Professional Documents

Culture Documents

M60 RS-232 Procedure

Uploaded by

davilson luzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M60 RS-232 Procedure

Uploaded by

davilson luzCopyright:

Available Formats

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.

USA-E99081-071-*

I. Set-up:

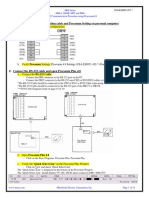

1) Set-up the RS-232 communication cable and Procomm Setting on personal computer

a. Verify the RS-232 Cable configuration.

(TD) (SD) (RTS) (CTS) (DSR) (DCD) (DTR) (SG)

2 3 4 5 6 8 20 7

2 3 7 8 1 4 6 5

(RD) (SD) (RTS) (CTS) (DCD) (DTR) (DSR) (SG)

b. Verify Procomm Settings [Procomm 4.8 Settings (USA-E99971-162-*) Document].

2) Connect the RS-232 cable and open Procomm Plus 4.8

a. Connect the RS-232 Cable;

- Connect the DB9 connector to the RS-232 port on the PC. - Connect the DB25 connector to the RS-232 onto CH2 (of F031/F032 cable) or the RS-232 port (on the HR377/8). *The RS-232 Cable should be connected to the CH2 of F031 or F032 Cable when using the HR211. *The RS-232 Cable should be connected to the RS-232 port of the HR377 or HR378. ** F030 Cable Diagram found on page 10 of 10.

RS-232

b. Open Procomm Plus 4.8

Click on the Start, Programs, Procomm Plus, Procomm Plus

c. Verify the Quick Select Line on the Procomm Plus Window

- Click on View and check Quick Select Line The Quick Select Line is displayed on the bottom of the Procomm Window. The Quick Select Line should display VT-100, ASCII, direct connect-COM1, 9600, E72

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 1 of 10

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

3) Set-up the M60 series I/O parameters

a. Access the I/O Parameters;

Press the [TOOL/PARAM] Function Key Press the [MENU] Key Press the [I/O PAR] Menu Key

You should see [I/O BASE PARAM] on the upper-left and page (1/7) on the upper-right of the NC screen.

b. Set DATA IN for Port 2 and Device 0;

On the [I/O BASE PARAM] page (1/7) - Press [9001], [>]cursor, [2] then [INPUT] - Press [9002], [>]cursor, [0] then [INPUT]

c. Set DATA OUT for Port 2 and Device 0;

On the [I/O BASE PARAM] page (1/7) - Press [9003], [>]cursor, [2] then [INPUT] - Press [9004], [>]cursor, [0] then [INPUT] You should see the following: <I/O> #<PORT No> DATA IN 9001 2 DATA OUT 9003 2

#<DEVIC No> 9002 0 9004 0

d. Set the Device 0 Parameters;

First Access the I/O Parameters then - Press [>] Page Key On the [I/O DEVICE PARAM] DEV. 0 page (2/7) - Press [9101], [>] cursor, [TSS] then [INPUT] - Press [9102], [>] cursor, [1] then [INPUT] - Press [9103], [>] cursor, [3] then [INPUT] - Press [9104], [>] cursor, [0] then [INPUT] - Press [9105], [>] cursor, [0] then [INPUT] - Press [9106], [>] cursor, [3] then [INPUT] - Press [9107], [>] cursor, [0] then [INPUT] - Press [9108], [>] cursor, [3] then [INPUT] - Press [9109], [>] cursor, [1] then [INPUT] - Press [9111], [>] cursor, [0] then [INPUT] - Press [9112], [>] cursor, [1] then [INPUT] - Press [9113], [>] cursor, [0] then [INPUT] - Press [9114], [>] cursor, [0] then [INPUT] - Press [9115], [>] cursor, [0] then [INPUT] - Press [9116], [>] cursor, [0] then [INPUT] - Press [9117], [>] cursor, [0] then [INPUT] - Press [9118], [>] cursor, [0] then [INPUT]

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 2 of 10

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

II. Disable Edit Locks:

1) Verify that the edit switch on the operation panel is set to OFF 2) Verify and set the Edit Lock B Parameter on the Process Parameter Screen

a. Access the Process Parameter;

Press the [TOOL/PARAM] Function Key Press the [MENU] Key Press the [PROCESS] Menu Key

You should see [PROCESS PARAMETER] on the upper left and page (1/4) on the upper right of the NC screen.

b. Verify and change the #8105 EDIT LOCK B parameter;

First access the Process Parameter then - Press [>] Page Key You should see [CONTROL PARAMETER] on the upper left and page (2/4) on the upper right of the NC screen. - View and write down the current value of parameter #8105. * You will need to set this back to the original value when completed. Press [8105], [>] cursor, [0] then [INPUT]

3) Verify and set the Edit Lock C Parameters on the Set-Up Parameter Screen

a. Access the Set-up Parameter;

Press the [TOOL/PARAM] Function Key Press the [MENU] Key Press the [SETUP] Menu Key Press the [Y] then [INPUT]

You should see [BASE SPEC. PARAM] on the upper left and page (1/14) on the upper right of the NC screen.

b. Verify and change the #1121 edlk_c and #1121 pglk_c parameter;

First access the Set-Up Parameter then. - Press [>] Page Key four times You should see [CONTROL PARAMETER] on the upper left and page (5/14) on the upper right of the screen. - View and write down the current value of #1121 and #1122. * You will need to set this back to the original value when completed. Press [1121], [>] cursor, [0] then [INPUT] Press [1122], [>] cursor, [0] then [INPUT]

III. Output and Input of User Data

1) Output of User Data - Programs, Tool Data, Common Variables and Macro Programs

a. Access the DATA OUTPUT screen

Press the [DIAGN IN/OUT] Function Key Press the [MENU] Key two times Press the [OUTPUT] Menu Key

You should see [DATA OUTPUT] on the upper left-side of the screen.

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 3 of 10

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

b. Output all Programs

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60Programs (it should save it as a .txt file) iii. Click Save On the M60, DATA OUTPUT screen; - Press [1], [>] cursor, [ALL], then [Input]

c. Output a single Program (For example program number 123)

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as Program123 (it should save it as a .txt file) iii. Click Save On the M60, DATA OUTPUT screen; - Press [1], [>] cursor, [123], then [Input]

d. Output a range of program (For example programs between 123 through 789)

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60programs2 (it should save it as a .txt file) iii. Press Save On the M60, DATA OUTPUT screen; - Press [1], [>] cursor, [123], [>] cursor,[789] then [Input]

e. Output all Tool Data

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60Tools (it should save it as a .txt file) iii. Press Save On the M60, DATA OUTPUT screen; - Press [2], [>] cursor, [ALL], then [Input]

f.

Output all Common Variables

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60Variables (it should save it as a .txt file) iii. Press Save On the M60, DATA OUTPUT screen; - Press [5], [>] cursor, [ALL], then [Input]

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 4 of 10

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

g. Output all Macro Programs

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60Tools (it should save it as a .txt file) iii. Press Save On the M60, DATA OUTPUT screen; - Press [30], [>] cursor, [ALL], then [Input]

2) Input of User Data - Programs, Tool Data, Common Variables and Macro Programs

a) Access the DATA INPUT screen

Press the [DIAGN IN/OUT] Function Key Press the [MENU] Key two times Press the [INPUT] Menu Key

You should see [DATA INPUT] on the upper left-side of the screen.

b) Input all Programs

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [1], [>] cursor, then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60Programs (it should save it as a .txt file) iii. Click Save

c) Input a single Program (For example program number 123)

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [1], [>] cursor, then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as Program123 (it should save it as a .txt file) iii. Click Save

d) Input all Tool Data

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [2], [>] cursor, then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60Tools (it should save it as a .txt file) iii. Press Save

e) Input all Common Variables

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [5], [>] cursor, then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60Variables (it should save it as a .txt file) iii. Press Save Mitsubishi Electric Automation, Inc. Page 5 of 10

www.meau.com

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

f) Input all Macro Programs

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [30], [>] cursor, then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60Macros (it should save it as a .txt file) iii. Press Save

IV. Stop PLC, Output and Input Maintenance Information

1) Stop the PLC to backup Maintenance Data

a) Prepare the machine

Command each axis to machine zero Press Reset Press the Emergency Stop Button

b) Access the Bit Select Screen

Press the [TOOL/PARAM] Function Key Press the [MENU] Key Press the [SETUP] Menu Key Press the [Y] then [INPUT] Key Press the [MENU] Key Press the [PLC] Menu Key Press [>] Page Key four times

You should see [BIT SELECT] on the upper left-side and page (5/6) on the upper right-side of the NC screen.

c) Enable the PLC On-board Function

First Access the Bit Select screen. - View and write down the current value of #6451 bit 0. * You will need to set this back to its original value. Press [6451], [>] cursor eight times, [1] (under bit-0), then [INPUT]

d) Access the 4RUN/SP screen

Press the [F0] Function Key Press the [MENU] Key Press the [FILE] Menu Key Press the [4RUN/SP] Menu Key

e) Stop the PLC

First access the 4RUN/SP screen - Press [1], then [INPUT]

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 6 of 10

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

2) SRAM Data Details

No. 100 102 103 105 106 107 108 109 110 111 112 113 114 ALL 1 Data Output Data Details System Common Parameters Axis Independent Parameters Machine Error Offset Data, Offset Amount PLC Constants, Work Counter (R2800~2899) PLC Timer PLC Timer Bit Selection Parameter (R2900~2947) (not used) Work Offset Registers (R2950~3639) R Register User Backup (R1900~2799) PLC Latch Relay PLC Switch ALL 2 Data Output Data Details Tool Length Offset (shape) Tool Offset (X shape) Tool Length Offset (wear) Tool Offset (X wear) Tool Diameter Offset (shape) Tool Offset (Z shape) Tool Diameter Offset (wear) Tool Offset (Z wear) Tool Offset (Y shape) Tool Life Tool Offset (Y wear) ALL 3 Data Output Data Details Ladder No. 115 116 117 130 133 134 135 136 138 140 141 142 150 152 No. 206 207 208 209 210 230 231 No. 270 Data Details Program Numbers Timer Cumulative Output Counter Cumulative Output Tool Life Management (R3000~3639) Position Switch PLC Timer Cumulative Current Value PLC Counter Cumulative Current Value R Register System Backup (R1880~1899) Tool Life Management II (R5480~6279) Spindle Parameters Communication Parameters Common Variable Name Data History (Operation History) Special Process Backup Data Details Nose R (shape) Nose R (wear) Nose Point No. Data Common Variables for Both (#500~ ) Common Variable Valid Flags for Both (#500~ ) Common Variables Independent for System (#100~ ) Common Variable Valid Flags Independent for System (#100~) Data Details Ladder Message

No. 200 201 202 203 204 205

No. 250

3) Output of Maintenance Data Parameters, ALL1, ALL2 & ALL3

a) Access the DATA OUTPUT screen

Press the [DIAGN IN/OUT] Function Key Press the [MENU] Key two times Press the [OUTPUT] Menu Key

You should see [DATA OUTPUT] on the upper left-side of the screen.

b) Output all Parameters

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60Parameters (it should save it as a .txt file) iii. Click Save On the M60, DATA OUTPUT screen; - Press [3], [>] cursor, [ALL], then [Input]

c) Output ALL1 Maintenance Data

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60ALL1 (it should save it as a .txt file) iii. Click Save On the M60, DATA OUTPUT screen; - Press [99], [>] cursor, [ALL1], then [Input]

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 7 of 10

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

d) Output ALL2 Maintenance Data

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60ALL2 (it should save it as a .txt file) iii. Press Save On the M60, DATA OUTPUT screen; - Press [99], [>] cursor, [ALL2], then [Input]

e) Output ALL3 Maintenance Data

First Access the DATA OUTPUT screen on the M60 control - Set-up Procomm to receive a file i. Press Ctrl+Alt+4 on the personal computer (make sure the Procomm Window is active) ii. Type in a file name such as M60ALL3 (it should save it as a .txt file) iii. Press Save On the M60, DATA OUTPUT screen; - Press [99], [>] cursor, [ALL3], then [Input]

4) Input of Maintenance Data Parameters, ALL1, ALL2 & ALL3

a) Open the system area

Press the [TOOL/PARAM] Function Key Press the [MENU] Key Press the [SETUP] Menu Key Press the [Y] then [INPUT] Press the [Page] Key Press the [1060], [>] cursor, [64], [>], [S] Press the [INPUT] two times

b) Access the DATA INPUT screen

Press the [DIAGN IN/OUT] Function Key Press the [MENU] Key two times Press the [INPUT] Menu Key

You should see [DATA INPUT] on the upper left-side of the screen.

c) Input all Parameters

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [3], [>] cursor, then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60Parameters (it should save it as a .txt file) iii. Click Save

d) Input ALL1 Maintenance Data

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [99], [>] cursor, [ALL1], then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60ALL1 (it should save it as a .txt file) iii. Click Save Mitsubishi Electric Automation, Inc. Page 8 of 10

www.meau.com

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

e) Input ALL2 Maintenance Data

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [99], [>] cursor, [ALL2], then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60ALL2 (it should save it as a .txt file) iii. Press Save

f) Input ALL3 Maintenance Data

First Access the DATA INPUT screen on the M60 control On the M60, DATA INPUT screen; - Press [99], [>] cursor, [ALL3], then [Input] Set-up Procomm to send a file i. Press Ctrl+Alt+3 on the personal computer (make sure the Procomm Window is active) ii. Choose the file such as M60ALL3 (it should save it as a .txt file) iii. Press Save

5) Restart the PLC

a. Access the Bit Select Screen

Press the [TOOL/PARAM] Function Key Press the [MENU] Key three times Press the [PLC] Menu Key Press the [>] Page Key four times

You should see [BIT SELECT] on the upper left-side and page (5/6) on the upper right-side of the NC screen.

b. Access the 4RUN/SP screen

Press the [F0] Function Key Press the [MENU] Key Press the [FILE] Menu Key Press the [4RUN/SP] Menu Key

c. Restart the PLC

First access the 4RUN/SP screen - Press [0], then [INPUT]

d. Cycle Power to the Machine

Power OFF the M60 control and Main Circuit Breaker Power ON the Main Breaker and M60

V. Set all changes back to original setting

1) Set the Edit Lock B Parameter to its original setting

a) Access the Process Parameter;

Press the [TOOL/PARAM] Function Key Press the [MENU] Key Press the [PROCESS] Menu Key

You should see [PROCESS PARAMETER] on the upper left and page (1/4) on the upper right of the NC screen.

b) Verify and change the #8105 EDIT LOCK B parameter to its original setting

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 9 of 10

M60 Series - M64A, M64B, M65 and M66 RS-232 Communication Procedure using Procomm4.8

2) Set the Edit Lock C Parameters to its original setting

a) Access the Set-up Parameter;

Press the [TOOL/PARAM] Function Key Press the [MENU] Key Press the [SETUP] Menu Key Press the [Y] then [INPUT]

You should see [BASE SPEC. PARAM] on the upper left and page (1/14) on the upper right of the NC screen.

b) Verify and change the #1121 edlk_c and #1121 pglk_c parameter to its original setting

3) Set the PLC On-board Bit Select to its original setting

a) Access the Bit Select Screen

Press the [TOOL/PARAM] Function Key Press the [MENU] Key three times Press the [PLC] Menu Key Press the [>] Page Key four times

You should see [BIT SELECT] on the upper left-side and page (5/6) on the upper right-side of the NC screen. b) Verify and change #6451 Bit 0 to its original setting

VI. F030 Cable

www.meau.com

Mitsubishi Electric Automation, Inc.

Page 10 of 10

You might also like

- M64 RS 232 Setup PDFDocument9 pagesM64 RS 232 Setup PDFLuthfi Naufal WaliyyudienNo ratings yet

- M60 RS 232 Procedure PDFDocument10 pagesM60 RS 232 Procedure PDFTony ChangNo ratings yet

- RS232 DNCDocument21 pagesRS232 DNChungNo ratings yet

- Meldas 64Document3 pagesMeldas 64Weng LOk100% (3)

- M320 Backup: Restore Meldas 320 Control with DIP SwitchesDocument2 pagesM320 Backup: Restore Meldas 320 Control with DIP SwitchesPhong HuynhNo ratings yet

- M500 Re-Initialization & Format Procedure: MELDAS 500 SeriesDocument4 pagesM500 Re-Initialization & Format Procedure: MELDAS 500 SeriesRafael López100% (1)

- MAZAK M PLUS T PLUS Memory Upgrade InstructionsDocument10 pagesMAZAK M PLUS T PLUS Memory Upgrade InstructionsraviNo ratings yet

- Bnp-b3484 Centro Usinagem L31-MazakDocument227 pagesBnp-b3484 Centro Usinagem L31-MazakAntonio LucasNo ratings yet

- Citizen M320LC-V Reinitialize and Restore Procedure L16 L20 MachinesDocument6 pagesCitizen M320LC-V Reinitialize and Restore Procedure L16 L20 MachinessunhuynhNo ratings yet

- 6-1. How To Adjust Spindle Orientation For Mitsubishi M520 - 140501Document4 pages6-1. How To Adjust Spindle Orientation For Mitsubishi M520 - 140501323ciNo ratings yet

- M500 Reinitialization & Format ProcedureDocument5 pagesM500 Reinitialization & Format ProcedureElectronicaMecatronics100% (2)

- Fanuc PMC PasswordDocument5 pagesFanuc PMC Passwordthanh_cdt01No ratings yet

- BNP B2288 MeldasDocument376 pagesBNP B2288 Meldaschidambaram kasi100% (2)

- GTXPRESS CNC Lathe Electrical Ladder DiagramDocument202 pagesGTXPRESS CNC Lathe Electrical Ladder DiagramLam PhamNo ratings yet

- Fanuc Pmc-Model Sa1/Sb7 Supplemental Programming Manual (LADDER Language)Document23 pagesFanuc Pmc-Model Sa1/Sb7 Supplemental Programming Manual (LADDER Language)mikeNo ratings yet

- Mitsubishi 500 Memory Installation ManualDocument5 pagesMitsubishi 500 Memory Installation ManualIgnatius Elga PmNo ratings yet

- Mitsubishi Alarm ListDocument19 pagesMitsubishi Alarm Listcoronaqc100% (1)

- Takamaz X-10i E F21iTB 002aDocument290 pagesTakamaz X-10i E F21iTB 002aAle_blessed80% (5)

- CNC Error Code Table AppendixDocument32 pagesCNC Error Code Table Appendixakirenavi100% (1)

- AR Manual Sect 8-10Document32 pagesAR Manual Sect 8-10yoyayoya123No ratings yet

- Fanuc 0 Communications ParametersDocument3 pagesFanuc 0 Communications Parameters88No1Fan50% (2)

- Mazak Matrix Automatic NC Backup ProcedureDocument6 pagesMazak Matrix Automatic NC Backup ProcedureTensaiga100% (2)

- Fanuc O Series Lathe Parameter ManualDocument174 pagesFanuc O Series Lathe Parameter ManualАлексей Зубков100% (3)

- CNC machine alarm codes and solutionsDocument3 pagesCNC machine alarm codes and solutionsAnonymous wBxc1VGtNo ratings yet

- HANDY-ROM User's ManualDocument10 pagesHANDY-ROM User's ManualJamilNo ratings yet

- M64 Series Maintenance DataDocument4 pagesM64 Series Maintenance Datavipvash100% (4)

- MAZAK M32 ParametersDocument67 pagesMAZAK M32 ParametersJesus Abraham Contreras Hernandez100% (4)

- Hi-ROM Instruction Manual (29x-140611)Document77 pagesHi-ROM Instruction Manual (29x-140611)kkcm100% (1)

- Fanuc Model C Serial RS232 Connection GuideDocument6 pagesFanuc Model C Serial RS232 Connection GuideSanchai ProgaeewNo ratings yet

- Parameter ManualDocument794 pagesParameter ManualEX LSNo ratings yet

- SQT 200 - 250 Maintenace OperationDocument179 pagesSQT 200 - 250 Maintenace Operationosteanu100% (4)

- Meldas 60 SeriesDocument443 pagesMeldas 60 SeriesAlinhart EquipamentosNo ratings yet

- FSSB Setup GuideDocument80 pagesFSSB Setup GuideVladimirAgeev100% (7)

- Fanuc: Spindle ControlDocument8 pagesFanuc: Spindle ControlTony AntonyNo ratings yet

- Mori Seiki GPS System Relocation GPSRMS - OperationManual - NFP - Dongle2015 - EngDocument34 pagesMori Seiki GPS System Relocation GPSRMS - OperationManual - NFP - Dongle2015 - EngJuana Chivo100% (3)

- Mazak MplusDocument3 pagesMazak MplusAdmir VukovicNo ratings yet

- Fanuc 0 C BACKUP PDFDocument2 pagesFanuc 0 C BACKUP PDFsunhuynhNo ratings yet

- BNP-A3040 Meldas5000 CNCDocument175 pagesBNP-A3040 Meldas5000 CNCchidambaram kasiNo ratings yet

- Specifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16Document15 pagesSpecifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16avalente112No ratings yet

- Yasnac J300 Connecting Manual (Type B)Document186 pagesYasnac J300 Connecting Manual (Type B)sunhuynh100% (1)

- Okuma Manuals 2771Document96 pagesOkuma Manuals 2771kkcm100% (1)

- COM - TM Series Servo Drive Operation Manual - E (RevB) - 140115 PDFDocument127 pagesCOM - TM Series Servo Drive Operation Manual - E (RevB) - 140115 PDFHakan BlgNo ratings yet

- MELDAS30OODocument164 pagesMELDAS30OOnam tran hoai75% (4)

- Mazak 640 Series How To Restore NC DataDocument4 pagesMazak 640 Series How To Restore NC DataTensaiga100% (1)

- Variaxis Electrical CircuitDocument218 pagesVariaxis Electrical CircuitPaolo GuarnizoNo ratings yet

- Triac Fanuc OM CDocument158 pagesTriac Fanuc OM Cozcnc1975100% (1)

- D5 M640T Parameter H734SA0033EDocument244 pagesD5 M640T Parameter H734SA0033Ezotya54No ratings yet

- Mazak Fusion 640M How To Disable A Servo or Spindle DriveDocument6 pagesMazak Fusion 640M How To Disable A Servo or Spindle DriveTensaigaNo ratings yet

- Mazatrol T-Plus Diagnostic Servo CodesDocument284 pagesMazatrol T-Plus Diagnostic Servo CodesMACKAY9999100% (8)

- Alarm Parameter ManualDocument459 pagesAlarm Parameter ManualDenise Roper50% (2)

- 1 3 4Document43 pages1 3 4JoeNo ratings yet

- M100741H MAI Memex Memory Upgrade For Fanuc 16 182Document32 pagesM100741H MAI Memex Memory Upgrade For Fanuc 16 182Nica BogdanNo ratings yet

- Serial No. 269443: Maintenance Manual Machine Relocation DetectorDocument18 pagesSerial No. 269443: Maintenance Manual Machine Relocation Detectoraditoma44100% (1)

- M520A RS-232 ProcedureDocument12 pagesM520A RS-232 ProcedurePatryk MarczewskiNo ratings yet

- Importantem500 With 9 Inch CRT RS-232 Communication Using Procomm ProcedureDocument6 pagesImportantem500 With 9 Inch CRT RS-232 Communication Using Procomm ProceduredantenromagnoliNo ratings yet

- Calmotion Usbcnc Mazak 5 3mDocument6 pagesCalmotion Usbcnc Mazak 5 3mbuckeyemarv967No ratings yet

- M64 RS-232 SetupDocument9 pagesM64 RS-232 Setupsunhuynh67% (3)

- Maincon Control Software Load Mill VER18 and Lathe VER11Document30 pagesMaincon Control Software Load Mill VER18 and Lathe VER11Hau Le TrungNo ratings yet

- Backup and Restore Procedures for NUM CNC SystemsDocument9 pagesBackup and Restore Procedures for NUM CNC SystemsЕгор ЕгорNo ratings yet

- NCsentry software quick start guideDocument8 pagesNCsentry software quick start guideslametNo ratings yet

- Fanuc LATHE CNC Program Manual Gcodetraining 588Document104 pagesFanuc LATHE CNC Program Manual Gcodetraining 588DOBJAN75% (12)

- FL7NM 3 WireDocument8 pagesFL7NM 3 Wiredavilson luzNo ratings yet

- Parede AngularDocument1 pageParede Angulardavilson luzNo ratings yet

- SVG1202 User GuideDocument58 pagesSVG1202 User Guidedavilson luzNo ratings yet

- History of C00 Software Version Up and Additional FunctionsDocument1 pageHistory of C00 Software Version Up and Additional Functionsdavilson luzNo ratings yet

- c64 Zero Return ProcedureDocument1 pagec64 Zero Return Proceduredavilson luzNo ratings yet

- CNC 8055 M Operator ManualDocument704 pagesCNC 8055 M Operator ManualemigrantuNo ratings yet

- c64 c64t Mode Select by Rotary SwitchDocument4 pagesc64 c64t Mode Select by Rotary Switchdavilson luzNo ratings yet

- Honeywell Vista 21ip Programming GuideDocument24 pagesHoneywell Vista 21ip Programming GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Leonova EmeraldDocument170 pagesLeonova EmeraldbungrisNo ratings yet

- Mill Operation Manual-EnDocument85 pagesMill Operation Manual-EnVahagn DanghyanNo ratings yet

- Logiq P6 Quickstarts: Beginning An ExamDocument5 pagesLogiq P6 Quickstarts: Beginning An ExamjamesNo ratings yet

- Table 23. List of Keyboard ShortcutsDocument2 pagesTable 23. List of Keyboard ShortcutsYahoosufyanNo ratings yet

- CPM For DLT-5500: Communication PlatformDocument54 pagesCPM For DLT-5500: Communication PlatformMauricio Contreras R.No ratings yet

- Function Keys: F1 Word Help) F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12Document8 pagesFunction Keys: F1 Word Help) F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12MUHAMMAD SHAHAZAD MANZOORNo ratings yet

- FLWinLab User's GuideDocument388 pagesFLWinLab User's Guideقاسم فوزي100% (1)

- Series 8000 Mill OperationDocument429 pagesSeries 8000 Mill OperationNumai EuNo ratings yet

- HNC 8 System Operating Manual Milling Machine v2.4 PDFDocument169 pagesHNC 8 System Operating Manual Milling Machine v2.4 PDFSam eagle goodNo ratings yet

- NX-10 Installers Manual English 1060789 R1.0Document257 pagesNX-10 Installers Manual English 1060789 R1.0lokinightmare0% (1)

- REPLAY 3 User GuideDocument141 pagesREPLAY 3 User GuideThe MostNo ratings yet

- Legion Y7000 2019 Series User GuideDocument68 pagesLegion Y7000 2019 Series User GuideYote MeNo ratings yet

- Change of Switching Authority Via Function KeysDocument6 pagesChange of Switching Authority Via Function Keysalex pardoNo ratings yet

- UserGuides TNM-U-E-0081 SRP9130 Plus Brief GuideDocument2 pagesUserGuides TNM-U-E-0081 SRP9130 Plus Brief Guidemoh12109No ratings yet

- 5952 User ManualDocument94 pages5952 User Manualjohnnyj247No ratings yet

- Operator's Manual: AutomatedDocument135 pagesOperator's Manual: AutomatedUladzimir KhmyzNo ratings yet

- Lecturer Computer Science Past Papers Solved Mcqs Download Click HereDocument88 pagesLecturer Computer Science Past Papers Solved Mcqs Download Click Herefozia48% (29)

- Computer Keyboard LayoutDocument7 pagesComputer Keyboard LayoutDanica Kristl Mapalo ConcepcionNo ratings yet

- MedTrak BillingReimbursement 3rdEdition-Revision April 2013Document210 pagesMedTrak BillingReimbursement 3rdEdition-Revision April 2013SkyTurnipNo ratings yet

- TRIA7500 Tot GB PDFDocument464 pagesTRIA7500 Tot GB PDFStefan Šegić100% (2)

- NCM S7 Ethernet Diagnostics: Simatic NetDocument15 pagesNCM S7 Ethernet Diagnostics: Simatic NetMazarel AurelNo ratings yet

- KARMA Kronos Help 2.2.11Document378 pagesKARMA Kronos Help 2.2.11Dan FlaniganNo ratings yet

- How to update the BIOS on your computer or laptop in under 40 stepsDocument3 pagesHow to update the BIOS on your computer or laptop in under 40 stepsAshish VarshneyNo ratings yet

- Computer Science Mcqs TestDocument70 pagesComputer Science Mcqs TestAman AlviNo ratings yet

- Exceljet Excel Shortcuts 160623 PDFDocument21 pagesExceljet Excel Shortcuts 160623 PDFAbdul QaiyoumNo ratings yet

- Manual Software Secure Ver 4.2.0.01 - EnglishDocument82 pagesManual Software Secure Ver 4.2.0.01 - EnglishsungminieNo ratings yet

- Manual Sartocheck4plus Bag Tester SPI6051-ADocument172 pagesManual Sartocheck4plus Bag Tester SPI6051-AGoGUtkokANo ratings yet

- VCP Application Manual PDFDocument522 pagesVCP Application Manual PDFUga GonzalezNo ratings yet

- Aspire 8942 8942gDocument310 pagesAspire 8942 8942gPaul CuşNo ratings yet