Professional Documents

Culture Documents

Synthesis of Activated Carbon From Tree Sawdust and Its Usage For Diminution of Color and Cod of Paper-Mill Effluents

Uploaded by

Nagwa MansyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Synthesis of Activated Carbon From Tree Sawdust and Its Usage For Diminution of Color and Cod of Paper-Mill Effluents

Uploaded by

Nagwa MansyCopyright:

Available Formats

Pak. J. Bot., 45(S1): 521-527, January 2013.

SYNTHESIS OF ACTIVATED CARBON FROM TREE SAWDUST AND ITS USAGE FOR DIMINUTION OF COLOR AND COD OF PAPER-MILL EFFLUENTS

MUHAMMAD FARHAN1,2*, ABDUL WAHID3, AMINA KANWAL4 AND J.N.B. BELL5

1

Department of Biological Sciences, Forman Christian College (A Chartered University), Lahore, Pakistan 2 Sustainable Development Study Centre, GC University, Lahore, Pakistan 3 Department of Environmental Science, BZ University, Multan, Pakistan 4 Department of Botany, G. C. University, Lahore, Pakistan 5 Centre for Environmental Policy, Imperial College London, Silwood Park Campus, SL5 7Py, U.K. * Corresponding authors e-mail: m.farhan_gcu@yahoo.com; ph: +92 321 4122078

Abstract

In present work, activated carbons were prepared from saw dust of Dalbergia sissoo, Cedrus deodara and Eucalyptus spp., using H3PO4, H2SO4 and BaCl2 as activating agents. The activated carbons were evaluated for reduction in color and chemical oxygen demand (COD) of a real paper industry effluents using batch-mode method to explore the effect of operating parameters (contact time, amount of activated carbon, wastewater concentration, solution pH etc). Statistical analysis revealed that all the activated carbons were significantly different in their efficacy for wastewater treatment. Cedrus deodara based activated carbon was most efficient; showed 93% COD reduction with 100% color removal and brought other physico-chemical parameters of wastewater within the permissible limits of WHO and NEQS. The maximum percent reduction of COD and color with Dalbergia sissoo activated carbon was 80% and 91%, respectively while with Eucalyptus spp., activated carbon; it was 74% and 85%, respectively. The effectiveness of activated carbon synthesized from sawdust of different plants for wastewater treatment was in the following order: Cedrus deodara > Dalbergia sissoo > Eucalyptus spp. The quality of wastewaters after treatment was found to be appropriate for direct discharge into streams and irrigation purpose. This study proved highly successful in addressing the local problem of paper industry effluents using locally available wood processing byproducts.

Introduction Due to population explosion, rapid industrialization and lack of proper planning, water pollution is increasing at an alarming rate (Richardson, 2007). Industries in Pakistan have increased hap hazardously, having no wastewater treatment plants. They emit pollutants directly in environment without treatment (Qadir et al., 2008). Not even a single step of 3Rs (Reduce, Reuse and Recycle) is being followed. Degh Nala, Pakistan receives effluents from two major industrial areas. There, the contamination level is very high. The concentration of mercury (Hg) was 72mg/l in water and 887g/g in sediments. DDT (1, 1, 1Trichloro-2, 2-Bis (p-chlorophenyl) ethane) and its metabolites were greater than 1.0g/g in sediment samples (Tehseen et al., 2004). Similarly, there is a significant variation in the spatio-temporal quality of water at Nullah Aik, tributary of the Chenab River of Pakistan (Qadir et al., 2008). The pulp and paper mill industry is a very waterintensive and sixth largest polluter (Anon., 1998). It generates as low as 1.5m3 of effluent/tone of paper produced (Szolosi, 2003). About 500 different chlorinated organic compounds have been identified in paper mill effluent (Savant et al., 2006). The high chemical diversity of these pollutants causes a variety of carcinogenic, endocrinic and mutagenic effects on aquatic communities (Ali & Sreekrishnan, 2001). The brownish color is mainly attributed to the complex compounds derived from polymerization between lignin-degraded products and tannin during various pulping and bleaching operations. Lignin and its derivatives are difficult to degrade naturally because of the strong linkages within their molecular structure, especially biphenyl-type carbon to carbon linkages (Karrasch et al., 2006).

Due to shortage in canal water (due to seasonal variation) and poor quality of ground water, farmers are using the contaminated water (domestic and industrial) to fulfill irrigation needs (Kakar et al., 2011). Soil and vegetables which were grown in the close vicinity of industrial drains are highly contaminated with Cd, Pb, Cr and Co (Ahmad et al., 2011; Butt et al., 2005). There is a need to develop a wastewater treatment technology for each industry. Various physical, chemical and biological process are used for wastewater treatment like, sedimentation, chemical precipitation, chemical coagulation/flocculation process (Amuda et al., 2006), membrane filtration, flotation, adsorption (Galambos et al., 2004), chemical oxidation process, ion exchange, reverse osmosis (Martinez et al., 2003) and biosorption (Hussein et al., 2004; Iram et al., 2012). Such treatment technologies are quite expensive to build, operate, maintain and require skilled personnel (Mazumder & Roy, 2000). Adsorption by using activated carbon had a long and productive history (Faust & Aly, 1986). Activated carbon is considered very effective for removal of dyes (Malik, 2004) chemical oxygen demand (COD) (Hami et al., 2007), biological oxygen demand (BOD) (Devi & Dahiya, 2008) and heavy metals (Hamadi et al., 2001) from wastewater. Research efforts are going on to develop activated carbonbased innovative technology with low cost carbonaceous materials. Any carbonaceous waste material can be converted into activated carbon, thus its significance is two folds. Firstly, it removes pollutant from wastewater and secondly, converts solid waste into useable activated carbon. Some of the low cost industrial waste/by-products that can be used for activated carbon with varying success include Bagasse (Satyawali & Balakrishnan, 2007),

522

MUHAMMAD FARHAN ET AL.,

Pecan shell (Bansode et al., 2004), Coconut fiber (Mohan et al., 2008), Date nut (Anand et al., 2009) and peels of Avocado fruits (Devi et al., 2008), This study was designed to synthesize activated carbon from indigenously available Dalbergia sissoo, Cedrus deodara and Eucalyptus spp., sawdust, to test their efficiency in paper mill wastewater treatment (with particular emphasis on color/COD reduction) and optimization of conditions for maximum efficiency of activated carbons and maximum treatment. Material and Methods Wastewater collection and analysis: Wastewater was collected from the wastewater outlet of Packages (Pvt) Ltd, stored at 2-3oC to prevent any change in physiochemical characteristics. pH, temperature, total solids, dissolved solids, suspended solids, color and COD were determined by the standard method prescribed in APHA (Anon., 1989) handbook, using analytical grade chemicals (Merck). Activated carbon synthesis: Saw dust of Dalbergia sissoo, Cedrus deodara and Eucalyptus spp., was collected free of cost from the local furniture workshops. Sawdust samples were sieved (pore size of 0.25 mm), washed several times to remove dust and dried at 110oC for 24h in drying oven. It was then used for the synthesis of activated carbons. H3PO4, H2SO4 and BaCl2 were used separately as activating agents for the synthesis of activated carbon. For activation, 100 g of saw dust (Dalbergia sissoo, Cedrus deodara and Eucalyptus spp.) was well mixed with 100 ml activating agent (H3PO4, H2SO4 and BaCl2 separately) having the strength of 2% and placed in the oven at 110oC for 24h. The sample was then soaked in distilled water and was subsequently replaced until the pH of the solution become stable. The sample was then washed with 2% HCl (v/v) or NaHCO3 (w/v), and then with distilled water to remove any activating agent. It was then dried at 110oC. The dried samples were transferred to the muffle furnace at 650oC for 6h, at the expiry of time the activated carbon obtained was used for the wastewater treatment. Activated carbon analysis: Activated carbon was analyzed for bulk density, moisture content, yield % and

ash content, using method described by (Ahmedna et al., 1997). Batch adsorption process: 250ml flask was filled with 100ml of wastewater. The desired pH was adjusted using 0.1N H2SO4 / 0.1N NaOH. Then weighed amount of activated carbon was added in the flask and transferred to the orbital shaker for predetermined interval of time. After the expiry of given times the flask was removed from the shaker. The solution was filtered using Watmann filter paper # 44. Filtrate was then examined for the COD and color. The difference in wastewater and filtrate, gives the % removal of COD and color. Effects of different factors like solution pH, amount of activated carbon, shaking time (contact time) and agitation speed were studied. Contact time was investigated by changing contact time during batch process from 1-6 h, and keeping all the other parameters fixed. Similarly effect of solution pH and amount of activated carbon was examined by changing one parameter and keeping other constant. All the batch experiments were conducted in triplicate. Statistical analysis: Data of three activated carbons for various parameters were subjected to one-way ANOVA followed by Duncans Multiple Range Test, in order to reach a certain conclusion about the most efficient activated carbon. Results and Discussion Wastewater analysis: The chemical analysis of wastewater from Packages Pvt. (Ltd) is given in Table 1, with Anon., (1995) limits. The effluent pH is about 20.6% higher than the permissible limits. Temperature of the effluent is 50% higher than standard limit. Total solids (TS), total dissolved solid (TDS), total suspended solids (TSS) and COD are 952.3%, 584.4%, 1760% and 446% higher than standard limit, respectively. The reason behind selection of one industrial waste was that activated carbons differ significantly in their surface characteristics (surface charge, pH, surface chemistry, porosity, etc.). Similarly, wastewater from different sources also differs in their characteristic (pH, number of pollutants, amount of pollutants, etc.), this makes activated carbons specific for specific functions.

Table 1. Physical-chemical properties of wastewater of paper mill along with WHO permissible limits (1995), for the release of treated wastewater to irrigation waterway. Parameters pH Color Temperature (oC) Total solids (mg/l) Total dissolved solids (mg/l) Total suspended solids (mg/l) Chemical oxygen demand (mg/l) Characteristics of wastewater 6.39 Dark brown 30 6810 3080 3720 1640 Characteristics after treatment 6.9 Colorless Ambient temperature > 100 > 70 > 32 > 147.6 20 655 450 200 300 WHO permissible limits 6.8 - 8.5

SYNTHESIS OF ACTIVATED CARBON FROM TREE SAWDUST

523

Activated carbon analysis: In general, activated carbons can be prepared from any carbonaceous material. But now the researchers are exclusively using waste material/by products for its preparation. The benefits of using waste materials are 2 folds. Firstly, the raw material is available at relatively free of cost. Secondly, the waste materials get used and do not create environmental pollution. In this research work, these two benefits were given prime importance. Dalbergia sissoo, Cedrus deodara and Eucalyptus spp., sawdust were selected because it is a byproduct of furniture industry and is available at very low cost. Other waste materials used by different researchers are, used tires (Hamadi et al., 2001), Bagasse (Satyawali & Balakrishnan., 2007), Coconut fiber (Mohan et al., 2008) and Date nut (Anand et al., 2009). Activated carbons analysis/comparison is given in Table 2. These activated carbons differed significantly in bulk density, yield, moisture content and ash content. Cedrus deodara based carbon shows best characteristics. Table 7 gives a comparative view of some of the activated carbons and their efficiency in removing/reducing COD and color. Effect of activated carbon amount on COD and color reduction: The equilibrium point by activated carbon amount for COD reduction by Cedrus deodara is 5g/l and for Dalbergia sissoo is 7g/l (Table. 3). Maximum COD reduction by Cedrus deodara and Dalbergia sissoo is 94% and 82%, respectively. Further increase in the amount of activated carbon beyond the equilibrium point will no more increase the COD reduction. However the Eucalyptus spp., did not show any equilibrium, its COD reduction capacity keeps on increasing with the increase in activated carbon amount. The three activated carbons

differ significantly in their COD capacity. This decrease in COD uptake capacity with increase in dose of activated carbon may be due to the formation of clusters of carbon particles resulting in decreased surface area (Nagda, 2006). At low concentration, the interaction between solute and solvent increase, so the solute has low tendency towards activated carbon and high affinity towards solvent (Nadeem et al., 2006). Amount of activated carbon effects color reduction significantly (Fig. 1). Minimum color reduction by Cedrus deodara is 40% and maximum is 100%. The rate of color reduction increase sharply from 1-5g/l. Dalbergia sissoo shows maximum growth at 10g/l with 100% color reduction. Fig. 1 shows that at lower concentration the color reduction is rapid but as the concentration increases from 7g/l the rate of color reduction decreases slowly. At the concentration of 10g/l the Cedrus deodara and Dalbergia sissoo shows no significant difference but they are still significantly better, compared to Eucalyptus spp. Eucalyptus spp., did not show better result, compared to other activated carbons. Effect of contact time on COD and color reduction: Table 4 reveals the data for COD reduction. All the three activated carbons differ significantly in COD reduction at different time duration. The equilibrium time (91.3% reduction) for Cedrus deodara is 4 hours, further increase in time (5 and 6hrs) do not significantly increase COD reduction (92.5%). the COD reduction increase sharply in lower time durations (1-4hrs). for Dalbergia sissoo the maximum of 82.6% COD reduction was achieved at 6hrs time. Statistical analysis revealed that all the activated carbons different significantly in their COD reduction at all the time treatments given (1-6hrs).

Activated carbons Cedrus deodara Dalbergia sissoo Eucalyptus spp.

Table 2. Comparison of activated carbons. Characteristic Bulk density (g/ml) Yield (%) Moisture content (%) 0.45 a 0.014 44 a 0.561 4.1 c 0.164 0.40 b 0.016 41b 0.652 5.6 b 0.471 0.38 c 0.12 39 c 0.343 5.9 a 0.354

Ash content (%) 5.2 c 0.451 5.8 b 0.406 6.8 a 0.521

Treatments means followed by different letters in each column are significantly different at p=0.05 according to Duncans Multiple Range Test

Table 3. Percentage COD reduction at different activated carbons types and amounts. Activated carbon amount (g/l) Activated arbons 1 2 3 4 5 6 7 8 9 43.5 a 92.1a 24.3a 64.2 a 81.8 a 90.7a 92.4a 93.3a 93.7a Cedrus deodara 0.34 0.64 0.52 0.67 0.38 0.81 0.65 0.44 0.30 6.4 b 15 b 30 b 51.1b 67.7b 76b 80b 81.2b 81.8b Dalbergia sissoo 0.54 0.52 0.32 0.45 0.87 0.31 0.55 0.84 0.61 1.9 c 5.8 c 16.9 c 28.4 c 44.1c 59.1c 68.1c 71.6c 75.7c Eucalyptus spp. 0.11 0.21 0.97 0.21 0.12 0.88 0.91 0.49 0.52

10 94a 0.34 82.1b 0.22 76.4c 0.71

Other operating conditions are time: 4hrs, pH 5, agitation speed: 800 rpm. Treatments means followed by different letters in each column are significantly different at p=0.05 according to Duncans Multiple Range Test.

Table 4. Percentage COD reduction at different activated carbons types and contact time. Contact time (hrs) Activated carbons 1 2 3 4 5 6 Cedrus deodara 37.4a 0.54 59.7a 0.98 81.9a 0.32 91.3a 0.54 92a 0.81 92.5a 0.39 Dalbergia sissoo 18.7b 0.34 31.2b 0.65 47.6b 0.21 75.7b 0.38 80.2b 0.55 82.4b 0.54 Eucalyptus spp. 8.6c 0.32 19c 0.71 34c 0.77 59c 0.83 63.9c 0.31 66.4c 0.67

Other operating conditions are, activated carbon amount: 5g/l, pH 5, agitation speed: 800 rpm. Treatments means followed by different letters in each column are significantly different at p=0.05 according to Duncans Multiple Range Test

524

MUHAMMAD FARHAN ET AL.,

Fig. 1. Effect of activated carbon amount on percentage Color reduction. time: 4hrs, pH 5, agitation speed: 800 rpm. Different letters in each treatment (at X-axis) are significantly different at p=0.05 according to Duncans Multiple Range Test.

Fig. 2. Effect of contact time on percentage Color reduction. adsorbent dose: 6g/l, pH 5, agitation speed: 800rpm. Different letters in each treatment (at X-axis) are significantly different at p=0.05 according to Duncans Multiple Range Test.

All the three activated carbons exhibit different behavior regarding color reduction (Fig. 2). At lower time concentrations (1-4hrs), Cedrus deodara shows very sharp decrease in color starting from 56% to 100%. Dalbergia sissoo has almost constant rate of reaction. Whereas Eucalyptus spp., exhibit less reduction from 13hrs but reduction shoots up sharply at 4hrs time duration, further increase from 4hrs to 6hrs does not significantly increase color reduction. A similar observation was reported previously by activated carbon using bamboo waste as raw material and phosphoric acid as activating agent (Pala & Tokat, 2002). They evaluated activated carbon for color and COD reduction of a textile mill effluent. A maximum reduction in COD and color of 75.21% and 91.84%, respectively was achieved. Devi et al., (2008) reported that as the treatment time progress, the activated carbon sites had the affinity towards saturation. Differences In reduction capacities of different activated carbons might be due to the difference in number of carbonaceous sites. at the start of experimentation, the pollutants are absorbed by the exterior surface of activated carbon, so the rate was high. When the exterior surface reached saturation, the molecules will diffuse through the pores of activated carbon to reach the interior surface. This mechanism takes comparatively longer time (Hami et al., 2007; Hamadi et al., 2001). However, Gupta et al., (2011) attained equilibrium of 60 min for Acid Blue 113 dye uptake .The decrease in dye reduction with time might be due to aggregation of dye molecules around the activated carbon. There will be no more reduction in COD, after the equilibrium point has reached. Infect at equilibrium the rate of adsorption of pollutant onto the activated carbon is almost equal to the rate of desorption (Mohan et al., 2008). Effect of pH on COD and color reduction: It is clear from the results (Table 6) that Cedrus deodara and Dalbergia sissoo based activated carbons perform best at

low pH. For Cedrus deodara based activated carbon the equilibrium pH is 5, beyond this point COD reduction do not increase significantly. Whereas, Eucalyptus spp., show maximum reduction at relatively neutral pH. Similar finding was relieved by (Devi et al., 2008). In case of color reduction all the activated carbons differ significantly at different pH (Fig. 3). Maximum color reduction by Cedrus deodara, Dalbergia sissoo Dalbergia sissoo and Eucalyptus spp., was 100%, 94% and 85%, respectively. There is a Sharpe decrease in color reduction by Cedrus deodara from pH 6 to pH 7. These results conclude that all the prepared activated carbons have different surface charges/properties, which are under the direct influence of change in pH. The possible mechanism of the better adsorption at lower pH may be related to the presence of high number of H+ ions (Nagda, 2006). These H+ ions combine with the-ve charged adsorbent surface (oxides of aluminum, calcium, silicon, iron, etc.) and neutralize them (Devi et al., 2008), and thereby reduce the hindrance to the diffusion of organic molecules. The lower adsorption at higher pH might be possible due to the presence of OH- ions. These OH- ions cause hindrance to the diffusion of organic (contributing to COD) ions (Das & Patnaik, 2001). The difference in COD and color mechanisms also relates to the heterogeneity (having different types of sites) or homogeneity (having same types of sites) of the activated carbon surface/sites (Satyawali & Balakrishnan, 2007). Activated carbon having heterogeneous sites may be capable in performing well in both acidic and basic pH. While those having homogenous sites will only function either in acidic, basic or neutral pH (Malik, 2004). The negative charge (hydroxyl groups) residing at activated carbon surface, provide active sites, causing strong electrostatic pull for the anionic pollutants in wastewater. This causes the ease in diffusion and adsorption process of pollutant for active sites. whereas, with increase in pH or alkaline conditions, protonation of pollutant is reduced, thus hinder diffusion and adsorption (Pala & Tokat, 2002).

SYNTHESIS OF ACTIVATED CARBON FROM TREE SAWDUST

525

Effect of agitation speed on COD and color reduction: Agitation speed effects the contact duration between pollutant and activated carbon. Agitation speed was evaluated from 200-1000 (rpm). The data for COD reduction is given in Table 5. Statistical analysis reveals that all the activated carbons differ significantly among each other. The highest efficiency was of Cedrus deodara, which reduces COD up to 94%. Dalbergia sissoo and Eucalyptus spp., were inferior having 81% and 74% COD reduction, respectively. Cedrus deodara achieved the equilibrium at 800rpm and does not significantly increase COD reduction with further

increase in agitation speed (1000rpm). Whereas Dalbergia sissoo and Eucalyptus spp., attain equilibrium at 1000rpm. Our results are in accordance with the previous finding (Devi & Dahiy, 2008; Satyawali & Balakrishnan, 2007) and Santhy & Selvapathy (2006) investigated BOD and COD reduction with 100-1000rpm agitation speed. Maximum reduction was observed around 600rpm, however at higher agitation speeds, the loosely attached molecules may re-enter into the activated carbon, thus lowering the potential of COD reduction (Nagda, 2006) (Fig. 4).

Fig. 3. Effect of pH on percentage Color reduction. time: 4hrs, adsorbent dose: 6g/l, agitation speed: 800rpm. Different letters in each treatment (at X-axis) are significantly different at p=0.05 according to Duncans Multiple Range Test.

Fig. 4. Effect of agitation speed on percentage Color reduction. time: 4hrs, adsorbent dose: 6g/l, pH 5. Different letters in each treatment (at X-axis) are significantly different at p=0.05 according to Duncans Multiple Range Test.

Table 5. Percentage COD reduction at different activated carbons types and agitation speed. Agitation speed (rpm) Activated carbons Cedrus deodara Dalbergia sissoo Eucalyptus spp. 200 59.8a 0.43 38.9b 0.21 13.4c 0.54 400 73.2a 0.76 44.5b 0.87 18.1c 0.45 600 84.1a 0.91 56.2b 0.48 29.6c 0.31 800 93a +0.85 76.4b 0.55 59.6c 0.37 1000 94.4a 0.71 81b 0.54 74.5c 0.27

Other operating conditions are time: 4hrs, activated carbon amount: 5g/l, pH 5. Treatments means followed by different letters in each column are significantly different at p=0.05 according to Duncans Multiple Range Test

Table 6. Percentage COD reduction at different activated carbons types and pH. Activated carbons 3 Cedrus deodara Dalbergia sissoo Eucalyptus spp. 96.5a 0.43 81.8b 0.23 32.9c 0.76 4 94.6a 0.87 80.5b 0.43 42.2c 0.56 5 92a 0.65 74b 0.74 58.5c 0.75 6 78a 0.34 58.8c 0.63 71.2b 0.76 pH 7 62.9b 0.85 47.3c 0.25 74a 0.26 8 58.8b 0.54 43.1c 0.24 69.6a 0.64 9 56.2a 0.62 40.6b 0.74 55.6a 0.33 10 55.3a 0.56 36.1c 0.15 47b 0.64 11 54.6a 0.43 30.7c 0.55 43.8b 0.56

Other operating conditions are time: 4hrs, activated carbon amount: 5g/l, agitation speed: 800 rpm. Treatments means followed by different letters in each column are significantly different at p=0.05 according to Duncans Multiple Range Test

526

MUHAMMAD FARHAN ET AL.,

Table 7. Comparison of COD and color reduction potential by various activated carbons (Ahmad & Hameed, 2009). Activated carbon type Cedrus deodara based activated carbon Dalbergia sissoo based activated carbon Eucalyptus spp based activated carbon Bamboo-based activated carbon Bagasse fly ash Powdered activated carbon Coconut fibers carbon Carbon developed from fertilizer waste Mixed adsorbent carbon Pecan shell-based activated carbon Wastewater Paper mill effluent Paper mill effluent Paper mill effluent Textile wastewater Pulp and paper wastewaters Textile wastewater Industrial (mixed) Industrial Domestic Municipal wastewater COD removal Color removal (%) (%) 92 80 74 75 50 78 5074 >50 96 >70 100 94 86 91 55 86 Reference This work This work This work Ahmad and Hameed, 2009 Srivastava et al., 2005 Pala et al., 2002 Mohan et al., 2008 Srivastava et al., 1993 Devi et al., 2008 Bansode et al., 2004

Conclusion This research study confirmed the usefulness of Cedrus deodara, Dalbergia sissoo and Eucalyptus spp., saw dust in removing COD and color for the first time in this region. It removed maximum COD up to 92% and 100% color reduction. The effectiveness of activated carbon synthesized from sawdust of different plants for wastewater treatment was in the following order: Cedrus deodara > Dalbergia sissoo > Eucalyptus spp. The final COD of treated wastewater was within the permissible limit of Anon. (1995), so that the treated water can be discharged safely, into streams. This study proved highly successful in addressing the local problem of paper industry effluents using locally available wood processing byproducts.

References Ahmad, A.A. and B.H. Hameed. 2009. Reduction of COD and color of dyeing effluent from a cotton textile mill by adsorption onto bamboo-based activated carbon. J. Hazard. Mat., 172: 1538-1543. Ahmad, M., A. WAHID, S.S. Ahmad, Z.A. Butt and M. Tariq. 2011. Ecophysiological responses of rice (Oryza Sativa L.) to hexavalent chromium. Pak. J. Bot., 43(6): 2853-2859. Ahmedna, M., M.M. Johns, S.J. Clarke, W.E. Marshall and R.M. Rao. 1997. Potential of agricultural by-product based activated carbons for use in raw sugar decolonization. J. Sci. Food Agri., 75: 117-124. Ali, M. and T.R. Sreekrishnan. 2001. Aquatic toxicity from pulp and paper mill effluent. Adv. Environ. Res., 5: 175-196. Amuda, O.S., I.A. Amoo and O.O. Ajayi. 2006. Performance optimization of some coagulants / flocculants in the treatment of beverage industrial wastewater. J. Hazard. Mat., 129: 69-72. Anand, K., A. Parande, A. Sivashanmugam, H. Beulah and N. Palaniswamy. 2009. Performance evaluation of low cost adsorbents in reduction of COD in sugar industrial effluent. J. Hazard. Mat., 168: 800-805. Anonymous. 1989. APHA, American Public Health Association. Standard Methods for Examination of Water and Wastewater, seventeenth ed., Washington DC, NY, USA. Anonymous. 1995. WHO, World Health Origination. Guidelines for Discharge of Industrial Effluent Characteristic. Geneva, vol. 3: 231-36.

Anonymous. 1998. Environmental Protection Agency and U.S. Department of Agriculture. Clean water action plan: restarting and protecting America is waters. EPA-840-R98-001, Washington. Bansode R.R., J.N. Losso, W.E. Marshall, R.M. Rao and R.J. Portier. 2004. Pecan shell-based granular activated carbon for treatment of chemical oxygen demand (COD) in municipal wastewater. Biores. Technol., 94: 129-135 Butt, M.S., K. Sharif, B.E. Bajwa and A. Aziz. 2005. Hazardous effects of sewage water on the environment: focus on heavy metals and chemical composition of soil and vegetables. Mgt. Environ. Qty., 16: 338-46. Das, C.P. and L.N. Patnaik. 2001. Use of industrial waste for reduction of COD from paper mill effluents. Ind. J. Environ. Health., 43(12): 21-27. Devi, R. and R.P. Dahiya. 2008. COD and BOD removal from domestic wastewater generated in decentralized sector. Biores. Technol., 99: 344-49. Devi, R., V. Singh and A. Kumar. 2008. COD and BOD reduction from coffee processing wastewater using Avocado peel carbon. Biores. Technol., 99: 1853-60. Faust, S.D and O.M. Aly. 1986. Adsorption Process for Water Treatment. Butterwoeths, Stoneham, pp. 14-23. Galambos, I.I., J.M. Molina, P. Jaray, G. Vatai and E. BekassyMolnar. 2004. High organic content industrial wastewater treatment by membrane filtration. Desalination, 162: 117-120. Gupta, V.K., B. Gupta, A. Rastogi, S. Agarwa and A. Nayak. 2011. A comparative investigation on adsorption performances of mesoporous activated carbon prepared from waste rubber tire and activated carbon for a hazardous azo dye-Acid Blue 113. J. Hazard. Mat., 186: 891-901 Hamadi, N.K., X.D. Chen, M.M. Farid and M.G. Lu. 2001. Adsorption kinetics for the removal of chromium (VI) from aqueous solution by adsorbents derived from used tires and sawdust. J. Chem. Eng., 84: 95-105. Hami, M.L., M.A. Al-Hashimi and M.M. Al-Doori. 2007. Effect of activated carbon on BOD and COD removal in a dissolved air flotation unit treating refinery wastewater. Desalination, 216: 116-122. Hussein, H., S.F. Ibrahim, K. Kandeel and H. Moawad. 2004. Biosorption of heavy metals from waste water using Pseudomonas sp. J. Electronic Biotechnol., 7(1): 24-29. Iram, S., Ahmad I., Riaz, Y. AND A. Zahra. 2012. Treatment of wastewater by Lemna minor. Pak. J. Bot., 44(2): 553-557. Kakar, S.R., A. Wahid, R.B. Tareen, S.A. Kakar and R. Jabeen. 2011. Impact of municipal wastewater of Quetta city on

SYNTHESIS OF ACTIVATED CARBON FROM TREE SAWDUST

527

some oil seeds crops of Pakistan: Effect of biomass, physiology and yield of sunflower (Helianthus annuus L.). Pak. J. Bot., 43(3): 1477-1484. Karrasch, B., O. Parra, H. Cid, H. Mehrens, M. Pacheco, P. Urrutia, R. Valdovinos and C. Zaror. 2006. Effects of pulp and paper mill effluents on the micro plankton and microbial self-purification capabilities of the Biobio River, Chile. Sci. Total Environ., 359: 194-208. Malik, P.K. 2004. Dye removal from wastewater using activated carbon developed from saw dust: adsorption equilibrium and kinetics. J. Hazard. Mat., B 113: 81-88. Martinez, N.S., J.F. Fernandez, X.F. Segura and A.S. Ferrer. 2003. Pre-oxidation of an extremely polluted industrial wastewater by the Fentons reagent. J. Hazard. Mat., B 101: 315-322. Mazumder, D. and B. Roy. 2000. Low cost options for treatment and reuse of municipal waste water. Ind. J. Environ. Prot., 20 (7):529-32. Mohan, D., P.S. Kunwar and K.S. Vinod. 2008. Wastewater treatment using low cost activated carbons derived from agricultural byproducts-A case study. J. Hazard. Mat., 152: 1045-1053 Nadeem, M., A. Mahmood, S.A. Shahid, S.S. Shah, A.M. Khalid and G. McKay. 2006. Sorption of lead from aqueous solution by chemically modified carbon adsorbents. J. Hazard. Mat., B138: 604-13. Nagda, G.K., V.S. Ghole and A.M. Diwan. 2006. Tendu leaves refuse as biosorbent for COD removal from Molasses fermentation based bulk drug industry effluent. J. Appl. Sci. Environ. Mgt., 10 (3): 15-20. Pala, A. and E. Tokat. 2002. Color removal from cotton textile industry wastewater in an activated sludge system with various additives. Ind J. Environ. Prot., 36: 2920-2925.

Qadir, A., R.N. Mailk and S.Z. Husain. 2008. Spatio-Temporal variation in water quality of Nulla Aik-tributary of the river Chenab, Pakistan. Environ. Monitor. Assessment, 14: 4359. Richardson, S.D. 2007. Water Analysis: Emerging Contaminants and Current Issues. Annual of Chemistry, 79: 4295-4324. Santhy, K. and P. Selvapathy. 2006. Removal of reactive dyes from wastewater by adsorption on coir pith activated carbon. Biores. Technol., 97: 1329-1336 Satyawali, Y. and M. Balakrishnan. 2007. Removal of color from biomethanated distillery spent wash by treatment with activated carbons. Biores. Technol., 98: 2629-2635 Savant, D.V.R. Abdul-Rahman and D.R. Ranade. 2006. Anaerobic degradation of absorbable organic halides (AOX) from pulp and paper industry wastewater. Biores. Technol., 97: 1092-1104. Srivastava, S.K., V.K. Gupta, D. Mohan and N. Pant. 1993. Removal of COD from reclaimed rubber factory effluents by using the activated carbon (developed from fertilizer waste material) and activated slag (developed from the blast furnace waste material) - a case study. Fresen. Environ. Bull., 2: 394-401. Srivastava, V.C., I.D. Mall and I.M. Mishra. 2005. Treatment of pulp and paper mill wastewaters with poly aluminum chloride and bagasse fly ash. Colloid. and Surf. A: Physicochem. Eng. Asp., 260: 17-28. Szolosi, O. 2003. Water cycle with zero discharge at Visy Pulp and Paper, Tumut, NSW. Water, (Australia) 30: 34-36. Tehseen, W.M., I.G. Hassen, S.G. Wood and M. Hanif. 2004. Assessment of chemical contaminations in water and sediment samples from Degh Nala in the province of Punjab, Pak. Arch. Environ. Cont. Toxicol., 26(1): 79-89.

(Received for publication 1 September 2012)

You might also like

- Electrooxidation and Subcritical Water Oxidation Hybrid Process For Pistachio Wastewater TreatmentDocument23 pagesElectrooxidation and Subcritical Water Oxidation Hybrid Process For Pistachio Wastewater TreatmentFleur D'amitiéNo ratings yet

- TSS, TDS and TS of Effluents From Potassium Hydroxide and Calcium Hypochlorite BleachingDocument11 pagesTSS, TDS and TS of Effluents From Potassium Hydroxide and Calcium Hypochlorite BleachingAnonymous CwJeBCAXpNo ratings yet

- Lawal 2017Document26 pagesLawal 2017Yon tinyayaNo ratings yet

- COD Reduction in Coffe Wastewater Through Flocculation An AOP PDFDocument6 pagesCOD Reduction in Coffe Wastewater Through Flocculation An AOP PDFJesus SerranoNo ratings yet

- Effect of Hydrogen Peroxide On Industrial Waste WaDocument9 pagesEffect of Hydrogen Peroxide On Industrial Waste WaBeant SinghNo ratings yet

- Chestnut Oak Shells Activated CarbonDocument41 pagesChestnut Oak Shells Activated CarbonVũ Văn NguyênNo ratings yet

- Harnessing Potential of Eucalyptus Derived Biochar To Improve Physico-Chemical Characteristics of Tannery EffluentDocument8 pagesHarnessing Potential of Eucalyptus Derived Biochar To Improve Physico-Chemical Characteristics of Tannery EffluentATIF NAUMANNo ratings yet

- Vo Cam Loai NikenDocument9 pagesVo Cam Loai NikenAnonymous g348UottZqNo ratings yet

- Treatment of Dairy Waste Water Using Low Cost AdsorbentsDocument2 pagesTreatment of Dairy Waste Water Using Low Cost AdsorbentsijsretNo ratings yet

- Ecological Engineering: Anuj Kumar, Subhajit Singha, Dalia Dasgupta, Siddhartha Datta, Tamal MandalDocument9 pagesEcological Engineering: Anuj Kumar, Subhajit Singha, Dalia Dasgupta, Siddhartha Datta, Tamal MandalNez ArdenioNo ratings yet

- s13201 019 1063 0Document12 pagess13201 019 1063 0AnisNo ratings yet

- Water Environment Research - 2018 - Deng - Textiles Wastewater TreatmentDocument15 pagesWater Environment Research - 2018 - Deng - Textiles Wastewater TreatmentShirley ramosNo ratings yet

- Adsorption of Cadmium Ions Using Activated Carbon Prepared From Coconut ShellDocument5 pagesAdsorption of Cadmium Ions Using Activated Carbon Prepared From Coconut ShellNastitiNo ratings yet

- COD and BOD Reduction From Coffee Processing Wastewater Using Avacado Peel CarbonDocument8 pagesCOD and BOD Reduction From Coffee Processing Wastewater Using Avacado Peel CarbonTom MOt'sNo ratings yet

- Potable Water From Industrial Wastewater: M. S. AliDocument4 pagesPotable Water From Industrial Wastewater: M. S. AliEr Omkar Ravindra MhatreNo ratings yet

- Advanced Oxidation Process and BiotreatmentDocument8 pagesAdvanced Oxidation Process and Biotreatmentparthdpatel131822No ratings yet

- Influent 84Document5 pagesInfluent 84IJASINI EZEKIELNo ratings yet

- Adsorption Evaluation of Herbicide Iodosulfuron Followed by Cedrus Deodora Sawdust-Derived Activated Carbon RemovalDocument17 pagesAdsorption Evaluation of Herbicide Iodosulfuron Followed by Cedrus Deodora Sawdust-Derived Activated Carbon RemovalDiana CarolinaNo ratings yet

- Removal of The Hazardous Dye Rhodamine B Through Photocatalytic and Adsorption TreatmentsDocument9 pagesRemoval of The Hazardous Dye Rhodamine B Through Photocatalytic and Adsorption TreatmentsGirish GuptaNo ratings yet

- Contribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Document9 pagesContribution of Activated Carbon Based On Cacao Peels (Theobroma Cacao L.) To Improve The Well Water Quality (COLOR, BOD, and COD)Van AlifNo ratings yet

- BBRC Vol 14 No 04 2021-30Document7 pagesBBRC Vol 14 No 04 2021-30Dr Sharique AliNo ratings yet

- Bioresource Technology: Jai Prakash Kushwaha, Vimal Chandra Srivastava, Indra Deo MallDocument10 pagesBioresource Technology: Jai Prakash Kushwaha, Vimal Chandra Srivastava, Indra Deo MallAAmitava ChakrabortyNo ratings yet

- Singh2008 PDFDocument8 pagesSingh2008 PDFAhoud AlhaimliNo ratings yet

- 13 - Batch and Fixed-Bed Column Studies For The Biosorption of Cuii and Pbii by Raw and Treated Date Palm Leaves and Orange PeelDocument15 pages13 - Batch and Fixed-Bed Column Studies For The Biosorption of Cuii and Pbii by Raw and Treated Date Palm Leaves and Orange PeelArriane Faith EstoniloNo ratings yet

- Physico-Chemical and Adsorption Studies of Activated Carbon From Agricultural WastesDocument8 pagesPhysico-Chemical and Adsorption Studies of Activated Carbon From Agricultural WasteszannubaqotrunnadhaNo ratings yet

- Adsorption Science and TechnologyDocument17 pagesAdsorption Science and Technologydeepika snehiNo ratings yet

- 1 s2.0 S0957582017301416 MainDocument16 pages1 s2.0 S0957582017301416 MainSeptian Perwira YudhaNo ratings yet

- tmp64AC TMPDocument8 pagestmp64AC TMPFrontiersNo ratings yet

- Pretreatment of Complex Industrial Wastewater by OzonationDocument9 pagesPretreatment of Complex Industrial Wastewater by OzonationAnonymous aYmVPmdcLjNo ratings yet

- Comparative Account of Untreated and Treated Sago Effluent Analysis by Investigating Different Physical and Chemical ParametersDocument4 pagesComparative Account of Untreated and Treated Sago Effluent Analysis by Investigating Different Physical and Chemical ParametersHadjer KermNo ratings yet

- Degradation of Azo Dyes by Laccase: Biological Method To Reduce Pollution Load in Dye WastewaterDocument14 pagesDegradation of Azo Dyes by Laccase: Biological Method To Reduce Pollution Load in Dye WastewaterKendria Santos CezarNo ratings yet

- Treatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsDocument8 pagesTreatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsIna ElenaNo ratings yet

- Niazmand Et Al. 2019Document8 pagesNiazmand Et Al. 2019Tatiana Sainara Maia FernandesNo ratings yet

- COD and BOD Reduction From Coffee Processing Wastewater Using Avacado Peel CarbonDocument8 pagesCOD and BOD Reduction From Coffee Processing Wastewater Using Avacado Peel CarbonFarah El ShahawyNo ratings yet

- Article AmolaDocument20 pagesArticle AmolaErwin Reinald Mouele MoughougouNo ratings yet

- 03 Review of LiteratureDocument10 pages03 Review of Literaturesahil masulkarNo ratings yet

- Production and Characterization of Granular Activated Carbon From Activated SludgeDocument10 pagesProduction and Characterization of Granular Activated Carbon From Activated SludgejshrikantNo ratings yet

- Characterization of Potassium Hydroxide (KOH) Modified Hydrochars From Different Feedstocks For Enhanced Removal of Heavy Metals From WaterDocument12 pagesCharacterization of Potassium Hydroxide (KOH) Modified Hydrochars From Different Feedstocks For Enhanced Removal of Heavy Metals From WaterbizmarketingzoneNo ratings yet

- Kurniawan - 2011 - Journal of The Taiwan Institute of Chemical Engineers - 1Document11 pagesKurniawan - 2011 - Journal of The Taiwan Institute of Chemical Engineers - 1Mafatih WebNo ratings yet

- Potensi Teknis - Ekonomis Daur Ulang Efluen Air Limbah Industri Tekstil Menggunakan Aplikasi Arang AktifDocument12 pagesPotensi Teknis - Ekonomis Daur Ulang Efluen Air Limbah Industri Tekstil Menggunakan Aplikasi Arang AktifrizkyNo ratings yet

- 10.1007@s11356 020 10613 6Document12 pages10.1007@s11356 020 10613 6Alexa RiveraNo ratings yet

- 158 2019 87Document10 pages158 2019 87hodcivilssmietNo ratings yet

- Cod ImportantDocument22 pagesCod ImportantFarah El ShahawyNo ratings yet

- Efficient Removal of 2,4 D From Solution Using A Novel Antibacterial Adsorbent Based On Tiger Nut Residues: Adsorption and Antibacterial StudyDocument15 pagesEfficient Removal of 2,4 D From Solution Using A Novel Antibacterial Adsorbent Based On Tiger Nut Residues: Adsorption and Antibacterial StudymyntikaniNo ratings yet

- Archive of SID: Removal of Surfactant From Industrial Wastewaters by Coagulation Flocculation ProcessDocument6 pagesArchive of SID: Removal of Surfactant From Industrial Wastewaters by Coagulation Flocculation ProcessrudymerchoNo ratings yet

- Bioremediatin YelypotrixDocument5 pagesBioremediatin YelypotrixIrinaSalariNo ratings yet

- AC 2011 Banana StalkDocument8 pagesAC 2011 Banana StalkFahmySihabNo ratings yet

- Chemically Enhanced Primary Wastewater Treatment (CEPT) in Conjunction With H O /UV Technology in Controlled AtmosphereDocument7 pagesChemically Enhanced Primary Wastewater Treatment (CEPT) in Conjunction With H O /UV Technology in Controlled Atmospherejmrozo3No ratings yet

- Mam Report NewDocument47 pagesMam Report NewAlps AnaNo ratings yet

- Application of Arac Á Fruit Husks (Psidium in The Preparation of Activated Carbon With Fecl For Atrazine Herbicide AdsorptionDocument12 pagesApplication of Arac Á Fruit Husks (Psidium in The Preparation of Activated Carbon With Fecl For Atrazine Herbicide AdsorptionCarolinne FerronatoNo ratings yet

- COD ReductionDocument12 pagesCOD ReductionS.Prabakaran S.PrabakaranNo ratings yet

- Tanning CD, CRDocument21 pagesTanning CD, CRLutfi amaliaNo ratings yet

- BambooDocument8 pagesBambooCatastroNo ratings yet

- Industrial Waste Water Treatment Using An Attached MediaDocument5 pagesIndustrial Waste Water Treatment Using An Attached Mediabahjath euNo ratings yet

- Accepted Manuscript: Process Safety and Environment ProtectionDocument37 pagesAccepted Manuscript: Process Safety and Environment ProtectionNestor Garay CahuanaNo ratings yet

- 1 s2.0 S0304389421017453 MainDocument13 pages1 s2.0 S0304389421017453 MainHaris NadeemNo ratings yet

- OzonoDocument8 pagesOzonoDaniella CelisNo ratings yet

- J. Inter Salaca Peel For Activated Carbon KOHDocument4 pagesJ. Inter Salaca Peel For Activated Carbon KOHYolanda Priscilia GustantiaNo ratings yet

- III - A - 3 - D - 2022 Jurnal IPA Vol8 No6Document8 pagesIII - A - 3 - D - 2022 Jurnal IPA Vol8 No6Dr. Kuswandi ST.,MTNo ratings yet

- Environmental Water: Advances in Treatment, Remediation and RecyclingFrom EverandEnvironmental Water: Advances in Treatment, Remediation and RecyclingNo ratings yet

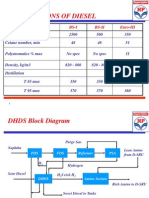

- Packed Bed2Document61 pagesPacked Bed2Nagwa MansyNo ratings yet

- Adsorption Column Design PDFDocument58 pagesAdsorption Column Design PDFCharles John Catan100% (1)

- 909162Document11 pages909162Nagwa MansyNo ratings yet

- Ion Exchange Design ProcedDocument30 pagesIon Exchange Design ProcedNagwa Mansy100% (1)

- 2010 BME 259 Problem Set 7 SolutionsDocument4 pages2010 BME 259 Problem Set 7 SolutionsNagwa Mansy50% (2)

- Adsorption Column DesignDocument58 pagesAdsorption Column DesignNagwa MansyNo ratings yet

- Lecture 16Document21 pagesLecture 16Nagwa MansyNo ratings yet

- 7 Coolingtower 091002080721 Phpapp01Document18 pages7 Coolingtower 091002080721 Phpapp01coolnitin2710_630298No ratings yet

- 7 Coolingtower 091002080721 Phpapp01Document18 pages7 Coolingtower 091002080721 Phpapp01coolnitin2710_630298No ratings yet

- Multi-Component Distillation: Prof. S. Scott, Che 128, Uc Santa BarbaraDocument23 pagesMulti-Component Distillation: Prof. S. Scott, Che 128, Uc Santa Barbarasch203100% (1)

- Tower SizingDocument6 pagesTower SizingNagwa MansyNo ratings yet

- Tutorial On Visual Minteq 2.30 AdsorptionDocument26 pagesTutorial On Visual Minteq 2.30 AdsorptionNagwa MansyNo ratings yet

- 120712ChE128 8 MulticompDistDocument23 pages120712ChE128 8 MulticompDistNagwa MansyNo ratings yet

- Phase Equilibrium LectureDocument17 pagesPhase Equilibrium LectureNagwa MansyNo ratings yet

- Phase Equilibrium LectureDocument17 pagesPhase Equilibrium LectureNagwa MansyNo ratings yet

- Extraction ChapterDocument40 pagesExtraction ChapterNagwa MansyNo ratings yet

- Cooling Tower Theory VyshDocument3 pagesCooling Tower Theory VyshNagwa MansyNo ratings yet

- CP302 Example 02 OKDocument4 pagesCP302 Example 02 OKsaadiis100% (1)

- 1 Mass TransferDocument18 pages1 Mass TransferNagwa MansyNo ratings yet

- 1 Mass TransferDocument18 pages1 Mass TransferNagwa MansyNo ratings yet

- Distillation Column1Document49 pagesDistillation Column1Nagwa MansyNo ratings yet

- F 20130617 Chak Krit 46Document71 pagesF 20130617 Chak Krit 46Nagwa MansyNo ratings yet

- Cooling TowerDocument16 pagesCooling TowerNagwa MansyNo ratings yet

- CHEG351 Spring 2008-Mass Transfer-Ahmed A AbdalaDocument275 pagesCHEG351 Spring 2008-Mass Transfer-Ahmed A AbdalaNagwa MansyNo ratings yet

- Lecture 16Document21 pagesLecture 16Nagwa MansyNo ratings yet

- Vol 2 3 3 IJESDocument4 pagesVol 2 3 3 IJESNagwa MansyNo ratings yet

- Vol1 No1 2Document14 pagesVol1 No1 2Nagwa MansyNo ratings yet

- Lecture 16Document21 pagesLecture 16Nagwa MansyNo ratings yet

- Cooling TowerDocument16 pagesCooling TowerNagwa MansyNo ratings yet

- CP302 Example 02 OKDocument4 pagesCP302 Example 02 OKsaadiis100% (1)

- Molecular Sieves PresentationDocument19 pagesMolecular Sieves PresentationVasant Kumar Varma100% (1)

- Peidong Yang Chemistry of Nanostructured MaterialsDocument386 pagesPeidong Yang Chemistry of Nanostructured MaterialsJose Abraham Lopez ValdezNo ratings yet

- Tratamiento de SulfinertDocument2 pagesTratamiento de SulfinertAgustin CesanNo ratings yet

- 31 New Interesting Applications For CCP - SW TES SeminarDocument48 pages31 New Interesting Applications For CCP - SW TES SeminarAlfonso José García LagunaNo ratings yet

- Complete WF Manual CobbDocument532 pagesComplete WF Manual CobbBogdan DavidescuNo ratings yet

- Activated Carbon FilterDocument9 pagesActivated Carbon Filtersanabilbaig100% (1)

- Characterization of Porous Materials: Gas & Vapor Sorption InstrumentsDocument40 pagesCharacterization of Porous Materials: Gas & Vapor Sorption InstrumentsKristine ReyesNo ratings yet

- Patil 2016Document75 pagesPatil 2016JOHNNo ratings yet

- Research AptitudeDocument69 pagesResearch Aptitudemj recillaNo ratings yet

- Electrodeposition in Ionic Liquids: by Adriana Ispas and Andreas BundDocument5 pagesElectrodeposition in Ionic Liquids: by Adriana Ispas and Andreas BundKashif RiazNo ratings yet

- Characterizing Adsorbents For Gas SeparationsDocument8 pagesCharacterizing Adsorbents For Gas SeparationsJohn AnthoniNo ratings yet

- Surface-Modified Iron-Amended Activated CarbonDocument8 pagesSurface-Modified Iron-Amended Activated CarbonSalah RafqahNo ratings yet

- Coal DensityDocument4 pagesCoal DensityAlam LazuardiNo ratings yet

- Schultz 1987Document18 pagesSchultz 1987Ruiz ManuelNo ratings yet

- HPCL IT DHDS Block OverviewDocument37 pagesHPCL IT DHDS Block OverviewSrija Mummidi100% (1)

- Computational Modelling For Lithium Extraction From Sea WaterDocument24 pagesComputational Modelling For Lithium Extraction From Sea WaterShivansh MishraNo ratings yet

- Structural Evolution of Atomically Dispersed PT Catalysts - P Christopher Nat MatDocument7 pagesStructural Evolution of Atomically Dispersed PT Catalysts - P Christopher Nat MatRaian Yousuf TanmoyNo ratings yet

- Highly Stable M/Nioemgo (M Co, Cu and Fe) Catalysts Towards Co MethanationDocument16 pagesHighly Stable M/Nioemgo (M Co, Cu and Fe) Catalysts Towards Co Methanationfarah al-sudaniNo ratings yet

- Metal-Organic Frameworks For Xylene Separation - From Computational Screening To Machine LearningDocument10 pagesMetal-Organic Frameworks For Xylene Separation - From Computational Screening To Machine LearningHanee Farzana HizaddinNo ratings yet

- TasemedeDocument2 pagesTasemedepranshit bathlaNo ratings yet

- PolySep PS 250Document9 pagesPolySep PS 250airmacmexNo ratings yet

- Additives Reference Guide 2013Document80 pagesAdditives Reference Guide 2013Victor MelloNo ratings yet

- What Are ZeolitesDocument26 pagesWhat Are ZeolitesborgiamatriceNo ratings yet

- Preregistration SeminarDocument34 pagesPreregistration Seminarchirag chawareNo ratings yet

- List of Functional Locally Improvised Apparatus-1Document23 pagesList of Functional Locally Improvised Apparatus-1Denver GuillermoNo ratings yet

- Ix. Answers To Study QuestionsDocument6 pagesIx. Answers To Study Questionsyessa gamuedaNo ratings yet

- Industrial Separation Processes: Fundamentals: Book ReviewDocument2 pagesIndustrial Separation Processes: Fundamentals: Book Reviewabcd efgNo ratings yet

- Degumming Process of Jute Fibre PDFDocument11 pagesDegumming Process of Jute Fibre PDFGuarded TabletNo ratings yet

- Applications of CatalysisDocument10 pagesApplications of CatalysisMelin YohanaNo ratings yet

- Competitive Adsorption of PB (II), Cu (II) and ZN (II) Onto Xanthate-Modified Magnetic ChitosanDocument7 pagesCompetitive Adsorption of PB (II), Cu (II) and ZN (II) Onto Xanthate-Modified Magnetic Chitosanekapratista26No ratings yet