Professional Documents

Culture Documents

NACA 4412 - Fluent

Uploaded by

Lei TuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NACA 4412 - Fluent

Uploaded by

Lei TuCopyright:

Available Formats

JOURNAL ARTICLES BY FLUENT SOFTWARE USERS JA065

Computer Simulation Helps Increase Life of Impeller in Alumina Hydrate Precipitation from 2 to 8 Years

By Ronald J. Weetman, Ph.D., Principal Research Engineer LIGHTNIN, A Unit of General Signal, Rochester, New York

Introduction

LIGHTNIN is one of the leading producers of mixers with over 1,000,000 units currently in the field. Among the variety of systems that are blended, alumina hydrate precipitation is one of the most difficult erosive mixing applications. In this case, a draft tube that separates the inside and outside of the tank is used to improve circulation. The tank is 10 meters in diameter and 30 meters tall. The single impeller is positioned at the top of the tank so a short drive shaft can be used. This eliminates the need for a bearing within the fluid that would cause maintenance problems. Fines are added to a supersaturated liquor to expedite crystal growth. The precipitative alumina particles are on the order of 100 microns in diameter, have a density of 2,500 kg /m 3 and are abrasive. The solids concentration is typically 20% to 40% by weight. The size of the tank means that a large impeller with a high tip speed needs to be used. A 3.2 meter high efficiency airfoil-type circular impeller with a detachable blade is mounted inside the draft tube. The impeller blades are constructed from an 8 mm thick top and bottom skin. The original blades had a NACA 4412 airfoil shape. The 4412 airfoil has 4% camber (meaning that the camber is 4% of the chord length or the width of the blade). These blades were failing due to erosion on the leading edge. The blades could be repaired and then lasted another two years before they were discarded. Field data showed the

JA065 Page 1 of 4

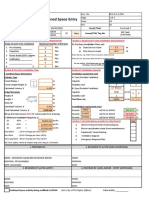

Fig 1. Velocity contours

Simulating the impeller and tank of a draft tube mixer using computational fluid dynamics (CFD) helped us extend the life of the impeller from two to eight years. The mixing process involved precipitation of alumina hydrate used in the production of aluminum. Experience has shown that the rate at which the impeller wears is a strong function of the velocity at the leading edge with an exponent between two and three. The computer simulation, using FLUENT CFD software from Fluent Inc., Lebanon, New Hampshire, made it possible for us to quickly evaluate the leading edge velocity of several proposed new designs. In addition, the analysis further helped us fix the problem by predicting the locations of wear patterns so that we could optimally place wear-resistant coatings at those sites.

www.cadfamily.com EMail:cadserv21@hotmail.com Copyright 1999 Fluent Inc. The document is for study only,if tort to your rights,please inform us,we will delete

rate of erosion of the original blade was proportional to the radius with an exponent of 2.8. Since the velocity of the slurry impinging on the blade is proportional to the radius, erosion is proportional to velocity to this same 2.8 exponent. This exponent is similar to that observed in other erosion phenomena.

Analysis of the Impeller

The first step we took was to analyze the existing blade using FLUENT to better understand the problem. Selecting the structure of the computational grid to use for the analysis of problems was critical. If care is not taken to provide a fine mesh in the areas of high velocity gradients and fine geometry detail, then the simulation will not give accurate results. In order to minimize numerical problems, it is also important to minimize the skewness of grids. Therefore, we used an "O" type grid that wraps around the airfoil and helps immensely in minimizing the skewness at the trailing edge. An axisymmetric model was created with 25,000 cells with appropriate refinement to capture the flow details near the airfoil surface.

leading edge, where the particles diverged. Some of the particles then wrap around the top surface at the leading edge in the very high velocity region. Some of these particles move away from the airfoil near the trailing edge. The analysis results show that the bottom surface at the leading edge receives high erosion from the impinging particles and the top surface or suction side receives high erosion from sliding erosion (figure 3). This information was very useful in selecting an alternative airfoil design in an effort to reduce erosion. Based on these results and engineering judgment, we selected a new airfoil as a proposed impeller design.

Fig 2. Accelerated abrasion tests with a model impeller show that reducing the leading-edge velocity cuts wear.

Validation of Modeling Results

Experimental data was available for the NACA 4412 airfoil that shows that the maximum velocity occurs at the leading edge, which is also where the observed maximum erosion occurs. The maximum velocity for this airfoil was 13.6 meters per second for an upstream velocity of 6.5 meters per second. The simulation results were compared with the NACA data and correlation was found to be excellent. The experimentally observed maximum erosion takes place at the leading edge, which is consistent with the position where maximum velocity occurs, according to the simulation (figure 2). These correlations provided us with a high level of confidence in using FLUENT software to predict maximum velocities and distributions for other airfoil shapes, which we wanted next to evaluate for this application.

My background in aerospace engineering was useful during this process. The new airfoil is symmetric and thinner near the leading edge. The new airfoil also has a larger amount of camber. These factors reduce the airflow velocity in the vicinity of the leading edge. Analyzing the new design with FLUENT at the same 6.5 m/s up-stream velocity showed a reduction in maximum velocity to 10.7 m/s, which is 20% less than the original design. With nearly a cubic relationship between velocity and erosion, this change in itself reduces erosion by 50%.

Applying Coating Optimally

We also considered the idea of coating the blades. Generally, applying a 0.040 inch wear-resistant coating will increase life by 100% but also increase the cost of the blade by the same amount. Knowing exactly where high velocities would be experienced in this case made it possible to cover the critical areas while only coating 20% of the blade. Protecting the leading edge of the blade prolongs the life of the leading edge and also prevents erosion from occurring downstream of this layer. With this change, we predicted that the life of the blade would be

JA065 Page 2 of 4

Particulate Interactions

In addition to examining velocities, the solid particle interactions with the airfoil were also examined using the computational analysis results. A stagnation point was observed on the bottom side of the airfoil at the

www.cadfamily.com EMail:cadserv21@hotmail.com Copyright 1999 Fluent Inc. The document is for study only,if tort to your rights,please inform us,we will delete

Fig 3. A real C 100 blade after four years' wear

Fig 4. Calculated values of fluid velocity agree with experimental results

that will give numerical instabilities in the computational model need to be avoided. The axisymmetric model had over 9,000 cells. The software produced a predicted path of 100 micron particles, which are injected into the flow field. Based on previous particle studies, it appeared that performance would be good. The new impeller was installed in the application and has provided excellent performance.

extended by a factor of four. A test apparatus was used to validate these predictions. Two steel coupons were run in a sand slurry for 24 hours. The coupons (one coated and one uncoated) were then weighed to determine material loss. These tests showed dramatic reductions in wear on the order of the amount that had been predicted.

Conclusion

I have been using FLUENT since 1989. I have found it considerably easier to use than other programs I have looked at. The Fluent code is user friendly and allows you to do complex simulations. Another advantage is that the program provides immediate graphical feedback during grid generation, model creation, and the solution process. One more thing that we have appreciated over the years is the outstanding technical support provided by Fluent Inc. The developer listens to me and has made a number of enhancements to the software based on my needs. We have used the program in quite a number of other areas including blending studies where we introduce a second species into the tank and determine how it is redistributed over time. We have also looked at gas dispersion, transitional flow, solids suspension and blending in other analyses. In the future, we are planning to create a model that will include the full tank yet provide fine enough detail to cover the impeller, thus eliminating the need for the experimental measurements described above. FLUENT has recently introduced the sliding mesh and unstructured grid capabilities needed for this type of

Testing the Redesigned Impeller

The next step was creating a full tank model of the blade in order to determine whether particle distribution in the tank would be sufficient with the new blade. A full-size prototype of the impeller was built and tested in water in a 15-meter square tank in our lab and at an alumina installation in Australia. Flow measurements were obtained using an Ott propeller meter and a Marsh McBirney Eddy Current Velocity Meter. The full scale measurements were obtained either at the outlet of the draft tube or over the vertical section above the lip of the draft tube. A Laser Doppler Velocimeter (LDV) was also used to generate velocity profiles in a 1.2 meter tank with a 0.41 meter impeller. We used a two-dimensional DANTEC Series 60 Fiber Optic System with enhanced burst spectrum analyzers for processing. The flow number of 0.62 measured with the LDV was within 5% of the measurements taken in the 15m tank and the field installation. A new FLUENT model of the entire tank was also constructed. The integrated flow measurements were then used as inputs through the draft tube.Specific details such as the thickness of the draft tube were critical in this model as well. Care is needed when modeling the draft tube inlet because highly skewed cell structures

Fig 5. Calculated and measured velocities for water agree well

www.cadfamily.com EMail:cadserv21@hotmail.com Copyright 1999 Fluent Inc. The document is for study only,if tort to your rights,please inform us,we will delete

JA065 Page 3 of 4

analysis. Beyond that, we plan to incorporate chemistry into the CFD analysis so we can measure the effect of the mixer on the reaction. All in all, the use of CFD has given us a competitive advantage in improving our product line and developing custom products for specialized applications.

www.cadfamily.com EMail:cadserv21@hotmail.com Copyright 1999 Fluent Inc. The document is for study only,if tort to your rights,please inform us,we will delete

JA065 Page 4 of 4

You might also like

- Galerkin Projection DynamicDocument21 pagesGalerkin Projection DynamicLei TuNo ratings yet

- Feed and Bleed LocaDocument8 pagesFeed and Bleed LocaLei TuNo ratings yet

- August 24 ColloquiaDocument1 pageAugust 24 ColloquiaLei TuNo ratings yet

- Model Reduction High DimensionDocument20 pagesModel Reduction High DimensionLei TuNo ratings yet

- 2000 ENDFB6 Delayed Neutron StudyDocument23 pages2000 ENDFB6 Delayed Neutron StudyLei TuNo ratings yet

- SqldocDocument68 pagesSqldocLei TuNo ratings yet

- Mc30 14 PaperDocument18 pagesMc30 14 PaperLei TuNo ratings yet

- Good Fortran 1Document18 pagesGood Fortran 1Lei TuNo ratings yet

- Introduction To ISS and SDTPDocument20 pagesIntroduction To ISS and SDTPLei TuNo ratings yet

- 10-50129-24 CAES ColloquiaDocument1 page10-50129-24 CAES ColloquiaLei TuNo ratings yet

- Em BrittleDocument24 pagesEm BrittleLei TuNo ratings yet

- Good Fortran 1Document18 pagesGood Fortran 1Lei TuNo ratings yet

- CFD1Document1 pageCFD1Lei TuNo ratings yet

- Hypermesh FluentDocument2 pagesHypermesh FluentLei TuNo ratings yet

- Using FLUENT 12.0 in Workbench: January 2009Document66 pagesUsing FLUENT 12.0 in Workbench: January 2009tomekzawistowskiNo ratings yet

- R O M H A H A: Educed Rder Odeling Ybrid Pproach Ybrid PproachDocument30 pagesR O M H A H A: Educed Rder Odeling Ybrid Pproach Ybrid PproachLei TuNo ratings yet

- Introduction ModelicaDocument5 pagesIntroduction ModelicaLei TuNo ratings yet

- HTR CNTHDocument8 pagesHTR CNTHLei TuNo ratings yet

- How To Write MathematicsDocument22 pagesHow To Write MathematicsLei TuNo ratings yet

- Math IDocument22 pagesMath ILei TuNo ratings yet

- 358241Document8 pages358241Lei TuNo ratings yet

- 604 F13.sylDocument1 page604 F13.sylLei TuNo ratings yet

- Introduction ModelicaDocument5 pagesIntroduction ModelicaLei TuNo ratings yet

- How To Write MathematicsDocument22 pagesHow To Write MathematicsLei TuNo ratings yet

- Nse v37 n2 pp186-191Document6 pagesNse v37 n2 pp186-191Lei TuNo ratings yet

- Wu GPT Ans Winter 2012Document21 pagesWu GPT Ans Winter 2012Lei TuNo ratings yet

- MatlabDocument4 pagesMatlabLei TuNo ratings yet

- Introduction ModelicaDocument5 pagesIntroduction ModelicaLei TuNo ratings yet

- Introduction ModelicaDocument5 pagesIntroduction ModelicaLei TuNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Air Blue E-TicketDocument1 pageAir Blue E-TicketMuneeb Ahmed100% (3)

- Law As A Command of SovereignDocument12 pagesLaw As A Command of SovereignAdv BL Dewasi100% (2)

- Microsoft Excel ExercisesDocument14 pagesMicrosoft Excel ExercisesJumaryse Marabut100% (2)

- Geometric Design of Highways for Optimal Traffic FlowDocument123 pagesGeometric Design of Highways for Optimal Traffic FlowGadisa TeferaNo ratings yet

- Ventilation Plan For Confined Space EntryDocument9 pagesVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- What Is Creole Language - Definition & PhrasesDocument2 pagesWhat Is Creole Language - Definition & PhrasesGabriel7496No ratings yet

- Laptop Power SequenceDocument16 pagesLaptop Power SequenceDelwar Hossain90% (10)

- Jda Connects The Dots at Its 209821Document5 pagesJda Connects The Dots at Its 209821Gerardo LujanNo ratings yet

- No Curfew for College Dorm StudentsDocument2 pagesNo Curfew for College Dorm Students陳玟蓁No ratings yet

- High Level Cyber Security Assessment - Detailed ReportDocument57 pagesHigh Level Cyber Security Assessment - Detailed Reportdobie_e_martinNo ratings yet

- Purchase OrderDocument2 pagesPurchase OrderNicole LomasangNo ratings yet

- Reynaers Product Overview CURTAIN WALLDocument80 pagesReynaers Product Overview CURTAIN WALLyantoNo ratings yet

- Sdo385 50hz Doosan GeneratorDocument4 pagesSdo385 50hz Doosan GeneratorsunshinemachineryNo ratings yet

- Tutorial Quartus II Simulation VHDLDocument27 pagesTutorial Quartus II Simulation VHDLHeitor B. S. BezerraNo ratings yet

- Solar Panel Cleaning System Design and DevelopmentDocument4 pagesSolar Panel Cleaning System Design and DevelopmentMohammed safarulla HNo ratings yet

- Assignment 2Document2 pagesAssignment 2shivam souravNo ratings yet

- Product PlanningDocument23 pagesProduct PlanningGrechen CabusaoNo ratings yet

- Safety and Arming Device Timer 6-7-1976Document5 pagesSafety and Arming Device Timer 6-7-1976nguyenhNo ratings yet

- Lorry AirBrakesDocument3 pagesLorry AirBrakesEnache CristinaNo ratings yet

- Scor Overview v2 0Document62 pagesScor Overview v2 0Grace Jane Sinaga100% (1)

- Piccolo: Operating and Maintenance Instructions For The Deck OvenDocument44 pagesPiccolo: Operating and Maintenance Instructions For The Deck OvenAdam B100% (1)

- Vision and Mission Analysis ChapterDocument15 pagesVision and Mission Analysis Chapterzaza bazazaNo ratings yet

- Strategic Management Impact on Unilever PerformanceDocument7 pagesStrategic Management Impact on Unilever PerformanceWachira kabugiNo ratings yet

- English Test 03Document6 pagesEnglish Test 03smkyapkesbi bjbNo ratings yet

- 5 & 6 Risk AssessmentDocument23 pages5 & 6 Risk AssessmentAzam HasanNo ratings yet

- ECU Designing and Testing Using NI ProductsDocument6 pagesECU Designing and Testing Using NI ProductsOmar Eladel MahmoudNo ratings yet

- Design of A Neural Network Function Block For Insertion Into The Function Block Library of A Programmable Logic ControllerDocument4 pagesDesign of A Neural Network Function Block For Insertion Into The Function Block Library of A Programmable Logic ControllerArmando Fermin PerezNo ratings yet

- Pointer C++ (UAMD)Document6 pagesPointer C++ (UAMD)SaiDj DulevicNo ratings yet

- Book 3 - Revised 2017-2Document41 pagesBook 3 - Revised 2017-2sales zfNo ratings yet

- Machine Guarding PrinciplesDocument5 pagesMachine Guarding Principlesliveconnectionz282No ratings yet