Professional Documents

Culture Documents

Lean FAQ

Uploaded by

nallasivam vCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lean FAQ

Uploaded by

nallasivam vCopyright:

Available Formats

What is Lean?

Lean production is aimed at the elimination of waste in every area of production including customer relations, product design, supplier networks and factory management. Its goals are to: use less inventory, less space, and less time become highly responsive to customer demand produce top quality products in the most efficient and economical manner possible. What is Lean Operations? Lean Operations in its purest form is the elimination of waste in a process. What is Business Lean Manufacturing Initiative? In todays competitive environment it has become more important than ever to continuously improve our operations and be as efficient as possible. his will allow !usiness to continue to grow and win new customers. One demonstrated way to improve our operations is through the application of Lean production techniques. he Lean "anufacturing Initiative will use Lean based tools, techniques and resources to improve !usinesss production and servicing processes. Why is it often called Lean Manufacturing? It was only by accident that Lean began in manufacturing and took than name. Its easier to trip over waste there than most anywhere else. How should be Lean implemented at business? Lean is an evolutionary process where process improvement and the sophistication of the tools applied increases over time. he following is a graphical depiction of this evolution:

T h eL e a nJ o u r n e y

%ool Sophistication

,ontrol the 'rocess

Single 'iece 3low Late 'oint ,onfiguration *anban 'ulse Stop the Line at !efects Moving Line 5'

&educe 0ariability

Set 1p %'M &eduction &eturnable ,ont4 'ull 'roduction %a)t %ime Level Load

2 pose the Waste

Supermar)et *itting

,ellular Layout Standard Wor)

. %ypes of Waste /ssessment Matri 0alue Stream Mapping 0isual (S . Ways Management

%ime + ,ultural Maturity

&I' Inventory WI' Inventory Span

Improvement-

How does Lean differ from Si Sigma? hough different, Lean and #i$ #igma are fully complimentary. #i$ #igma is based on the use of statistical tools to reduce product and process defects while Lean uses a set of management and problem solving tools to eliminate waste. !ecause Lean and #i$ #igma are fully compatible some lean tools will be incorporated in the #i$ #igma !ook of %nowledge for !! and "!! training. How !o "#Sigma $ Lean %ools &elate? Lean and #i$ #igma are complimentary but are not the same. he basic premise of #i$ #igma is to reduce or eliminate defects. he basic premise of Lean is to eliminate waste &defects being one type of waste'. he lean tools are less statistical than #i$ #igma tools and there are quite a few tools in the Lean tool set that are not in the #i$ #igma tool set and vice versa. (or e$ample, #i$ #igma does not describe value stream maps, quick changeover methodology, )#, *+, single piece flow, cellular layout, etc. Lean and si$ sigma tools working together should allow us to achieve even better results.

Si Sigma 'rofessionals %raining

What is advantage for Business having implemented Si Sigma?6 !usiness with fully implemented #i$ #igma is in a better position to implement Lean than most companies, because Lean builds on ,ork-Out and #i$ #igma. Lean uses the intelligence and e$perience of our employees . both hourly and salaried . to improve a process in the way ,ork-Out did when it was first implemented . when it was a /town meeting0 approach to finding the best idea. !ut lean cannot bring a process under statistical control like #i$ #igma can, and #i$ #igma alone cannot dramatically improve speed. If it ta)es the same number of people7 where8s the benefit? (aster cycle times, for one thing, and the increased sales that usually brings. Less inventory, for another, be it ,I+ material in a manufacturing location or unbilled labor hours in a repair facility. 1nd dont overlook the benefit in cycle efficiency itself. In the table above, if you are an average machine shop with 23 cycle efficiency &meaning the material spends 443 of the time at your shop waiting for someone to physically add value to it' there are tremendous advantages . and many opportunities . in cutting some of that waste. Lean sounds li)e another word for 9fewer people46 Is that true? 5sually not. 1t I++ it took more people, in fact, but the work was done much faster and with fewer total man-hours. One of the 6apanese Lean techniques is called mi7usumashi, which translates as /water spider.0 In the 6apanese 8ob shop environment the water spider is a senior machinist, sometimes working with an apprentice, who gathers all the tooling and information for a 8ob together with the materials and ensures that the other machinists have everything they need. Lean often entails a shift in who does what, using the same number of people. !ecause Lean develops a /rhythm,0 there are periods of time that people will be available for planned maintenance &Lean calls it %otal 'roductive Maintenance, or +"'. !ecause we consider Indirect Labor undesirable we need to ensure that +" is truly productive, and control it with #tandard Operations. If you find that Lean requires fewer people because your cycle time is so much better youd best put those people on preparing for e$tra volume because thats what youre going to get in this cycle-driven business. !o you really believe there8s that much waste? ,alk through your shop and count how many people are actually adding value to the part or assembly they are working on . how many are changing the physical state of the product to bring it closer to what the customer wants, like applying weld, making chips, wrapping insulation, spraying paint, etc. 9ow many people do you count moving material, looking for a tool or some information, setting up a machine tool or determining 8ob status:

What percentage of people in that snapshot view are actually adding value to the product? In the lingo of Lean, this is called your cycle efficiency. In most cases your snapshot will be comparable to the more accurate measurement . value-added time over total lead time. 9eres an eye-opening chart: 1pplication "achining (abrication 1ssembly ;ontinuous "anufacturing !usiness +rocesses . ransactional !usiness +rocesses . ;reative@;ognitive ypical ;ycle <fficiency 23 2>3 2)3 *>3 2>3 )3 ,orld-;lass ;ycle <fficiency =>3 =)3 *)3 ?>3 )>3 =)3

Si Sigma 'rofessionals %raining

/ction Wor) Out? What is that? 1ction ,ork Outs, or 1,Os are blue 8ean, get dirty days that both hourly and management personnel en8oy. #ome have a 6apanese #ensei &/teacher0' and some are done internally. In both of them several teams of hourly and salaried people focused on the Lean aspects that will best improve cycle efficiency at that location, focused on the ;enter "anagers goals. #mall shops who want to implement Lean prefer to have a small group meet bi-weekly to identify and address specific issues. It is often the same group as the Arassroots eam assembled for ;ulture ;hange. he methods are typically low tech and low buck . quite a change from my last 8ob where the digiti7ation team was always looking at how technology might solve the problem. Isn8t this 9:ust in %ime6 manufacturing? 6I is simply receiving a shipment of inventory 8ust as you are about to run out. It is little more than delaying your replenishment order. Lean, in contrast, is all about moving a product or repair through the shop faster. Where can I get more information about Lean? 1dditional information about lean can be found on this site. In addition, there is a list of recommended reading materials, which provide a good foundation for understanding lean principles, but Bou have to remember that Lean is real actionable work. Its the purest work on business process and it can give Bou only practical Lean 1ction ,ork Out. %OOLS How !o I !efine a Line or ,ell? It has to do with how equipment is arranged so people C materials interact in an efficient fashion. +rocess steps need to follow the +D analysis with no material queuing between process steps. he net effect is the lead time &cycle time' is shortened. his is why we create lines or cells. 9ere are the defining attributes of a line or cell: #ingle +iece (low 1% ime +roduction +ull +roduction #tandard ,ork #tandard ,I+ Why is a Model Line Important? #ince Lean is derived from the oyota production system, our businesses need to understand how the Lean tools apply to them. he most effective way to do this is to pick one place in a business and deploy as much of the Lean toolkit as possible. his gives you the ability to demonstrate the use of the tools so you are no longer talking theory. his pays off big-time when you begin translating the toolkit to other parts of your business.

What !oes %ranslation Mean? Once you build a model line, you have demonstrated how the lean concepts apply to your business. ,e can take those learnings and apply them to other parts of the business through translation. ,e are translating concept for instance, the way that E1#9 designed pull may not be the e$act way you do it. Bour solution should be tailored to your needs. his is how lean is designedF lean teaches the concepts. It is up to everyone in your area to work together to convert the concept to a solution that works for you C your customers.

How do I )now if I should do )itting or a ;#bin style material presentation? here is no definitive answer to this however, we do have factors to consider. Like most of the Lean tools, 1% ime will be our reference point. 9eres a good rule of thumb. If the kit accumulation time is more than =)3 of the , you may be spending too much time making the kit, and a = bin system might be the best solution for you.

Si Sigma 'rofessionals %raining

/t What 'ercent on the '< 'areto Should I ,utoff Ma)e#%o#3orecast $ do Ma)e#%o#Order? here is no definitive answer to this, but there are factors to consider. ?>@=> Dule, esting ime, Guality Issues C #upplier Lead imes for the low runners on the +G paretto. 1s you become more proficient with 9ei8unka you should migrate to producing as many of the models as possible to "ake- o(orecast. Who 'erforms %'M in My Shop? +" is performed by a professional group within your organi7ation, not the operators. Operators are responsible for ensuring quality standards C performing standard work.

Si Sigma 'rofessionals %raining

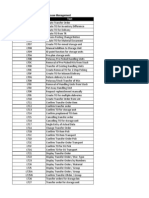

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SA 8000 Social Accounatbility Standard AwarenessDocument56 pagesSA 8000 Social Accounatbility Standard Awarenessnallasivam v100% (3)

- 21 Action Points For Good ExecutivesDocument1 page21 Action Points For Good Executivesnallasivam vNo ratings yet

- Hindi ISO 22000 Nutshell FSMS Food Sfaety Management Systems Standard NoteDocument14 pagesHindi ISO 22000 Nutshell FSMS Food Sfaety Management Systems Standard Notenallasivam vNo ratings yet

- Educational Nutshell - Tamil 1Document4 pagesEducational Nutshell - Tamil 1nallasivam vNo ratings yet

- Lean Self Assessment ToolDocument29 pagesLean Self Assessment Toolnallasivam v50% (2)

- ISO14001 Tamil NutshellDocument4 pagesISO14001 Tamil Nutshellnallasivam vNo ratings yet

- Iso 22000 Mandatory RecordsDocument1 pageIso 22000 Mandatory Recordsnallasivam v87% (15)

- SA 8000 Audit Check List VeeraDocument6 pagesSA 8000 Audit Check List Veeranallasivam v92% (12)

- ISO 9001:2000 IN A NUTSHELL (First Revision)Document5 pagesISO 9001:2000 IN A NUTSHELL (First Revision)nallasivam v100% (1)

- ISO9001 List of Mandatory RecordsDocument1 pageISO9001 List of Mandatory Recordsnallasivam vNo ratings yet

- STANDARD PRINCIPLES OF INFECTION CONTROL Staff LeafletDocument2 pagesSTANDARD PRINCIPLES OF INFECTION CONTROL Staff Leafletnallasivam vNo ratings yet

- Sa8000 NutshellDocument3 pagesSa8000 Nutshellnallasivam v100% (4)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SrsDocument92 pagesSrsStephen Ngigi KaranjaNo ratings yet

- Screening For Dollars: Craig Wallin September 3, 2014Document2 pagesScreening For Dollars: Craig Wallin September 3, 2014James ZacharyNo ratings yet

- Chapter 4 The Revenue Cycle SummaryDocument13 pagesChapter 4 The Revenue Cycle Summary0nionringsNo ratings yet

- MGMT 661 Final Team Assignments Final VersionDocument22 pagesMGMT 661 Final Team Assignments Final VersionAndrew RossNo ratings yet

- Instruction: You Have 3 Hours To Complete This Examination Including Accomplishing The Google Answer SheetDocument16 pagesInstruction: You Have 3 Hours To Complete This Examination Including Accomplishing The Google Answer SheetasdfghjNo ratings yet

- Levis Personal PairDocument6 pagesLevis Personal Pairarijit16No ratings yet

- Procter and GambleDocument29 pagesProcter and Gamblepanchitoperez2014No ratings yet

- Warehouse Management TransactionsDocument4 pagesWarehouse Management TransactionsstarimpactNo ratings yet

- DLP EIM Types of FormDocument5 pagesDLP EIM Types of FormJoel Magcamit CaoliNo ratings yet

- Name: Faizan Ullah Semester: 5 Program: MBA 3.5 (2017-21) Process Analysis Practice Problem Manufacturing of Bunk Beds SolutionDocument9 pagesName: Faizan Ullah Semester: 5 Program: MBA 3.5 (2017-21) Process Analysis Practice Problem Manufacturing of Bunk Beds SolutionFaizan Ullah67% (3)

- Financial Management at Beacon Pharmaceuticals LimitedDocument24 pagesFinancial Management at Beacon Pharmaceuticals LimitedFarhanUddinAhmedNo ratings yet

- Financial Accounting Mid Term ExamDocument4 pagesFinancial Accounting Mid Term ExamMamoonah HassanNo ratings yet

- MBA 1.5 OutlinesDocument19 pagesMBA 1.5 OutlinesMuhammad Zahid FaridNo ratings yet

- Working Capital ManagementDocument11 pagesWorking Capital ManagementNirav ShahNo ratings yet

- Marketing Management Unit3Document29 pagesMarketing Management Unit3Durdana NasserNo ratings yet

- Ikea Group 1Document27 pagesIkea Group 1euniceNo ratings yet

- Scarborough Eesbm8 tb01Document28 pagesScarborough Eesbm8 tb01Anosha jamshedNo ratings yet

- APICS, Greg P. Allgair, Al Bukey, Alan L. Milliken, Peter W. Murray - CSCP 2020 Module 2 Section A - Libgen - LiDocument395 pagesAPICS, Greg P. Allgair, Al Bukey, Alan L. Milliken, Peter W. Murray - CSCP 2020 Module 2 Section A - Libgen - LiPhùng Tuấn100% (2)

- Chap8 PDFDocument63 pagesChap8 PDFFathinus SyafrizalNo ratings yet

- Store Purchase RulesDocument90 pagesStore Purchase Ruleskashyap_873823904No ratings yet

- G12 Fabm2 Week 8Document11 pagesG12 Fabm2 Week 8Whyljyne GlasanayNo ratings yet

- OmDocument8 pagesOmRishabh ShekharNo ratings yet

- Ap Tip Preweek 2017Document58 pagesAp Tip Preweek 2017Jay-L Tan100% (1)

- Bill Ackman's Ira Sohn JCP PresentationDocument64 pagesBill Ackman's Ira Sohn JCP PresentationJohnCarney100% (1)

- RSC CafeteriaDocument19 pagesRSC Cafeteriaapi-436277602No ratings yet

- L5 DipBM - Assignment Briefs - September 2021Document24 pagesL5 DipBM - Assignment Briefs - September 2021Umar AliNo ratings yet

- Hype Cycle For Supply Chain Management 2010Document41 pagesHype Cycle For Supply Chain Management 2010spirit_abodeNo ratings yet

- BAb 6 Warren AKUNTANSI UNTUK PERUSAHAAN DAGANGDocument76 pagesBAb 6 Warren AKUNTANSI UNTUK PERUSAHAAN DAGANGbambangNo ratings yet

- Aggregate PlanningDocument57 pagesAggregate PlanningSanjeev RanjanNo ratings yet

- Chap 015Document43 pagesChap 015Ponkiya AnkitNo ratings yet