Professional Documents

Culture Documents

Opportunities For Six Sigma in Bangladeshi Industries

Uploaded by

Raihan KabirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Opportunities For Six Sigma in Bangladeshi Industries

Uploaded by

Raihan KabirCopyright:

Available Formats

International Conference on Mechanical, Industrial and Energy Engineering 2010

23-24 December, 2010, Khulna, BANGLADESH

MIE10-002

Opportunities for Six Sigma in Bangladeshi Industries

1, 2, 3

Kazi Arif-Uz-Zaman1, Md. Rezaul Hasan Shumon2, Md. Abdul Quddus3 Department of Industrial Engineering and Management, Khulna University of Engineering & Technology, Khulna-9203, BANGLADESH

ABSTRACT The purpose of the paper is to illustrate the process about the implementation of Six Sigma at Bangladesh Cable Shilpa Ltd.Khulna (BCSL). Major fundamental streams had been introduced to outline the concept of Six Sigma for Bangladeshi industries perspective, relating the methodologies for the project and finally finding out the sigma level of BCSL, Khulna. Practicing Six Sigma could enable the company to eliminate a wide range of long standing process variation problem. This research had been undertaken to highlight the importance of a structured process and the importance data collection. Originality, it could drawn attention to the managers of how Six Sigma can be used to enhance existing improvement efforts, and could use specific example to show how the approach can be used to tackle long standing, and often hidden, quality issues. Keywords: Quality tool, Six Sigma, DPMO (Defect per million Opportunities), Belt System. 1. Introduction Six Sigma is a business process improvement strategy which essentially checks what a business is doing, what its customers want, most effective process and what variation could be removed from that process to provide significantly improved consistency. Motorola pioneered the concept of six sigma program in the 1980s.Since then many other companies have developed their own six-sigma programs, including General Electric, Texas Instruments, Eastman Kodak, and Allied signal. From the beginning, a general definitions has been developed, which is a useful quality tool. It could equally applicable to any process in any business sector-from banking to construction and much, much more. Literally speaking, the 18th letter in the Greek alphabet, Sigma, is the symbol for standard deviation. It is a measure of variance. Six is the number of sigma measured in a process, when the variation around the target is such that only 3.4 outputs out of one million are defects under the assumption that the process average may drift over the long term by as much as 1.5 standard deviations [1]. Six Sigma is a highly disciplined approach to decision making that helps people focus on improving process to make them as near perfect close to zero defects as possible [2]. The Fig.1 shows that the mean is at the centre and as the variations increase, the width of the curve increases. The essence of Sigma is to reduce variations. 2. Significance of the research Six Sigma has become very popular throughout the whole world. There are several reasons for this popularity. First, it is regarded as a fresh quality management strategy which can replace TQC, TQM and others. Many companies, which were not quit successful in implementing previous management strategies such as TQC and TQM, are eager to introduce Six Sigma. It is viewed as a systematic, scientific, statistical and smarter (4s) approach for management innovation which is quit suitable for use in a knowledge-based information society. The essence of Six Sigma is the integration of four elements (customer, process, manpower and strategy) to provide management innovation [3]. Six Sigma provides a scientific and statistical basis for quality assessment for all processes through measurement of quality levels. The six sigma methods allow us to draw comparisons among all processes, and tell how good a process is. Through this information, top-level management learns what path to follow to achieve process innovation and customer satisfaction. Second, six sigma provides efficient man power cultivation and utilization. It employs a belt system in which the levels of mastery are classified as green belt, black belt, master black belt and champion [2]. As a person in a company obtains certain training, he acquires a belt. Usually, a black belt is the leader of a projecting and several green belts work together for the project team. Motorola, GE, Allied Signal, IBM, DEC, Texas Instruments, Sony, Kodak, Nokia, Philips Electronics, LG, Samsung, Hyundai groups etc. But Bangladeshi industries are lack behind because of not implementing yet six sigma programs [4]. So it is necessary to implement six sigma programs immediately to cope with others world-class industries. Lastly, six sigma provides flexibility in the new millennium of 3Cs, which are: Changes: Changing society

Fig.1 Variation of six sigma level * Corresponding author. Tel.: +88-01711385906 E-mail address: zaman735@yahoo.com

International Conference on Mechanical, Industrial and Energy Engineering 2010

23-24 December, 2010, Khulna, BANGLADESH

Customer: Power is shifted to customer and customer demand is high Competition: Competition in quality and productivity. The pace of change during the last decades has been unprecedented, and the speed of change in this new millennium is perhaps faster than ever before. Most notably, the power has shifted from producer to customer. The producer-oriented industrial society is over, and the customer-oriented information society has arrived. The customer has all the rights to order select and buy goods and services. Specially, in e-business, the customer has all-mighty power. Competition in quality and productivity has been ever increasing. Second-rate quality goods cannot survive anymore in the market. Six sigma with its 4S (systematic, scientific, statistical and smarter) approaches provides flexibility in managing a business unit. Six sigma improvement projects typically has one or more objectives such as reducing defects, reducing cost, reducing product and / or process variability, reducing delivery time, increasing productivity, or improving customer satisfaction. 3. Methodology At first a clear concept has gained about six sigma by studying different sources such as quality related books, journal and web site. BCSL (Bangladesh Cable Shilpa Limited), Khulna had been sorted out for the implementation among other competitive companies since the company already had their own standard quality procedure but had the potentiality for further improvements. The company is situated on the bank of the river Bhairab in Shiromoni Industrial area about 15 kilometers north from Khulna city. With direct collaboration from the Production Planning & Quality Control Department, we had identified the steps of project and implementation procedures. Initially eight quality parameters had identified in the targeted factory. The quality department had been working with two types of characteristics which are physical and electrical. All the properties had studied before and after extrusion to provide defect rate of experimented eight specifications of the wire. In terms of length, the defect lengths had been cumulated to calculate the defect per million opportunities (DPMO). This research had advanced by using a calculator to analyze the sigma level where DPMO had been utilized along with total defects and production. 4. Data Analysis Implementing Six- Sigma and its application in Bangladesh Cable Shilpa Ltd. (BCSL) and analysis their quality parameter, the quality department and the relevant personnel had been asked some parameters and criteria as, their existing quality procedures, process and culture to achieve the desired quality level, satisfy on quality level, their quality criteria, existing quality check points and Sigma level and finally problems to achieve better quality.

4.1 Quality parameters Quality had been checked and inspected in 8 criteria in 8 steps by the company as: Diameter (before insulation) Elongation Conductor loop resistance Insulation resistance Mutual capacitance Capacitance unbalance Other (time loss, water tightness, etc) 4.2 Physical Characteristics Bangladesh Cable Shilpa Ltd. (BCSL) usually produces four types of wire according to the customer requirements. The physical characteristic of the wire had been given in Table 1. Table 1 Specification for Different Types of Conductor Wire Nominal Minimum Maximum Elongation Type conductor conductor conductor diameter diameter diameter (mm) (mm) (mm) % 01 02 03 04 0.4 0.5 0.6 0.9 0.4 0.5 0.6 0.9 0.408 0.508 0.608 0.909 25-31 25-31 25-31 30-40

4.3 Electrical characteristics Five basic electrical characteristics ( given in Table 2) had been strictly maintained by BCSL company to meet quality product which were Loop resistance, mutual capacitance, capacitance unbalance and high voltage for in process products like Quad and 10 pairs sub unit had been done as well as for semi finished and finished products. When any one of these specification limit had not been met, then preventive measure had been taken and unbalance portion had then cut off. 4.4 Wire specification (after extrusion) Cores had filled with compound (petroleum jelly) and wrapped into non hygroscopic tapes and laminated sheath with aluminum tape and had been jacked by black polyethylene. Conductor diameter had calculated as 0.4, 0.5, 0.6, 0.9 mm as well as insulated wire diameter had measured by digital micrometer. Tolerance of conductor was 0.004 mm and 0.03mm respectively. Elongation of conductor and insulation had been measured and stated in Table 3. 4.5 Defect magnitude Defective quantity in 8 specified quality check posts had been recorded and tabulated to identify the sigma and quality level with the help of the defect per million opportunities and Six-Sigma calculator. The magnitude had been recorded for the deviation in specified conformities supplied by the customer in physical properties (diameter, elongation) and electrical MIE10-002- 4

International Conference on Mechanical, Industrial and Energy Engineering 2010

23-24 December, 2010, Khulna, BANGLADESH

properties (loop and insulation resistance, Mutual capacitance, Capacitance unbalance, Dielectric strength) and others which had tabulated in table 4. Conductor Diameter Table 2 Specification of Electrical Characteristic parameters Dielectric Strength Capacitance Mutual Insulation Conductor Unbalance Capacitance Resistance Loop Between Between Resistance (max.av) (max) (min) (max) Conductor Conductor & Screen /km 295.0 187.0 130.0 56.6 M.km 5000 5000 5000 5000 nF / km 55 55 55 55 pF/km 500 500 500 500 0.5 KV AC 1.5KV AC 0.5 KV AC 1.5KV AC 0.5 KV AC 1.5KV AC 0.5 KV AC 1.5KV AC

Wire Type

01 02 03 04

(mm) 0.4 0.5 0.6 0.9

SL No. 1 2 3 4 5 6 7 8 9 10

Wire type 0.4/0.72 0.4/0.82 0.5/0.9 0.5/1.02 0.6/1.1 0.6/1.22 0.8/1.63 0.9/1.75 0.9/1.65 0.9/1.60

Table 3 Insulated wire specification after extrusion Insulation Conduction Insulated wire Wall Material Diameter Diameter Thickness mm mm mm Foam-skin 0.396-0.402 0.71-0.18 0.14-0.18 Solid PE Foam-skin Solid PE Foam-skin Solid PE Solid PE Solid PE Foam-skin Foam-skin 0.396-0.402 0.494-0.502 0.494-0.502 0.594-0.602 0.594-0.602 0.794-0.802 0.896-0.903 0.894-0.903 0.894-0.903 0.81-.83 0.89-0.93 1.00-1.13 1.09-1.13 1.20-1.24 1.61-1.66 1.72-1.76 1.63-1.66 1.58-1.62 0.19-0.23 0.19-0.23 0.24-0.28 0.24-0.28 0.29-0.33 0.39-0.43 0.41-0.46 0.33-0.38 0.31-0.36

Conduction Elongation % 18-25 18-25 20-28 20-28 20-28 22-31 22-31 22-31 22-31 22-31

Date/ Nove mber/ 2009 13 14 15 16 17 Total

Target

Dia met er mm 95 83 100 78 85 441

Elo nga tion mm 45 59 54 86 29 273

Table 4 Defective quantity/day on September, 2009 Capacitance Insulation Mutual Loop resistance resistance capacitance unbalance /km 30 68 53 28 27 206 M.km 21 27 18 26 24 116 nF / km 15 26 25 35 29 130 pF / km 26 6 11 16 13 72

Dielectric strength KV AC 8 4 8 14 10 44

Othe r

total

4000 4000 4000 4000 4000 20000

290 310 210 240 230 1280

530 583 479 523 447 2562

MIE10-002- 4

International Conference on Mechanical, Industrial and Energy Engineering 2010

23-24 December, 2010, Khulna, BANGLADESH

Photo 1 Six sigma calculator 5. Result and findings From BCSL five consecutive days production target quantity of wire and defective length for eight quality parameter had been tabulated. 5.1 Defect per million opportunities After finding total defective length, DPMO was calculated from the following equation: Production capacity = 4000 ckm/day Defect = 2562 ckm Opportunities = 20000 ckm Defect Opportunities = 8 No. of defect *1000000 DPMO= (No of defect opportunities / unit) * (Number of units) = 16012.5 5.2 Six sigma calculator For finding Sigma level of BCSL. Khulna we have introduced a software name as six sigma calculator which is given in photo 1 [5]. 5.2.1 Six sigma table Table 5 Sigma level/ DPMO Sigma level DPMO 1 690000 2 308537 3 66807 4 6210 5 233 6 3.4 5.2.2 Sigma level Sigma level is a sign of quality level of the industry .Sigma level of the industry is 3.6 6. Limitation and future recommendation One week defect rates had been recorded and calculated to determine the sigma level of the company wherever more than one month data could be more reliable and effective. Most of the companies of Bangladesh are not achieving their expected sigma level for lack of proper management, electricity, skill labor. Now a days electricity problem is a vital issue. The company was counting 500 kilo cable per hour loss due to the electricity problem. It could be minimized for total

* Corresponding author. Tel.: +88-01711385906 E-mail address: zaman735@yahoo.com

International Conference on Mechanical, Industrial and Energy Engineering 2010

23-24 December, 2010, Khulna, BANGLADESH

expense reduction and increase the per hour production to increase the overall quality and sigma level. Although Six Sigma originated in manufacturing industry, it has been successfully adopted by many other public or private sectors, from financial services to health care delivery and management, from information technology to knowledge management. The successful implementation over twenty years supports the hypothesis that basic thinking and methods that are used in Six Sigma have lasting values, even though they will be marketed by new names in the future[7, 8]. These ideas can be integrated with other productivity improvement methods, for example the recent focus on Lean Six Sigma. These methods will continue to show their endurance in the global business environment. 7. Conclusion Bangladesh is lack behind in quality sector as well as applying the quality tool like six sigma, TQM, KAIZEN, 5s etc. This paper had identified the current sigma level and quality position compare to the standard. It could not be possible to compare with other industries in developed countries like Japan, Korea, USA, UK, but this sigma level could be very effective and efficient for the developing country as well since the increased quality and procedure could enhance the productivity and efficiency as well as customer satisfactions which would lead us to more competitive market and greater revenue. The primary reason for the success of Six Sigma is that it provides a systematic approach for quality and process improvement, and it is not just a collection of tools. During most quality training in academia, industry and government, students and professionals usually are taught a number of individual tools such as DOE, SPC, FMECA, FTA, QFD, etc., and leave the course without a mental big picture about how all these tools fit together[9]. While implementing project by project, Six Sigma provides an overall process of improvement that clearly shows how to link and sequence individual tools.

Six Sigma and Competitive Advantage, 1(2), 2005. [8] Kapur, K.C., Feng, Q., Statistical Methods for Product and Process Improvement, a chapter in Springer Handbook of Engineering Statistics, Pham, Hoang (Ed.), Springer, London, 2006. [9] Yang, K. and El-Haik, B., Design for Six Sigma: A Roadmap for Product Development, McGraw-Hill, New York, 2003.

REFERENCES [1] Sung H. Park, Six Sigma for Quality and Productivity promotion. [2] Stevenson J. William, Operations management, 8th edition, ISBN 0-07-286905-4. [3] Montgomery C. Douglas, Introduction to Statistical Quality Control, 4th edition, ISBN 9974-51-351-X. [4] Thomas Pyzdek,, The Six Sigma Project Planner. [5] http://home.xtra.co.nz/hosts/smtconz/Quality/Simp le%20Six%20Sigma%20Calculator.xls .

[6] Engineer Sirajul Islam, B.Sc. Engr. (EE) FIEB, Manager (production), Production Planning & Quality Control Department

[7] Kapur, K.C., Feng, Q., Integrated Optimization Models and Strategies for the Improvement of the Six Sigma Process. International Journal of MIE10-002- 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Industrial Engineering Techniques and ApplicationsDocument6 pagesIndustrial Engineering Techniques and ApplicationsRaihan KabirNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Reduction Process of Weight For Folding Stroller Bygoal Driven OptimizationDocument6 pagesReduction Process of Weight For Folding Stroller Bygoal Driven OptimizationRaihan KabirNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Fouling of HVAC Fin and Tube Heat ExchangersDocument9 pagesFouling of HVAC Fin and Tube Heat ExchangersRaihan KabirNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Experiment of Briquetting MachineDocument4 pagesExperiment of Briquetting MachineRaihan KabirNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Facing OperationsDocument8 pagesFacing OperationsRaihan KabirNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Little ScienceDocument39 pagesLittle ScienceRaihan KabirNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Ideal Candidate Profile WorksheetDocument4 pagesIdeal Candidate Profile WorksheetDavid LeNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Caterpillar Tractor Co. FinalDocument11 pagesCaterpillar Tractor Co. FinalSanket Kadam PatilNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Group 2 - SPL Final PaperDocument28 pagesGroup 2 - SPL Final PaperJane GaliciaNo ratings yet

- Computer Reseller News April 09Document44 pagesComputer Reseller News April 09CRN South AfricaNo ratings yet

- 1625426853empresas Que Emitiram Vistos de Trabalho Na Irlanda - Jul 2021Document76 pages1625426853empresas Que Emitiram Vistos de Trabalho Na Irlanda - Jul 2021Marina Fenato Mariani XuNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Economics 102 Orange Grove CaseDocument21 pagesEconomics 102 Orange Grove CaseairtonfelixNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pay rates for Miscellaneous Award 2010Document8 pagesPay rates for Miscellaneous Award 2010JoshNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- TOGAF and BIAN Service LandscapeDocument43 pagesTOGAF and BIAN Service Landscapehanan100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Ultimate Meeting Guide - How To Run A Meeting Like A ProDocument21 pagesThe Ultimate Meeting Guide - How To Run A Meeting Like A ProAca ChchNo ratings yet

- Pasuquin High School Business ProposalDocument1 pagePasuquin High School Business Proposaldan malapiraNo ratings yet

- Jedi Mind Tricks: How To Get $700,000 of Advertising For $10,000Document5 pagesJedi Mind Tricks: How To Get $700,000 of Advertising For $10,000dario_james_1No ratings yet

- Ebook Sap OmDocument39 pagesEbook Sap OmmarcosoliversilvaNo ratings yet

- Policy Surrender Form CANARA HSBC OBC LIFE INSURANCEDocument2 pagesPolicy Surrender Form CANARA HSBC OBC LIFE INSURANCEvikas71% (7)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fringe Benefits AnswersDocument5 pagesFringe Benefits AnswersJonnah Grace SimpalNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Aligning Training With StrategyDocument10 pagesAligning Training With Strategysalonid170% (1)

- Business Plan Report PDFDocument17 pagesBusiness Plan Report PDFNur Izzah AnisNo ratings yet

- Restaurant Social Media Marketing PlanDocument8 pagesRestaurant Social Media Marketing PlanFarah Al-ZabenNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Customs Unions and Free Trade AreasDocument6 pagesCustoms Unions and Free Trade AreasÖzer AksoyNo ratings yet

- SPMSDocument51 pagesSPMSChris HNo ratings yet

- Domino's Pizza SWOT AnalysisDocument17 pagesDomino's Pizza SWOT AnalysisNora FahsyaNo ratings yet

- Learning SolutionsDocument28 pagesLearning SolutionsSRAVANSUJA100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Lazy River Scalping StrategyDocument10 pagesLazy River Scalping StrategyPanayiotis Peppas0% (1)

- 01 Fairness Cream ResearchDocument13 pages01 Fairness Cream ResearchgirijNo ratings yet

- Llora Motors Vs DrilonDocument2 pagesLlora Motors Vs DrilonTedd JavarNo ratings yet

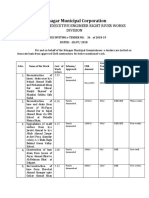

- Srinagar Municipal Corporation: Office of The Executive Engineer Right River Works DivisionDocument7 pagesSrinagar Municipal Corporation: Office of The Executive Engineer Right River Works DivisionBeigh Umair ZahoorNo ratings yet

- Food Safety Manager's ResumeDocument5 pagesFood Safety Manager's ResumeMarsit Med AmineNo ratings yet

- PwC Fact Sheet: Global Accounting Firm by the NumbersDocument1 pagePwC Fact Sheet: Global Accounting Firm by the NumbersZel tanuNo ratings yet

- Quiz 1-CfasDocument8 pagesQuiz 1-CfasRizelle ViloriaNo ratings yet

- Consumer Behavior in Relation To Insurance ProductsDocument52 pagesConsumer Behavior in Relation To Insurance Productsprarthna100% (1)

- Labor Standards Law Case ListDocument4 pagesLabor Standards Law Case ListRonel Jeervee MayoNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)