Professional Documents

Culture Documents

127 - Understanding Connections

Uploaded by

SameOldHatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

127 - Understanding Connections

Uploaded by

SameOldHatCopyright:

Available Formats

AnalyzingAssembliesI UnderstandingConnectionsLecture UnderstandingConnections.

mp3

Understanding Connections

Connections define the relationship between assembly components in Mechanica.

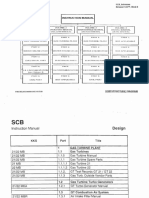

Interface o Free o Contact o Bonded Welds Rigid Link Weighted Link Fasteners

Weighted Link Connection

Contact Connection

Fastener Connection

Rigid Connection LectureNotes Understanding Connections When it comes to analyzing assemblies, Mechanica will by default assume all components with coincident surfaces should be merged and function as one body. While this default behavior can be changed, connections offer you the option to connect assembly components in very specific ways. The available connections can all be created under the Insert > Connections menu. The following connection types are available:

Interface: There are three different types of Interfaces. Free interfaces prevent the surfaces they are assigned to from being merged, but they will do nothing to prevent interpenetration. Contact interfaces will prevent surfaces from being merged, but they will also prevent interpenetration and calculate contact pressure and loads (when used with a contact analysis). Bonded interfaces will merge the surfaces selected (if that is not the default behavior).

Welds: Welds are used to create or extend existing idealizations to connect components. They are not welds in the traditional sense nor do they simulate the kind of bond that would be created by arc welding, oxy-acetylene welding, and so on. End welds, perimeter welds, and Pro/WELD feature welds are used for extending or creating shell elements between midsurface components, and spot welds are used to connect components using a beam element. Rigid Link: Rigid Links prevent the entities selected from deforming and make them move as a single rigid body. Weighted Link: Weighted Links are used to take masses or loads acting at a single source point and distribute it over a collection of selected entities. Fasteners: Fasteners are used to simulate bolt or screw connections.

Best Practices With regard to welds, Mechanica detects which midsurface components should be connected and automatically applies link elements to connect them. Though this has diminished the need for defining welds, it is important to understand how welds work and how each type connects the two components to which they are defined. You should also be aware that each of these weld types can add material to the model, and therefore the models mass in the analysis may appear greater than what is reported by Pro/ENGINEER.

You might also like

- Effect of Densification On Tensile Strength and Stiffness Parallel To The GrainDocument41 pagesEffect of Densification On Tensile Strength and Stiffness Parallel To The GrainSameOldHatNo ratings yet

- 163 - Understanding Prestress Static AnalysesDocument4 pages163 - Understanding Prestress Static AnalysesSameOldHatNo ratings yet

- 167 - Process Advisor OverviewDocument5 pages167 - Process Advisor OverviewSameOldHatNo ratings yet

- 166 - Post ProcessingDocument6 pages166 - Post ProcessingSameOldHatNo ratings yet

- 162 - Mechanica Thermal LoadsDocument6 pages162 - Mechanica Thermal LoadsSameOldHatNo ratings yet

- 154 - Understanding Dynamic Time AnalysesDocument34 pages154 - Understanding Dynamic Time AnalysesSameOldHatNo ratings yet

- 156 - Understanding Dynamic Random AnalysesDocument20 pages156 - Understanding Dynamic Random AnalysesSameOldHatNo ratings yet

- 159 - Advanced Topics - IntroductionDocument1 page159 - Advanced Topics - IntroductionSameOldHatNo ratings yet

- 142 - Design and Sensitivity Studies - IntroductionDocument1 page142 - Design and Sensitivity Studies - IntroductionSameOldHatNo ratings yet

- 129 - Using Perimeter WeldsDocument7 pages129 - Using Perimeter WeldsSameOldHatNo ratings yet

- 126 - Analyzing Assemblies I - IntroductionDocument1 page126 - Analyzing Assemblies I - IntroductionSameOldHatNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Oredigger Issue 24 - April 26, 2010Document12 pagesThe Oredigger Issue 24 - April 26, 2010The OrediggerNo ratings yet

- TSC 247 PrinterDocument2 pagesTSC 247 Printerr4zorxNo ratings yet

- Anandarup Ray CVDocument4 pagesAnandarup Ray CVsrihariNo ratings yet

- Senthil Kumaran ResumeDocument3 pagesSenthil Kumaran ResumeRamkumar SelvarajNo ratings yet

- What MobileDocument100 pagesWhat MobiledoarraulNo ratings yet

- GRE Sentence CompletionDocument3 pagesGRE Sentence Completionapi-3699142No ratings yet

- IBM Flex System p270 Compute Node Planning and Implementation GuideDocument630 pagesIBM Flex System p270 Compute Node Planning and Implementation GuideAnonymous Qvouxg2aNo ratings yet

- Fertilizer Industry Wastewater TreatmentDocument1 pageFertilizer Industry Wastewater TreatmentAnmol UpadhyayNo ratings yet

- Difference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Document2 pagesDifference Between Dictionary Managed Tablespace (DMT) and Locally Managed Tablespace (LMT)Rose MaNo ratings yet

- WAM-The Weighted Average Method or Predicting The Performance of Systems With Bursts of Customer SessionsDocument10 pagesWAM-The Weighted Average Method or Predicting The Performance of Systems With Bursts of Customer SessionsArunNo ratings yet

- Hoses & AppliancesDocument92 pagesHoses & Appliancestheguy 21100% (1)

- CVision AVR Man3 PDFDocument513 pagesCVision AVR Man3 PDFsigiloNo ratings yet

- SI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53Document2 pagesSI Failure of Bremi Ignition Coils E36 - 7, E39, E46, E53strexxNo ratings yet

- Water Filtration System - Method StatementDocument7 pagesWater Filtration System - Method Statementsunil_v575% (4)

- AcetophenoneDocument1 pageAcetophenoneDinda Melissa ArdiNo ratings yet

- Apple Value ChainDocument3 pagesApple Value ChainKeng Keat Lim100% (2)

- Fastshapes - Sprocket: Typical ApplicationsDocument23 pagesFastshapes - Sprocket: Typical ApplicationsJimmy MyNo ratings yet

- d1 - Evaluation - Justify Content Designs and Formats - FinalDocument5 pagesd1 - Evaluation - Justify Content Designs and Formats - Finalapi-466034593No ratings yet

- Nitrile RubberDocument1 pageNitrile RubberMohamedNo ratings yet

- Manual de Parts ES16D6Document36 pagesManual de Parts ES16D6Eduardo CortezNo ratings yet

- Mine Survey CertificationDocument37 pagesMine Survey CertificationAgustin Eliasta Ginting100% (1)

- Saep 1116Document5 pagesSaep 1116Anonymous 4IpmN7OnNo ratings yet

- KX Tde600 FeatureDocument460 pagesKX Tde600 Featureabg121No ratings yet

- Understanding The 808Document3 pagesUnderstanding The 808Israel LuRuvalNo ratings yet

- Gas Turbine Manual PDFDocument721 pagesGas Turbine Manual PDFZakki Afifi100% (2)

- Assessment of Rotational Capacity Test Procedure FINALDocument21 pagesAssessment of Rotational Capacity Test Procedure FINALzaheerahmed77No ratings yet

- GERMAN Embassy ContractDocument79 pagesGERMAN Embassy ContractVE.03 QELNo ratings yet

- PSD Coarse AggregateDocument3 pagesPSD Coarse AggregateMohd Syafiq AkmalNo ratings yet

- 825P A Rele E3000Document4 pages825P A Rele E3000asssasas100% (1)

- Geology 1Document2 pagesGeology 1Mike SantosNo ratings yet