency Process Safety

5 3 3 3 Overall Total Credit

14

140

Table 4.1. The content of OSH syllabus.

Chapter 1 Content HEALTH, SAFETY AND ENVIRONMENT MANAGEMENT 1.1 Introduction to OSH 1.2 OSHA 1994 (Act 514) 1.3 FMA 1967 1.4 EQA 1974 1.5 Occupational Safety and Health Management System 1.6 Safety, Health and Environment Culture RISK MANAGEMENT AND ASSESSMENT

2.1 Introduction to Risk Management 2.2 Risk Assessment Techniques 2.3 HIRARC PHYSICAL INJURY AND CONTROLS 3.1 Introduction to Physical Injury 3.2 Construction Work 3.3 Electrical Work 3.4 Mechanical Work 3.5 Chemical Work HEALTH HAZARDS 4.1 Introduction to Health Hazards & Hygiene 4.2 Chemical Hazards 4.3 Physical Hazards 4.4 Biological Hazards 4.5 Hygiene ACCIDENT INVESTIGATION AND REPORTING 5.1 Introduction 5.2 Accident Investigation 5.3 Investigations and Causes of Incident 5.4 Incident Analysis and Data Collection Method

12

You might also like

- Bauhaus Building, GropiusDocument3 pagesBauhaus Building, Gropiusivicanikolic100% (2)

- ENM203 Business Essentials CourseworkDocument10 pagesENM203 Business Essentials CourseworknealvazNo ratings yet

- Aiming For Integrity Answer GuideDocument4 pagesAiming For Integrity Answer GuidenagasmsNo ratings yet

- Project Documentation TemplateDocument8 pagesProject Documentation TemplateYug KumarNo ratings yet

- Dost AssignmentDocument20 pagesDost AssignmentAffendi MickyNo ratings yet

- 1.6 Safety CultureDocument59 pages1.6 Safety CultureAinur Sya Irah100% (4)

- The Awareness Level of The Safety and HeDocument8 pagesThe Awareness Level of The Safety and Hebern bazanNo ratings yet

- OshDocument11 pagesOshMuhammad KasranNo ratings yet

- Case Study of NioshDocument3 pagesCase Study of NioshNur Hadirah Afiqah Binti Abdul RazakNo ratings yet

- Text Utm Manual OshDocument130 pagesText Utm Manual OshEncik AhmadNo ratings yet

- Research Project 3Document26 pagesResearch Project 3Lawrence MaradzeNo ratings yet

- Occupational Safety and Health Practices in Manufacturing IndustryDocument12 pagesOccupational Safety and Health Practices in Manufacturing IndustryN GNo ratings yet

- A Project Report On Labour Welfare and SafetyDocument86 pagesA Project Report On Labour Welfare and SafetyShahid Khan81% (21)

- Full Report EISDocument73 pagesFull Report EISjen_ann_2100% (2)

- Introduction To Workshop SafetyDocument42 pagesIntroduction To Workshop SafetyIzzad FikriNo ratings yet

- Sample of TesisDocument12 pagesSample of TesisMohamad Khalid B Hassan100% (1)

- OSHADocument15 pagesOSHAap190163No ratings yet

- Department of OSH MalaysiaDocument6 pagesDepartment of OSH MalaysiaSuleymanNo ratings yet

- Process Safety ManagementDocument32 pagesProcess Safety ManagementSyafyn AmmylyaNo ratings yet

- Tugas Inggris UasDocument14 pagesTugas Inggris UasWulan DariNo ratings yet

- 12.topic 10 - Employee Safety & HealthDocument28 pages12.topic 10 - Employee Safety & HealthA Ahmad NazreenNo ratings yet

- Environmental Health and Safety Management System in Different Industries in BangladeshDocument18 pagesEnvironmental Health and Safety Management System in Different Industries in BangladeshMozakkir AzadNo ratings yet

- Krusant PatelDocument30 pagesKrusant Pateldevamshah286No ratings yet

- 1msiagrip Cisho BrochureDocument3 pages1msiagrip Cisho BrochurefaizNo ratings yet

- Lecture 8.1&2 Process Safety Management Ilearn PDFDocument32 pagesLecture 8.1&2 Process Safety Management Ilearn PDFMuhammad AshmanNo ratings yet

- Executive Diploma in Project Management Occupational Safety and Environmental Parameters Lt. Kol. Ahmad Zubir JX78946HP702 Feb 23, 2009Document24 pagesExecutive Diploma in Project Management Occupational Safety and Environmental Parameters Lt. Kol. Ahmad Zubir JX78946HP702 Feb 23, 2009Mohamad SyafiqNo ratings yet

- Basic Occup0ational Safety and HealthDocument93 pagesBasic Occup0ational Safety and HealthGabriel Galiza100% (1)

- Safety Climate in Ohsas 18001-Certified Organisations: Antecedents and Consequences of Safety BehaviourDocument14 pagesSafety Climate in Ohsas 18001-Certified Organisations: Antecedents and Consequences of Safety BehaviourAmany Ben FredjNo ratings yet

- Hafwan Affiq AssignmentDocument10 pagesHafwan Affiq AssignmentMohd Hafwan Affiq Abdul ManafNo ratings yet

- Risks Assessment and Reporting SystemDocument5 pagesRisks Assessment and Reporting SystemJbee TrendsNo ratings yet

- Osha FPDocument17 pagesOsha FPChanramughi ChanramohanNo ratings yet

- BBSH4103 AnswerDocument13 pagesBBSH4103 AnswerRyan JeeNo ratings yet

- Contractors' Compliance On Occupational Safety and Health (Osh) Policies in Malaysia'S Construction IndustryDocument7 pagesContractors' Compliance On Occupational Safety and Health (Osh) Policies in Malaysia'S Construction IndustryabdirahmanNo ratings yet

- Hamid 2019 IOP Conf. Ser. Earth Environ. Sci. 220 012043Document9 pagesHamid 2019 IOP Conf. Ser. Earth Environ. Sci. 220 012043abdirahmanNo ratings yet

- 02.influence and Effect of Occupational Health and Safety On Employees Performance A Study of Afghanistan International BankDocument7 pages02.influence and Effect of Occupational Health and Safety On Employees Performance A Study of Afghanistan International BankAung Pyae Sone MaungNo ratings yet

- Chapter 1Document4 pagesChapter 1Fatin NajwaNo ratings yet

- Lecture1-HSE Movement 2Document30 pagesLecture1-HSE Movement 2izzdanialNo ratings yet

- Lecture Notes - Occupational Safety and HealthDocument7 pagesLecture Notes - Occupational Safety and HealthmichsantosNo ratings yet

- OSH and IndustryDocument7 pagesOSH and IndustryfairusNo ratings yet

- Employee Health and SafetyDocument4 pagesEmployee Health and Safetypooji25No ratings yet

- Occupational Safety and Health Act 5.1 What Is Occupational Safety and Health Act?Document7 pagesOccupational Safety and Health Act 5.1 What Is Occupational Safety and Health Act?Addyana YadiyNo ratings yet

- Health and Safety Dissertation1Document34 pagesHealth and Safety Dissertation1Arjuna Cuttaree100% (3)

- ISCSM 2018 VlachosTh. PDFDocument10 pagesISCSM 2018 VlachosTh. PDFKay MuzeeNo ratings yet

- Ahmad Aminuddin Bin Ahmad JamjuriDocument5 pagesAhmad Aminuddin Bin Ahmad JamjuriAhmad Aminuddin Ahmad JamjuriNo ratings yet

- Job Safety and HealthDocument10 pagesJob Safety and HealthKomal ShujaatNo ratings yet

- Suresh Nava Rat Nam InterviewDocument8 pagesSuresh Nava Rat Nam InterviewLOHAS87No ratings yet

- DOSH Master PlanDocument6 pagesDOSH Master PlanJafar Sedek OmbitNo ratings yet

- Occupational HealthDocument4 pagesOccupational Healthintan1234No ratings yet

- Occupational Safety and Health Management Among Five ASEAN Countries: Thailand, Indonesia, Malaysia, Philippines, and SingaporeDocument6 pagesOccupational Safety and Health Management Among Five ASEAN Countries: Thailand, Indonesia, Malaysia, Philippines, and SingaporeRalph Segundo SalvadorNo ratings yet

- OSH ProgrammingDocument21 pagesOSH ProgrammingMichael JayNo ratings yet

- 11186-Article Text-36526-1-10-20201023Document5 pages11186-Article Text-36526-1-10-20201023Clarissa AnastasiaNo ratings yet

- Chapter 2 - OSHA 1994 NoteDocument14 pagesChapter 2 - OSHA 1994 NoteFx Niubie75% (4)

- IOSH Article For ISO 45001Document9 pagesIOSH Article For ISO 45001Offn Mio100% (1)

- 6 LPPM - Ums - Ac - IdDocument19 pages6 LPPM - Ums - Ac - IdTiara Ayu DwilistyaningsariNo ratings yet

- Level of Awareness On Behaviour-Based Safety (BBS)Document12 pagesLevel of Awareness On Behaviour-Based Safety (BBS)Sakinah Mhd ShukreeNo ratings yet

- Ir HJ Rosli Hussin - Niosh MalaysiaDocument28 pagesIr HJ Rosli Hussin - Niosh MalaysiaakubestlahNo ratings yet

- Central Labour InstituteDocument15 pagesCentral Labour InstituteSmita KNo ratings yet

- Occupational Safety and Health Act (OSHA) 1994Document69 pagesOccupational Safety and Health Act (OSHA) 1994WAN HAZIMNo ratings yet

- Lecture1 HSE MovementDocument29 pagesLecture1 HSE MovementBhalvindrakumar MaranNo ratings yet

- Implementing OSHA in The Construction Industry - A ReviewDocument24 pagesImplementing OSHA in The Construction Industry - A Reviewz969862100% (4)

- Bab IDocument5 pagesBab ILisda MawaddahNo ratings yet

- Topic 1 DUW1012 - Intro To OSH LegislationDocument22 pagesTopic 1 DUW1012 - Intro To OSH LegislationNazrina RinaNo ratings yet

- Systematic Approach to Training for Nuclear Facility Personnel: Processes, Methodology and PracticesFrom EverandSystematic Approach to Training for Nuclear Facility Personnel: Processes, Methodology and PracticesNo ratings yet

- Development of Seismic Vulnerability Assessment Methodologies Over The Past 30 YearsDocument6 pagesDevelopment of Seismic Vulnerability Assessment Methodologies Over The Past 30 YearsrashidkingNo ratings yet

- Karachi To Kotri - The First Railways in PakistanDocument14 pagesKarachi To Kotri - The First Railways in PakistanrashidkingNo ratings yet

- Tructural Ealth Onitoring: M. Mayur S.I.E.T.K PutturDocument37 pagesTructural Ealth Onitoring: M. Mayur S.I.E.T.K PutturrashidkingNo ratings yet

- Brrda: FCGKJ Xzkeh.K Ifk Fodkl, TsalhDocument2 pagesBrrda: FCGKJ Xzkeh.K Ifk Fodkl, TsalhrashidkingNo ratings yet

- SHSCP 11 ArchDocument1 pageSHSCP 11 ArchrashidkingNo ratings yet

- FlashDocument1 pageFlashrashidkingNo ratings yet

- First General StatutesDocument6 pagesFirst General StatutesrashidkingNo ratings yet

- Karachi Water & Sewerage Board: Office of The Purification PlantDocument6 pagesKarachi Water & Sewerage Board: Office of The Purification PlantrashidkingNo ratings yet

- Environment and Urbanization 2003 Ahmed 33 42Document10 pagesEnvironment and Urbanization 2003 Ahmed 33 42rashidkingNo ratings yet

- 2008 Earthquake ConferenceDocument1 page2008 Earthquake ConferencerashidkingNo ratings yet

- 1.3153330 HAZUS Second ImportantDocument12 pages1.3153330 HAZUS Second ImportantrashidkingNo ratings yet

- DPR Historic Structure Assessment FormDocument6 pagesDPR Historic Structure Assessment FormrashidkingNo ratings yet

- PaganiEtAl 2014 OpenQuake EngineDocument11 pagesPaganiEtAl 2014 OpenQuake EnginerashidkingNo ratings yet

- Seismic Vulnerability Functional Method For Rapid Visual Screening of Existing BuildingsDocument15 pagesSeismic Vulnerability Functional Method For Rapid Visual Screening of Existing BuildingsrashidkingNo ratings yet

- Addresses 1Document5 pagesAddresses 1rashidkingNo ratings yet

- 2006 Roussillon Etal CrossDocument10 pages2006 Roussillon Etal CrossrashidkingNo ratings yet

- State of Manuscripts in PakistanDocument9 pagesState of Manuscripts in PakistanZain Ul HussainNo ratings yet

- Babcock University Bookshop An Babcock University BookshopDocument11 pagesBabcock University Bookshop An Babcock University BookshopAdeniyi M. AdelekeNo ratings yet

- Faculty of Engineering Technology: Lesson PlanDocument6 pagesFaculty of Engineering Technology: Lesson PlanAdam KNo ratings yet

- Ess Ia Criteria 1Document7 pagesEss Ia Criteria 1leoNo ratings yet

- School-Based Telemedicine For AsthmaDocument9 pagesSchool-Based Telemedicine For AsthmaJesslynBernadetteNo ratings yet

- Assignment 2Document2 pagesAssignment 2CJ IsmilNo ratings yet

- Jinyu Wei Lesson Plan 2Document13 pagesJinyu Wei Lesson Plan 2api-713491982No ratings yet

- Feedback Control System SyllabusDocument3 pagesFeedback Control System SyllabusDamanMakhijaNo ratings yet

- Module 5 Curriculum ImplementationDocument38 pagesModule 5 Curriculum ImplementationRen Ren100% (5)

- Group Dynamics and Teamwork: Ian GrigorDocument15 pagesGroup Dynamics and Teamwork: Ian GrigorKhabir IslamNo ratings yet

- Hameroff - Toward A Science of Consciousness II PDFDocument693 pagesHameroff - Toward A Science of Consciousness II PDFtempullybone100% (1)

- What Is A Spiral Curriculum?: R.M. Harden & N. StamperDocument3 pagesWhat Is A Spiral Curriculum?: R.M. Harden & N. StamperShaheed Dental2No ratings yet

- Debate, SpeechDocument2 pagesDebate, SpeechelizabethNo ratings yet

- Suchita Srivastava & Anr Vs Chandigarh Administration On 28 August 2009Document11 pagesSuchita Srivastava & Anr Vs Chandigarh Administration On 28 August 2009Disability Rights AllianceNo ratings yet

- Main Ideas in Paragraphs (Getting The Big Ideas) : Professor Karin S. AlderferDocument52 pagesMain Ideas in Paragraphs (Getting The Big Ideas) : Professor Karin S. AlderferEnglish HudNo ratings yet

- Didactic Unit Simple Present Tense ReviewDocument3 pagesDidactic Unit Simple Present Tense ReviewEmersdavidNo ratings yet

- Evidence Law Reading ListDocument9 pagesEvidence Law Reading ListaronyuNo ratings yet

- A Proposed Program To Prevent Violence Against Women (Vaw) in Selected Barangays of Batangas CityDocument16 pagesA Proposed Program To Prevent Violence Against Women (Vaw) in Selected Barangays of Batangas CityMarimarjnhioNo ratings yet

- Learning and Cognition EssayDocument6 pagesLearning and Cognition Essayapi-427349170No ratings yet

- Final Superintendent Recommendation 2023Document30 pagesFinal Superintendent Recommendation 2023ABC Action NewsNo ratings yet

- Makalah Bahasa InggrisDocument2 pagesMakalah Bahasa InggrisDinie AliefyantiNo ratings yet

- Devendra Bhaskar House No.180 Block-A Green Park Colony Near ABES College Chipiyana VillageDocument3 pagesDevendra Bhaskar House No.180 Block-A Green Park Colony Near ABES College Chipiyana VillageSimran TrivediNo ratings yet

- Test Manual: English ComprehensionDocument9 pagesTest Manual: English ComprehensionAnonymous EU0KgOEPNo ratings yet

- MQ 63392Document130 pagesMQ 63392neeraj goyalNo ratings yet

- Matalino St. DM, Government Center, Maimpis City of San Fernando (P)Document8 pagesMatalino St. DM, Government Center, Maimpis City of San Fernando (P)Kim Sang AhNo ratings yet

- Cmd. 00427992039203 Cmd. 00427992039203 Cmd. 00427992039203 Cmd. 00427992039203Document1 pageCmd. 00427992039203 Cmd. 00427992039203 Cmd. 00427992039203 Cmd. 00427992039203Younas BalochNo ratings yet

- Health TipsDocument23 pagesHealth TipsKhalil ShaikNo ratings yet