Professional Documents

Culture Documents

O & M Manual For Boiler

Uploaded by

Ashwani DograOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

O & M Manual For Boiler

Uploaded by

Ashwani DograCopyright:

Available Formats

.

OPERATION & MAINTENANCE MANUAL

FOR 1 X 41TPH 100% INDIAN COAL FIRED

ATMOSPHERIC FLUIDISED BED COMBUSTION BOILER

SUPPLIED TO

HARE KRISHNA METALLICS LIMITED

KOPAL, KARNAKATA

THERMAX PROJECT NO.: PD 0161

THERMAX LIMITED BOILER & HEATER GROUP PUNE, INDIA

0 REV SSC 03.12.2008 AA 05.12.2008 USU 08.12.2008 0 REVISION DESC. / REMARK

PREPARED BY

CHECKED BY

APPROVED BY

Operation & Maintenance Manual

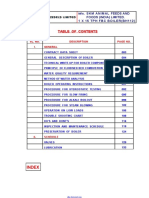

Contents

Volume 1 Boiler Description ....................................................................................................1 Section A................................................................................................................................2 1 Design Specications of Steam Generator ....................................................................3 2 Design Code...............................................................................................................3 3 Material Specications Pressure Parts .....................................................................3 4 Heating Surface Area ..................................................................................................5 5 Fuel ...........................................................................................................................5 6 Fuel Analysis (% By Wt.) .............................................................................................5 6.1 Ultimate Analysis ...............................................................................................5 6.2 Fuel size ...........................................................................................................5 7 Bed Material ...............................................................................................................6 7.1 Bed Material Specications - Crushed Refractory ................................................6 8 Continuous Blowdown .................................................................................................6 9 Intermittent Blowdown .................................................................................................6 10 Feed Water Recommended Quality ............................................................................6 11 Boiler Water Recommended Quality ...........................................................................7 12 Utilities .....................................................................................................................7 12.1 Electrical Power...............................................................................................7 12.2 Cooling Water..................................................................................................7 12.3 Instrument Air ..................................................................................................8 12.4 Service Air.......................................................................................................8 13 Chemicals for Dosing ................................................................................................8 14 Site Condition ...........................................................................................................8 15 Fans.........................................................................................................................8 16 HP Dozing System ....................................................................................................9 17 Rotary Feeders ....................................................................................................... 10 17.1 Capacity Chart............................................................................................... 10 18 Gauge Glass........................................................................................................... 11 18.1 Drum Level Gauge......................................................................................... 11 18.2 Blow Dowm Tank Level Gauge ....................................................................... 11 19 Safety Valves .......................................................................................................... 11 20 Temperature Prole ................................................................................................ 13 20.1 Gas Temperature ........................................................................................... 13 20.2 Water Temperature ........................................................................................ 13 20.3 Air Temperature ............................................................................................. 13 21 Flue Gas Pressure Prole ........................................................................................ 13 22 Process Flow Diagram............................................................................................. 13 Section B ............................................................................................................................. 14 1 Section Overview ...................................................................................................... 15 2 Feed Water System................................................................................................... 16 2.1 Feed Water Control Station .............................................................................. 16 2.2 Attemperation Control Station........................................................................... 17 3 Boiler Pressure Part Description................................................................................. 17 3.1 Economizer ..................................................................................................... 17 3.2 Steam Drum .................................................................................................... 17 3.3 Water Drum..................................................................................................... 18 3.4 Down Comer Tubes ......................................................................................... 18 3.5 Furnace .......................................................................................................... 19 3.6 Inbed Evaporator ............................................................................................. 20 3.7 Riser Tubes..................................................................................................... 20 3.8 Super Heater................................................................................................... 20 3.9 Attemperator ................................................................................................... 20 3.10 Convection Bank ........................................................................................... 21

Operation & Maintenance Manual

Main Steam Piping .................................................................................................... 21 Boiler Blow Down System .......................................................................................... 21 5.1 Drain Lines...................................................................................................... 22 5.2 CBD Drain....................................................................................................... 22 5.3 IBD Drain ........................................................................................................ 22 5.4 Other Drains.................................................................................................... 23 5.5 Blow down Tank .............................................................................................. 23 6 Air and Gas System .................................................................................................. 24 6.1 System Description: ......................................................................................... 24 6.2 FD Fan ........................................................................................................... 24 6.3 Air Pre Heater ................................................................................................. 24 6.4 PA Fan............................................................................................................ 25 6.5 Air Ducts ......................................................................................................... 25 7 Flue Gas System ...................................................................................................... 27 7.1 System Description .......................................................................................... 27 7.2 Electrostatic Precipitator (ESP)......................................................................... 27 7.3 ID Fan............................................................................................................. 27 8 Fuel Feeding & Firing System .................................................................................... 28 8.1 Fuel Bunker..................................................................................................... 28 8.2 Rotary Feeders................................................................................................ 28 8.3 Fuel Mix Nozzles ............................................................................................. 29 8.4 Combustor ..................................................................................................... 29 8.5 Bed Drain System............................................................................................ 30 8.6 Ash Drain ........................................................................................................ 30 9 Chemical Dosing & Sampling System......................................................................... 30 9.1 HP Dosing System........................................................................................... 30 9.2 Description of Dosing System Skid HP)............................................................. 30 9.3 Sampling System............................................................................................. 31 Section C ............................................................................................................................. 32 1 Boiler Start Up .......................................................................................................... 32 1.1 Start-up of a Cold Boiler ................................................................................... 32 1.2 Procedure For Normal Operation ...................................................................... 36 2 Operational Control ................................................................................................... 39 2.1 Load Operation................................................................................................ 39 2.2 Bed Level Control ............................................................................................ 40 2.3 Bed Ash Alkali Control ..................................................................................... 40 2.4 Adequate Bed Temperature.............................................................................. 41 2.5 Fuel and Bed Material Sieve Analysis as per the Designed Conditions ................ 41 3 Balance of Plant Start Up (Boiler) ............................................................................... 42 3.1 Deaerator Charging ......................................................................................... 42 3.2 Air Pre Heater ................................................................................................. 43 4 Part Load Operation By Bed Slumping ....................................................................... 43 4.1 Bed Slumping Procedures ................................................................................ 43 4.2 Slumped Bed to Active Bed .............................................................................. 43 5 Warm / Hot Start Up .................................................................................................. 44 5.1 Case-I (Bed Ash Temperature > 600C) ............................................................ 44 5.2 Case-II (Bed Ash Temperature < 600C) ........................................................... 44 6 Boiler Shutdown........................................................................................................ 45 6.1 Planned Shut Down ........................................................................................ 45 6.2 Boiler Emergency Trip...................................................................................... 45 7 Dos and Donts......................................................................................................... 47 8 Controls.................................................................................................................... 48 9 Troubleshooting Chart ............................................................................................... 49 10 Walkdown Checklist during Operation....................................................................... 52 11 Boiler Safety ........................................................................................................... 53

4 5

ii

Operation & Maintenance Manual

11.1 Emergency Procedures .................................................................................. 53 12 Operational Precautions for Safety ........................................................................... 55 Section-D ............................................................................................................................. 59 1 Section Overview ...................................................................................................... 59 2 Recommended Maintenance Practice ........................................................................ 59 2.1 Preventive Maintenance................................................................................... 59 3 Conditioned Based Maintenance................................................................................ 60 3.1 Daily Checks ................................................................................................... 60 3.2 Daily Maintenance ........................................................................................... 62 3.3 Weekly Checks................................................................................................ 63 3.4 Monthly Checks ............................................................................................... 63 3.5 Checks Every Six Months................................................................................. 64 3.6 Checks Every Year .......................................................................................... 64 3.7 Annual Maintenance Check Sheet .................................................................... 65 4 Boiler Annual Maintenance and Overhaul ................................................................... 72 4.1 Planning Before Overhaul ................................................................................ 72 4.2 Shutdown and Cooling the Boiler ...................................................................... 72 4.3 Inspection after Cooling.................................................................................... 72 4.4 Drum Inspection .............................................................................................. 72 4.5 Inspection of Screen, Primary & Secondary Superheater, Evaporator I/ II & Economiser................................................................................................ 73 4.6 Expansion Joints ............................................................................................. 73 4.7 Insulation and Cladding.................................................................................... 73 4.8 Other Equipment ............................................................................................. 73 4.9 Feed & Boiler Water Conditioning ..................................................................... 73 4.10 Fans ............................................................................................................. 75 4.11 Safety Valves, Start Up Vent Valves And Other Isolating Valves ........................ 76 5 Boiler Preservation Procedure.................................................................................... 77 5.1 Denitions OF Water Quality ............................................................................ 77 5.2 Dry Storage Preservation ................................................................................. 77 5.3 Wet Storage Preservation ................................................................................ 78 5.4 Nitrogen Blanket .............................................................................................. 79 5.5 Hot Draining .................................................................................................... 79 5.6 Alkaline Water Dozed With Hyderzine ............................................................... 79 5.7 Preservation Of External Surfaces Of Pressure Parts During Long Shut Down......................................................................................................... 80 5.8 Boiler Lay Up Procedures................................................................................. 80 5.9 Preservation of Rotating Equipments ................................................................ 80 5.10 Preservation of Instruments ............................................................................ 80 5.11 Tube Thickness Survey .................................................................................. 81 6 Tube Failures............................................................................................................ 81 6.1 Tube Failure Investigation / Analysis Method ..................................................... 81 6.2 Tube Thickness Survey Data Collection Format .............................................. 84 6.3 Failure Reporting Formats ................................................................................ 85 7 Water Chemistry ....................................................................................................... 87 7.1 Undissolved and Suspended Solid Materials ..................................................... 87 7.2 Dissolved Salts and Minerals............................................................................ 87 7.3 Dissolved Gases.............................................................................................. 88 7.4 Other Materials................................................................................................ 88 7.5 pH Value of the Water and its Importance.......................................................... 88 7.6 Effects of Impurities ......................................................................................... 88 7.7 Feed & Boiler Water Conditioning ..................................................................... 90 8 Welding Procedure Specications (WPS) ................................................................... 92 8.1 Window Patch Welding .................................................................................... 93 8.2 General Principle of Weld Repairs .................................................................... 94

iii

Operation & Maintenance Manual

8.3 Weld Repair of Small Cracks in Tube ................................................................ 98 8.4 Plugging Tubes in Drums & Headers................................................................. 98 8.5 Replacement of Tube Section......................................................................... 100 8.6 Removing Tubes from Drums, Headers & Tube Plates ..................................... 100 8.7 Attached gures 13 to 21 ............................................................................... 101 Section E............................................................................................................................ 110 Volume 2 Drawings.............................................................................................................. 111 List of Drawings .................................................................................................................. 112 Volume 3 E & I Specications.............................................................................................. 113 Section 01 .......................................................................................................................... 114 Section 02 .......................................................................................................................... 114 Section 03 .......................................................................................................................... 114 Section 04 .......................................................................................................................... 114 Section 05 .......................................................................................................................... 114 Section 06 .......................................................................................................................... 114 Section 07 .......................................................................................................................... 114 Section 08 .......................................................................................................................... 114 Section 09 .......................................................................................................................... 114 Section 10 .......................................................................................................................... 115 Volume 4 Vendor Manuals ................................................................................................... 116 Section 01 .......................................................................................................................... 117 Fan TLT Engineering ................................................................................................ 117 Section 02 .......................................................................................................................... 117 H.P / LP. Dosing System - NM Enterprises ..................................................................... 117 Section 03 .......................................................................................................................... 117 Level Gauge Hi Tech Systems (Tyco) ........................................................................ 117 Section 04 .......................................................................................................................... 117 Level Gauge Chemtrol.............................................................................................. 117 Section 05 .......................................................................................................................... 117 Tight Shout off Damper Virgo ..................................................................................... 117 Section 06 .......................................................................................................................... 118 Kniff Gate Valve Orbinox .......................................................................................... 118 Section 07 .......................................................................................................................... 118 Process Valve KSB ................................................................................................. 118 Section 08 .......................................................................................................................... 118 Safety Valves Tyco Sanmar ...................................................................................... 118 Section 09 .......................................................................................................................... 118 Motors Siemens........................................................................................................ 118 Section 10 .......................................................................................................................... 118 Rotary Feeder - Nova Bulk............................................................................................ 118 Volume 5 Vendor Manuals ................................................................................................... 119 Section 01 .......................................................................................................................... 120 Pressure Transmitter Emerson.................................................................................. 120 Section 02 .......................................................................................................................... 120 Temperature Transmitter Emerson ............................................................................ 120 Section 03 .......................................................................................................................... 120 I/P Converter ABB..................................................................................................... 120 Section 04 .......................................................................................................................... 120 Pressure Switch Switzer ........................................................................................... 120 Section 05 .......................................................................................................................... 120 5.1 Orice Plate General Instruments ......................................................................... 120 5.2 Thermocouple General Instruments ..................................................................... 120 Section 06 .......................................................................................................................... 120 Pressure Gauge Gages Bourdon .............................................................................. 120

iv

Operation & Maintenance Manual

Section 07 .......................................................................................................................... 120 Local Indicator Nishko ............................................................................................... 120 Section 08 .......................................................................................................................... 121 Control Valves MIL .................................................................................................... 121 Section 09 .......................................................................................................................... 121 Power Cylinder Keltron.............................................................................................. 121 Section 10 .......................................................................................................................... 121 ACVFD Drives ABB.................................................................................................. 121 Index.................................................................................................................................. 123

Operation & Maintenance Manual

vi

Operation & Maintenance Manual

Volume 1 Boiler Description

Chapters Covered in this Part Section A Section B Section C Section-D Section E

Volume 1 Boiler Description

Operation & Maintenance Manual

Section A

Topics Covered in this Chapter Design Specications of Steam Generator Design Code Material Specications Pressure Parts Heating Surface Area Fuel Fuel Analysis (% By Wt.) Bed Material Continuous Blowdown Intermittent Blowdown Feed Water Recommended Quality Boiler Water Recommended Quality Utilities Chemicals for Dosing Site Condition Fans HP Dozing System Rotary Feeders Gauge Glass Safety Valves Temperature Prole Flue Gas Pressure Prole Process Flow Diagram

Section A

Operation & Maintenance Manual

Number and Type of Boiler 1 no. AFBC, Bi Drum, outdoor, water tube, natural circulation, balance draft, Under-bed ring system, Bottom Supported with RCC construction..

Design Specications of Steam Generator

Parameters

Unit

Value

Boiler Rating [MCR] Steam Pressure at Main Steam Stop Valve Outlet from minimum Load upto MCR Steam Temperature at the Main Steam Stop valve at MCR Main Steam Temperature Control range at the Main Steam Stop Valve Outlet. Feed Water Temperature at Economiser Inlet / Spray water temp Flue Gas Temperature at APH Outlet Main Fuel Start Up Fuel for Coal Fuel Zizing Boiler Performance Testing Procedure

TPH Kg/cm2(g)

41 66

Deg C

490+/- 5

% MCR

60 100

Deg C

130

Deg C

160 Indian Coal Charcoal Sprayed with diesel fuel. 100 % Indian coal < 6mm , 30%(max) <1mm ASME PTC 4.1 Indirect addreviated heat loss method on GCV Basis

Design Code

: As per IBR

Boiler & Economiser / Pressure Parts

Material Specications Pressure Parts

Description Steam Drum Details Shell Dished End (SEMI-ELIPSOIDAL) Shell Water Drum Riser Dished End (SEMI-ELIPSOIDAL) Tube Size In Mm 4540 X 1000 X 70 Thk 1375 I.D. X 70Thk 3173 X 2500 X 50 Thk 960 I.D. X 50 Thk 101.60 O.D. x 5.74 Thk. SA 516 Gr.70 Material

SA 516 Gr.70 SA 516 Gr.70 SA 210 Gr A1

Section A

Operation & Maintenance Manual

Description

Details Top Header Bottom Header Panel Tubes Bend Tube Top Header Bottom Header Panel Tubes Opening Tubes Top Header Bottom Header Panel Tubes Opening Tubes Top Header Bottom Header Panel Tubes Opening Tubes DC1-DC11 Reducer

Size In Mm 200 NB X SCH 160 200 NB X SCH 160 63.5 O.D x 4.06 Thk 63.5 O.D x 4.06 Thk 200 NB X SCH 160 200 NB X SCH 160 63.5 O.D x 4.06 Thk 63.5 O.D x 4.06 Thk 200 NB X SCH 160 200 NB X SCH 160 63.5 O.D x 4.06 Thk 63.5 O.D x 4.06 Thk 200 NB X SCH 160 200 NB X SCH 160 63.5 O.D x 4.06 Thk 63.5 O.D x 4.06 Thk 100 x Sch 80 200 x 100Nb x Sch 80 168.3 O.D x 10.97 Thk 100 x Sch 80 63.5 O.D x 4.0 Thk 44.5O.D x 4.06 Thk

Material SA 106 Gr B SA 106 Gr B SA 210 Gr A1 SA 210 Gr A1 SA 106 Gr B SA 106 Gr B SA 210 Gr A1 SA 210 Gr A1 SA 106 Gr B SA 106 Gr B SA 210 Gr A1 SA 210 Gr A1 SA 106 Gr B SA 106 Gr B SA 210 Gr A1 SA 210 Gr A1 SA 106 Gr B SA 234 WPB SA 106 Gr B SA 234 WPB SA 210 Gr A1 SA 210 Gr A1 SA 210 Gr A1 SA 213 Gr T11 SA 213 Gr T22 SA 106 Gr B SA 213 T22 SA 106 Gr B SA 106 Gr B SA 106 Gr B SA 210 Gr A1 SA 106 Gr B SA 210 Gr A1 SA 106 Gr B SA 210 Gr A1

RH Panel

Front Panel

LH Panel

Rear Panel

Down comers

Pipe 90 Elbow Tube Stub

Super Heaters (CSH & RSH)

Coils

44.5O.D x 4.06 Thk 44.5O.D x 4.06 Thk 44.5O.D x 4.06 Thk

Pipe Super Heaters (CSH & RSH) Tube Pipe Pipe Attemperator Inbed Coils Inbed Header Economiser Boiler bank Header Tube Header Tube Top & Bottom headers Tube

219.1 O.D x 18.26 Thk 44.5O.D x 4.06 Thk 88.9 O.D x 7.62Thk 88.9 O.D x 7.62Thk 219.1 O.D X 18.26 thk 50.8 O.D X 6.35 Thk. 200 O.D x Sch 120 38.1 O.D x 3.66 Thk 168.3 O.D x 14.27 Thk 50.8 O.D x 4.06 Thk

Section A

Operation & Maintenance Manual

Heating Surface Area

Zone Boiler Bank Zone Water wall Zone Super Heater Zone Inbed coils Economiser Total Heating Surface Unit Sq.Mtr Sq.Mtr Sq.Mtr Sq.Mtr Sq.Mtr Sq.Mtr Value 354.0 242.1 688.0 81.6 566.0 1931.7

Fuel

Fuel Type Main Fuels Start up Fuel Indian Coal Charcoal sprayed with Diesel fuel. Fuel Name

Fuel Analysis (% By Wt.)

6.1 Ultimate Analysis

Composition Hydrogen Carbon Nitrogen. Oxygen. Moisture Ash Sulphur Caloric Value (GCV) Unit % Wt % Wt % Wt % Wt % Wt % Wt % Wt Kcal/kg Indian Coal 2.30 37.1 0.70 6.60 8.00 45.0 0.30 3500 Char 0.42 40.30 0.17 2.84 3.21 52.68 0.38 3200

6.2 Fuel size

Indian Coal 100 % Up to 30 % (Max.) Char 100 % Up to 30 % (Max.) Coal: - Non caking type. We have consider standard analysis for India Coal & Char available It is recommended that the fuels be stored in covered yards to prevent choking and bridging of fuel storage and feeding system due to surface moisture. All the Fuels should be free from chlorine. Predicted Thermal efciency on 70% Indian Coal, + 30 % Char ( Mixing by weight Basis) Firing Shall be 83 +/- 1% : : < 3mm < 1mm : : < 6 mm < 1mm

Section A

Operation & Maintenance Manual

Bed Material

: : : : 60 Metric Tonnes (Approx.) 0.8 mm to 2.36 mm (100 %) 10001100 AL2O3 % 35 to 45 SiO2 % 55 to 65

Required Per start Up Lump Size Bluk Density Chemical Composition

7.1 Bed Material Specications - Crushed Refractory

Material refractory Bulk Density Temperature SIZE Shape Chemical Composition SIO2 AL2O3 FEO TIO2 MNO CAO MGO P2O5 NA2O K2O : : : : : : : : : : : : : : : Sieved natural sand/Crushed 1200 1400 Kg/m3 >1300 deg C 0.7 to 2 (for sand) Fusion Sub Angular / Spherical. Percentage limits 5060 37-40 , Min 30% required <2.0 1.67 Traces 0.54 0.23 0.08 0.22 0.45

Continuous Blowdown

Max Normal : : 3 %/ Hr 1 %/ Hr

Intermittent Blowdown

Once in 8 Hours : 6%

10 Feed Water Recommended Quality

Parameters General Appearance Total Hardness as CaCO3 ppm Unit Value Clear & Colorless Nil

Section A

Operation & Maintenance Manual

Parameters Total Fe Total Cu Total O2 Oil & Organic. pH Value at 25 Deg C Total Dissolved Solids Silica as SIO2 Hyderzine residual

Unit ppm ppm ppm ppm ppm ppm ppm

Value <0.01 <0.003 <0.007 Nil. 8.5 9.5 0.1 <0.02 0.02 0.04

11 Boiler Water Recommended Quality

Parameters pH at 25 deg C Phosphates PO4 Total Alkalinity Sodium Sulphite Oil & Organic p value Silica as SiO2 Unit ppm ppm ppm ppm mval/kg Ppm Value 9.5 10.2 2- 6 4 max. Nil Nil 0.1 2

12 Utilities

12.1 Electrical Power

Parameters Voltage Frequency Type Voltage Frequency Type For Field Transmitters Voltage Frequency Type V Hz 24 NA DC V Hz Units V Hz Value 415 +/- 10% 50 +/- 5% AC, 3 Phase, 4 WIRE 110 50 AC, 1 Phase, 2 Wire,

For LT motors (UPTO AND INCLUDING 160 KW)

For Instrumentation (eld switches, Level gauge illumination, solenoid valves etc.)

12.2 Cooling Water

Parameters Supply Pressure Unit Kg/cm2(g) Value 34

Section A

Operation & Maintenance Manual

Parameters Supply Temperature Quality Duty

Unit Deg C

Value Ambient SOFT & Chlorine free Sample Cooling.

12.3 Instrument Air

Parameters Pressure Dew point Temperature Unit Kg/cm2(g) Deg C Deg C Value 67 -40 Ambient

12.4 Service Air

Parameters Pressure Temperature Quality Duty Unit Kg/cm2(g) Deg C Value 7 Ambient Dry & Oil Free General purpose

13 Chemicals for Dosing

HP Dosing LP Dosing Tri sodium phosphate Hydrazine

14 Site Condition

Site Location Ambient Temperature Performance Maximum Minimum Electrical Design Relative Humidity Altitude Seismic coefcient 36 C 45 C 20 C 60 C 60% 890 m above MSL As per IS 1893, Part 1,2002, Zone-2 Kopal, Karnataka

15 Fans

FD fan Duty conditions Make Model Unit Test Block Conditions TLT Engineering 2218 / 758 ID Fan Test Block Conditions TLT Engineering 16378B 982 PA Fan Test Block Conditions TLT Engineering 3166256

Section A

Operation & Maintenance Manual

FD fan Duty conditions Quantity Nature of medium Air /Gas density Volume Gas Temperature at Fan Inlet Absorbed Power / Rated Fan Power Differential static head Fan Speed Static Pressure Kg/N M3 Kg/hr Deg C KW mmWc Rpm mmWC Unit Nos. Test Block Conditions 1 Clean Air 1.29 77486 45 250 860 1480 8437 22220 EK/C3 Free/Fixed Bearing Housing SNH-520 22220 EK/C3 SNH-520 Bearing Lubrication Motor Servogem; EP-2 250 KW 4 Pole Siemens Make Flexible Resilient Coupling Model / Make Size 212A Wellman MakeI

ID Fan Test Block Conditions 1 Flue Gas 1.31 86970 150 90 200 980 1962 222216 EK/C3 SNH-516 222211 EK/C3 SNH-511 Servogem; EP-2 90 KW 6Pole Siemens Make Flexible Resilient Size 212A Wellman MakeI

PA Fan Test Block Conditions 2 Clean Air 1.29 15300 45 50 760 2920 2920 222176 EK/C3 LOE-217 222174 EK/C3 LOE-214 Servogem; EP-2 55 KW 2Pole Siemens Make Flexible Resilient Size 212A Wellman MakeI

16 HP Dozing System

Make : N M Enterprises Drg no : NMEDS-HP-21 Rev -1 Description Pumps Make Model Type Flow Discharge Pressure Relief Valve Set Pressure Motor for Dosing Pumps Metachem Pump MC 2 Reciprocating Plunger 10 LPH by Stroke Adjustment 86 kg/cm2 g 110 kg/cm2 g HP

Section A

Operation & Maintenance Manual

Description Make Type Rating Motor for agitator Make Type Rating Storage Working Volume Fluid To Be Handled.

HP Crompton/Siemens 0.5HP, 1500 RPM, TEFC-IP55, 50 Deg C amb. ,415 V, 50 Hz 0.5 HP / 1500 rpm N M Enterprises AG 2 Model, Motorised propeller type 750 rpm (material SS 304) 0.5 HP / 1500 rpm 300 litres Tri sodium phosphate.

17 Rotary Feeders

Make - Nova Bulk Handlers (P) Ltd. Refer G.A for Drag Chain Feeder. Drg No : Nova /48/ 0708. 2 sheets Description Type Capacity Material Used Location Length Of Feeder Rotary Feeder Horizontal See Table Below Indian Coal l At Bunker Outlet 781mm 2.2 KW with Variable Frequency Drive. Geared Motor (2 HP , 4 Pole Frame) 3 HP , 4 Pole Frame size- 100L; Make :Siemens Chain Sprocket; Head & Tail Type of Drive Rotor Size Simples 1.25 pitch (Reduction 1:2.53) Simplex 1.25 pitch Motorised With VFD Drive Dia 208 mm X 625 MM LG

17.1 Capacity Chart

Indian Coal Capicity Speed Through Loading Capicity Per Unit time per Revelation Char Capicity Unit Kg/hr RPM % Kg/hr/reve 0.00234 Unit Kg/hr Design 2100 100% MCR 1750 50% MCR 875 Min 438 Design 3840 7.2 95 100% MCR 3200 6.0 50% MCR 1600 3.0 Min 800 1.5

Section A

10

Operation & Maintenance Manual

Char Speed Through Loading Capicity Per Unit time per Revelation

Unit RPM % Kg/hr/reve

Design 3.14 95 0.00234

100% MCR 2.62

50% MCR 1.31

Min 0.65

18 Gauge Glass

18.1 Drum Level Gauge

Description Make Tag No. Type Location Operating Pressure Design Pressure Hydrotest Pressure C/C Distance Visibility Range Operating Temp. Details HI- TECH SYSTEMS AND SERVICES LTD. LG-600A & LG-600B Bicolor Port type Steam drum 72.7 kg/cm2 (g) 78.8 kg/cm2 (g) 315 BAR 800 mm 403 mm 289 Deg C (Saturated) Normal Operating

18.2 Blow Dowm Tank Level Gauge

Description Make Tag No. Type Location Operating Pressure C/C Distance Visibility Range Operating Temp. Details Chemtrol Samils (I) Pvt Ltd. LG-550 Tubular Level Gauge Blow Down Tank 05 kg/cm2 (g) 500 mm 360mm 200 Deg C (Saturated) Normal Operating

19 Safety Valves

Description Application Type Make Size Orice Set Pressure Kscg 1.5/ H/3.0 78.8 Unit Drum LHS Drum RHS Spring Loaded Tyco Sanmar Ltd 1.5/ H/3.0 80.0 1.5/H /3.0 71.8 SH

Section A

11

Operation & Maintenance Manual

Description Application Tag No Model Rated Capacity Quantity

Unit

Drum LHS B7 HC56 W-IBR-SPL

Drum RHS B8 HC56 W-IBR-SPL 19313 1 / BLR

SH S4 HCA58 W-IBR-SPL 13892 1 / BLR

Kg/Hr

19027 1 / BLR

Section A

12

Operation & Maintenance Manual

20 Temperature Prole

20.1 Gas Temperature

At the outlet of furnace At the outlet of bank tubes At the outlet of economiser At the outlet of air-preheater At the outlet of ESP : : : : : 875 Deg C. 445 Deg C. 250Deg C. 160Deg C. 160Deg C.

20.2 Water Temperature

Condensate from process Process return Make up water inlet of FW Pumps the inlet of economiser At the outlet of economiser : : : : : : 47 Deg C. 100 Deg C. 32 Deg C. 130 Deg C. 130 Deg C. 216Deg C.

20.3 Air Temperature

t the inlet of air heater At the outlet of air heater : : 45 Deg C. 150 Deg C.

21 Flue Gas Pressure Prole

Furnace After Boiler Bank After Economiser After Air Heater After ESP At ID Fan Inlet At ID Fan Out let : : : : : : : 5 40 80 110 135 135 +5

22 Process Flow Diagram

Process Flow Diagram

Section A

13

Operation & Maintenance Manual

Section B

Topics Covered in this Chapter Section Overview Feed Water System Boiler Pressure Part Description Main Steam Piping Boiler Blow Down System Air and Gas System Flue Gas System Fuel Feeding & Firing System Chemical Dosing & Sampling System

Section B

14

Operation & Maintenance Manual

Section Overview

GENERAL DESCRIPTION The main parameters of the boiler are Maximum Continuous Rating Steam Pressure Steam Temperature Fuel Fired 41TPH 66 kg/cm2 490+/- 5 Deg C Indian Coal and Char

This section gives a brief overview of the boiler and its associated systems. The description of the various systems that form part of the boiler package is also included. The aim of this section is to make the reader familiar with the boiler package components before introducing the operation and maintenance sections.. Brief Overview The boiler package supplied by Thermax Ltd, Pune, India and has been designed for 41 TPH steam generation, 66 kg/cm2 (g) pressure, 490 +/- 5 deg C Super Heated Steam output designed for ring with 100% Indian Coal and secondary fuel 70% Indian Coal + 30% Char. This boiler is AFBC, Bi-Drum, outdoor, natural circulation, Water tube, uidised bed combustion, Underbed Fuel Feeding System, balance draft, Bottom Supported with Steel construction & Hopper Bottom design. Fuel Combustion will be in an Atmospheric Bed Combustor (AFBC) xed at the Boiler bottom. Fuel is stored in Bunker. Rotary feeders are connected at the bottom of hoppers (below the bunker). The fuel is fed by these feeders to under-bed fuel feeding system and transported to the furnace for ring in the bed. As a complete unit the boiler plant is equipped with the following circuits. Feed water and steam system. Pressure parts circuit. Boiler Steam circuit. Boiler Blow down circuit. Sample coolers. Chemical dosing system Combustor Combustion Air Fuel handling storage & Fuel feeding system Flue gas circuit Refractory and insulation. Electrical and Instrumentatio Chimney

The boiler has been designed to conrm to Indian Boiler Regulations (IBR) The boiler is divided into a combustion zone i.e. furnace and non-combustion zone i.e. economiser, air heater etc. The furnace sides, front and rear are of membrane panel construction providing a gas tight sealing. For all the four water wall bottom headers, water is fed through supply pipes from water drum. The sidewall, front wall and rear wall panel tubes top headers are connected to the steam drum through risers. The front wall panel tubes form the roof of the furnace. Feed water is pumped by feed water pumps from deaerator to economiser through feed water control station. The feed water from economiser outlet is then led to the steam drum. Steam is generated in the furnace membrane wall tubes. The resulting water-steam mixture from the riser tubes of membrane panel returns to the steam drum where the separation of steam from water takes place. The saturated steam is led through the supply pipes to the PSH inlet header. From the PSH inlet header steam passes through the coils to PSH O/l header, then steam is led to Attemperator and then to the Sec SH inlet header and passed through coils to the Sec SH outlet header. Finally from the Sec SH outlet header steam is passed to the main steam line to Turbine. Combustion of the fuel takes place in the furnace bed where the fuel is spread with the help of the fuel feeding screw feeders over the Bedplate. Combustion air is sucked from the plant environment by the motor driven FD fan and combustion air is passed through specially designed air nozzles which are welded in distributor plate or Bed plate. Secondary Air arrangement is done to: Suppress the unburnt fuel materials from escaping the combustion zone.

Section B

15

Operation & Maintenance Manual

Maintains the super heater temperature by controlled combustion. Balanced draft conditions inside the furnace suitable for combustion is being maintained by I.D fan. Air pre-heater, ESP and nally into the stack by ID fan. The starting, stopping and safe shut down of boiler are done by manual intervention systematically and sequentially through DCS control system from control room. Details of equipments, their brief operational and maintenance features are elaborated in the subsequent sub-sections and chapters of this manual.

kept closed. This drain is to be opened only to drain the line when control valve has to be opened for inspection/maintenance. Following instruments are provided at the inlet of feed water control station: Flow nozzle FE-500 with ow transmitter FT-500 is provided for total feed water ow measurement. Flow transmitter transmits the water ow signal to ow indicating controller at control panel. A 25 NB pipe tapping with W33 valve for the SH desuperheater. Control valve is operated through the Flow indicating controller (FIC-600). Input signals are given to FIC-600 by Level indicating controller (LIC-600), steam ow transmitter (FT-604) and feed water ow transmitter (FT-500). Ref. three element control for detail operation of drum level controller. From the control station feed water ows to economiser inlet header (bottom) through an 100 NB non return valve (W-24). Thermocouple TG-501 is located before the Eco. inlet header to measure the feed water temperature prior to Eco. Pressure gauge PG-501 is provided with isolation valves (W15 & W16)to measure the FW pressure at Eco. inlet. From the economiser bottom header, water ows to the outlet (top) header through coils. Heated water ows from Eco. top header to steam drum, through feed water Eco. outlet piping. . 2.1.1 Single & Three-element control 1. Drum level control is the single most important process control for any steam generator. The simplest of the control loops involve measuring the drum level and comparing with a xed set point. A control signal to operate the control valve will be calculated based on the deviation between the set point and the process variable. This calculated signal would be a function of the loop conguration parameters. The simplicity of the loop is its advantage at low loads and constant loads. However, at higher loads and with load swings, this loop fails to control the process parameter. This has necessitated the introduction of two more elements (process parameters) into the control loop. The additional elements that are measured are steam ow & water ow. In the three-element drum level control, drum level is maintained as a function of the drum level and the steam ow. The control signal is a suitable summation of these two elements. This variable is compared to the measured water ow

Feed Water System

(Ref. P & I Diagram D12-1PD-6499P, R-2) Feed water system consists of the following: 1. Feed water control station.

2.1 Feed Water Control Station

When the boiler is in service, feed water must be continuously supplied to maintain near- normal water level in the steam drum. It is unsafe to operate the boiler at lower water levels. Feed water control station regulates the water ow to the steam drum to maintain the steady & required water level Feed water control station consists of the following: Feed water control station consists of one welded type ow control valve of 100 % capacity (FCV-500), which is pneumatically actuated by a spring opposed diaphragm actuator The 100 % FCV is provided with isolation valve W12 & W12 at upstream and downstream respectively, whereas W12 is manual valve. There are two bypass valves one is 100% bypass manual globe valve & another is FCV-500B 30% bypass pneumatic control valve, W13 is isolation valve of 30% bypass valve having manual isolation valve W13 & W13. Whereas W17 is 100% manual bypass valve. These main isolation valves are normally kept closed before the main valve is opened during pump start-up. The bypass valve should also be closed during pump start-up. The bypass is used only if the control valve is out of service. Drain valves W-14 is provided after the 100% control valve. Theses drain valves are normally

Section B

16

Operation & Maintenance Manual

and a suitable control signal is generated which is used to drive the 100% control valve. The major advantage of the loop is its ability to maintain drum level during load swings, variations & throw conditions that are certain to occur during the operating regime of any steam generator. Though this loop is advantageous from an operation point of view, it is recommended to use this loop at loads > 30%, as the single element control loop is optimised for low load conditions with its control valve sizing & parameter tuning

Provision of this additional heating surface, increases the efciency of the steam-generating unit and saving in fuel consumption is achieved. Economiser is located in between boiler bank outlet and Air Pre-heater. A continuous loop tube Economiser assembly is constructed with rows of 38.1 O.D x 3.66 thick tubes, and two headers. Both the ends of the coil were terminated to the top and bottom headers by welding. Feed water ows from the bottom header to the top headers through these coils. Heated water ows out from the top header to steam drum through the connecting pipe. The economiser is fully drainable by the drain valves W-26 located on the inlet header. Economiser top header is provided with the following attachments: 25 NB air vent with two valves (Tag No. W 28 which will be kept open during initial lling to remove the air trapped between the coil. Closed after free ow of water from the vent. Pressure indicator PG-502 with twin isolation valve W 27. Thermocouple (TE-502) is provided for panel mounted temperature indicator. Pressure gauge(PG-502) is provided for Local Indication.

2.2 Attemperation Control Station

A tapping 25 NB from Feed Water line is provided, to supply spray water for Attemperator. This line is provided with a manual isolation valve W-33 & NRV W37. A temperature control valve TCV-604 with isolation valves W-34 is provided. A by-pass manual valve W-35 is provided. This line connects to Attemperator through a NRV W-36.

Boiler Pressure Part Description

This boiler is AFBC design, BI-Drum, outdoor, natural circulation, Water tube, uidised bed combustion, Underbed Fuel Feeding System, balance draft, Bottom Supported with STEEL construction & Hopper Bottom design. Various pressure parts are grouped as follows: 1. Economiser 2. Steam drum 3. Water drum 4. Down comer Tubes 5. Furnace 6. RH & LH Inbed Evaporator 7. Furnace membrane water walls 8. Riser Tubes 9. Saturated steam supply tubes 10. Super heater 11. Attemperator 12. Boiler bank

3.2 Steam Drum

(Refer Drg no: P21-1PD-43823, Rev-1) Steam drum (1375 ID X 70-mm thk.) is a welded cylindrical vessel made of SA 516 Gr.70 material. The cylindrical portion of the vessel is made of 70-mm thick plates and the two Torispherical dish ends are 70mm. thick. Two elliptical manholes at either end of the drum provide access inside the drum. These manholes are closed tight at either end by 70-mm thick plates, bolted against the manhole rim by two holding bars. A gasket is tted between the cover plate and the mating machined surfaces in the end shield. The cover plate swing inside the drum, for convenience during opening. Steam drum is supported by saddle supports on the super structure of the boiler. Steam drum is tted with several components to perform important functions, which are listed below: Direct water level gauge LG 600A & LG 600B that shows the water level inside the steam

3.1 Economizer

Refer Drg no: PL4-1PD-45132, R-0 Function of an Economiser in a steam-generating unit is to absorb heat from ue gases & add this as a sensible heat to the feed water, before the water enters to the steam drum.

Section B

17

Operation & Maintenance Manual

drum. DWLGS are provided at both ends of the drum. Two nos. Level transmitters are provided LT 600A B C which transmit the actual water level to the remote indicators i.e. at control room and provide drum level signal to the drum level controller Drum safety valves B 7 & B 8 which protects the boiler and the personnel against the consequences of abnormal pressure increase because of sudden load decrease, malfunctioning of ring system, steam stop valve etc. Level indicator LI 600: this gauge is mounted at the ring oor, so as the ring oor attendant can view the drum level. H.P dosing connection: To dose phosphate in to the steam drum to maintain the boiler water quality. Continuous blow down (CBD): To drain the boiler water during operation to maintain the water concentration. Also the water sample is taken from this blow down. It is connected to the common IBD tank directly as well as through CBD tank. Two air vent with isolation valves B 6 that will be closed at 2 Kg/cm2 (g) during pressure rising and open at 2 kg/cm2 (g) during cooling. Local Pressure gauge PG 600A with isolation B9 & B9 shows the drum pressure near steam drum and PG-600B with isolation B11 & B11 at operator oor. One pressure transmitter PT-600 is given to three element drum level control compensation. 3.2.1 Steam Drum Internals (Refer Drg. no. P21-1PD-41824, R-0) Steam drum internals are provided to supply moisture free steam to S.H coils. Steam drum receives water/steam mixture from the water wall panels through the raiser tubes in the bafes of the boiler drum. In this steam/water mixture, high-density water is separated from steam and trickle down to mix with water in the drum. Steam raises upward to ow through the demister pads and nally moisture free saturated steam goes out of the steam drum. Feed water pipe 1 No. 100 NB perforated pipe with holes is installed in the drum with holes positioned at 7 & 7 O clock position while looking from RH Side (i.e. towards boiler front). This will

ensure the uniform distribution of feed water in the entire length of the steam drum. Pipe is made in two pieces for installation ease and provided with anged joint. Continuous blow down pipe (CBD) 1 no 25NB perforated pipe with 6-7 holes is installed in the drum with holes at 6 O clock position. CBD pipe is provided to drain the boiler water to maintain the boiler water concentration at the specied limit. Pipe is made in two pieces for installation ease and provided with a drain hole to drain the water during shut down. HP dosing pipe 1 no 25NB perforated pipe with 6-4 holes is installed in the drum with holes at 12 Oclock position. As the pipe is of perforated type the chemical is uniformly distributed across the length of the drum. Chemical dosing at steam drum is, to maintain boiler water concentration as per the specied limit. Pipe is made in two pieces for installation ease and provided with a drain hole to drain the water during shut down.

3.3 Water Drum

(Refer Drg no: P21-1PD-43928, Rev-1) Water drum is a shell welded cylindrical vessel made of SA 516 Gr.70 material I.D. 960 and 50 mm thick. The cylindrical portion of the vessel is made of 50mm thick plates and the two semi-ellipsoidal dish ends. Two elliptical manholes at either end of the drum to provide access to the drum. A gasket is tted between the cover plate and the end shield. The cover plate swing inside the drum for convenience during opening. There is also arrangement of blow-off bafe with clamp arrangement inside the water drum.. Water drum is tted with intermittent blow down connection (IBD) of size 40 NB with isolation valves (D3 & IBD Valve D4) through which the water can be removed during emergency situations like high water level and high concentration situation.

3.4 Down Comer Tubes

(Refer Drg no. P73-1PD-46307, R- 1) Down comer tubes are of 323.9 O D x 33.3 THK size, which supplies water to furnace wall & convection bank headers from steam drum.

Section B

18

Operation & Maintenance Manual

There are two main down comers from water drum which supplies water to all bottom headers these have O.D 323.9 and 33.32 thk. And material is SA 106 Gr. B. Two branch supply pipes are taken from these downcomers to supply water to bottom headers. Supply pipes are taken for RHS and LSH evaporator panel bottom header each had been provided. And supply pipes are taken for front wall bottom header & for rear wall bottom header each.

shape under the expansion conditions. Front wall tubes are supported through rod slings with rocker washer from the super structure. Front wall bottom header is provided with a 25 N.B. drain connection, which normally remains closed during operation of the boiler. It is to be used to drain the boiler during shut down and start-up.. 3.5.2 Rear Wall (Refer Drg no. P45-1PD 45012)

3.5 Furnace

Furnace is the part of the boiler where the chemical energy in the fuel is converted into thermal energy by absorbing the heat produced through combustion of fuel. The furnace is designed for efcient and complete combustion, with due consideration to the factors that effect, combustion efciency like fuel residence time inside the furnace, temperature and the turbulence required for complete mixing of fuel and air.. Following are the distinct advantages of the furnace design: Heat transfer is facilitated inside the furnace in addition to combustion Practically no maintenance for refractory is required in case of membrane wall furnace Due to heat transfer inside the furnace, higher loading is possible, as part of heat generated, is already absorbed by the furnace tubes leaving the ue gas temperature out of furnace within acceptable limits into super heater zone. Furnace is constructed with shop fabricated membrane (water wall) construction. It comprises of Front panel, Rear panel, L.H panel and R.H panel. Furnace is 7380 mm long x 5040 mm wide. 3.5.1 Front Wall (Refer Drg no. P42-1PD 45013, R-1) Front wall is formed with front header (200NB x SCH 160) and 63.5 O.D x 4.06 Thick tubes. One end is connected to the bottom header and the other end is terminated to the top header. Front wall tubes receive water from steam drum through supply pipes. To strengthen the wall tubes, Buckstays beams are provided all around the furnace. The buck stay beams are supported on cleats from the water wall panels and exibly interconnected at the corners. The buck stay beams help to retain the furnace shape within permissible deviations of furnace pressure. Corner end connecting links maintain furnace

Rear wall is formed with rear bottom header (200 NB x SCH 160 THK) and 63.5 OD x 4.06 thick tubes (One end is welded to the bottom header and the other end is terminated to the top header. Rear wall tubes receive water from steam drum through supply pipes. To strengthen the wall tubes buck stay beams have been provided. Rear wall tubes are supported through rod slings with rocker washer from the super structure. Rear wall bottom header is provided with a 25 N.B. drain connection, which normally remain closed during operation of the boiler. It is to be used to drain the boiler during shut down and start-up. 3.5.3 R.H & L.H Side Wall (Refer Drg no. P43-1PD-45215 , R-1) P41-1PD45213 &

L.H & R.H Side wall is formed with Inbed evaporator top header & sidewall panel top headers (200 NB x SCH 160) and 63.5 O.D x 4.06 thick tubes. Both ends of tubes are terminated at bottom and top headers. Sidewall panels are connected to steam drum through riser tubes from either sidewall . Both the wall assemblies are supported through sling rods with rocker washers from the super structure of the boiler. To strengthen the wall tubes buckstay beams have been provided. Sidewall headers are provided with a 25 N.B. drain connection, which normally remain closed during operation of the boiler. It is to be used to drain the boiler during shut down and start-up. Some of the tubes of the LHS wall are specially bent to accommodate one burner at front of the boiler for boiler 2, RHS for boiler 1. A large furnace volume has been provided to obtain complete combustion of fuel, full radiant heat transfer to the water wall panels to ensure that there is no ame radiation in the second pass and only hot ue gas ows to the second pass. Interlaced Secondary air nozzles are provided at single elevation on LHS & RHS wall. Membrane wall construction of the furnace and the second pass provided a totally gas

Section B

19

Operation & Maintenance Manual

sealed enclosure suitable for balanced draft operation. Adequate number of access doors (which normally remain tightly closed) have been provided in the furnace and in the second pass for inspection of observation of the bed/Flame and for addition bed material during regular operation.

Superheated steam also eliminates the formation of condensate in steam piping which is harmful to the turbine blades and pipelines. There are two stages of superheater in this boiler. They are SH-1 & 2. From the steam drum dry saturated steam enters the SH-1 i.e. 1st stage inlet header (O.D 219.1 x 18.26) through saturated steam supply tubes. From the 1st stage inlet header, steam ows to 1st stage outlet header through 44.45 O.D x 4.06 Thk coils. SH-1 is installed vertically above the goose neck zone with adequate supports. The SH headers are supported through saddle supports. 1st stage outlet header is connected to SH-2 i.e.2nd stage inlet header with Attemperator. From the 2nd stage inlet header, steam ows to 2nd outlet header through 44.5 OD x 4.06 thick coils. 150 NB Steam outlet line is taken from the 2nd stage outlet header of Superheater SH-2. Following connection is attached to primary S.H. Inlet header: 15NB sampling line with isolation valve S-17, which is used to take saturated steam sample. A 25 NB air vent with twin isolation valves S-1 & S-1 is provided for the PSH I/L header.

3.6 Inbed Evaporator

(Drg No. PD1-1PD-45751, R-1)

Figure 1 Inbed Evaporator

In-bed coils (50.8 OD x 6.35 THK Tubes) are provided inside the furnace. Water mixture enters the in bed evaporator bottom header through down comers from steam drum (D1 to D4) and the steam water mixture exits through in bed evaporator top header and then through water wall panel tubes to water wall top headers. Both R.H & L.H Inbed Evaporator bottom headers receive water from the steam drum through supply pipes. Inbed evaporator outer and Inner coils bottom loops are provided with round studs at an angle of 120 deg to reduce direct impingement of particles on the bare tubes and to avoid erosion. Phoscast 90 XR Refractory has been applied over the bends for reducing the erosion and extend the life of the coils.

3.9 Attemperator

(Refer Drg no. PB1-1PD-42672, R-0) Attemperator is provided in between the two stages of superheater in this boiler. From the PSH outlet steam enters the Attemperator made of 219.1 OD x 12.7 thk SA 335 P11 material. Function of Attemperator is to control the nal temperature of the steam to a pre-determined value by spraying required quantity of feed water. Inner SS sleeve is provided to shield the header from thermal stresses due to temperature variations. The inner shield is rmly held at one end by location pins welded on to header and is free to expand at the other end. Flanged joints on to the header hold the spray nozzle. The Spray nozzle at the blind end rests on a guide to with stand the force of the steam. Water is sprayed along the steam ow direction. Spray water for attemperation is taken from feed water line branch after ow nozzle, through spray water control station. Following are the connections attached to Inlet & Outlet pipes of Spray type Attemperator:

3.7 Riser Tubes

(Refer Drg no. P71-1PD-41465, R-1) Purpose of these tubes is to carry the saturated steam from front, rear & sidewall panels to steam drum. Sidewall panels are connected to steam drum through 101.6 ODx5.74 Thk riser tubes. Front wall top header is connected to steam drum through 4 nos. 150 NB x SCH 8 riser tubes and rear wall top header is connected through 10nos. 101.6 O.D x 5.6 THK riser tubes. Convection Bank top headers are connected through 14 nos. 101.6 O.D x 5.6 THK riser tubes (6 from each top header).

3.8 Super Heater

(Refer Drg no. PA1-1PD-45809, R-1/ PA2-2PD-41254, R-1 / PA3-1PD-45937 R-1) Super-heaters are provided to raise the steam temperature above the saturation temperature by absorbing heat from the ue gas. By increasing the temperature of the steam, the useful energy that can be recovered increases, thereby increasing efciency of the cycle also.

Section B

20

Operation & Maintenance Manual

Thermocouple (TE-601) is provided on inlet pipe for panel mounted temperature indicator (TI-601). Thermocouple (TE 602) is provided at the outlet of the Attemperator header for panel mounted temperature indicator (TI-602) . After Attemperator steam enters the secondary super-heater inlet header.

of pressure at panel, for steam density correction and for pressure indicating PI 404 for Steam ow compensation. Start up vent: Start up vent, with pneumatic control valve (S3) and manual isolation valve (S2) is used to vent the steam to atmosphere during boiler start up, as the main steam stop valve & by-pass valve remains closed till the boiler reaches the operating pressure. This also protects the SH coils from over heating during start up. To reduce the noise level from the steam venting to atmosphere, a silencer is provided to the start up vent line. If there is any interruptions in steam ow due to sudden turbine trip / load cut by the end users, start up vent valve to be opened immediately to maintain boiler pressure else safety valve will blow. Drain connection with twin valves S8 & S8 before the main steam stop valve. Drain is terminated to Blow down tank. 150 NB Main Steam Stop Valve (MSSV) S-9 (M 131 ), along with a integral bypass/equalising valve S -10 (S 9 ). Both the valves are motorised valves and bypass Valve S 10is manual operated Valve. During regular operation of the boiler, MSSV is kept fully open supplying steam from the boiler to the plant. Integral bypass valve is opened during the start up of the boiler for initial warming of the main steam line before opening the MSSV. A 15 NB line with twin isolation valves (S12 & S12) is taken from Main steam line for Sample cooler. A NRV (S13) is provided before the stop valve to prevent back ow of the steam from the plant to the boiler. Steam ow-measuring device, i.e. ow nozzle (FE-606) along with ow transmitter Tag no. FT-606 with impulse piping and isolation alves (Tag No. S-11)

3.10 Convection Bank

(Refer Drg no. P61-2PD-40326, R-1) The name itself indicates that heat transfer in this area is by convection mode. This is a Bi-drum boiler, the steam drum (Top drum) and the water drum (mud drum) is connected by a set of tubes called convection bank tubes. Convection bank tubes are constructed of 50.8 O.D x 4.06 thk. Both ends of the tubes are terminated at water / steam drum, and the ends are xed to drums by expansion of the tubes. Bank sides were covered with refractory tiles followed with insulation and outer MS casing. Also the tubes are strengthened by buck stay arrangement at one elevations. An Ash hopper has been provided below convection bank to collect y ash, which is disposed to Ash Handling System (AHS).

Main Steam Piping

Super heated steam from IBSH outlet header is connected to common steam distribution header by the main steam piping. Main steam piping is of 150 N.B. pipe with the following attachments: Safety valve S 4 is provided on steam line. To reduce the noise level from the steam venting to atmosphere, a silencer is provided to the safety valve exhaust line. Pressure Gauge (PG-604) with twin isolation valves (S5 & S5) for indication of main steam pressure.. Thermocouple (TE-604) is provided for main steam temperature control loop. Temperature indicator (TI 604) is provided for local temperature indication in the operating oor and for temperature indicating controller (TIC 604) for steam ow compensation Pressure Transmitter (PT-604) with twin isolation valves (S7 & S7) for remote indication

5

Aim

Boiler Blow Down System

This chapter describes the Boiler Blow down system for safe draining of high pressure and temperature steam and water from the boiler using the Blow down tank.

Section B

21

Operation & Maintenance Manual

System Description P & I Diagram (D12-1PD-6499P, R 21) (Steam and Water system) show the various drains from the boiler, main steam lines, etc. A common drain system has been provided for both he boilers. Large quantities of steam of high pressure / temperature water are not drained through open canals for the following reasons: a) Such draining will cause splashing of high volumes of steam, which can be a nuisance by the noise it creates, and also it affects the visibility around the draining area. b) High temperatures of these drains can cause scalding injuries to workmen who may come in contact with it. c) The force and temperature of these drains will erode the linings of the drain canals. d) Low-pressure steam, which can be recovered, if required, is wasted.

LH In-bed evaporator bottom header RH In-bed evaporator bottom header Economiser header drains Eco I/L header Drain header has following A 50 NB -thk drain line for draining Furnace Drain Header to nearest trench. An 50 NB thk initial lling line with W -26 and isolation valve W-26. The water is supplied from DM water transfer pump. Drain line is connected to IBD tank with an isolation valve W - 40 5.1.2 SH Drain Line Following drains (All 25 NB) are connected to the SH drain header ). Main steam line drain before and after main steam stop valve. Main steam line drain before main steam stop valve has 25 NB drain line with isolation valve (S-8) this line is connected to the BD tank.

5.1 Drain Lines

A 50 NB Common drain line is provided which is connected to the Blowdown tank with an isolation valve W40. Two drain lines from sidewall panel headers are connected to this common drain line. Also Economiser drain is connected with same line. A 50 NB initial lling with isolation valve and NRV DW 16 & DW 17 is connected to the common drain line. 5.1.1 Furnace Drain Line A furnace drain header 50 NB is provided as a common collection point for the drains from various points of the boiler. The following drains (All 25 NB ) of the boiler are connected to the Furnace drain header. All water wall drains fromSOURCE Continuous Blow down from Drum Intermittent Blow down from Drum VALVE TAG NOS.

5.2 CBD Drain

A CBD is tapped from STEAM drum, A 25 NB line for continuous blow down (CBD) is connected to the blow down tank. A CBD valve (D-2) is provided on CBD line. Isolation valve (D-1) is provided.

5.3 IBD Drain

IBD is tapped from WATER drum with a 40 NB pipeline with isolation valve (D-3) and IBD VALVE (D-4). Intermittent blow down (IBD) which is connected to the blow down tank. Table shown below is a summary of such drains with tag nos High Pressure / High Temperature Steam And Water Drains TEMP. OF DRAIN C 306 FREQUENCY OF USAGE Continuous (depending on quality of Boiler water) During high levels in drum and during boiler draining.

D1 isolation, D-2 CBD VALVE.

D-3 isolation, D-4 IBD VALVE.

306

Section B

22

Operation & Maintenance Manual

SOURCE S.H. & Main steam drain Furnace & Economiser drains

VALVE TAG NOS. FOR M.S. LINE isolation valves S-8 For ECO drains isolation valves are W-26, and for furnace W.W isolation valves are W-39.

TEMP. OF DRAIN C Varying from 70 to 520 ~70 - 150

FREQUENCY OF USAGE Draining of condensate during start-up and after a shut down. During boiler start-up and shutdown.

Drains indicated in the above Table are connected to the common intermittent blow down (IBD) tank except CBD drain and various samples. CBD tank is connected to IBD tank while samples to the nearest drain trench.

5.4 Other Drains

Other drains of the boiler are open drains and are connected to the nearest trench within the boiler area. The drains are All level control station drain All pressure control station drain Steam drum level indicator. Steam drum safety valve drains Sample cooler sample let off drain

of the tank, such that the drain uid is directed circumferentially around the inner wall of the tank. Tangential ow of the drain uid into the tank separates steam from the water. Steam rises to the top of the tank and water collects at its lower portion. A vent is provided at the top of the tank. Following connections are connected to the common BD tank. A Level gauge glass LG-550 with isolation valves D6 & D6 has been tted on the tank to verify water level in the tank. Tank is provided with a 50 NB drain pipe with a valve (Tag no. D-7) for ushing purpose. Connections from CBD line, from IBD line, from Drain line, and from MS Drain line. An air vent to atmosphere.

5.5 Blow down Tank

Blow down tank is a pressure vessel capable of separating steam from the drained hot water. This drain is connected tangentially in the upper half

Section B

23

Operation & Maintenance Manual

Air and Gas System

( P & I DIAGRAM D12-1PD-6500P, R- 2) Air System This chapter describes supply of primary and secondary air to the boiler. The components that form part of air system are FD Fan Air Pre-Heater (APH) Air ducts Combustion air to Windbox Secondary Air OR Over re air. Secondary Air For Air Spray Nozzle

the required fan output pressure and ow. The VFD receives input signal from furnace pressure indicating controller (HZ 200). Fan Discharge Duct 1. To minimise the force due to possible movement of the discharge duct on the fan, as well as to isolate fan vibrations being passed on to the duct, the fan is connected to the discharge duct through bellows type expansion joint (1no) Test pockets temp. gauge and pressure gauge is provided on outlet duct. A Draft Gauge (DG 200) is provided with an isolation valve (A1) at the outlet duct. Fan outlet is connected to air pre-heater (APH) through a ducting. Aerofoil An Airfoil to measure the airow is provided (AFM 200). The airow is measured by the principle of pressure drop across the element being proportional to the airow passing across it. Flow transmitter (FT-200) gives input to a controller (FIC-200), which also get inputs from combustion control and ultimately it controls suction air by power cylinder. Please refer Vendor Manual for safe Operation & Maintenance of FD fans.

6.1 System Description: 6.2 FD Fan

Figure 2 FD Bearing

Each Boiler is provided with 1x 100 %. F.D fans driven by electric motor to supply main combustion air to the furnace and various other equipment. FD fan is of centrifugal type, with radial, backward curved blades. FD Fan Suction Side FD fan is provided with a suction duct with silencer for cold combustion air from the plant environment. The details are elaborated below in the component wise description. FD Fan Suction Duct Bird Screen & Silencer At the inlet of the FD fan suction duct rain cowl with bird screen is provided. An absorption type silencer is installed to attenuate the noise. FD Fan Suction Damper Suction damper (inlet guide vane) control has been tted on the suction of the FD fan. FD fan sucks air from environment through the suction duct and inlet damper. The percentage opening of the inlet damper (guide vane) regulates the capacity of the fan to meet the combustion air and other requirements of the boiler. Fan inlet damper gets input signal from pressure indicating controller (HZ 200). A pneumatic actuator (HY 200) is provided to operate the damper. The actuator is provided with limit switches (ZSC 0/C 200) for 0% & 100% positions, which are used as safety interlocks for fan start permissive. VFD is provided. In VFD mode, the inlet damper is kept full open and the motor speed is varied to get

6.3 Air Pre Heater

Reference drg no: A32 - 1PD - 44980 R 0 Air heater provided is of tubular type and the purpose is to recover a portion of the sensible heat from ue gases by all incoming combustion air, thereby improving combustion efciency. The hot ue gas passes through the tubes to heat air while the air from F.D fans passes from out side of the tubes for heating. APH is single ue gas pass and double air pass. APH is assembled on a steel structure enclosed with a 4-mm thick steel casing. Bottom Tube sheet is plate 3495 X 2035 X 16 THK. and the Top Tube sheet is 3495 X 2035 X 12 THK , Middle Tube sheet is 3495 X 1851 X 10 THK. APH tubes are 63.5 mm OD X 2.34-mm thk. Every tube is expanded in top and bottom sheet. Bafe plates are provided to support and strengthen APH tubes between top and bottom tube sheets. To avoid cold end corrosion some rows of CORTEN STEEL are provided. APH is a non-mixing type heat exchanger in which ue gases pass through the tubes and air out side the tubes. Flues enter in APH from bottom of APH-I, enter in to APH-II & leave from top of

Section B

24

Operation & Maintenance Manual