Professional Documents

Culture Documents

CEP - Saving

Uploaded by

Manoj UpadhyayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CEP - Saving

Uploaded by

Manoj UpadhyayCopyright:

Available Formats

POWER PLANT EFFICIENCY NEWSLETTER

The Monthly Newsletter No.1

March 2010

I N S I D E

Make Indian Thermal Power Plants World Class Development of service providers network for Indian thermal power plants

CII-Sohrabji Godrej Green Business Centre (CII-Godrej GBC) is promoting the concept of Make Indian Thermal Power Plants world class, with the support of all the stake holders in Indian power sector. The main objective is to facilitate continuous performance improvement in Individual Indian thermal power plants and help them in achieving the world class standards. Indian thermal power plants offer enormous potential for efficiency improvement, however, the actual implementation of the efficiency improvement projects are not taking place at the required pace. The following reasons have been repeatedly highlighted in many of the CII forums by end users are:

F Lack of awareness about the latest technological developments &

Make Indian Thermal Power Plants World Class Development of service providers network for Indian thermal power plants Application of Variable frequency drives for Power plant Auxiliaries

- CII - Godrej GBC

performance improvement techniques

F Very limited or non availability of capable service providers for the Indian

thermal power plants Against this background, as part of the initiative of Make Indian thermal power plants world class, CII-Godrej GBC has started facilitating the development of service providers network for Indian thermal power plants. The U.S. Department of Energy (DOE) and its National Energy Technology Laboratory (NETL) and the India Mission of the U.S. Agency for International Development (USAID/INDIA) are supporting the initiatives related to the development of the service providers network. CII-Godrej GBC is taking up the following activities for facilitating the development of service providers network for Indian thermal power plants:

F Awareness creation - centre wise / unit wise training programmes

Thermal Power Plant Efficiency & Boiler Optimization

- Stephen K. Storm, Storm Technologies, Inc. (USA)

and workshops for creating awareness about latest efficiency improvement techniques

F Information dissemination through periodic news letter with technical

articles on latest developments and case studies

F Acting as a nodal agency for transfer of technologies and technical

services

F Facilitation of demonstration of performance improvement projects in

Indian thermal power plants The monthly newsletter Power plant efficiency brought out with the sole purpose of disseminating information amongst the end users would throw light on various technological developments, best practices from Indian & International thermal power plants. The newsletter will also highlight the current happenings in the power sector at national and international level.

01

Application of Variable frequency drives for Power plant Auxiliaries

Background Motor-driven systems are often designed with safety margins to handle peak loads and extreme conditions. These excess margins lead to energy inefficiency in systems and increased power consumption. The ability to adjust motor speed enables closer matching of motor output to load and results in significant reduction in energy consumption. The variable frequency drive varies the speed of the motor by changing the frequency and voltage of the motor keeping the v/f ratio constant. Variable speed drives are used for the following reasons: 1. To vary the capacity of the motor driven equipment to match with the changing load requirements To minimize the excess margin built in the equipment For accurate and continuous process control

Typically, all of the auxiliary equipments in power plants, such as pumps and fans, are designed with excess margins to ensure reliability of the plant and also to meet requirements during extreme operating conditions. These excess margins lead to increased auxiliary power consumption during the normal operating conditions of the plant. With the help of the variable frequency drives, the operating speed of the auxiliary equipment can be optimized to reduce power consumption and to match actual requirements. A 250 MW thermal Indian power plant has installed variable frequency drive for centrifugal equipments, such as the condensate extraction pump (CEP) and seal air fans. This has resulted in significant energy savings. The details of the project related to installation of VFD for the CEP are given below. Previous Status A condensate extraction pump of the following specifications is in operation in a 250-MW thermal power plant. Capacity Head Motor rating No of stages 770 m3/hr 205 m 650 kW 5

2.

3.

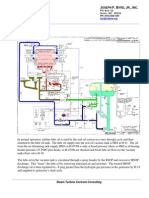

The schematic diagram of the system is shown below.

02

The operating parameters of the CEP at full load operating conditions are given below. Parameters Discharge Pressure Deaerator Pressure Flow Motor speed Power Consumed Values 21.3 kg/cm2 6.9 kg/cm2 640 TPH 1450 rpm (50 Hz) 590 kWh

3. 4.

A soft starter for the motor is no longer required. Controlled ramp-up speed in a liquid system can eliminate water hammer problems. The ability of a VFD to limit torque to a userselected level can protect driven equipment that cannot tolerate excessive torque.

5.

In view of the above-listed additional benefits, the plant installed a HT VFD for the CEP , even though it costs much more than stage removal. The details of the operating condition of the CEP after installing the VFD are given below. CEP Parameters Discharge Pressure Deaerator Pressure Flow (TPH) Motor speed Control valve CD14 position Power Consumed Benefits of the project Energy Savings achieved Electrical Energy Saving 1.26 Million Units Rs 4.52 Million/ year 671 Tons/ year 2460 Tons/ year Annual Savings Saving of Coal Reduction of CO2 Emissions Financial analysis The annual savings achieved is Rs 4.52 million (USD 0.09 million). The investment made for installation of VFD is Rs 6.00 million (USD 0.12 million). The simple payback period is 16 months. Replication Potential In a typical 250-MW thermal power plant, the auxiliary power consumption for the CEP is around 0.27% of the total plant output. The savings that can be achieved by installing an HT VFD varies from about 15-20%. This project has high replication potential in majority of the captive and utility thermal power plants in India. Considering the present installed capacity of the coalbased thermal power plants in India, the replication potential of this performance improvement project is estimated to be as high as 30 MW. With HT VFD drive 17.5 kg/cm2 6.9 kg/cm2 640 1250 rpm (42 Hz) 95% 440 kWh

The control valve is only about 60% open during normal operating condition. This valve throttling leads to pressure loss across the valve and hence energy loss. The pressure loss across the control valve is estimated as 7.5 kg/cm2 based on pressure measurements taken before and after the control valve. Performance improvement project The operating conditions and the measurements clearly indicate that there is an excellent potential to minimize the pressure drop across the control valve and reduce energy consumption. This can be achieved by optimizing the number of stages of the pump or installing a VFD for the pump with feed-back control. In addition to energy savings and better process control, installation of VFDs has the following benefits compared to the stage reduction. 1. Maintenance costs can be lower, because lower operating speeds result in longer life for bearings and motors. Eliminating the throttling valves and dampers also does away with maintaining these devices and all associated controls.

2.

03

Thermal Power Plant Efficiency & Boiler Optimization

Stephen K. Storm Storm Technologies, Inc. (USA)

Around the globe, we all bear the responsibility of using our energy resources wisely. However, one of the greatest challenges we face is the conversion of affordable fossil fuels into electricity as efficiently and cleanly as possible. Electric power generation from coal is the most affordable energy on the planet and we must use it responsibly in our effort to achieve sustainable power generation growth. Coal will continue to serve as a primary source of energy worldwide, and it will be the bridge to our future, as we develop new means of renewable energy and other means of generating electricity. An example of a responsible, yet mutually beneficial, climate change program in the power sector is the Performance Optimization and Efficiency Program supported by Storm Technologies at selected power plants in India over the past several years. Storm's program reviews power plant performance by inter-relating the variables of performance with fuel quality, operations and maintenance (O&M), and plant reliability. Sustaining optimum plant performance and reliability is a must for all plants, even if they have not been rehabilitated. An introduction, or refresher course, on best practices for O&M of existing and future coal-fired generating plants in India is worthy of the resources needed to implement such a program. Storm Technologies' introduction of the best practices is an important paradigm shift in the O&M of the existing fleet and future coal-fired generating plants in Asia, as well as the United States. The main objective of the program is to demonstrate the importance and the environmental benefits of combustion and boiler optimization and overall plant efficiency/heat rate improvement. Storm Technologies' program has been used by the U.S. Department of Energy to promote Best Practices under the Asia Pacific Partnership on Clean Development and Climate (APP). The program included fourteen comprehensive areas of evaluation including pulverizer systems, fuel lines, burner performance, as well as total combustion airflow measurement, furnace exit flue gas profiling, and measurement and monitoring at several points between the boiler and the stack.

The basic purpose of the program's protocol utilized was to provide a process for the plant to periodically test, tune and comprehensively evaluate opportunities for plant efficiency and heat rate improvement. It should also be noted that the program was purposely designed for replication at the Indian super thermal power plants selected for demonstration. Some of the typical challenges today's plants are faced with in India are related to plant efficiency, fuel conservation, reduced generation and limited coal supplies. Taking these into consideration, the key to the program is essentially identification of opportunities for improvement through the implementation of a performance preservation program. Program Overview Quite often, there are numerous low-hanging fruit opportunities for combustion and plant efficiency improvement, and some of these include coal pulverizer and burner performance, the opportunity to improve lower furnace heat absorption, reduce furnace exit gas temperatures, reduce carbon in ash levels, as well as reducing air in-leakage, both upstream and downstream of the air heater, to name a few. Most of these factors at the boiler influence heat rate and efficiency, generation and environmental performance. In an effort to evaluate the previously identified opportunities for improvement, a series of performance tests were completed.

These included measurement of:

F Gross Turbine Cycle Heat Rate F Mill / Fuel Line Performance F Total Airflow Measurement & Calibration F Furnace Exit Gas Profiling F Flue Gas

and Fly ash Measurement for Performance Evaluation

Ultimately, the goal of such an evaluation is to determine the stealth losses and/or the unaccountable losses impacting heat rate performance. What is different about this program as compared to most combustion tuning programs is that the protocol used at the participating Indian power plants evaluates the entire boiler system, with the fuel lines and combustion airflow paths regarded as the inputs.

04

Furthermore, furnace exit profiling and flue gas measurements from the boiler to the stack are also used to evaluate overall performance. Considering the comprehensive nature of such a program, Storm Technologies has developed a simplified Annual Plant Performance Longevity and Evaluation Program (APPLES) to help establish such testing protocols. The development of the standards for performance can take time and requires a true team effort. However, once completed, the plants enhance their ability to maximize load generation and performance while simultaneously improving environmental performance. It is not untypical to find thermal plants operating between 5% 10% lower than the plants design thermal efficiency and this correlates with a tremendous opportunity for heat rate improvement, fuel savings, as well as overall CO2 emissions reduction. Quite often, many of the deviations are not related solely to the turbine. However, boiler performance and auxiliary horsepower consumption are equally as important and often neglected. Recently, Storm Technologies presented the project completions of work completed in India at POWER-GEN Asia. Based on the facts collected thus far, over the past year and the result of the program identified, on average a deviation of ~124,000 tons of CO2 was identified (on average for each of the two 210-MW units). For two thermal plants with 6 units each, the potential for reduced CO2 emissions would be on the order of ~744,000 tonnes of CO2/year. It should also be noted that, by reducing CO2 emissions, the program has demonstrated how fuel consumption can also be substantially reduced. By implementation of recommendations on these units, payback for the program investments yielded short-term payback with respect to efficiency improvement and improved generation performance and is gaining a substantial amount of attention in the country. By demonstrating the capability to improve load generation, reducing fuel consumption and simultaneously improving environmental performance, the benefits of the program are obvious.

Key Points of the Program Some key points that were instrumental in the program's success were:

F Team training and the personnel commitment

of comprehensive diagnostic testing ports was essential F Optimization of the excess oxygen as proven at the furnace exit was required to validate actual combustion performance F Pulverizer performance and fuel balance is a critical component of the optimization program F Total airflow management is mandatory F Burner tolerance and mechanical maintenance of the firing system is essential F Boiler efficiency and air in-leakage measurements are critical to the support of the team

F

F Installation

Once again, it should be noted that efficiency opportunities also resulted in the plants ability to simultaneously improve plant capacity and reduce emissions. Achieving energy efficiency within thermal power plants is a mandatory requirement for sustainable and responsible power generation and demands a fundamental and proven approach which has been demonstrated by a small group of Indian coal-fired power plants who are to be commended for their leadership by example. For more information about Storm Technologies, Inc., you can visit www.stormeng.com or Contact Stephen Storm at stephen.storm@stormeng.com.

05

About CII, CII Godrej GBC CII is a non-government, not-for-profit, industry-led and industry-managed organisation, playing a proactive role in India's development process. Founded over 113 years ago, it is India's premier business association, with a direct membership of over 6500 organisations from the private as well as public sectors, including SMEs and MNCs, and an indirect membership of over 90,000 companies from around 350 national and regional sectoral associations. The Government of Andhra Pradesh, CII, and the House of Godrej, with the technical support of the United States Agency for International Development (USAID) have launched the CII-Sohrabji Godrej Green Business Centre to offer much needed Green Services to Indian industry. Cll-Godrej GBC is a Centre of Excellence in Energy Efficiency, Green Buildings, Renewable Energy, Water, Environment & Recycling and Climate Change activities in India. CII-Godrej GBC is promoting the concept of Make Indian thermal power plants world class. The main objective is facilitating continuous performance improvement in thermal power plants and there by achieving world class standards. As part of this, CII-Godrej GBC is also facilitating development of a service provider's network for Indian thermal power plants. Supported by USDOE, NETL & USAID/India The U. S. Department of Energy's (DOE), National Energy Technology Laboratory (NETL) is providing technical support for power plant efficiency improvement on the Greenhouse gas Pollution Prevention (GEP) Project of the India Mission of USAID. CII-Godrej GBC is supporting the GEP Project by developing a service provider's network for Indian thermal power plants. This technical bulletin has been developed as part of the information dissemination programme of this effort.

For further information, Please contact

S Karthikeyan s.karthikeyan@cii.in

Survey No 64, Kothaguda Post, Near HITEC City, Ranga Reddy Dist., Hyderabad - 500 084 Tel: +91 40 23112971-73, Fax: +91 40 23112837 www.greenbusinecentre.com

06

You might also like

- Thermal Cycles of Heat Recovery Power PlantsFrom EverandThermal Cycles of Heat Recovery Power PlantsRating: 5 out of 5 stars5/5 (2)

- Power Palnt Performance PDFDocument161 pagesPower Palnt Performance PDFrafik1995100% (1)

- CEP SamalkotDocument96 pagesCEP SamalkotkukugargNo ratings yet

- LMI-Flexible Operation of Dadri Coal Fired UnitsDocument8 pagesLMI-Flexible Operation of Dadri Coal Fired Unitssumit kontNo ratings yet

- 115 Flexibility Report WEBDocument116 pages115 Flexibility Report WEBThanasate PrasongsookNo ratings yet

- Energy Audit Methology For Turbine Cycle - M.V. Pande & Dy - Director PDFDocument33 pagesEnergy Audit Methology For Turbine Cycle - M.V. Pande & Dy - Director PDFtolga ALTINTAŞ100% (1)

- PDFDocument33 pagesPDFsourav mahapatraNo ratings yet

- ORT-Aug R1Document67 pagesORT-Aug R1Vishal Kumar LaddhaNo ratings yet

- 02 Boiler Design in General - Part 2Document70 pages02 Boiler Design in General - Part 2sriramojNo ratings yet

- Front & Rear Wall BoilerDocument93 pagesFront & Rear Wall BoilerAravazhi Ramasami Thangaraj100% (1)

- ORT ReportDocument71 pagesORT ReportNaveen ChodagiriNo ratings yet

- Auxiliary Power Consumption Reduction in Thermal Power StationsDocument3 pagesAuxiliary Power Consumption Reduction in Thermal Power StationsbarunNo ratings yet

- Ennore Thermal Power StationDocument14 pagesEnnore Thermal Power StationRajesh Kumar100% (2)

- SSTPS LMI On Optimaization of Ash Water Utilaization Revision-2 - Agupta SirDocument18 pagesSSTPS LMI On Optimaization of Ash Water Utilaization Revision-2 - Agupta SirGautamupadhyayNo ratings yet

- Auxiliary Power ConsumptionDocument27 pagesAuxiliary Power ConsumptionAbdulyunus AmirNo ratings yet

- Analysis of Feed WaterDocument9 pagesAnalysis of Feed Watersanju0156No ratings yet

- Final Ea R-Infra Dahanu TpsDocument84 pagesFinal Ea R-Infra Dahanu TpsLakshmi NarayanNo ratings yet

- Npti 210 MW Power Plant ManualDocument6 pagesNpti 210 MW Power Plant ManualSaiNo ratings yet

- Power Management InstituteDocument2 pagesPower Management InstituteAhamed JalaludeenNo ratings yet

- Difficulties FacedDocument6 pagesDifficulties FacedJackSparrow86No ratings yet

- 03 APC ReductionDocument55 pages03 APC ReductionDevanshu SinghNo ratings yet

- Power Plant - 180 - 09 - JSW - Energy - Ratnagiri - 0Document37 pagesPower Plant - 180 - 09 - JSW - Energy - Ratnagiri - 0singhishpal24374No ratings yet

- Coal Management SystemDocument12 pagesCoal Management SystemBiswajit DuttaNo ratings yet

- COal Fired Plants FlexibilityDocument32 pagesCOal Fired Plants FlexibilityVeerabhadra Rao KorimilliNo ratings yet

- Why Efficiency in Thermal Power Plant Is LowDocument1 pageWhy Efficiency in Thermal Power Plant Is LowNallathambiNo ratings yet

- Air Pre-Heater: - An Essential Component in Fossil Fuel Fired PlantDocument66 pagesAir Pre-Heater: - An Essential Component in Fossil Fuel Fired PlantRaushan Kumar100% (1)

- CFBC Boiler Performance Calculation4 PDFDocument43 pagesCFBC Boiler Performance Calculation4 PDFrizalNo ratings yet

- Heat Rate ImprovementDocument25 pagesHeat Rate ImprovementRanjeet KumarNo ratings yet

- PocketDiary SantaldihDocument198 pagesPocketDiary SantaldihJoydev GangulyNo ratings yet

- Clean Air Flow TestDocument4 pagesClean Air Flow TestLakshminarayanNo ratings yet

- Circulating Fluidized Bed Boiler Gyanendra Sharma NPTI DelhiDocument48 pagesCirculating Fluidized Bed Boiler Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Effect of Coal QualityDocument17 pagesEffect of Coal QualityAmit AgarwalNo ratings yet

- 01 Boiler Design General (Compatibility Mode) PDFDocument82 pages01 Boiler Design General (Compatibility Mode) PDFTaraknath MukherjeeNo ratings yet

- Apc PPT PDFDocument15 pagesApc PPT PDFrasiganeshNo ratings yet

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDocument15 pages3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGNo ratings yet

- Mill - PerformanceDocument51 pagesMill - PerformanceRavi Satyapal100% (1)

- U4OHREPORT2008Document88 pagesU4OHREPORT2008Anonymous pKsr5vNo ratings yet

- Reduction in Boiler Cooling TimeDocument16 pagesReduction in Boiler Cooling Timejp mishraNo ratings yet

- Cep 1Document17 pagesCep 1Nilamani Umashankar Jena100% (1)

- Operation Best PracticesDocument30 pagesOperation Best Practicesjp mishraNo ratings yet

- NTPC Limited Anta Gas Power Station: First Prize Thermal Power StationsDocument20 pagesNTPC Limited Anta Gas Power Station: First Prize Thermal Power Stationsmaknu2827 Jain100% (1)

- Research in Varying Burner Tilt Angle To Reduce Rear Pass Temperature in Coal Fired BoilerDocument9 pagesResearch in Varying Burner Tilt Angle To Reduce Rear Pass Temperature in Coal Fired BoilerraitoNo ratings yet

- Thermodynamic Correction Curves For Model n600-16 7538538 Steam TurbineDocument27 pagesThermodynamic Correction Curves For Model n600-16 7538538 Steam Turbinearunrajmech09No ratings yet

- Blending of Coals in Power StationsDocument20 pagesBlending of Coals in Power StationsPankaj GuptaNo ratings yet

- Feed Heater Performance PDFDocument32 pagesFeed Heater Performance PDFsukdev_22No ratings yet

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNo ratings yet

- Auxiliary Power ConsumptionDocument3 pagesAuxiliary Power ConsumptionNicko LastardaNo ratings yet

- Regulatory and Comm Aspects of Power Generation - 24.06.2019Document56 pagesRegulatory and Comm Aspects of Power Generation - 24.06.2019dks12No ratings yet

- Presented By: Souvanik Chakravorty S Anil Kumar Tatithuri G SrikantDocument30 pagesPresented By: Souvanik Chakravorty S Anil Kumar Tatithuri G Srikants anil kumar tatithuriNo ratings yet

- DSM Case FinalDocument9 pagesDSM Case Finalshidupk5 pkNo ratings yet

- Boiler Turbine Dynamics in Power Plant ControlDocument12 pagesBoiler Turbine Dynamics in Power Plant ControlAmanjit SinghNo ratings yet

- Project ReportDocument89 pagesProject ReportgoyalzNo ratings yet

- Energy Efficiency in Sugar Plant Steam and Power Generation PDFDocument6 pagesEnergy Efficiency in Sugar Plant Steam and Power Generation PDFSrikanth SriNo ratings yet

- 2011 - Technical Study Report - Energy Efficiency ImprovemenDocument85 pages2011 - Technical Study Report - Energy Efficiency Improvemenmatealoredana8015No ratings yet

- Technology: Evolution of Motor and Variable Frequency DriveDocument12 pagesTechnology: Evolution of Motor and Variable Frequency DriveWalidAdrarNo ratings yet

- Green Motor Drive©: by Dr. Abe Shahrodi Power Magnetronics SolutionsDocument14 pagesGreen Motor Drive©: by Dr. Abe Shahrodi Power Magnetronics Solutionsalex696No ratings yet

- SME Case Study-Steel Re-Rolling MillDocument4 pagesSME Case Study-Steel Re-Rolling MillVijay RathiNo ratings yet

- Base Paper For The Workshop On Renovation and Modernization and Water Optimization in Thermal Power StationsDocument7 pagesBase Paper For The Workshop On Renovation and Modernization and Water Optimization in Thermal Power StationsAmit SharmaNo ratings yet

- Power Palnt PerformanceDocument0 pagesPower Palnt PerformanceSHIVAJI CHOUDHURY100% (2)

- Att PDFDocument26 pagesAtt PDFManoj UpadhyayNo ratings yet

- TSC 2Document15 pagesTSC 2Manoj UpadhyayNo ratings yet

- Turbine ProtectionsDocument8 pagesTurbine ProtectionsManoj UpadhyayNo ratings yet

- Ch15 TaylorDocument12 pagesCh15 Taylorramnadh803181No ratings yet

- Turbine ProtectionsDocument8 pagesTurbine ProtectionsManoj UpadhyayNo ratings yet

- Governing - General PDFDocument49 pagesGoverning - General PDFManoj Upadhyay100% (1)

- Attitude and SucessDocument51 pagesAttitude and SucessManoj UpadhyayNo ratings yet

- SO4 On RGMODocument5 pagesSO4 On RGMOrajaNo ratings yet

- Turbine ProtectionsDocument8 pagesTurbine ProtectionsManoj UpadhyayNo ratings yet

- BHEL Supplied Supercritical Steam TurbineDocument20 pagesBHEL Supplied Supercritical Steam Turbinenetygen1No ratings yet

- BHEL Automation Migration SolutionDocument27 pagesBHEL Automation Migration SolutionSiva KumarNo ratings yet

- Fuel SystemDocument8 pagesFuel SystemManoj UpadhyayNo ratings yet

- Signed Order Pet 66 2003 FGMODocument25 pagesSigned Order Pet 66 2003 FGMOManoj UpadhyayNo ratings yet

- Lecture 27 Model Steam Turbine Gov SystemDocument60 pagesLecture 27 Model Steam Turbine Gov Systemlogiclover100% (1)

- Effect of Reactive PowerDocument12 pagesEffect of Reactive PowerManoj UpadhyayNo ratings yet

- 660 MW Governing System PresentationDocument49 pages660 MW Governing System Presentationgaurav tiwari100% (1)

- 660 MW Governing System PresentationDocument49 pages660 MW Governing System Presentationgaurav tiwari100% (1)

- Seal Oil OperationDocument2 pagesSeal Oil OperationManoj Upadhyay100% (1)

- FaultDocument18 pagesFaultManoj UpadhyayNo ratings yet

- Generator ProtectionDocument69 pagesGenerator ProtectionkarthikNo ratings yet

- Performance ReviewDocument25 pagesPerformance ReviewManoj UpadhyayNo ratings yet

- 06 TransformerprotectionDocument0 pages06 TransformerprotectionManoj UpadhyayNo ratings yet

- Seal Oil SystemDocument3 pagesSeal Oil SystemManoj UpadhyayNo ratings yet

- BSNL (Bharat Sanchar Nigam Limited) : A Presentation OnDocument25 pagesBSNL (Bharat Sanchar Nigam Limited) : A Presentation OnMahesh Kumar NigamNo ratings yet

- 1 - Santosh Mahadeo MestryDocument17 pages1 - Santosh Mahadeo MestryAnandapadmanabhan RamabhadranNo ratings yet

- Air MoniterDocument108 pagesAir MoniterManoj UpadhyayNo ratings yet

- Auxiliary Power Reduction in Thermal Power PlantDocument27 pagesAuxiliary Power Reduction in Thermal Power PlantManoj Upadhyay100% (1)

- SAC WorksheetDocument16 pagesSAC WorksheetManoj UpadhyayNo ratings yet

- Auxiliary PowerDocument29 pagesAuxiliary PowerManoj UpadhyayNo ratings yet

- Week 4 SimDocument3 pagesWeek 4 SimJEZUE REMULTANo ratings yet

- Environmental Policy in Your Country MemoDocument2 pagesEnvironmental Policy in Your Country MemoZoraida Ortega PoloNo ratings yet

- Zimbabwe PDFDocument44 pagesZimbabwe PDFanon_692297461100% (1)

- Geography Notes For Class: X (Social Science) : Prepared byDocument21 pagesGeography Notes For Class: X (Social Science) : Prepared byRakshak AwasthiNo ratings yet

- FSC 111Document5 pagesFSC 111Moloy Das100% (1)

- Loans Extended To Tourism SectorDocument54 pagesLoans Extended To Tourism Sectorsonal patil80% (5)

- Twin Pines Minerals - Saunders Demonstration Mine - Surface Mining Application - 6-19-2020Document14 pagesTwin Pines Minerals - Saunders Demonstration Mine - Surface Mining Application - 6-19-2020Mary LandersNo ratings yet

- Rabbit Habitats and HabitsDocument6 pagesRabbit Habitats and HabitsMonu Lal BurnwalNo ratings yet

- Society For The Conserv Ation of Philippine Wetlands. IncDocument23 pagesSociety For The Conserv Ation of Philippine Wetlands. IncKris OliquinoNo ratings yet

- 4 5891012804307060500Document18 pages4 5891012804307060500Lemma BerisoNo ratings yet

- Conservation of Plants and AnimalsDocument36 pagesConservation of Plants and AnimalsAngeelina AgarwalNo ratings yet

- Debarry Watershed Processes and MGMTDocument17 pagesDebarry Watershed Processes and MGMTJames K. KirahukaNo ratings yet

- CREEDDocument3 pagesCREEDSabareesh SureshNo ratings yet

- Mit PDFDocument197 pagesMit PDFgayathriNo ratings yet

- Giant Hogweed Fact SheetDocument4 pagesGiant Hogweed Fact SheetNicoleKleinsteuberNo ratings yet

- RESOLUTION Commending SAMAPUSI Inc For Environmental AwardDocument1 pageRESOLUTION Commending SAMAPUSI Inc For Environmental AwardMai Momay100% (1)

- Industrial Ecology 1Document35 pagesIndustrial Ecology 1Yogesh KumbharNo ratings yet

- Polar-Bear e A4Document0 pagesPolar-Bear e A4Riadh FantarNo ratings yet

- FRA CFR Draft - Report06012021Document20 pagesFRA CFR Draft - Report06012021DebiGoenkaCATNo ratings yet

- Fao 2008Document231 pagesFao 2008marcoaureliorottaNo ratings yet

- Coral Reef Ecosystem QuestionsDocument4 pagesCoral Reef Ecosystem Questionsamabelle sibugNo ratings yet

- Wildlife Without Borders: Tiger Conservation ProgramDocument2 pagesWildlife Without Borders: Tiger Conservation ProgramDebraj DattaNo ratings yet

- Vision IAS Environment Part 1Document169 pagesVision IAS Environment Part 1Anup ShindeNo ratings yet

- Asia Conserved (For Web)Document450 pagesAsia Conserved (For Web)Sitta KongsasanaNo ratings yet

- Intro. To PaintingDocument46 pagesIntro. To PaintingIanMonisNo ratings yet

- HNT.E - Đề chuẩn Tiếng Anh 2020 - Đề 3Document27 pagesHNT.E - Đề chuẩn Tiếng Anh 2020 - Đề 3Trần NgânNo ratings yet

- RFP Development of Central Green Park in Gift City09092021011413Document151 pagesRFP Development of Central Green Park in Gift City09092021011413akashNo ratings yet

- Spray Plaster Combined 28 July 2011Document8 pagesSpray Plaster Combined 28 July 2011gsebrenmaniNo ratings yet

- Causes and Effects of Global WarmingDocument2 pagesCauses and Effects of Global Warmingtislm1No ratings yet

- Analysing Recent Land Use Land Cover Change PDFDocument66 pagesAnalysing Recent Land Use Land Cover Change PDFHerb Clemen100% (1)