Professional Documents

Culture Documents

The Condenser Liquid Level Influence in A Cryogenic Distillation Column Operation

Uploaded by

carneoliaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Condenser Liquid Level Influence in A Cryogenic Distillation Column Operation

Uploaded by

carneoliaCopyright:

Available Formats

G

A

L

L

Y

P

R

O

O

F

1

7417

Asian Journal of Chemistry Vol. 20, No. 7 (2008), 0000-0000

Condenser Liquid Level Influence in a Cryogenic

Distillation Column Operation

CLAUDIA PEARSICA*, LIVIU OVIDIU STEFAN, ANISOARA PREDA and FELICIA VASUT

Institute for Cryogenic and Isotopic Technologies Rm.Valcea, Romania

Fax: (40)(250)732746; E-mail: claudia@icsi.ro

It was studied the behaviour of the cryogenic distillation

column at the influence of an external factor. For this, it was

analyzed the non steady state for the column when exist a

variation in the control system from the cooling circuit of the

cryogenic distillation plant, which determine the fluctuation

of the hydrogen level from the cryogenic distillation column

condenser. The column has H height and NT theoretical stages,

with the feed stream bicompound mixture of tritium and deu-

terium. The mathematical model for the simulation of the

process is based on the equations of balance on the column,

for the stages and for the condenser. The column is operated

at total reflux. The variation of the level from condenser was

considered as a sinusoidal function. The results were repre-

sented in specific diagrams and plots. There can be followed

concentrations profiles at any moment of time. Each param-

eter can offer information about the behaviour of the distilla-

tion column operated at total reflux with sinusoidal oscilla-

tion of the liquid level in condenser.

Key Words:

INTRODUCTION

The hydrogen distillation is one of the modern methods of hydrogen

isotopes separation. From experience, we observed a great sensibility of

the isotopes separation installation owing to the specific process.

To achieve a correct functioning of the distillation column that belongs

to a liquid hydrogen isotopic plant, it is necessary to be maintained con-

stant all the functioning parameters, this would correspond to a steady state.

In practice this can not be achieved, so the operating of the column

will suffer some perturbations, taking place in a non-steady state. The ef-

fect of the functioning in a non-steady state is the low separation power of

the column. We are going to observe the way that the level of liquid from

condenser influences the functioning of the isotopic distillation column.

Such a perturbation determines a quick modification of the liquid flow

capacities, in time and in length and also a modification in time of the

holdup from the condenser on the contact unity.

G

A

L

L

Y

P

R

O

O

F

2

7417

This work is dwelling on another possible situation, which is, the varia-

tion of the liquid level in the column condenser, following the generic

behaviour of a cryogenic distillation column for the separation of the hy-

drogen isotopes with N

T

theoretical stages and H

col

height.

Mathematic pattern for studying the non-steady state of a separation

column working at total reflux with perturbation in condenser

The perturbation of flow capacity from the column due to the variation

in time of the liquid level from the condenser is absorbed all the way through

the column, this way the boiling vessel functioning from the bottom of

column is not influenced by the perturbation. A direct consequence of this

observation is that the gas flown throughout the column is going to stay

constant in the variation of the flow, caused by the variation level of the

liquid from the condenser and is fully taken by the variation of the liquid

flow.

We make the simplifying theory that the pressure variation from the

column does not influence the separation factor . The variation of the gas

holdup from the condenser due to the energy fluctuation which is intro-

duced into the system through the modification of the liquid level from the

condenser, leads to the variation between the liquid and the gas capacities

flow which are circling in contra current in the column.

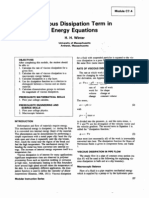

In a situation like this the distillation column is the one represented in

Fig. 1.

Hp0

Hc yc

L c xc

Ln+

1

Ln

G

G

y

L1 x1 G y0

GyN

Condenser

Column with NT levels

Platter n

Boiling vessel

Fig. 1

G

A

L

L

Y

P

R

O

O

F

3

7417

The holdup from the distillation column filling is uniformly distrib-

uted all the way. The equilibrium equation for the column:

0

t

H

N

t

H

n c

=

(1)

The total vapourization in the boiling vessel, operated at total reflux,

x1 = y0

Equilibrium equation for plate n for the condenser.

Balance for stage n:

n 1 n

n

L L

t

H

=

+

(2)

( )

( )

n n 1 n 1 n n 1 n

n n

x L x L y y G

t

y H

+ =

+ +

(3)

For condenser:

c

c

L G

t

H

=

(4)

( )

c c N

c c

x L Gy

t

y H

=

(5)

It is considered a sinusoidal variation in the condenser, after the equa-

tion:

t sin A H H

0 c c

+ = (6)

where A is the amplitude with the following values:

>

=

=

0 t for A

0 t for 0

) t ( A

(7)

After the calculation it is obtained:

t cos

N

A

L L

1 n n

+ =

+

(8)

For the last plate it can be written:

t cos A

N

1 N

G L

N

=

(9)

t cos A

N

1 n

G L

n

=

For the stage n (10)

Making the next calculation it can be obtained the concentrations

throughout the column. Applying the method of fixed differences, the gas

phase concentration throughout the column, on each different stage:

G

A

L

L

Y

P

R

O

O

F

4

7417

( )

n

n

n

1 n

n

1 n

1 n

n

n

n

1 m , n

x

H

t L

x

H

t L

y y

H

t G

y t cos

H

t

N

A

1 y

n

+

|

|

\

|

+ =

+

+

+

(11)

The liquid phase concentration results from the relation of separation

factor:

( ) 1 y 1

y

x

1 m , n

1 m , n

1 m , n

+

=

+

+

+ (12)

In a similar way, for the condenser:

c

c

c

c

N

c

1 m , c

x

H

t ) t cos A G (

y )

H

t cos t A

1 ( y

H

t G

y

=

+ (13)

( ) 1 y 1

y

x

1 M , c

1 m , c

1 m , c

+

=

+

+

+ (14)

The equation system that describes the process which takes place in

the column at the liquid level variation in the condenser is formed of the

eqns. 10-14, which together with the functions that describe the variation

of the hold up in the condenser on each platter will be resolved for the

determination throughout the column. The program is developed under the

logical diagram described in Fig. 2.

RESULTS AND DISCUSSION

For the analysis of the perturbation influence owed to the variation of

the liquid level in distillation column condenser operated at total reflux,

we considered the following cases:

- initial concentrations of 25 and 50 % tritium in the tritium-deuterium

mixture

- variable sinusoidal amplitude function between 0 and 40 % from H

co

- sinusoidal function period between 0 and 30 min.

The rolling results are presented in diagrams. In Figs. 3 and 5 there are

the concentration profiles along the column at the entrance in steady state

for the case when the initial concentration is 25 % T/T+D, for different

values of amplitude and the period is kept constant at 15 min.

In the same way, there was dealt the situation when amplitude was

kept constant at a value of 10 % and takes place a variation of the perturba-

tion frequency: 10, 15 and 30 min. The same situation is dealt in the case

when initial concentration is 50 %, in Figs. 4 and 6.

G

A

L

L

Y

P

R

O

O

F

5

7417

START

Read input data

Concentration vectors initialization at t=0

Define the functions Hc,Hn,Ln

Time counter m=0

n=1

Boundary conditions for the vaporizer

and condenser

Calculate the concentrations along the

column

yy(n,m+1) xx(n,m+1)

n=n+1

n?NT

NU

yc(m)-yc(m+1) <

yc(m)

D

A

Write concentration profiles at the

entrance in steady state

DA

m=m+1

STOP

Figure 2

Logical diagram

Calculate yc(m+1),NF,IUT

NU

Fig. 2.

For these situations there is observed that together with the growth of

the amplitude value, the profile displaces in the way of decreasing the sepa-

ration capacity, as a consequence, as the amplitude value grows, the more

detrimental the situation is. Noticing with attention the profiles drawn in

Fig. 4, there is observed that after 30 % amplitude there takes place an

G

A

L

L

Y

P

R

O

O

F

6

7417

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

A=40%

A=15%

A=10%

Fig. 3. Concentration profile along the column at different amplitudes and

T = 15 min, initial concentration is 25 %

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

y

Hcol [m]

I

n

a

l

t

i

m

e

c

o

l

o

a

n

a

T=10min

T=15min

T=30min

Fig. 4. Concentration on gaseous phase along the column the entrance in steady

state Different values of amplitude and the period T = 0.5 h ; initial

concentration is 50 %

inversion of the concentration curvature profile. Considering that this re-

sult gets out of normality there is recommended to avoid to achieve or to

overcome the value of 30 % amplitude function which represents the per-

turbation from the distillation column condenser.

G

A

L

L

Y

P

R

O

O

F

7

7417

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

y

Hcol[m]

T=30min

T=15min

T=10min

Fig. 5. Concentration profile along the column on gaseous phase. Amplitude

A = 10 % and different periods. Initial concentration 25 %

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

y

Hcol [m]

A=40%

A=15%

A=10%

Fig. 6. Concentration on gaseous phase along the column at the entrace in steady

state. Amplitude A = 10 % and different periods. Initial concentration

50 %

G

A

L

L

Y

P

R

O

O

F

8

7417

What concerns the case when the amplitude is maintained constant but

the frequency varies, it is also not recommended to get or to overcome the

value of 40 % of the amplitude function that represents the perturbation

from the distillation column condenser.

For the case when the amplitude is maintained constant but perturba-

tion frequency varies, from the calculations we get to the conclusion that

for acceptable values of the perturbation frequency, I mean a frequency of

2-4 times an hour, the concentration profile at the entrance in steady state

is almost the same, while once overcome the frequency of 4 times an hour

takes to a deep lack of balance, case when the distillation column manipu-

lation becomes difficult and to achieve the time of steady state is further.

The liquid level variation from the distillation column condenser takes

to the decrease of the separation capacity of the column, this one being

lower as the perturbation is stronger.

The graphic representations can give information about the running of

a distillation column operated in the conditions of non-steady state, re-

sulted as a consequence of perturbation in sinusoidal shape of the liquid

level in condenser. In this way, there can be supervised the concentrations

profiles along the column at its evolution in time, but most of all, at the

entrance in steady state, there can be determined different values as S sepa-

ration, Fenske number N

F

or the height of the transfer unit IUT. Every

measure, by itself, may offer information upon the behaviour of the distil-

lation column operated at total reflux when the perturbation from con-

denser is described by sinusoidal function.

The model allows the representation of this profile at any time, the file

of *.dat kind containing the necessary data for this kind of representations

if we want to analyze the evolution in time of the concentrations along the

column. The profiles represented in the previous figures represent the mo-

ment of entrance in steady state.

The models of calculation realized can be used to study more aspects

of the evolution of the non-steady state in the distillation plant.

REFERENCES

1. C. Stratula, V. Marinoiu and Gh. Sorescu, Metode Si Programe De Calcul Al Proceselor

De Distilare, Fractionare Si Absorbtie, Ed. Tehnica, Bucuresti (1976).

2. M. Peculea, Instalatii Criogenice, Ed. Conphys (1997).

3. D.M. Constantinescu, A. Dimulescu, M. Peculea and I. Ursu, Influenta Instabilittaii

Vaporizatorului Asupra Functionarii Coloanelor De Distilare Izotopica, St. Cerc. Fiz.,

Tom 31, Nr. 2, P 119-127, Bucuresti (1979).

4. Claudia Pearsica, Contributions On The Non-Steady In A Liquid Hydrogen Isotopic

Distillation Plant, Ph.D. Thesis (2007).

5. M. Toma, I. Odagescu, Metode Numerice Si Subrutine, Ed. Tehnica, Bucuresti (1980).

(Received: ; Accepted: ) AJC

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Mandalas of Bright Words Gratitude To Nature English PDFDocument16 pagesMandalas of Bright Words Gratitude To Nature English PDFcarneoliaNo ratings yet

- Strength of Materials Thin Curved BarsDocument18 pagesStrength of Materials Thin Curved Barshamza100% (1)

- Pipe Stress Analysis and Layout of Hot and Cold PipingDocument27 pagesPipe Stress Analysis and Layout of Hot and Cold PipingJosé Antonio Alarcón LeónNo ratings yet

- IEEE STD 43-1974 (A)Document18 pagesIEEE STD 43-1974 (A)NghiaNo ratings yet

- HDPE Friction Loss TableDocument6 pagesHDPE Friction Loss TableMathew Yoyakky50% (2)

- Homework Extruder TorqueDocument12 pagesHomework Extruder TorqueIbrahimFikry100% (2)

- Week 3 (Vector Addition)Document51 pagesWeek 3 (Vector Addition)Aris Dwyane M PascualNo ratings yet

- Accident Analysis RBMKDocument70 pagesAccident Analysis RBMKcarneoliaNo ratings yet

- Ipr ReservoirDocument40 pagesIpr ReservoirDr-Jitendra VaishNo ratings yet

- Multiphase Flow in Pipes, 2006, Critical Velocity, PresentacionDocument62 pagesMultiphase Flow in Pipes, 2006, Critical Velocity, PresentacionjoreliNo ratings yet

- Tech Drilling SurgeSwabPressDocument40 pagesTech Drilling SurgeSwabPressdaongocha108No ratings yet

- Fluid Mechanics White 7th SOL Part1 Part6Document5 pagesFluid Mechanics White 7th SOL Part1 Part6Jose EscobarNo ratings yet

- Beams-Shear and Moment 2Document28 pagesBeams-Shear and Moment 2ZdenkoNo ratings yet

- Formal Lab Report-Packed BedsDocument18 pagesFormal Lab Report-Packed BedsPatricia Bianca Dela CruzNo ratings yet

- Enercon Finals Assignment 5Document18 pagesEnercon Finals Assignment 5Ezekiel Brizuela100% (2)

- PRESENTATION Plant Control System Display and SupportDocument22 pagesPRESENTATION Plant Control System Display and SupportcarneoliaNo ratings yet

- Viscous Diss Tern in Energy EquationsDocument14 pagesViscous Diss Tern in Energy EquationsJohn Jonnalagadda100% (1)

- Flow in Circular Pipes: ObjectiveDocument35 pagesFlow in Circular Pipes: ObjectivemamunruetNo ratings yet

- Interacting and Non Interacting SystemDocument17 pagesInteracting and Non Interacting SystemGoutham Here100% (1)

- Fluid DynamicsDocument62 pagesFluid DynamicsAmmad Ud DinNo ratings yet

- Tray Distillation Column With RefluxDocument26 pagesTray Distillation Column With RefluxMelvin MoorNo ratings yet

- The Entanglement Concept in Polymer RheolgyDocument179 pagesThe Entanglement Concept in Polymer RheolgysachinbobadeNo ratings yet

- 221 06Document25 pages221 06Fransiscus Leo ChandraNo ratings yet

- Fluid Flow in Circular TubeDocument38 pagesFluid Flow in Circular Tubeahmed50% (2)

- HW Set 1Document6 pagesHW Set 1GsusKrystNo ratings yet

- Tubular Reactor bp101bDocument17 pagesTubular Reactor bp101bMuhamad Hafifi AjwadNo ratings yet

- Leakage Calculation Through ClearancesDocument7 pagesLeakage Calculation Through Clearanceschandrasingh4564No ratings yet

- Calculating Reliability Impact VelocityDocument8 pagesCalculating Reliability Impact VelocitydrdreghNo ratings yet

- IPC ManualDocument26 pagesIPC ManualAbhishek DipakNo ratings yet

- Study On Wave Calculation of An Air CushionDocument27 pagesStudy On Wave Calculation of An Air CushionEng Bagaragaza RomualdNo ratings yet

- Application of Cyclic Operation To Acetic-Water Separation Patrut 2019Document6 pagesApplication of Cyclic Operation To Acetic-Water Separation Patrut 2019nehaNo ratings yet

- D.V.S. MurthyDocument14 pagesD.V.S. Murthypusd_9040% (5)

- Chap. 4.2 Desigh and Rating of Tube Bundle Heat ExchangersDocument22 pagesChap. 4.2 Desigh and Rating of Tube Bundle Heat ExchangersMeshal Al-mutairiNo ratings yet

- Viscous Dissipation Term in Energy EquationsDocument14 pagesViscous Dissipation Term in Energy Equationsscience1990No ratings yet

- An Introduction To Convective Heat Transfer AnalysisDocument24 pagesAn Introduction To Convective Heat Transfer AnalysishamidNo ratings yet

- Chemical Reactors: DC DT RDocument8 pagesChemical Reactors: DC DT ROsas Jessica UwoghirenNo ratings yet

- A Fast Numerical Procedure For Steady Capillary Flow in Open ChannelsDocument12 pagesA Fast Numerical Procedure For Steady Capillary Flow in Open ChannelsplabonNo ratings yet

- Polymer Engineering ExerciseDocument10 pagesPolymer Engineering ExerciseMiguel A. GraneroNo ratings yet

- J. Chem. Ed ArticleDocument4 pagesJ. Chem. Ed ArticleJames WilliamsNo ratings yet

- Active Control of Rotating Stall in Axial CompressorsDocument4 pagesActive Control of Rotating Stall in Axial Compressorsinam vfNo ratings yet

- Experiment 8 - The Venturi Meter, The Determination of Discharge From A PipeDocument8 pagesExperiment 8 - The Venturi Meter, The Determination of Discharge From A Pipebkewill6No ratings yet

- TFR ReportDocument23 pagesTFR ReportJessie Ctiffany EveNo ratings yet

- 3P04 Tutorial 5 MockQuiz 2008Document4 pages3P04 Tutorial 5 MockQuiz 2008Khaled KamalNo ratings yet

- 1980-On The Existence of Thermoconvective Rolls, Transverse To A Superimposed Mean Poiseuille Flow-J.-m. LUIJKX and J. K. PLATTENDocument5 pages1980-On The Existence of Thermoconvective Rolls, Transverse To A Superimposed Mean Poiseuille Flow-J.-m. LUIJKX and J. K. PLATTENkiuriganNo ratings yet

- Keywords: Steam Reforming, Dynamics, Hydrogen, Fuel Cell, SimulationDocument7 pagesKeywords: Steam Reforming, Dynamics, Hydrogen, Fuel Cell, SimulationMuhammad HarisNo ratings yet

- Analytical Model of An Oil-Free Screw CompressorDocument10 pagesAnalytical Model of An Oil-Free Screw CompressorAmany Moawad SarhanNo ratings yet

- Lab 3Document12 pagesLab 3Madhumita KumarNo ratings yet

- Dymamics of Fluid Flow: Uniform Depth Open Channel FlowDocument10 pagesDymamics of Fluid Flow: Uniform Depth Open Channel FlowlawanNo ratings yet

- Viscosity in Fluids: By: Rahim HassanzadehDocument15 pagesViscosity in Fluids: By: Rahim Hassanzadehsharif_94No ratings yet

- 58 FTPDocument10 pages58 FTPsanh137No ratings yet

- Ch20 Young Freedman2Document28 pagesCh20 Young Freedman2Andrew MerrillNo ratings yet

- Mto Lab Manuals - All ExperimentsDocument121 pagesMto Lab Manuals - All ExperimentsAnmol JainNo ratings yet

- Liquid Vis Cos I TiesDocument7 pagesLiquid Vis Cos I TiesGabriella WidjajaNo ratings yet

- Introduction To Vapor Liquid EquilibriumDocument35 pagesIntroduction To Vapor Liquid Equilibriumshiv007anshNo ratings yet

- Stoichiometric TableDocument22 pagesStoichiometric TableMark Antony LevineNo ratings yet

- Experiments and CFD Simulation of Stratified Horizontal Two-Phase FlowDocument7 pagesExperiments and CFD Simulation of Stratified Horizontal Two-Phase Flowsmmousavi1363No ratings yet

- Impo1 9Document20 pagesImpo1 9mouhcine maouhoubNo ratings yet

- Chapter 4Document49 pagesChapter 4Ibrahim Al-HammadiNo ratings yet

- S. Boon-Long C. Laguerie J.P. Couderc - Mass Transfer From Suspended Solids To A Liquid in Agitated VessDocument7 pagesS. Boon-Long C. Laguerie J.P. Couderc - Mass Transfer From Suspended Solids To A Liquid in Agitated VessAntung PutraNo ratings yet

- Groundwater Flow and Solute Transport: Solved With Comsol Multiphysics 3.5ADocument9 pagesGroundwater Flow and Solute Transport: Solved With Comsol Multiphysics 3.5AmacryneNo ratings yet

- Reactors Sizing: Transesterification ReactorsDocument20 pagesReactors Sizing: Transesterification ReactorsJobb Six-steps MatheusNo ratings yet

- Osterhuis Ühler Ilcox Van Der EERDocument5 pagesOsterhuis Ühler Ilcox Van Der EERmhdmkNo ratings yet

- Pergamon: Chemical Engineering Science, Vol. 51, No. 10, Pp. 1725-1734, 1996Document10 pagesPergamon: Chemical Engineering Science, Vol. 51, No. 10, Pp. 1725-1734, 1996gconstantinoNo ratings yet

- 0207 Sin 2Document5 pages0207 Sin 2bogodavidNo ratings yet

- IsentropicDocument42 pagesIsentropicDeepak JayNo ratings yet

- Tercera Asignación Control de Procesos 2021 - IIDocument7 pagesTercera Asignación Control de Procesos 2021 - IIBrayanNo ratings yet

- الاسبوع الثالثDocument18 pagesالاسبوع الثالثmalek mustafaNo ratings yet

- Homework 4: X =μ∗X−D∗X S= μ∗X Y D∗ (S S)Document7 pagesHomework 4: X =μ∗X−D∗X S= μ∗X Y D∗ (S S)katelynNo ratings yet

- TubularDocument15 pagesTubularSharing CaringNo ratings yet

- Abstracte TraumaDocument4 pagesAbstracte TraumacarneoliaNo ratings yet

- Sanatate 2019 Bucurie 2019Document3 pagesSanatate 2019 Bucurie 2019carneoliaNo ratings yet

- The Significance of The AmygdalaDocument2 pagesThe Significance of The AmygdalacarneoliaNo ratings yet

- PB RT Star BorderDocument4 pagesPB RT Star BordercarneoliaNo ratings yet

- Flower CornersDocument6 pagesFlower Cornerscarneolia100% (1)

- DecompensareDocument1 pageDecompensarecarneoliaNo ratings yet

- Guidelines For Evaluating Test-Anxiety As A DisabilityDocument3 pagesGuidelines For Evaluating Test-Anxiety As A DisabilitycarneoliaNo ratings yet

- R115Patients PDFDocument14 pagesR115Patients PDFcarneoliaNo ratings yet

- Similarity and Model TestingDocument14 pagesSimilarity and Model Testingnico NicoNo ratings yet

- Physics ClassroomDocument76 pagesPhysics ClassroomSkefadiutoNo ratings yet

- Foundation HU Lec 4Document40 pagesFoundation HU Lec 4zeru3261172No ratings yet

- Design of Fluid Thermal Systems SI Edition 4th Edition by Janna ISBN Solution ManualDocument43 pagesDesign of Fluid Thermal Systems SI Edition 4th Edition by Janna ISBN Solution Manualtimothy100% (17)

- 5SY42047 Datasheet enDocument6 pages5SY42047 Datasheet enRiver Trash andNo ratings yet

- LAB # 01 Digital Sequences (Unit Step, Unit Impulse) : Background ReviewDocument6 pagesLAB # 01 Digital Sequences (Unit Step, Unit Impulse) : Background ReviewZohaib KhanNo ratings yet

- Setup 5-Axis Transformation TRAORI: Configuration of Machine DataDocument11 pagesSetup 5-Axis Transformation TRAORI: Configuration of Machine DataNaveen KumarNo ratings yet

- Fundamentals of Gas Law of ChemistryDocument17 pagesFundamentals of Gas Law of ChemistryPawan BabelNo ratings yet

- Continuity Equation DerivationDocument3 pagesContinuity Equation Derivationvijay kumar honnaliNo ratings yet

- Multicomponent Equilibrium Flash Calculation: TotalsDocument2 pagesMulticomponent Equilibrium Flash Calculation: Totalsprateek_bhoirNo ratings yet

- Torque LabDocument14 pagesTorque Labapi-359167484No ratings yet

- Solution For Dieter NumericalsDocument3 pagesSolution For Dieter NumericalsokokNo ratings yet

- 3C43 Lasers & Modern Optics Revision Checklist (Final Version)Document2 pages3C43 Lasers & Modern Optics Revision Checklist (Final Version)ShootingStarPhotonsNo ratings yet

- Protection PresentationDocument15 pagesProtection PresentationAlmiqdad AldeekNo ratings yet

- Correcting Batch WeightDocument16 pagesCorrecting Batch Weight김성훈No ratings yet

- Seac 2 - Strength of Materials (No Answers)Document6 pagesSeac 2 - Strength of Materials (No Answers)Joshua John JulioNo ratings yet

- Mec 201Document27 pagesMec 201Lovepreet SinghNo ratings yet

- Sinyal Dan Sistem Latihan Soal Dan SolusiDocument12 pagesSinyal Dan Sistem Latihan Soal Dan SolusiMuh Indjra DijeNo ratings yet

- 6 - Breakdown in Solid and Liquid DielectricDocument53 pages6 - Breakdown in Solid and Liquid Dielectricatik jawadNo ratings yet

- (L4) - (JLD 2.0) - Mole Concept - 20 AprDocument48 pages(L4) - (JLD 2.0) - Mole Concept - 20 AprUmair KhanNo ratings yet

- Fluid Mechanics TestDocument13 pagesFluid Mechanics TestSudhanshu Pandey100% (1)

- PHYSICS-03-03 - (12th & 13th) Paper 1.pdf SOLUTIONDocument8 pagesPHYSICS-03-03 - (12th & 13th) Paper 1.pdf SOLUTIONRaju SinghNo ratings yet