Professional Documents

Culture Documents

Heat Balance Template LM 53 3+3

Uploaded by

Sai Sricharan ReddyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Balance Template LM 53 3+3

Uploaded by

Sai Sricharan ReddyCopyright:

Available Formats

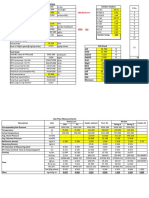

THERMAL BALANCE - Reference 0 degC

Material Flow Water Injection Flowrate Clinker Temperature Atmospheric Pressure 140 5.2 125 990 INPUTS T Enthalpy kcal/h (C) (kcal/Nm3/C) kcal/kg ck (kcal/kg/C) 125 0.205 3229 25.6 10 10 10 99 10 0.2 0.2 0.353 0.31 0.31 14 14 25 10689 179 2532 0 0.1 2.0 0.2 84.8 1.4 20.1 0.0 % t/h m3/h degC mbar OUTPUTS T (C) 92 Enthalpy kcal/h (kcal/Nm3) (kcal/kg) 0.31 11306 3720 kcal/kg ck 89.7 29.5 %

Clinker Feed Gypsum Feed Limestone Feed Water Injection Mill Inlet Air False Air Mill + Filter Absorbed Power Mill Table Heat From Pyro-Processing System (or HGG)

19% Mill Outlet Air 0% Water Vaporization 0% 0% Radiation & Convection Losses 64% Cement Product - Filter Airslide 1% TOTAL 15% 0% Difference =

65% 21%

0 87 0.195 2375 17401

0.0 18.9 138.1

0% 14% 100%

718 4.30%

TOTAL

16682

132.4

100%

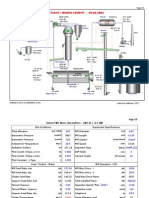

Gas Balance - Loesche Mill + Filter

Inputs Nm3/h Recirculation Water vapor coming from material Water vapor coming from water injection Fresh Air False Air TOTAL 332079 700 6500 16215 41624 397118 21 %O2 21 % 84 Total Air Flow (Recirculation + Stack) 0 Water Vapor (Cement Residual Moisture) 2 4 10 100 TOTAL Difference 396938 0% 100 Outputs Nm3/h 396418 520 %O2 %

21 100 0

Air Volume Mill Outlet Air Volume Filter Outlet Air Volume Downstream Draft Fan

m3/h 563019 590000 558875

Nm3/h 384526 396418 396418

TC 92 92 102

Air Volume Mill Inlet

489083

348294

99

Air Volume Recirculation Fresh Air TOTAL

332079 16215

102 10

Ecart =

Pressure (mbar) -65 -80 -3 (Nm3/h)*(C) 34481147

33872100 162150 34034250 1%

Data Ambiant Temperature Total Mill Feed Rate Gypsum Clinker Limestone

10 140 7 126 7

Measures to be performed at the mill outlet stack Dry Temperature 100.5 C Wet Temperature 54 C Condensation Temperature 50 C Pour le calcul des kg eau la chemine cf courbes ci-jointes Inputs % H20 Gypsum Clinker Fresh Air False Air Water Injection TOTAL 10 0 5C -70% Hr 5C - 70% Hr 16215 41624 Volume (Nm3) Kg Water 700 0 220 564 5200 6683 TOTAL Difference Ciment (humid. rsiduelle) Outputs

Air - Stack

Mass % H20 0.3

Volume (Nm3) Kg Water 420

8.5

63500

6693

7113 6%

Loesche Thermal Balance - Preparation & Measures

Date

Comments on mill operating conditions

Observations gnrales

Clinker + Gypsum Feed Rate

t/h

Ambiant Temperature (C) Atmospheric Pressure

10 760 mmHg

Material

Clinker Gypsum Cement Product - Airslide Water Rejects

Time

T C

125 5 85 5

% H20

Samples

Time Main Motor Draft Fan Separator

Speed (rpm) 22.4 950 120

Power (Kw) 3200 1650 300

Loesche Thermal Balance - Preparation & Measures

Thermal Balance - Loesche Mill - Preliminary Measures & Calculations

MESURES Stack Flow Rate Recirculation Flow Rate Total Air Flow Rate Fresh Air Flow Rate HGG Flow Rate (coming with recirculation) Clinker Feed Rate Gypsum Feed Rate Limestone Feed Rate Water Injection Flow Rate Cement Inherent Moisture Gypsum Moisture Limestone Moisture Fresh Air Mill Inlet Gas Temperature Clinker Temperature Gypsum Temperature Limestone Temperature Injected Water Temperature Ambiant Temperature Recirculation Air Temperature Air Temperature Downstream HGG Cement Temperature Downstream Filter (Airslide) Air Temperature at Stack Air Temperature Downstream Filter Mill Inlet Temperature (1) Mill Inlet Temperature (2) Separator Temperature Mill Inlet Pressure (1) Mill Inlet Pressure (2) Separator Pressure Mill Outlet Pressure (1) - (Inlet Filter) Filter Outlet Pressure (= Total Air Flow) Quantit de gaz injecte au brleur Capacit calorifique GAZ (Th/m3) Diamtre chemine Diamtre recirculation Diamtre air flow total 63500 332079 395579 16215 0 126 7 7 5.2 0.3 8 8 100 99 125 10 10 10 10 103 87 100.5 92 99 99 7 7 Nm3/h Nm3/h Nm3/h Nm3/h Nm3/h t/h t/h t/h t/h % % % % C C C C C C C C C C C C C C mbar mbar mbar mbar mbar CALCULS PRELIMINAIRES Valeurs arrondies Gas Flow Rate Entering Filter False Air Flow Rate Entering Filter Water Vapor Volume - Material Water Vapor Volume - Cement (Inherent Moisture) Water Vapor Injected Volume Gas Flow Rate After Draft Fan and Recirculation Gas Flow Rate Exiting Mill (without water vapor) Gas Flow Rate Coming to Mill Before Recirculation Clinker + Gypsum + Limestone on a dry basis Nm3/h Nm3/h 700.0 Nm3/h 519.8 Nm3/h 6500 Nm3/h Nm3/h Nm3/h Nm3/h 139 t/h Nm3/h Nm3/h Nm3/h Nm3/h Nm3/h Nm3/h Nm3/h t/h

Stack Air Recirculation Air Total Air Flow Air HGG (coming from recirculation) Injected Water External Air (Ambiant Air) Clinker (at 20C) Clinker (at 125C) Gypsum / Limestone Cement Final Product (Airslide)

Cpm (kcal/Nm3/C) Enthalpie (Kcal/Nm3) 0.31 0.31 0.31 0.34 0.353 0.31 0.18 0.205 0.2 0.195

80 0 8.904423 1,6 m 2,65 m 3,01 m

Measured Air Flowrate (after filter and before draft fan)

590000

m3/h

Air Volume

Air Flowrate Before Draft Fan Temperature Pressure False Air Filter False Air Mill Water Material (water from feed material) Warer Injection Hot Gases Mill Outlet Temperature Pressure Hot Gases Mill Inlet Temperature Pressure 590000 m3/h 92 3 7.5 0.2 5.2 563019 92 489083 C % % m3/h m3/h m3/h C m3/h 136 156 -80 mbars 164

-65 mbars 99 C -7 mbars

m3/s

396418 Nm3/h

11893 29731 250 6500 m3/s 384526

Nm3/h Nm3/h Nm3/h Nm3/h Nm3/h

m3/s

348294

Nm3/h

You might also like

- Heat & Mass BalanceDocument2 pagesHeat & Mass Balancesneha_21100% (1)

- Model lime kilns optimize performanceDocument40 pagesModel lime kilns optimize performancearv_devNo ratings yet

- Heat Calculation by SG.Document26 pagesHeat Calculation by SG.TIRIANTO0% (2)

- Mod 6Document49 pagesMod 6mkpq100% (1)

- Heat Output CalculationsDocument17 pagesHeat Output CalculationsgvrrNo ratings yet

- Vertical Raw Mill Heat Balance - SolutionDocument3 pagesVertical Raw Mill Heat Balance - SolutionSai Sricharan Reddy80% (5)

- 3500TPD Cement Plant Heat BalanceDocument2 pages3500TPD Cement Plant Heat BalanceIrshad HussainNo ratings yet

- Heat Balance of Kilns and Coolers and Related Topics PDFDocument62 pagesHeat Balance of Kilns and Coolers and Related Topics PDFAli HüthütNo ratings yet

- Kiln Heat Balance 1Document33 pagesKiln Heat Balance 1Vipan Kumar Dogra75% (4)

- Useful Equations For Kiln & CoolerDocument7 pagesUseful Equations For Kiln & CoolerAbul Qasim100% (2)

- Flame MomentumDocument1 pageFlame Momentumayaskant751001No ratings yet

- Cooler EfficiencyDocument58 pagesCooler Efficiencyayaskant75100150% (2)

- Precalciner Systems Cement IndustryDocument22 pagesPrecalciner Systems Cement IndustryfaheemqcNo ratings yet

- HOCM MAR Fez CoolerHeatBalanceDocument1 pageHOCM MAR Fez CoolerHeatBalanceOUSSAMA LAKHILI100% (2)

- Kiln EquationsDocument189 pagesKiln EquationsAnonymous NxpnI6jC100% (2)

- Kiln Ins Pection SheetDocument1 pageKiln Ins Pection SheetAbul Qasim QasimNo ratings yet

- Cooler Design and Operation CriteriaDocument19 pagesCooler Design and Operation Criteriatricky777100% (1)

- Grinding Media Pattern & Charge CalcDocument1 pageGrinding Media Pattern & Charge CalcJayaram SudhakarNo ratings yet

- Kiln Heat and Mass Balance September 2010Document20 pagesKiln Heat and Mass Balance September 2010samuel libsework50% (2)

- Fan Flow CalculationDocument1 pageFan Flow CalculationvvijaybhanNo ratings yet

- Raw Mill Nozzle Ring Area AnalysisDocument6 pagesRaw Mill Nozzle Ring Area AnalysisMohd Ali100% (7)

- Heat Balance of Kilns and Coolers and Related TopicsDocument62 pagesHeat Balance of Kilns and Coolers and Related TopicsAde Oktaviani Chaniago100% (2)

- 04 MillingDocument21 pages04 MillingMKPashaPasha100% (1)

- Ball Mill Control (Compatibility Mode)Document31 pagesBall Mill Control (Compatibility Mode)Nael100% (1)

- Cement Kiln Performance CalculationsDocument9 pagesCement Kiln Performance Calculationsvvijaybhan0% (2)

- Kiln Feed Mix CalculationsDocument2 pagesKiln Feed Mix CalculationsElwathig Bakhiet100% (3)

- Pheater Heat BalanceDocument2 pagesPheater Heat BalanceRaji SuriNo ratings yet

- Design Criteria For PH & PCDocument6 pagesDesign Criteria For PH & PCtricky777No ratings yet

- KilnDocument2 pagesKilnSSAC PVT.LTD.100% (1)

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- Cement Plant - Energy OptimisationDocument12 pagesCement Plant - Energy OptimisationSatya MakhijaNo ratings yet

- Raw Mill-Ball Mill Heat BalanceDocument16 pagesRaw Mill-Ball Mill Heat BalanceAbhishekNo ratings yet

- Mod 8-Application of Heat and Mass BalancesDocument218 pagesMod 8-Application of Heat and Mass BalancesTamer Fathy100% (3)

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocument1 pageRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan80% (5)

- By-Pass Calculation Method - DocbDocument2 pagesBy-Pass Calculation Method - DocbElwathig BakhietNo ratings yet

- RMH & GrindingDocument132 pagesRMH & Grindingmkpq100% (1)

- Optimisation of The Rotary KilnDocument34 pagesOptimisation of The Rotary KilnSampathkumar Mtech100% (3)

- Cement Kiln Dust CKD Methods For ReductioDocument21 pagesCement Kiln Dust CKD Methods For ReductiofaheemqcNo ratings yet

- MASS BALANCE SUMMARYDocument51 pagesMASS BALANCE SUMMARYirfan100% (1)

- Kiln System Mass and Energy BalanceDocument24 pagesKiln System Mass and Energy BalanceAnonymous Cxriyx9HIX100% (1)

- Cement Plant Fan Technology Training Course DetailsDocument71 pagesCement Plant Fan Technology Training Course Detailsbulentbulut100% (7)

- Najran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportDocument2 pagesNajran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportIrfan AhmedNo ratings yet

- Cement MillDocument28 pagesCement Millsaji kumar100% (2)

- Optimization of Vertical Raw Mill OperationDocument32 pagesOptimization of Vertical Raw Mill OperationNael93% (40)

- Conversion Factor For NOx and SOx CalculationsDocument2 pagesConversion Factor For NOx and SOx CalculationsvvijaybhanNo ratings yet

- By Pass Mass-BalanceDocument10 pagesBy Pass Mass-BalancejagrutNo ratings yet

- Kiln Audit H&M Balance Calculation 2012Document24 pagesKiln Audit H&M Balance Calculation 2012Anonymous 3ESYcrKP100% (7)

- Vertical Mill CalculationsDocument11 pagesVertical Mill CalculationsSai Sricharan Reddy84% (19)

- Material Residence Time in KilnDocument2 pagesMaterial Residence Time in KilnVijay Bhan100% (2)

- Rotary Kiln Brick CountDocument5 pagesRotary Kiln Brick CountThaigroup CementNo ratings yet

- Heat BalanceDocument33 pagesHeat BalanceIrshad Hussain100% (2)

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesDocument3 pagesRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliNo ratings yet

- FD Fan Efficiency CalculationDocument6 pagesFD Fan Efficiency CalculationPraveen VaratharajanNo ratings yet

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Hot AirDocument6 pagesHot AirElancheran RengaNo ratings yet

- Model Calculation NKarthickDocument24 pagesModel Calculation NKarthickSeenu Hassan100% (2)

- Tips On Kiln OperationDocument10 pagesTips On Kiln OperationElwathig Bakhiet100% (2)

- Bestway Cement Limited heat balance and WHR analysisDocument4 pagesBestway Cement Limited heat balance and WHR analysisKiran Veerubhotla100% (1)

- 20V4000L32 - 93800050099 - en - GB - MZ80 - 2Document2 pages20V4000L32 - 93800050099 - en - GB - MZ80 - 2hadi0% (2)

- Grate Cooler Thermal AnalysisDocument14 pagesGrate Cooler Thermal Analysisaman131No ratings yet

- 41 Vertical Mills - V2-0Document56 pages41 Vertical Mills - V2-0Sai Sricharan Reddy86% (14)

- Sweden ReportDocument0 pagesSweden ReportSai Sricharan ReddyNo ratings yet

- Optimize Vertical Roller Mills OperationsDocument4 pagesOptimize Vertical Roller Mills OperationsSai Sricharan Reddy83% (6)

- Vertical Mill CalculationsDocument11 pagesVertical Mill CalculationsSai Sricharan Reddy84% (19)

- Comparison of cement grinding technologiesDocument28 pagesComparison of cement grinding technologiesSai Sricharan Reddy100% (3)

- Ultratech Kotputli CementDocument44 pagesUltratech Kotputli CementSai Sricharan ReddyNo ratings yet

- Vertical Raw Mill Heat Balance - SolutionDocument3 pagesVertical Raw Mill Heat Balance - SolutionSai Sricharan Reddy80% (5)

- Cement Vertical Mill Vs Ball MillDocument17 pagesCement Vertical Mill Vs Ball Millanrulo50% (2)

- Bits Ps-II Eos FDBK I Sem 2012-13Document1 pageBits Ps-II Eos FDBK I Sem 2012-13Sai Sricharan ReddyNo ratings yet

- Brochure Furnace Slag enDocument24 pagesBrochure Furnace Slag enSai Sricharan ReddyNo ratings yet

- Vertical raw mill operation and designDocument88 pagesVertical raw mill operation and designSai Sricharan Reddy50% (2)

- 2 200901loeschetadipatri 120803014722 Phpapp01Document4 pages2 200901loeschetadipatri 120803014722 Phpapp01Sai Sricharan ReddyNo ratings yet

- TIRODA THERMAL DESIGN REPORTDocument38 pagesTIRODA THERMAL DESIGN REPORTmithun46100% (2)

- ABS RulesDocument172 pagesABS RulesKrionikaNo ratings yet

- Instrument Check List PDFDocument9 pagesInstrument Check List PDFBrijesh Srivastav100% (1)

- Scientific Notation CalculationsDocument32 pagesScientific Notation CalculationsMelanie Niña CullarNo ratings yet

- Railway ProjectDocument51 pagesRailway Projectsanojjose75No ratings yet

- Request A One Time Passcode: DBS Online Account GuidanceDocument3 pagesRequest A One Time Passcode: DBS Online Account GuidanceColly Boston-DuckNo ratings yet

- The Hydrocracker Explosion and Fire: MarchDocument21 pagesThe Hydrocracker Explosion and Fire: MarchMoca PhoenixNo ratings yet

- Anatomy and Disorders of the Oral CavityDocument24 pagesAnatomy and Disorders of the Oral CavityMuhammad SalmanNo ratings yet

- Stiffness Matrix MethodDocument102 pagesStiffness Matrix MethodAkash PaudelNo ratings yet

- Direct Electrical Arc Ignition of Hybrid Rocket MotorsDocument91 pagesDirect Electrical Arc Ignition of Hybrid Rocket MotorsHyan GontijoNo ratings yet

- Halo Carro PDFDocument5 pagesHalo Carro PDFRege PunkNo ratings yet

- Engine Masters - Winter 2015Document76 pagesEngine Masters - Winter 2015RichardNo ratings yet

- Ming-Yung Hsu: Voltnar Control Istribution SubstationsDocument7 pagesMing-Yung Hsu: Voltnar Control Istribution SubstationsAsja AvdićNo ratings yet

- Fossil Watch Instructions EN US PDFDocument23 pagesFossil Watch Instructions EN US PDFsuNo ratings yet

- Component Views: Veiw A-ADocument2 pagesComponent Views: Veiw A-Ajose quispeNo ratings yet

- OmsiPFT PC4-3000Document2 pagesOmsiPFT PC4-3000Rio de MarioNo ratings yet

- FMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiDocument9 pagesFMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiKevin JordanNo ratings yet

- A Current Carrying Coil Behave Like A MagnetDocument3 pagesA Current Carrying Coil Behave Like A MagnetAdlin SeedonNo ratings yet

- Manual QuickCODultra 07E4317 PDFDocument270 pagesManual QuickCODultra 07E4317 PDFpreciosariyazNo ratings yet

- Danfoss RT101Document7 pagesDanfoss RT101Thomas WilliamNo ratings yet

- Mathematics 5 Q1 W10Document31 pagesMathematics 5 Q1 W10Aices Jasmin Melgar BongaoNo ratings yet

- Chapter 1 MATLAB Basics 2015 An Introduction To MATLAB Programming and Numerical Methods For EngineersDocument13 pagesChapter 1 MATLAB Basics 2015 An Introduction To MATLAB Programming and Numerical Methods For EngineersSneeakyAsianNo ratings yet

- Polarity and Intermolecular ForcesDocument59 pagesPolarity and Intermolecular ForcesAntonio Louis LlarenaNo ratings yet

- 145 - Cafco MANDOLITE CP2 - Cellular BeamsDocument0 pages145 - Cafco MANDOLITE CP2 - Cellular Beamswidayat81No ratings yet

- The Standard Model of Particle PhysicsDocument95 pagesThe Standard Model of Particle PhysicsaliakouNo ratings yet

- Thyristors, Triacs, DiacsDocument5 pagesThyristors, Triacs, DiacsAnonymous n50GmJNo ratings yet

- CHP574 - NSD570 Teleprotection EquipmentDocument2 pagesCHP574 - NSD570 Teleprotection EquipmentMichael Parohinog GregasNo ratings yet

- Conditional SentencesDocument14 pagesConditional SentencesIvana StankovicNo ratings yet

- Global Payroll Peoplesoft 9.1Document1,420 pagesGlobal Payroll Peoplesoft 9.1alencarr7759No ratings yet

- Design of Circular Liquid or Gas PipesDocument6 pagesDesign of Circular Liquid or Gas PipessereutyNo ratings yet