Professional Documents

Culture Documents

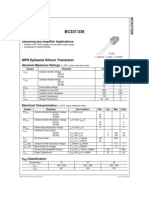

.CN 980MR2C

Uploaded by

Albert GT0 ratings0% found this document useful (0 votes)

59 views0 pagesOriginal Title

Datasheet.eeworld.com.Cn 980MR2C

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

59 views0 pages.CN 980MR2C

Uploaded by

Albert GTCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

Page: 1

FLUX LED SPECIFICATION

Fatures

Single color

High bright output

High Current Operation

Low power consumption

High reliability and long life

Descriptions

Dice materialAlGaInP

Emitting ColorSuper Red

Device Outline7.6mmX7.6mm

Lens TypeWater Clear

NOTE:

All dimensions are millimetres.

Tolerance is +/-0.25mm unless otherivise

CATHODE

? 3.0 0.2

1.5mm

DIRECTIVITY

R

e

l

a

t

i

v

e

L

u

m

i

n

o

u

s

I

n

t

e

n

s

i

t

y

Radiation Angle

0 90 60 30 0.5 1.0

1.0

0.5

0

0

30

60

90

Ta=25 C

IF=20mA

980MR2C

LED SPECIFICATION

Page: 2

Absolute maximum ratingsTa = 25

Value

Parameter Symbol Test Condition

Min. Max.

Unit

Reverse Voltage VR IR = 30A 5 -- V

Forward Current IF ---- ---- 30 mA

Power Dissipation Pd ---- ---- 75 mW

Pulse Current Ipeak Duty=0.1mS1kHz ---- 100 mA

Operating Temperature Topr ---- -40 +85

Storage Temperature Tstr ---- -40 +100

Electrical and optical characteristics Ta = 25

Value

Parameter Symbol Test Condition

Min. Typ. Max.

Unit

Forward Voltage VF IF = 70mA V3~V5

Reverse Current IR VR = 5V ---- ---- 30 A

Dominate Wavelength d IF = 70mA R1~R3

Spectral Line half-width IF = 70mA 20 nm

Luminous Flux IV IF = 70mA H,J

Viewing Angle 21/2 IF = 70mA 80 90 Deg.

Bin Code LM Bin Code LM Bin Code LM Bin Code LM

A <=0.46 E 1.0-1.3 J 2.8-3.6 N 7.8-10.0

B 0.46-0.60 F 1.3-1.7 K 3.6-4.7 P 10-13

C 0.60-0.77 G 1.7-2.2 L 4.7-6.0 Q 13-17

D 0.77-1.0 H 2.2-2.8 M 6.0-7.8 R 17-22

Ligth Col. Bin Code Wavel. (nm) Ligth Col. Bin Code Wavel. (nm)

B1 450-455 YG1 555-558

B2 455-460 YG2 558-561

B3 460-465 YG3 561-564

B4 465-470 YG4 564-567

B5 470-475 YG5 567-570

B6 475-480 YG6 570-573

G1 491-494 YG7 573-576

G2 494-497 Y1 582-585

G3 497-500 Y2 585-588

G4 500-503 Y3 588-591

G5 503-506 Y4 591-594

G6 506-509 Y5 594-597

G7 509-512 YO1 597-600

G8 512-515 YO2 600-603

G9 515-518 YO3 603-606

G10 518-521 YO4 606-609

G11 521-524 O1 609-612

G12 524-527 O2 612-615

G13 527-530 O3 615-618

G14 530-533 R1 618-621

G15 533-536 R2 621-624

G16 536-539 R3 624-627

G17 539-542 R4 627-630

G18 542-545 R5 630-633

G19 545-548 R6 633-636

Bin Code VF (V) Bin Code VF (V) Bin Code VF (V) Bin Code VF (V)

V1 1.6-1.8 V5 2.4-2.6 V9 3.2-3.4 V13 4.0-4.2

V2 1.8-2.0 V6 2.6-2.8 V10 3.4-3.6 V14 4.2-4.4

V3 2.0-2.2 V7 2.8-3.0 V11 3.6-3.8 V15 4.4-4.6

V4 2.2-2.4 V8 3.0-3.2 V12 3.8-4.0 V16 4.6-4.8

FORWARD VOLTAGE (VF) BIN

RED

BLUE

WAVELENGTH BIN

PURE

GREEN

FLUX BIN FOR PIRANHA (UFO) LEDS

YELLOW

YELLOW

ORANGE

PURE

ORANGE

YELLOW

GREEN

BLUE

GREEN

Page: 4

FLUX LED SPECIFICATION

Typical electrical/optical characteristic curves

750 450 500 600 550 650 700

75

25

50

0

Wavelength (nm)

R

e

l

a

t

i

v

e

L

u

m

i

n

o

u

s

I

n

t

e

n

s

i

t

y

100

R

a

d

i

a

n

t

I

n

t

e

n

s

i

t

y

Ambient Temperature TA ( )

-30 -10 10

0

0.5

1.0

1.5

70 90 50 30

RADIANT INTENSITY Vs.

AMBIENT TEMPERATURE

2.0

2.5

F

o

r

w

a

r

d

C

u

r

r

e

n

t

(

m

A

)

R

a

d

i

a

n

t

I

n

t

e

n

s

i

t

y

(

m

W

/

s

r

)

R

e

l

a

t

i

v

e

V

a

l

u

e

a

t

I

F

=

7

0

m

A

F

o

r

w

a

r

d

C

u

r

r

e

n

t

(

m

A

)

80

Ambient Temperature TA ( )

40

0

0 20

20

40

60

80 60

100

40

IF-Forward Current (mA)

Forward Voltage(V)

0 20

FORWARD CURRENT

DERATING CURVE

100

2.8 2.0

0

2.4

20

40

60

3.2 0

0.5

1.0

1.5

60 80 100

RADIANT INTENSITY Vs.

FORWARD CURRENT

FORWARD CURRENT Vs

FORWARD VOLTAGE

80

100

2.0

2.5

1.6 1.2

LED LAMP APPLICATION

SOLDERING

METHOD SOLDERING CONDITIONS REMARK

DIP

SOLDERING

Bath temperature: 2605

Immersion time: with 5 sec

Solder no closer than 3mm from the

base of the package

Using soldering flux, RESIN FLUX

is recommended.

SOLDERING

IRON

Soldering iron: 30W or smaller

Temperature at tip of iron: 260 or lower

Soldering time: within 5 sec.

During soldering, take care not to

press the tip of iron against the

lead.

(To prevent heat from being

transferred directly to the lead, hold

the lead with a pair of tweezers

while soldering

1) When soldering the lead of LED in a condition that the package is fixed with a panel (See Fig.1),

be careful not to stress the leads with iron tip.

2) When soldering wire to the lead, work with a Fig (See Fig.2) to avoid stressing the package.

Page : 5

Panel

(Fig.1)

Lead wries

Leave a slight

clearance

Lead wries

( Fig. 2)

3) Similarly, when a jig is used to solder the LED to PC board, take care as much as possible to

avoid steering the leads (See Fig.3).

4) Repositioning after soldering should be avoided as much as possible. If inevitable, be sure to

preserve the soldering conditions with irons stated above: select a best-suited method that

assures the least stress to the LED.

5) Lead cutting after soldering should be performed only after the LED temperature has returned to

normal temperature.

LED MOUNTING METHOD

1) When mounting the LED by using a case, as shown Fig.4, ensure that the mounting holds on

the PC board match the pitch of the leads correctly-tolerance of dimensions of the respective

components including the LED should be taken into account especially when designing the

case, PC board, etc. to prevent pitch misalignment between the leads and board holes, the

diameter of the board holes should be slightly larger than the size of the lead. Alternatively, the

shape of the holes should be made oval. (See Fig.4)

Page : 6

PC board

ig.3 F

jig

Fig.4

case

pc board

LED LAMP APPLICATION

2) Use LEDs with stand-off (Fig.5) or the tube or spacer made of resin (Fig.6) to position the LEDs.

FORMED LEAD

1) The lead should be bent at a point located at least 2mm away from the package. Bending

should be performed with base fixed means of a jig or pliers (Fig.7)

2) Forming lead should be carried our prior to soldering and never during or after soldering.

3) Form the lead to ensure alignment between the leads and the hole on board, so that stress

against the LED is prevented. (Fig.8)

Page : 7

Stand-off

Fig.5 Fig.6

Tube

2

m

m

Fig.7

LED LAMP APPLICATION

LEAD STRENGTH

1) Bend strength

Do not bend the lead more than twice. (Fig.9)

2) Tensile strength (@Room Temperature)

If the force is 1kg or less, there will be no problem. (Fig.10)

HANDLING PRECAUTIONS

Although rigid against vibration, the LEDs may damaged or scratched if dropped. So take care

when handling.

CHEMICAL RESISTANCE

1) Avoid exposure to chemicals as it may attack the LED surface and cause discoloration.

2) When washing is required, refer to the following table for the proper chemical to be sued.

(Immersion time: within 3 minutes at room temperature.)

SOLVENT ADAPTABILITY

Freon TE

Chlorothene

Isopropyl Alcohol

Thinner

Acetone

Trichloroethylene

--Usable --Do not use.

Page : 8

Fig.9

OK

Fig.10

1Kg

NOTE: Influences of ultrasonic cleaning of the LED

resin body differ depending on such factors

as the oscillator output, size of the PC board

and the way in which the LED is mounted.

Therefore, ultrasonic cleaning should only be

performed after confirming there is no problem by

conducting a test under practical.

LED LAMP APPLICATION

Experiment Item:

Test Condition

Item

Lamp & IR

Reference Standard

OPERATION LIFE

Ta 255

IF= 20mA RH=60%RH

DYNAMIC:100mA 1ms 1/10 duty

STATIC STATE: IF20mA

TEST TIME:

168HRS-24HRS+24HRS

500HRS-24HRS+24HRS

1000HRS-24HRS+72HRS

MIL-STD-7501026

MIL-STD-8831005

JIS C 7021B-1

HIGH

TEMPERATURE

HIGH HUMIDITY

STORAGE

Ta 655

RH 9095%RH

TEST TIME240HRS2HRS

MIL-STD-202103B

JIS C 7021 B-1

TEMPERATURE

CYCLING

10525-5525

30min 5min 30min 5min

10CYCLES

MIL-STD-202107D

MIL-STD-7501051

MIL-STD-8831010

JIS C 7021 A-4

THERMAL SHOCK

1055-555

10min 10min

10CYCLES

MIL-STD-202107D

MIL-STD-7501051

MIL-SYD-8831011

SOLDER

RESISTANCE

Tsol2605

DWELL TIME10lsec

MIL-STD-202210A

MIL-STD-750-2031

JIS C 7021A-1

SOLDERABILITY

Tsol2305

DWELL TIME5lsec

MIL-STD-202208D

MIL-STD-7502026

MIL-STD-8832003

JIS C 7021 A-2

Page : 9

LED LAMP PASSED TESTS

Drive Method

Circuit model A Circuit model B

(A)Recommended circuit.

(B)The difference of brightness between LED`s could be found due to the Vf-If characteristics of LED.

All Datasheets Cannot Be Modified Without Permission

Copyright Each Manufacturing Company

This datasheet has been downloaded from:

www.EEworld.com.cn

Free Download

Daily Updated Database

100% Free Datasheet Search Site

100% Free IC Replacement Search Site

Convenient Electronic Dictionary

Fast Search System

www.EEworld.com.cn

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Snet Pro 2 Service Software User ManualDocument36 pagesSnet Pro 2 Service Software User ManualAlbert GT100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 485 FLDocument14 pages485 FLAlbert GT100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Sony Vaio Flip 13n Svf13n Series SCHDocument36 pagesSony Vaio Flip 13n Svf13n Series SCHSelmar CavalcantiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Panasonic VariadorDocument7 pagesPanasonic VariadorMarcos GonzalezNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 218 Y CablesDocument1 page218 Y CablesAlbert GTNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elx PP 4071 PTCDocument2 pagesElx PP 4071 PTCAlbert GTNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Terios Wiring Diagram ForewordDocument2 pagesTerios Wiring Diagram ForewordAlbert GTNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Solectrics 10695772Document251 pagesSolectrics 10695772Albert GTNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Section GI - General InformationDocument3 pagesSection GI - General InformationAlbert GTNo ratings yet

- Delta BreakoutDocument1 pageDelta BreakoutAlbert GTNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Service Manual: HCD-GNX700/GNX800Document86 pagesService Manual: HCD-GNX700/GNX800Albert GTNo ratings yet

- Hebei I.T. (Shanghai) Co., Ltd. Part No.: S12LY9C: FeaturesDocument2 pagesHebei I.T. (Shanghai) Co., Ltd. Part No.: S12LY9C: FeaturesAlbert GTNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Data SheetDocument13 pagesData SheetLuizNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Samsung Un32 40d5500rfDocument80 pagesSamsung Un32 40d5500rfmarquitos550bNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Mitsubishi Magnetic Contactors and Magnetic Starters Exceed ExpectationsDocument84 pagesMitsubishi Magnetic Contactors and Magnetic Starters Exceed ExpectationsDuctoanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2SC1827 Complementary 2SA769Document1 page2SC1827 Complementary 2SA769isaiasvaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Tact Switch 3 RS ComponentDocument9 pagesTact Switch 3 RS ComponentAlbert GTNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- BC337Document3 pagesBC337Emanuele100% (2)

- Tact Switch 3 RS ComponentDocument9 pagesTact Switch 3 RS ComponentAlbert GTNo ratings yet

- Bottom Tact Switch 3 RS ComponentDocument3 pagesBottom Tact Switch 3 RS ComponentAlbert GTNo ratings yet

- MH50 MH50-35Document2 pagesMH50 MH50-35Albert GTNo ratings yet

- Hebei I.T. (Shanghai) Co., Ltd. Part No.: S12LY9C: FeaturesDocument2 pagesHebei I.T. (Shanghai) Co., Ltd. Part No.: S12LY9C: FeaturesAlbert GTNo ratings yet

- Bottom Tact Switch 2 RS ComponentDocument1 pageBottom Tact Switch 2 RS ComponentAlbert GTNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bottom Tact Switch RS ComponentDocument1 pageBottom Tact Switch RS ComponentAlbert GTNo ratings yet

- 9NM60NDocument16 pages9NM60NAlbert GTNo ratings yet

- 1527115562Document1 page1527115562Albert GTNo ratings yet

- Tept 5700Document5 pagesTept 5700Albert GTNo ratings yet

- .CN 530MY8CDocument10 pages.CN 530MY8CAlbert GTNo ratings yet

- TSTS7303Document5 pagesTSTS7303Albert GTNo ratings yet

- Unit 2 Me1203Document20 pagesUnit 2 Me1203Muthuvel MNo ratings yet

- Hard Turning On LatheDocument105 pagesHard Turning On LatheJitendraNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- MS5002EDocument8 pagesMS5002EMatt AgonyaNo ratings yet

- Original KSB Spare Parts Kits: For Eta PumpsDocument2 pagesOriginal KSB Spare Parts Kits: For Eta Pumpsayham100% (1)

- 11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolDocument1 page11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolLeomarini100% (1)

- Final Year Mechatronics Projects List - Frigate - 9486164606Document3 pagesFinal Year Mechatronics Projects List - Frigate - 9486164606Frigate Mechanical Projects India75% (4)

- Ese652 - Process Control Ii Chapter 5.2 - Distillation ColumnDocument5 pagesEse652 - Process Control Ii Chapter 5.2 - Distillation ColumnJennifer HughesNo ratings yet

- Programación EIAISODocument684 pagesProgramación EIAISOManuel Alejandro SerranoNo ratings yet

- Nitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes RapidlyDocument14 pagesNitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes Rapidlyapi-25909541No ratings yet

- Roll Mill 1Document48 pagesRoll Mill 1klasiko bente tresNo ratings yet

- 01 Heating PL 2017 Rs v03 Svu 5.4 FinalDocument77 pages01 Heating PL 2017 Rs v03 Svu 5.4 FinalKajak Klub DrinaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- English For Industrial Machinery StudentsDocument4 pagesEnglish For Industrial Machinery StudentsDíaz YvonneNo ratings yet

- 7 9layerblownfilmlinesDocument6 pages7 9layerblownfilmlinesductoan32No ratings yet

- Pipe Alcorcon1Document85 pagesPipe Alcorcon1Christopher Ysit100% (1)

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Estane Skythane S185A TPU: TypeDocument1 pageEstane Skythane S185A TPU: Typejuliushasan2No ratings yet

- Bramat2011 ProgramDocument25 pagesBramat2011 Programmtierean100% (1)

- QweqDocument2 pagesQweqPraYush RajbhandariNo ratings yet

- Authorised Examiners Lifting EquipmentDocument13 pagesAuthorised Examiners Lifting EquipmentdunglxNo ratings yet

- DATABASE Kawasan Industri PolugadungDocument20 pagesDATABASE Kawasan Industri PolugadungRina Rachman100% (1)

- Turboexpander Lubricant Problems.Document3 pagesTurboexpander Lubricant Problems.dr_kh_ahmedNo ratings yet

- Is 10446 1983 PDFDocument60 pagesIs 10446 1983 PDFJothimanikkam SomasundaramNo ratings yet

- How To Make Sure You Select The Right Dry Vacuum Pump: Rotary ScrewDocument2 pagesHow To Make Sure You Select The Right Dry Vacuum Pump: Rotary ScrewVu Van KhacNo ratings yet

- Advantages of Steel As A Structural MaterialDocument3 pagesAdvantages of Steel As A Structural MaterialIrfan MunirNo ratings yet

- Door Built Up RateDocument6 pagesDoor Built Up RateSebb seebNo ratings yet

- How To Test A SolenoidDocument3 pagesHow To Test A SolenoidVyas SrinivasanNo ratings yet

- Deutz 165 MK3 Electrial 1Document100 pagesDeutz 165 MK3 Electrial 1chrideerNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Circular Pelletizing Technology General Presentation: We Just Made It BetterDocument46 pagesCircular Pelletizing Technology General Presentation: We Just Made It BetterkalaiNo ratings yet

- Magnetic Effects of Electric Current ( (Term I)Document15 pagesMagnetic Effects of Electric Current ( (Term I)Tapas BanerjeeNo ratings yet