Professional Documents

Culture Documents

Miri Crude Assay RPT

Uploaded by

apiskaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Miri Crude Assay RPT

Uploaded by

apiskaiCopyright:

Available Formats

ORIGINAL

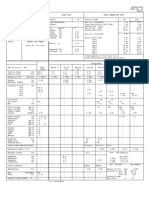

CRUDE OIL ASSAY REPORT

ASSAY CONDUCTED FOR : SAMPLE DESCRIPTION: Chemsain Konsultant Sdn Bhd Miri Crude Oil

SAMPLE NO: REPORT NO: JOB NUMBER: DATE REPORTED: PREPARED AND CHECKED BY:

C4104/07 LB4867 ( Revision 1 ) 1452/07 12/17/2007 Gerard Chin

TBP & SIMULATED DIST. GRAPH

600

500

400

TEMPERATURE ( C )

TRUE BOILING POINT CURVE

300

SIMULATED DISTILLATION CURVE 200

100

0 0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0 90.0 100.0 CUMMULATIVE WEIGHT %

04 Dec 2007

Miri Crude Oil Assay Report

SUMMARY OF PRODUCT CUT POINTS AND YIELDS

CUT POINT ( C ) PRODUCT LPG C5 - 140 140 - 185 185-230 140 - 230 230 - 330 330-370 230-370 370 - 450 450-513 513+ Naphtha Naphtha / Kerosene Kerosene Kerosene Kerosene / Light Gas Oil Heavy Gas Oil Light Gas Oil / Heavy Gas Oil Light Vacuum Gas Oil Vacuum Gas Oil Vacuum Residue YIELD ON YIELD ON

CRUDE ( vol. % ) CRUDE ( wt. % ) 0.56 0.35 15.16 8.57 8.84 17.42 37.34 8.11 45.45 15.33 1.86 4.23 13.56 8.22 8.69 16.91 37.82 8.39 46.21 16.14 2.06 4.78

4 Dec 2007

Miri Crude Assay Report

TRUE BOILING POINT DATA

CUT NUMBER 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 CUT POINT AET C LPG 70 90 140 155 185 220 230 260 330 340 350 370 380 450 513 513+ YIELD % ON CRUDE WEIGHT % VOLUME CUT CUM ml 0.35 0.35 55.0 1.79 2.14 216.3 2.23 4.36 261.0 9.54 13.91 1022.0 2.65 16.56 275.2 5.57 22.12 573.1 5.65 27.77 571.9 3.04 30.81 303.0 13.19 44.01 1294.4 24.63 68.63 2399.4 2.66 71.30 255.9 1.80 73.10 172.7 3.93 77.03 374.1 2.05 79.08 195.3 14.09 93.17 1321.4 2.06 95.22 183.8 4.78 100.00 418.4 DENSITY at 15 C kg/l 0.5315 0.6959 0.7166 0.7848 0.8082 0.8166 0.8298 0.8440 0.8566 0.8625 0.8751 0.8760 0.8826 0.8822 0.8960 0.9404 0.9592

WEIGHT gram 29.2 150.5 187.0 802.1 222.4 468.0 474.6 255.7 1108.8 2069.5 223.9 151.3 330.2 172.3 1184.0 172.8 401.3

VOLUME % CUT CUM 0.56 0.56 2.19 2.74 2.64 5.38 10.33 15.71 2.78 18.49 5.79 24.29 5.78 30.07 3.06 33.13 13.08 46.21 24.25 70.47 2.59 73.05 1.75 74.80 3.78 78.58 1.97 80.56 13.36 93.91 1.86 95.77 4.23 100.00

HOLD UP LOSS

WEIGHT OF SAMPLE ( gm )

184.2 73.4 8661.2 0.8714 9939.4

DENSITY @ 15C OF CHARGE ( kg/l )

VOLUME OF CHARGE @ 15C ( vol )

4 Dec 2007

Miri Crude Assay Report

SIMULATED DISTILLATION DATA

Boiling Point ( C ) IBP 2.6 1 29.1 2 52.9 3 70.5 4 83.0 5 92.8 6 104.3 7 104.9 8 105.4 9 114.2 10 120.4 11 124.2 12 128.1 13 136.7 14 141.3 15 147.6 16 153.6 17 161.0 18 165.7 19 170.7 20 175.3 21 181.5 22 187.4 23 193.6 24 197.8 25 203.1 26 208.6 27 213.3 28 217.0 29 221.4 30 226.2 31 230.5 32 233.2 33 235.9 34 239.7 35 244.1 36 247.9 37 251.0 38 253.0 39 254.9 40 256.7 41 259.8 42 261.9 43 264.6 44 266.5 45 268.8 46 271.4 47 273.4 48 276.6 49 279.9 50 282.7

No

Cum Yield ( Mass % ) 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

No 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

Boiling Point ( C ) 286.1 288.6 292.4 295.9 298.4 301.9 303.9 304.8 308.1 311.8 315.5 318.2 321.7 326.0 330.2 333.1 337.7 342.3 345.8 350.5 355.3 359.3 364.5 369.3 374.1 379.6 384.0 389.7 394.3 400.0 405.0 411.2 416.3 421.8 426.4 431.2 435.2 439.7 443.2 447.5 452.1 457.2 462.5 468.7 476.7 490.1 505.0 524.1 555.0

Cum Yield ( Mass % ) 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

4 Dec 2007

Miri Crude Assay Report

LIGHT HYDROCARBON ANALYSIS

RESULTS COMPOSITION METHOD LIQUIFIED PETROLEUM GAS WT % ON FRACTION METHANE GC 3.40 ETHANE GC 10.99 PROPANE GC 42.68 I-BUTANE GC 16.19 N-BUTANE GC 20.18 I-PENTANE GC 3.01 N-PENTANE GC 1.32 N-HEXANE+ GC 0.33 CARBON DIOXIDE GC 1.90

NO. 1 2 3 4 5 7 8 9 10

4 Dec 2007

Miri Crude Assay Report

DETAILED HYDROCARBON ANALYSIS

RESULTS NAPHTHA (C5 - 140 ) WT % ON FRACTION 40.54 0.00 48.79 10.14 0.00 0.53 0.12 1.78 6.49 18.94 30.60 24.66 13.77 3.09 0.02 0.00 0.00 0.00 0.12 1.78 5.57 7.95 7.12 9.24 6.14 2.62 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.92 10.46 20.44 10.73 5.87 0.36 0.02 0.00 0.00 0.54 3.04 4.68 1.77 0.11 0.00 0.00 RESULTS NAPHTHA (C140 - 185) WT % ON FRACTION 36.20 0.00 25.48 29.59 0.00 8.73 0.00 0.00 0.05 0.54 4.50 15.25 26.83 31.50 10.48 2.12 0.00 8.73 0.00 0.00 0.03 0.09 0.45 2.90 7.24 17.40 7.02 1.06 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.02 0.42 3.23 6.82 9.54 4.34 0.89 0.23 0.00 0.02 0.82 5.53 10.05 9.77 2.56 0.84

NO.

COMPOSITION

METHOD

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

PARAFFINS OLEFINS NAPHTHENE AROMATIC HEAVIES UNKNOWNS TOTAL C3 TOTAL C4 TOTAL C5 TOTAL C6 TOTAL C7 TOTAL C8 TOTAL C9 TOTAL C10 TOTAL C11 TOTAL C11+ TOTAL HEAVIES TOTAL UNKNOWNS C4 PARAFFINS C4 PARAFFINS C5 PARAFFINS C6 PARAFFINS C7 PARAFFINS C8 PARAFFINS C9 PARAFFINS C10 PARAFFINS C11 PARAFFINS C12 PARAFFINS C13 PARAFFINS C14 PARAFFINS C5 OLEFINS C6 OLEFINS C7 OLEFINS C8 OLEFINS C9 OLEFINS C10 OLEFINS C11 OLEFINS C12 OLEFINS C13 OLEFINS C5 NAPHTHENE C6 NAPHTHENE C7 NAPHTHENE C8 NAPHTHENE C9 NAPHTHENE C10 NAPHTHENE C11 NAPHTHENE C12 NAPHTHENE POLYNAPHTHENE C6 AROMATIC C7 AROMATIC C8 AROMATIC C9 AROMATIC C10 AROMATIC C11 AROMATIC C12 AROMATIC

DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA DHA

4 Dec 2007

Miri Crude Assay Report

PRELIMINARY ANALYSIS ON CHARGE

NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 TEST Density @ 15 C API Gravity Basic Sediment & Water Water Content Reid Vapor Pressure @ 37.8C Total Acid Number Flash Point Pour Point ASTM Color Total Sulphur Salt Content Nitrogen Content Ash Content Wax Content Kinematic Viscosity @ 40C Kinematic Viscosity @ 70C Characterisation Factor Gross Calorific Value Mercury Asphaltenes Distillation IBP 5 % recovery 10 % recovery 20 % recovery 30 % recovery 40 % recovery 50 % recovery 60 % recovery 70 % recovery 80 % recovery 90 % recovery 95 % recovery FBP Recovery Residue Loss Metal Sodium (Na) Potassium (K) Copper (Cu) Lead (Pb) Iron (Fe ) Nickel (Ni) Vanadium (V) Arsenic (As) METHOD ASTM D4052 ASTM D1298 ASTM D4007 ASTM D4006 ASTM D323 ASTM D664 IP 170 ASTM D97 ASTM D1500 ASTM D4294 ASTM D3230 ASTM D4629 ASTM D482 DIN 52015 ASTM D445 ASTM D445 UOP 375-59 ASTM D240 CVAFS ASTM D3279 ASTM D86-96 UNIT kg/l degree vol. % vol. % kPa mgKOH/g C C wt % lb/1000bbls ppm wt wt % wt % cSt cSt MJ/kg ppb wt % C C C C C C C C C C C C C % vol % vol % vol ASTM D5863 ASTM D5863 ASTM D5863 ASTM D5863 ASTM D5863 ASTM D5863 ASTM D5863 AAS ppm wt ppm wt ppm wt ppm wt ppm wt ppm wt ppm wt ppb wt RESULTS 0.8714 30.79 0.05 <0.1 16.6 0.19 -11 +3 8.0 0.14 4.2 240 0.066 3.5 3.939 1.987 12.1 43.95 2.58 <0.5 63.5 99.0 125.0 167.5 217.0 249.5 272.0 294.5 328.5

cracking @ 338

22

25.8 1.8 <1.0 7.5 <1.0 4.7 <1.0 <10

4 Dec 2007

Miri Crude Assay Report

ANALYSIS FOR PRODUCT CUT

Tests Yield on Crude Yield on Crude Density @ 15C API Gravity Sulphur Sulphur Nitrogen Total Acid Number Smoke Point Flash Point ( Abel ) Freezing Point Aniline Point Colour Saybolt Kinematic Viscosity @ - 20C Reid Vapour Pressure Cetane Index Ash Content Mercaptan Sulphur Hydrocarbon Types - Paraffins - Olefins - Naphthenes - Aromatics Naphathalene Content Mercury Distillation - Initial Boiling Point - 5% - 10% - 20% - 30% - 40% - 50% - 60% - 70% - 80% - 90% - 95% - Final Boiling Point - Recovery - Residue - Loss Remark : 1) @ - insufficient sample Method Unit vol % wt % kg/l ppm wt wt % ppm wt mgKOH/g mm C C C cSt kPa wt % ppm wt vol % vol % vol % vol % vol % ppb C C C C C C C C C C C C C vol % vol % vol % C5 - 70 2.19 1.79 0.6647 81.33 <3 1 70 - 90 2.64 2.23 0.7267 63.16 <3 1 RESULTS 90 - 140 140 - 155 10.33 2.78 9.54 2.65 0.7625 0.7886 54.01 47.85 16 48 1 1 <0.05 19.5 16.5 >-51 44 + 30 1.103 21.6 0.002 10.4 72.47 0.00 26.31 1.22 <1.0 18 37 43 49 53 58 61 66 71 81 38.50 0.00 57.00 4.43 <1.0 52 67 72 76 79 82 84 87 89 91 94 96 100 99.8 0.2 0.0 35.03 0.00 51.10 13.13 1.62 88 98 105 106 108 111 115 120 125 131 139 147 169 99.2 0.8 0.0 37.89 0.00 33.97 24.39 <0.01 <1.0 120 130 133 137 140 144 148 152 156 160 165 169 180 98.5 1.3 0.2 140 - 185 8.57 8.22 0.8018 45.11 <0.01 2 <0.05 17.0 25.0 >-51 46 + 30 2.126 25.0 0.005 10.2 36.20 0.00 25.48 29.59 <0.01 <1.0 131 141 145 149 154 158 163 168 173 178 183 189 197 99.0 1.0 0.0 155 - 185 5.79 5.57 0.8056 44.06 <0.01 2 <0.05 21.9 29.5 >-51 46 + 30 2.386 27.6 0.006 3.9 35.26 0.00 20.27 27.59 <0.01 <1.0 139 149 153 158 162 166 170 174 178 182 188 193 198 98.5 1.3 0.2

ASTM D 4052 ASTM D 3120 ASTM D 4294 ASTM D 4629 ASTM D 974 ASTM D 1322 IP 170 ASTM D 2386 ASTM D 611 ASTM D 156 ASTM D 445 ASTM D 323 ASTM D 976 ASTM D 482 IP 104 DHA DHA DHA DHA ASTM D 1840 CVAFS ASTM D 86

+ 30 108.7

+ 30

@

+ 30 13.2

87 84.0 0.2 15.8

4 Dec 2007

Miri Crude Assay Report

ANALYSIS FOR PRODUCT CUT

Tests Yield on Crude Yield on Crude Density API Gravity Sulphur Nitrogen Total Acid Number Smoke Point Flash Point ( Abel ) Flash Point ( PMCC ) Freezing Point Aniline Point Colour Saybolt Kinematic Viscosity @ - 20C Kinematic Viscosity @ 40C Kinematic Viscosity @ 50C Kinematic Viscosity @ 75C Kinematic Viscosity @ 100C Cetane Index Refractive Index @ 20C Mercaptan Sulphur Hydrocarbon Types - Aromatics - Olefins - Saturates Naphthalene Content Distillation - Initial Boiling Point - 5% - 10% - 20% - 30% - 40% - 50% - 60% - 70% - 80% - 90% - 95% - Final Boiling Point - Recovery - Residue - Loss Method Unit vol % wt % kg/l wt % ppm wt mgKOH/g mm C C C C cSt cSt cSt cSt cSt ppm wt vol % vol % vol % vol % C C C C C C C C C C C C C vol % vol % vol % 185 - 220 5.78 5.65 0.8338 38.12 0.02 4 <0.05 18.9 52.5 >-51 51 + 29 4.910 1.319 RESULTS 220 - 230 3.06 3.04 0.8476 35.36 0.05 5 <0.05 15.5 75 >-51 54 + 25 8.245 1.635 1.396 1.038 0.744 35.9 1.4665 17.5 13.6 7.1 79.4 <0.01 200 207 210 215 218 220 223 226 229 233 238 242 247 99.0 0.8 0.2 230 - 260 13.08 13.19 0.8648 32.04 0.04 17 <0.05 13.9 92 - 44 56 -2 16.185 2.344 1.852 1.345 1.014 36.9 1.4758 6.5 17.4 12.7 69.9 <0.01 223 230 233 236 239 241 244 248 251 254 258 263 273 99.5 0.5 0.0

ASTM D 4052 ASTM D 4294 ASTM D 4629 ASTM D 974 ASTM D 1322 IP 170 ASTM D 93 ASTM D 2386 ASTM D 611 ASTM D 156 ASTM D 445 ASTM D 445 ASTM D 445 ASTM D 445 ASTM D 445 ASTM D 976 ASTM D 1218 IP 104 ASTM D 1319 ASTM D 1319 ASTM D 1319 ASTM D 1840 ASTM D 86

32.6 7.1 13.5 6.7 79.9 <0.01 165 181 185 190 194 198 202 206 212 217 226 237 252 99.0 0.8 0.2

4 Dec 2007

Miri Crude Assay Report

ANALYSIS FOR PRODUCT CUT

Tests Yield on Crude Yield on Crude Density API Gravity Sulphur Nitrogen Total Acid Number Smoke Point Flash Point ( PMCC ) Freezing Point Aniline Point Cloud Point Pour Point Colour Saybolt Colour ASTM Kinematic Viscosity @ Kinematic Viscosity @ Kinematic Viscosity @ Kinematic Viscosity @ Reid Vapour Pressure Cetane Index MCRT - 100% Sample Refractive Idex @ 20C Hydrocarbon Types Aromatics - Olefins - Saturates Polycyclic Aromatic Vacuum Distillation - Initial Boiling Point - 5% - 10% - 20% - 30% - 40% - 50% - 60% - 70% - 80% - 90% - 95% - Final Boiling Point - Recovery - Residue - Loss Method Unit vol % wt % kg/l wt % ppm wt mgKOH/g mm C C C C C cSt cSt cSt cSt kPa wt % vol % vol % vol % wt % C C C C C C C C C C C C C vol % vol % vol % 260 - 330 24.25 24.63 0.8866 28.01 0.08 34 0.12 8.5 131 - 15 59 -14 - 15 0.5 4.941 3.976 2.156 1.543 41.0 1.4914 26.2 27.8 46.1 12.7 267 275 278 282 285 287 291 295 300 306 313 319 326 99.5 0.5 0.0 RESULTS 330 - 340 2.59 2.66 0.9139 23.25 0.16 125 0.41 165 59 +7 +6 1.5 11.74 8.071 4.885 3.055 40.0 1.5090 62 +13 +12 2.0 11.16 5.718 3.289 40.5 0.06 1.5102 340 - 350 1.75 1.80 0.9176 22.62 0.16 191 0.31 350 - 370 3.78 3.93 0.9356 19.65 0.15 324 0.28 182 64.0 +25 +24 3.0 33.76 11.54 6.179 37.5 0.05 1.5218

ASTM D 4052 ASTM D 4294 ASTM D 4629 ASTM D 974 ASTM D 1322 ASTM D 93 ASTM D 2386 ASTM D 611 ASTM D 2500 ASTM D 97 ASTM D 156 ASTM D 1500 ASTM D 445 ASTM D 445 ASTM D 445 ASTM D 445 ASTM D 323 ASTM D 976 ASTM D 4530 ASTM D 1218 ASTM D1319 ASTM D 1319 ASTM D 1319 ASTM D2425 ASTM D 1160

40C 50C 75C 100C

22.7 330 333 334 335 336 337 338 338 339 340 342 345 349 99.0 0.8 0.2

18.9 192 340 345 352 354 356 357 360 361 362 362 362 420 99.0 1.0 0.0

21.1 293 396 408 413 416 420 421 425 429 433 445 454 466 99.0 1.0 0.0

4 Dec 2007

10

Miri Crude Assay Report

ANALYSIS FOR PRODUCT CUT

Tests Yield on Crude Yield on Crude Density API Gravity Sulphur Nitrogen Total Acid Number Flash Point ( PMCC ) Aniline Point Cloud Point Pour Point Colour ASTM Kinematic Viscosity @ 50C Kinematic Viscosity @ 75C Kinematic Viscosity @ 100C Ash Content MCRT - 100% Sample Asphaltene Arsenic Wax Content Nickel Vanadium Vacuum Distillation - Initial Boiling Point - 5% - 10% - 20% - 30% - 40% - 50% - 60% - 70% - 80% - 90% - 95% - Final Boiling Point - Recovery - Residue - Loss Method Unit vol % wt % kg/l wt % ppm wt mgKOH/g C C C C cSt cSt cSt wt % wt % wt % ppb wt % ppm wt ppm wt C C C C C C C C C C C C C vol % vol % vol % 370+ 21.42 22.98 0.9709 14.16 0.17 1001 0.27 N/D +36 7.5 398.7 67.01 44.87 0.052 1.40 <0.5 <10 21.4 6.6 <1.0 340 422 433 439 446 453 463 476 495 536 559 @ RESULTS 370 - 380 380 - 450 1.97 13.36 2.05 14.09 0.9413 0.9490 18.73 17.52 0.14 0.14 349 0.27 0.41 236 67 N/D +28 +24 +36 3.5 4.5 437.7 13.58 48.55 7.489 16.60 0.015 0.034 0.05 0.05 <0.5 <0.5 <10 <10 20.5 37.0 2.6 3.8 <1.0 <1.0 290 353 386 418 424 429 432 435 443 452 466 470 471 98.0 2.0 0.0 248 313 352 410 421 428 433 437 444 450 469 473 477 98.0 2.0 0.0 450 - 513 1.86 2.06 0.9892 11.46 0.23

ASTM D 4052 ASTM D 4294 ASTM D 4629 ASTM D 974 ASTM D 93 ASTM D 611 ASTM D 2500 ASTM D 97 ASTM D 1500 ASTM D 445 ASTM D 445 ASTM D 445 ASTM D 482 ASTM D 4530 IP 143 AAS UOP 46 IP 470 IP 470 ASTM D 1160

N/D +48 8.0 345.2 63.44 0.047 0.86 <0.5 <10 9.8 4.0 <1.0 376 447 456 461 477 482 487 495 501 508 518 519 521 98.0 2.0 0.0

Remarks : 1) @ - Reach pot maximum temperature at 400 deg.C 2) N/D - Not Detected

4 Dec 2007

11

Miri Crude Assay Report

ANALYSIS FOR PRODUCT CUT

Tests Yield on Crude Yield on Crude Density API Gravity Sulphur Ash Content MCRT - 100% Sample Method Unit vol % wt % kg/l wt % wt % wt % RESULT 513+ 4.23 4.78 0.9945 10.70 0.24 0.061 8.60

ASTM D 4052 ASTM D 4294 ASTM D 482 ASTM D 4530

4 Dec 2007

12

Miri Crude Assay Report

GENERAL CONDITIONS OF SERVICE

1. General (a) Unless otherwise agreed in writing or except where they are at variance with (i) the regulations governing services performed on behalf of governments, government bodies or any other public entity or (ii) the mandatory provisions of local law, all offers or services and all resulting contractual relationship(s) between any of the affiliated companies of SGS SA or any of their agents (each a "Company") and Client (the "Contractual Relationship(s)") shall be governed by these general conditions of service (hereinafter the "General Conditions") (b) The Company may perform services for persons or entities (private, public or governmental) issuing instructions (hereinafter, the "Client"). (c) Unless the Company receives prior written instructions to the contrary from Client, no other party is entitled to give instructions, particularly on the scope of the services or the delivery of reports or certificates resulting therefrom (the "Reports of Findings"). Client hereby irrevocably authorises the Company to deliver Reports of Findings to a third party where so instructed by Client or, at its discretion, where it implicitly follows from circumstances, trade custom, usage or practice. 2. Provision of Services (b) Unless a shorter period is established in the invoice, Client will promptly pay not later than 30 days from the relevant invoice date or within such other period as may be established by the Company in the invoice (the "Due Date") all fees due to the Company failing which interest will become due at a rate of 1.5% per month (or such other rate as may be established in the invoice) from the Due Date up to and including the date payment is actually received. (c) Client shall not be entitled to retain or defer payment of any sums due to the Company on account of any dispute, counter claim or set off which it may allege against the Company. (d) Company may elect to bring action for the collection of unpaid fees in any court having competent jurisdiction. (e) Client shall pay all of the Company's collection costs, including attorney's fees and related costs. (f) In the event any unforeseen problems or expenses arise in the course of carrying out the services the Company shall endeavour to inform Client and shall be entitled to charge additional fees to cover extra time and cost necessarily incurred to complete the services. (g) If the Company is unable to perform all or part of the services for any cause whatsoever outside the Company's control including failure by Client to comply with any of its obligations provided for in clause 3 above the Company shall nevertheless be entitled to payment of:

(a) The Company will provide services using reasonable care and skill and in accordance with Client's specific instructions as confirmed by the Company or, in the absence of such (1) the amount of all non-refundable expenses incurred by the Company; and instructions: (2) a proportion of the agreed fee equal to the proportion of the services actually carried (1) the terms of any standard order form or standard specification sheet of the Company; out. and/or (2) any relevant trade custom, usage or practice; and/or 5. Suspension or Termination of Services (3) such methods as the Company shall consider appropriate on technical, operational and/or financial grounds. (b) Information stated in Reports of Findings is derived from the results of inspection or testing procedures carried out in accordance with the instructions of Client, and/or our assessment of such results on the basis of any technical standards, trade custom or practice, or other circumstances which should in our professional opinion be taken into account. (c) Reports of Findings issued further to the testing of samples contain the Company's opinion on those samples only and do not express any opinion upon the lot from which the samples were drawn. (d) Should Client request that the Company witness any third party intervention, Client agrees that the Company's sole responsibility is to be present at the time of the third party's intervention and to forward the results, or confirm the occurrence, of the intervention. Client agrees that the Company is not responsible for the condition or calibration of apparatus, instruments and measuring devices used, the analysis methods applied, the qualifications, actions or omissions of third party personnel or the analysis results. (e) Reports of Findings issued by the Company will reflect the facts as recorded by it at the time of its intervention only and within the limits of the instructions received or, in the absence of such instructions, within the limits of the alternative parameters applied as provided for in clause 2(a). The Company is under no obligation to refer to, or report upon, any facts or circumstances which are outside the specific instructions received or alternative parameters applied. (f) The Company may delegate the performance of all or part of the services to an agent or subcontractor and Client authorises Company to disclose all information necessary for such performance to the agent or subcontractor. (g) Should Company receive documents reflecting engagements contracted between Client and third parties or third party documents, such as copies of sale contracts, letters of credit, bills of lading, etc., they are considered to be for information only, and do not extend or restrict the scope of the services or the obligations accepted by the Company. (h) Client acknowledges that the Company, by providing the services, neither takes the place of Client or any third party, nor releases them from any of their obligations, nor otherwise assumes, abridges, abrogates or undertakes to discharge any duty of Client to any third party or that of any third party to Client. (i) All samples shall be retained for a maximum of 3 months or such other shorter time period as the nature of the sample permits and then returned to Client or otherwise disposed of at the Company's discretion after which time Company shall cease to have any responsibility for such samples. Storage of samples for more than 3 months shall incur a storage charge payable by Client. Client will be billed a handling and freight fee if samples are returned. Special disposal charges will be billed to Client if incurred. 3. Obligations of Client The Client will: (a) ensure that sufficient information, instructions and documents are given in due time (and, in any event not later than 48 hours prior to the desired intervention) to enable the required services to be performed; (b) procure all necessary access for the Company's representatives to the premises where the services are to be performed and take all necessary steps to eliminate or remedy any obstacles to, or interruptions in, the performance of the services; (c) supply, if required, any special equipment and personnel necessary for the performance of the services; (d) ensure that all necessary measures are taken for safety and security of working conditions, sites and installations during the performance of services and will not rely, in this respect, on the Company's advice whether required or not; (e) inform Company in advance of any known hazards or dangers, actual or potential, associated with any order or samples or testing including, for example, presence or risk of radiation, toxic or noxious or explosive elements or materials, environmental pollution or poisons; (f) fully exercise all its rights and discharge all its liabilities under any relevant sales or other contract with a third party and at law. 4. Fees and Payment (a) Fees not established between the Company and Client at the time the order is placed or a contract is negotiated shall be at the Company's standard rates (which are subject to change) and all applicable taxes shall be payable by Client. The Company shall be entitled to immediately and without liability either suspend or terminate provision of the services in the event of: (a) failure by the Client to comply with any of its obligations hereunder and such failure is not remedied within 10 days that notice of such failure has been notified to Client; or (b) any suspension of payment, arrangement with creditors, bankruptcy, insolvency, receivership or cessation of business by Client. 6. Liability and Indemnification (a) Limitation of Liability: (1) The Company is neither an insurer nor a guarantor and disclaims all liability in such capacity. Clients seeking a guarantee against loss or damage should obtain appropriate insurance. (2) Reports of Findings are issued on the basis of information, documents and/or samples provided by, or on behalf of, Client and solely for the benefit of Client who is responsible for acting as it sees fit on the basis of such Reports of Findings. Neither the Company nor any of its officers, employees, agents or subcontractors shall be liable to Client nor any third party for any actions taken or not taken on the basis of such Reports of Findings nor for any incorrect results arising from unclear, erroneous, incomplete, misleading or false information provided to the Company. (3) The Company shall not be liable for any delayed, partial or total non-performance of the services arising directly or indirectly from any event outside the Company's control including failure by Client to comply with any of its obligations hereunder. (4) The liability of the Company in respect of any claim for loss, damage or expense of any nature and howsoever arising shall in no circumstances exceed a total aggregate sum equal to 10 times the amount of the fee paid in respect of the specific service which gives rise to such claim or US$20,000 (or its equivalent in local currency), whichever is the lesser. (5) The Company shall have no liability for any indirect or consequential loss (including loss of profits). (6) In the event of any claim, Client must give written notice to the Company within 30 days of discovery of the facts alleged to justify such claim and, in any case, the Company shall be discharged from all liability for all claims for loss, damage or expense unless suit is brought within one year from: (i) the date of performance by the Company of the service which gives rise to the claim; or (ii) the date when the service should have been completed in the event of any alleged non-performance. (b) Indemnification: Client shall guarantee, hold harmless and indemnify the Company and its officers, employees, agents or subcontractors against all claims (actual or threatened) by any third party for loss, damage or expense of whatsoever nature including all legal expenses and related costs and howsoever arising relating to the performance, purported performance or non-performance, of any services. 7. Miscellaneous (a) If any one or more provisions of these General Conditions are found to be illegal or unenforceable in any respect, the validity, legality and enforceability of the remaining provisions shall not in any way be affected or impaired thereby. (b) During the course of providing the services and for a period of one year thereafter Client shall not directly or indirectly entice, encourage or make any offer to Company's employees to leave their employment with the Company. (c) Use of the Company's corporate name or registered marks for advertising purposes is not permitted without the Company's prior written authorisation. 8. Governing Law, Jurisdiction and Dispute Resolution Unless specifically agreed otherwise, all disputes arising out or in connection with Contractual Relationship(s) hereunder shall be governed by the substantive laws of Switzerland exclusive of any rules with respect to conflicts of laws and be finally settled under the Rules of Arbitration of the international Chambers of Commerce by one or more arbitratiors appointed in accordance with the said rules. The arbitration shall take place in Paris (France) and be conducted in the English language.

12

1 June 2004

You might also like

- Crude Oil Assay Report: OriginalDocument14 pagesCrude Oil Assay Report: Originaldassi99No ratings yet

- Walio Crude SummaryDocument19 pagesWalio Crude SummaryMaria MonguiNo ratings yet

- Al Shaheen AssayDocument23 pagesAl Shaheen Assaydassi99No ratings yet

- North West Shelf Condensate Feb 2012Document3 pagesNorth West Shelf Condensate Feb 2012hbatesNo ratings yet

- Ostra Crude Oil (70 - 30)Document1 pageOstra Crude Oil (70 - 30)coolwet90No ratings yet

- Crude Oil Assay (Assignment 1) (FINAL)Document12 pagesCrude Oil Assay (Assignment 1) (FINAL)Fabliha KhanNo ratings yet

- Crude Oil Doba Assay PDFDocument1 pageCrude Oil Doba Assay PDFHariajahNo ratings yet

- Bach Ho Crude Oil AssayDocument11 pagesBach Ho Crude Oil Assayhbates0% (1)

- Arabian Light Crude Oil AnalysisDocument2 pagesArabian Light Crude Oil AnalysisShahzeb HassanNo ratings yet

- Viscosity IndexDocument3 pagesViscosity Indexdassi99No ratings yet

- 2013 Capline Crude Oil Assay ReportDocument4 pages2013 Capline Crude Oil Assay Reportkwing175No ratings yet

- Crude Oil Analysis ResultsDocument18 pagesCrude Oil Analysis Resultslutfi awnNo ratings yet

- AttakaDocument6 pagesAttakaM Alim Ur RahmanNo ratings yet

- Assay of Crude OilDocument1 pageAssay of Crude OilabdsalNo ratings yet

- Alcohol OctaneDocument18 pagesAlcohol OctanetoanvmpetrologxNo ratings yet

- CFC 1criterionbrochureDocument19 pagesCFC 1criterionbrochureSuraj Amin100% (1)

- Benchmarking of Refinery CO2 EmissionsDocument4 pagesBenchmarking of Refinery CO2 EmissionsChKaldNo ratings yet

- Density and Values of Crude Oil PDFDocument9 pagesDensity and Values of Crude Oil PDFRichard Amorin0% (1)

- Crude AssayDocument11 pagesCrude AssayTrịnh Nguyên TrườngNo ratings yet

- Hydrogen Management in An Oil RefineryDocument1 pageHydrogen Management in An Oil RefineryOMID464No ratings yet

- Sokol15F: 3225 Gallows Road, 4B0418 Fairfax, Virginia 22037-0001Document1 pageSokol15F: 3225 Gallows Road, 4B0418 Fairfax, Virginia 22037-0001asad razaNo ratings yet

- Characteristics and Properties of Heavy Crude Oil FractionsDocument10 pagesCharacteristics and Properties of Heavy Crude Oil FractionsIlian DinkovNo ratings yet

- Crude Oil Assay From South LokicharDocument10 pagesCrude Oil Assay From South LokicharKivuti100% (1)

- 02 Assay WTI OGJDocument21 pages02 Assay WTI OGJHassan Funsho AkandeNo ratings yet

- Classification of Crude OilDocument3 pagesClassification of Crude OilY. Dutt50% (4)

- Meaning of CompatibilityDocument19 pagesMeaning of CompatibilityRodrigo FernandesNo ratings yet

- Global Crude Assay Report 15-4019 Doba Crude Rev2Document16 pagesGlobal Crude Assay Report 15-4019 Doba Crude Rev2hbates100% (1)

- Crude assay template for PetroPlan analysisDocument4 pagesCrude assay template for PetroPlan analysisEdi SaputraNo ratings yet

- Lecture 3 Conversion and Characterisation - IITB - 2022Document35 pagesLecture 3 Conversion and Characterisation - IITB - 2022J JayaNo ratings yet

- Asphatene Ppt. in Crude Oils PDFDocument19 pagesAsphatene Ppt. in Crude Oils PDFOguamahIfeanyiNo ratings yet

- Properties of Crude Oil and Petroleum ProductsDocument54 pagesProperties of Crude Oil and Petroleum ProductsMihaelaPaval0% (1)

- Crude Oil Assay ManualDocument41 pagesCrude Oil Assay Manualman45039No ratings yet

- Crude OilDocument5 pagesCrude OilSyed Bakhtyar AhmedNo ratings yet

- Liverpool Bay Crude Oil Assay ReportC5 - 70C5 -1583.4- 12.82.5- 10.29.47.770 - 140158 - 28412.8- 31.810.2- 27.819.017.6wgt%vol%wgt%vol%0.1160.0840.0840.0840.0980.0980.0980.0980.0980.0980.0980.0980Document15 pagesLiverpool Bay Crude Oil Assay ReportC5 - 70C5 -1583.4- 12.82.5- 10.29.47.770 - 140158 - 28412.8- 31.810.2- 27.819.017.6wgt%vol%wgt%vol%0.1160.0840.0840.0840.0980.0980.0980.0980.0980.0980.0980.0980santhoshkumar_g100% (1)

- Crude Oil Assay Database - Crude Oil Data Source References - KnovelDocument3 pagesCrude Oil Assay Database - Crude Oil Data Source References - KnovelValeanu Ermil100% (1)

- Basra Light - Summary Crude Oil Assay ReportDocument3 pagesBasra Light - Summary Crude Oil Assay ReportAhmed Mohamed KhalilNo ratings yet

- Crude Assay - Lecture NotesDocument18 pagesCrude Assay - Lecture Notessam joseph100% (1)

- LP-Staffing & BlendingDocument15 pagesLP-Staffing & BlendingJobayer Islam TunanNo ratings yet

- Lec 4Document7 pagesLec 4اسامه عمر عثمانNo ratings yet

- 3 Classification of PetroliumDocument42 pages3 Classification of PetroliumHatif AlamNo ratings yet

- CrudeDocument4 pagesCrudeTaha Khan100% (1)

- 2012 PHD Thesis Asok Tharanivasan - Shell 16000 - P Value PDFDocument211 pages2012 PHD Thesis Asok Tharanivasan - Shell 16000 - P Value PDFHimanshu SharmaNo ratings yet

- Prediction of Viscosities of Petroleum Fractions, Yavuz Yorulmaz, 2009Document13 pagesPrediction of Viscosities of Petroleum Fractions, Yavuz Yorulmaz, 2009Anonymous Xy309m9Sm9No ratings yet

- Crude Oil Assay SlateDocument2 pagesCrude Oil Assay Slatemahmoudmaklad100% (1)

- Estimating PVT Properties of Crude Oil Systems Based On A Boosted Decision Tree Regression Modelling Scheme With K-Means ClusteringDocument15 pagesEstimating PVT Properties of Crude Oil Systems Based On A Boosted Decision Tree Regression Modelling Scheme With K-Means ClusteringLibya TripoliNo ratings yet

- Calculation of Blend Octane PDFDocument18 pagesCalculation of Blend Octane PDFmohanspathak0% (1)

- Crude Assay vs. HTSDDocument0 pagesCrude Assay vs. HTSDmahmoudmakladNo ratings yet

- Optimize oil blending decisions with linear programmingDocument8 pagesOptimize oil blending decisions with linear programmingjulio49No ratings yet

- Naptha Hydrotreating Catalysts PDFDocument2 pagesNaptha Hydrotreating Catalysts PDFElena Ricci100% (1)

- Crude and Refinery CalculationsDocument4 pagesCrude and Refinery Calculationsbakhtyar21100% (1)

- Notes On Petroleum ProcessingDocument94 pagesNotes On Petroleum ProcessingVânia CunhaNo ratings yet

- Transportation of Waxy Crude OilsDocument23 pagesTransportation of Waxy Crude OilsIshan Haider100% (2)

- Effect of Heavy Metals in Crude OilDocument6 pagesEffect of Heavy Metals in Crude OilDarl NwokomaNo ratings yet

- Innovation For Refinery With ModellingDocument5 pagesInnovation For Refinery With ModellingJulio Adolfo López PortocarreroNo ratings yet

- Sweet Crude CompositionDocument278 pagesSweet Crude Compositionthermo_engineerNo ratings yet

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Bintulu Condensate RegularDocument12 pagesBintulu Condensate Regulardassi99No ratings yet

- Distillation Column CostinglaaDocument2 pagesDistillation Column CostinglaaapiskaiNo ratings yet

- EO Purifier - My ReportDocument71 pagesEO Purifier - My ReportapiskaiNo ratings yet

- 5411 1Document12 pages5411 1apiskaiNo ratings yet

- OGP 390-Aircraft Management Guidelines 2013Document214 pagesOGP 390-Aircraft Management Guidelines 2013Daniela ColmenaresNo ratings yet

- Syukri Hashim 1Document2 pagesSyukri Hashim 1apiskaiNo ratings yet

- Optimizin ProdDocument12 pagesOptimizin ProdAdian AndrewsNo ratings yet

- SyukkDocument9 pagesSyukkapiskaiNo ratings yet

- Plant Design 101Document6 pagesPlant Design 101apiskaiNo ratings yet

- A Study On Different Water Cuts and Effect of Halide IonicDocument4 pagesA Study On Different Water Cuts and Effect of Halide Ionicapiskai3096No ratings yet

- Chapter 03Document37 pagesChapter 03apiskaiNo ratings yet

- 272AADocument154 pages272AAapiskaiNo ratings yet

- Selection of ControlsDocument12 pagesSelection of ControlsapiskaiNo ratings yet

- Vessel Inspection Check List 1 PDFDocument49 pagesVessel Inspection Check List 1 PDFapiskai100% (2)

- Logistics of Production and InventoryDocument747 pagesLogistics of Production and InventoryMauro Andres100% (2)

- A Conceptual Design of Novel Reactor For Liquid-Phase Oxidation of P-XyleneDocument2 pagesA Conceptual Design of Novel Reactor For Liquid-Phase Oxidation of P-XyleneNoi Chem-EnNo ratings yet

- Petrol General Information: Key PointsDocument5 pagesPetrol General Information: Key PointsapiskaiNo ratings yet

- A Conceptual Design of Novel Reactor For Liquid-Phase Oxidation of P-XyleneDocument2 pagesA Conceptual Design of Novel Reactor For Liquid-Phase Oxidation of P-XyleneNoi Chem-EnNo ratings yet

- ENERGY SAVING POTENTIAL FOR NATURAL GAS HYDRATE TRANSPORTATIONDocument2 pagesENERGY SAVING POTENTIAL FOR NATURAL GAS HYDRATE TRANSPORTATIONapiskaiNo ratings yet

- EIS July 06Document3 pagesEIS July 06apiskaiNo ratings yet

- Table of ContentsDocument2 pagesTable of ContentsapiskaiNo ratings yet

- Production 01Document20 pagesProduction 01Rizwan FaridNo ratings yet

- ME4105 NUS Offshore Oil and Gas Technology Lecture 3Document15 pagesME4105 NUS Offshore Oil and Gas Technology Lecture 3fardin77No ratings yet

- API GravityDocument3 pagesAPI Gravityargon sanjayaNo ratings yet

- Project Title:: Production of Candles (Rewax) Using Vegetable Shortening Instead of Paraffin WaxDocument4 pagesProject Title:: Production of Candles (Rewax) Using Vegetable Shortening Instead of Paraffin WaxainaNo ratings yet

- Welding Manual PDFDocument767 pagesWelding Manual PDFraghavender1No ratings yet

- Toxicology of Hydrocarbons: Classification, Characteristics, Toxicity and ManagementDocument18 pagesToxicology of Hydrocarbons: Classification, Characteristics, Toxicity and ManagementHusam ShawagfehNo ratings yet

- Hydrocarbon 4Document35 pagesHydrocarbon 4AjayNo ratings yet

- Kuster Company ManualDocument28 pagesKuster Company ManualarjmandquestNo ratings yet

- MAN B - W 46-26 MC - MC-C-TII Type Engines PDFDocument315 pagesMAN B - W 46-26 MC - MC-C-TII Type Engines PDFisrafatNo ratings yet

- 2013 Fractured Weathered Basement Reservoirs Best Practices For Exploration Production - Examples From USA, Venezuela, and Brazil - Tako KoningDocument29 pages2013 Fractured Weathered Basement Reservoirs Best Practices For Exploration Production - Examples From USA, Venezuela, and Brazil - Tako KoningHafizhan Abidin SetyowiyotoNo ratings yet

- Heatmor Pellet BurnerDocument12 pagesHeatmor Pellet BurnerHelicon1No ratings yet

- Julian Banzon: Filipino ChemistDocument3 pagesJulian Banzon: Filipino ChemistJeanne Martin100% (1)

- Downstream Processing Prof. Mukesh Doble Department of Biotechnology Indian Institute of Technology, Madras Lecture No - 35 CrystallisationDocument40 pagesDownstream Processing Prof. Mukesh Doble Department of Biotechnology Indian Institute of Technology, Madras Lecture No - 35 CrystallisationPavanNo ratings yet

- Engine Oil for Gasoline and Diesel EnginesDocument2 pagesEngine Oil for Gasoline and Diesel EnginesdnoaisapsNo ratings yet

- ULTRAMAX High Power Cartridge HeatersDocument33 pagesULTRAMAX High Power Cartridge HeatersThiago SoaresNo ratings yet

- Meeting Growing Alky LateDocument18 pagesMeeting Growing Alky LateChristianGuerreroNo ratings yet

- Wim de Greyt - Desmet Ballestra Group - Introduction On Glycerol As Co-Product of Biodiesel ProductionDocument12 pagesWim de Greyt - Desmet Ballestra Group - Introduction On Glycerol As Co-Product of Biodiesel Productionsamyusekhar100% (1)

- Dryer: Owner'S ManualDocument92 pagesDryer: Owner'S ManualCarlos SalcedoNo ratings yet

- Eurofire Training Ef6 IgnitionDocument23 pagesEurofire Training Ef6 IgnitionFG SummerNo ratings yet

- Steiner 525 OpDocument34 pagesSteiner 525 OpMuhamad Nur Firdaus100% (1)

- Report 10Document144 pagesReport 10Muhib Ullah KhanNo ratings yet

- Petroleum Refining Crude Oil Refining Processes PDFDocument6 pagesPetroleum Refining Crude Oil Refining Processes PDFJAPAN NANAVATI0% (1)

- GSX-R750 1996-'99 Parts ListDocument102 pagesGSX-R750 1996-'99 Parts ListCarlos Gustavo Flores TalaveraNo ratings yet

- Yllana Bay View College, IncDocument6 pagesYllana Bay View College, IncJoel Cabusao Lacay100% (1)

- Water & Gas Coning in Horizontal & Vertical WellDocument21 pagesWater & Gas Coning in Horizontal & Vertical WellNoraeen EleanorNo ratings yet

- 9 Tubing Tools 15Document70 pages9 Tubing Tools 15Radu ChibzuiNo ratings yet

- EB00002 RK23191 Marine WIF ProbeDocument2 pagesEB00002 RK23191 Marine WIF ProbeWrkDeeNo ratings yet

- 2016 MC 280Document7 pages2016 MC 280MUHAMMA ASADNo ratings yet

- ESTERSDocument10 pagesESTERSMimie Yasmin KamalNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFNicolae VisanNo ratings yet