Professional Documents

Culture Documents

Speed Control of DC Motors With The L292 Switchmode Driver-CD00003926

Uploaded by

Dan EsentherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Speed Control of DC Motors With The L292 Switchmode Driver-CD00003926

Uploaded by

Dan EsentherCopyright:

Available Formats

AN241 Application note

Speed control of DC motors with the L292 switch-mode driver

Features

The L292 is a monolithic power IC which functions effectively as a power transconductance amplifier. It delivers a load current proportional to an input voltage, handling up to 2A at 1836V with a bridge output stage. Completely self-contained, it incorporates internal switchmode circuitry and all the active components to form a current feedback loop. The L292 is designed primarily for use with an L290 and L291 in DC motor servo positioning applications. However, the L292 can be useful in a wide range of applications as shown in the following two examples. The first is a simple tachometer feedback circuit, the speed of which is controlled by a DC voltage; direction is controlled by the polarity of this voltage. The second circuit is controlled digitally and includes an L291 D/A converter.

November 2006

Rev 2

1/16

www.st.com

Contents

AN241

Contents

1 System with DC control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Calculation of R1, R2, R3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System with digital control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Response to input step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2/16

AN241

System with DC control

System with DC control

In this system, the control quantity is a dc voltage variable between + ViM and ViM Since the quantity under control is the speed of the motor, it is required that it varies linearly in function of the control voltage. A simplified circuit diagram of the system is shown in fig. 1. The current I1, proportional to the set voltage Vi, and the current I2, proportional to the speed of the motor, are fed to the sum point of the error amplifier. Assuming that the motor does not drain current, the system is in a steady-state condition whenever I1 = I2; as a matter of fact, in this case the output from the error amplifier Vo is 0V. During transients, the voltage Vo will assume a value Vo = R3 (I1 + I2) and consequently, since the L292 integrated circuit operates as a transconductance (Gm), a mean current Im = Gm. Vo will flow in the motor determining an acceleration proportional to it. Figure 1. Simplified circuit diagram of DC control system.

1.1

Calculation of R1, R2, R3

Let us call: ViM the maximum control voltage value nM the maximum speed allowed for the motor Kg voltage constant of the dynamo The balance condition corresponds to the maximum rotation speed, the following equation is therefore obtained: Since R2 is the impedance which the tachometer dynamo is loaded on to, and its value is recommended by the manufacturer, it is possible from the previous relationship to determine the value of R1. V IM Kg nM I 1 = I 2 ; --------- = -----------------R2 R1

3/16

System with DC control

AN241

Resistor R3 determines the system gain. Its best to keep the gain as high as possible (and consequently R3 as high as possible) to obtain a high response speed of the system, even of for small variations in the control voltage. On the other hand, an excessive gain would cause excessive overshoot around the balance conditions at the end of transients. Consequently, a trade-off must be made between the two opposing requirements in selecting the final gain. The value for R3 should be theoretically determined by studying the transfer function, by knowing the electrical and mechanical constants of the motor as well as the load applied to it. A complete diagram of the circuit actually realized is shown in fig. 2, while fig. 3, shows the characteristic n = f (Vi) obtained. Resistor R2 drawn in the simplified circuit diagram has been split here into two parts and, in addition, a capacitor has been interposed to ground, to filter the signal coming from the tachometer dynamo. The curve n. 1 in fig. 3 refers to the operation of the motor in no-load condition, with a current drain of 200mA; the curve n. 2 refers to a motor loaded so as to drain a current of 1A. By disregarding the discontinuity around the origin, it can be noted that the characteristics are linear over the whole control voltage range. By analyzing the curves around the origin, it can be noted that the motor stands still as long as the input signal does not exceed a certain threshold level, which increases proportionally with the current drained by the motor. Let us call Gm the transconductance of L292, and I the starting current of the motor; the voltage which must be available at the input of L292 in order that the motor starts turning is: mA I - (typical value) - with G m = 220 -------V o = -------V Gm The corresponding control voltage will be: I R1 R1 -------- -------= V i = V o ------R3 G m R3 and it is as much lower as the gain of the error amplifier is higher. The presence of a control voltage interval, in which the motor stands still, can be useful when it is required that, for a certain position of potentiometer P1 (see fig. 2), the motor speed be zero. An other method to hold the motor still is to use the inhibits of L292, for instance by grounding pin 13.

4/16

AN241 Figure 2. Complete circuit diagram.

System with DC control

It can be noted from fig. 3 that, by keeping the control voltage Vi constant, the speed varies according to the motor current drain.

Let us call DI the current variation; the voltage variation required at the input of L292 is I V o = -------Gm since the control voltage is constant, to generate this Vo it is necessary that the rotation speed be varied by a quantity n such as to have: R3 I- = V o = -------K g n ------R2 Gm R2 I - ------ n = --------------G m K g R3 ( I shall be taken with its sign) In this case too, the variation n is as much lower as the error amplifier gain is higher. With the circuit shown in fig. 2 n is approximately 30 turns/min. with I = 800 mA, n = 0.037 turns/mA.min appromimately. It is possible to adopt a circuit which prevents the variation in the number of turns in function of motor current. The problem is to sense the current flowing through the motor and to send a current proportional to it to the sum point of the error amplifier. The complete circuit which includes, beside the voltage feedback loop, also a current feed-back loop, is illustrated in fig. 4. In the integrated circuit L292, a current proportional to the mean current, drained by the motor, flows between pin 5 and pin 7.

5/16

System with DC control

AN241

An operational amplifier, amplifies the voltage drop provoked by this current across a 510 resistor and sends a current to the sum point, which is consequently proportional to the mean current in the motor, the value of which can be made to vary by acting on potentiometer P2. By properly adjusting P2, a condition can be achieved in which the speed does not change when the current drained by the motor varies. The discontinuity around the origin, which was present in the previous circuit (fig. 2), is practically negligible in the circuit shown in fig. 4. The characteristic n = f (Vi) relevant to the circuit of fig. 4 is shown in fig. 5, and this characteristic does not substantially change, over the whole range of currents allowed by the L292 (up to 2A). In the circuit described above if the motor stall condition is requested. It is preferable to act on the inhibits of the integrated circuit L292, for instance by grounding pin 13, instead of adjusting potentiometer P1: as a matter of fact, the exact position of this potentiometer is difficult to obtain, since the characteristic crosses the axis Vi in one only point (this mean that n is only 0 for a very narrow interval of Vi). Figure 3. Output characteristics of the circuit in fig. 2.

6/16

AN241 Figure 4. Complete circuit with current feedback.

System with DC control

Figure 5.

Output characteristics of the circuit in fig. 4.

7/16

System with DC control Figure 6. Simplified circuit diagram (digital control).

AN241

8/16

AN241

System with digital control

System with digital control

In this system the speed information is given to the circuit by a binary code made up of 5 information bits plus one sign bit, which determines whether the movement shall the clockwise or counter-clockwise. For the circuit implementation, the integrated circuits L291 (which includes a D/A converter and two operational amplifiers) and L292 are used. A simplified circuit diagram is shown in fig. 6. The current value I1 depends on the value of Iref and on the value of inputs b1 through b5, where its sign depends on the bs input. The maximum value for I1, which is obtained whenever inputs b1 through b5 are low, is: V ref 31 I 1mx = I ref 31 ----- = ---------- ----R1 16 16 In order to have the system in a steady state condition (no current drained by the motor), it must be: I1 = I2 By imposing the balance condition at the maximum speed, one obtains: I1 max = I2 max V ref 31 K g n M ---------- ----- = -------------R1 16 R2 where Kg = dynamos voltage constant nM = maximum speed preset for the motor. The current Iref, and consequently the ratio Vref/R1, must lie within a certain range imposed by the D/A converter actually used. In our case, this range is 0.3 to 1 mA. The values of R1 and R2 can be determined from the previous relationship. The same considerations made in the description of the DC control system apply for the selection of R3. A complete diagram of the circuit implemented, is indicated in fig. 7, while the input versus the output characteristics is shown in fig. 8.

9/16

System with digital control Figure 7. Complete circuit diagram.

AN241

In the graph of fig. 8 the rotation speed of the motor is represented on y-axis, while the decimal speed code, corresponding to the binary code applied to inputs b1 through b5, is represented on the x-axis. A 1 on the x-axis corresponds to the minimum speed code, i.e. input b1 low and remaining inputs high, since the least significant input is b1 and the active status of inputs is low. A speed code of 31 on the x-axis corresponds to the maximum speed code, i.e. all inputs b1 through b5 low. The negative points on the graph have been obtained by changing the status of the bs input. The graph in fig. 8 should have been made up of a number of dots; these dots have been joined together with an solid line for convenience. This graph has the same features as the graph in fig. 3, i.e. the curve features a discontinuity around the origin, and it lowers as long as the motor current drain increases. Also, the circuit in fig. 7 can be modified to prevent the speed varying with the motor load, by adding a current loop in the control circuit, by using the remaining operational amplifier available in the integrated circuit L291. Since this amplifier has only the inverting input available, while the non-inverting input is grounded, a circuit arrangement as schematically shown in fig. 9 has been adopted in order to have an output signal referred to ground, given an input signal referred to a reference voltage (in L292) of approximately 8V. Resistors RA and RB must be high-precision resistors in order to have output 0 with no Im current present. In the practical implementation, resistors with an accuracy of 5% are used and the ends of a potentiometer are interposed between resistors RB and the output to the sum point of the error amplifier is made through the cursor. The gain of this current loop is proportional to the ratio R3/RB. A complete circuit diagram is shown in fig. 10.

10/16

AN241

System with digital control Since, for reasons of gain, resistor RB must be 27 k and, if connected to pin 7 of L292, should have subtracted too much current, thus affecting the correct operation of L292, it has been connected to pin 11, having the same potential as pin 7. Consequently, the resistance value between pin 11 and ground has been modified, in order to maintain the switching frequency of L292 unchanged. In order to have a correct adjustment of potentiometer P1, it is enough to set the 0 speed code (b1 through b5 high) and turn the cursor until the motor stops. The input versus output characteristic obtained with the circuit of fig. 10 is indicated in fig. 11. Figure 8. Output characteristic of the circuit in fig. 7.

11/16

System with digital control Figure 9. Translator circuit.

AN241

Figure 10. Complete circuit with current feedback.

12/16

AN241 Figure 11. Output characteristic of the circuit in fig. 10.

System with digital control

2.1

Response to input step

Measurements have been taken on the circuits described in the previous paragraphs, in order to analyze how the motor speed varies when a step variation is imposed to the input. For the system DC control, the control voltage has been changed from 0 to the maximum value ViM and down to 0 again. For the digital system the speed code has been changed from 0 (b1 through b5 high) to the maximum value (b1 through b5 low) and down to 0 again. When the control quantity changes from 0 to the maximum value, the output voltage of the error amplifier (Vo, fig. 1 and fig. 6) assumes its maximum value, since the feed-back signal coming from the tachometer dynamo initially 0. In these conditions, L292 supplies the motor with the maximum current (2A) and maintains it until the motor speed is sufficiently close to the maximum value. Since the motor is powered from a constant current, it moves with a constant current, and it moves with a constant acceleration and consequently its speed grows linearly from 0 up to the maximum value over the time interval ta. The time needed for the motor to reach the maximum speed also depends, besides the current, on the electrical and mechanical characteristics of the motor and on the moment of inertial of the load applied to the motor. When the control quantity changes from the maximum value to 0, the output of the error amplifier Vo assumes the maximum value, but with an opposite sign with respect to the previous case, and the current flowing in the motor is also reversed and tends to brake it, by

13/16

System with digital control

AN241

making the speed linearly decrease from the maximum value down to 0 over the time period tf. The no-load characteristics, relevant to the motor used for the previous tests, are shown in fig. 12. The times ta and tf are not equal to each other, which circumstance is basically due to the frictions which, during the acceleration phase, oppose increase of speed, while during the deceleration phase they contribute to make the speed decrease. As a matter of fact, from the movement equation: J " + D' + Tf = KT IM where: J = System moment of inertia D = Coefficient of viscous friction Tf = Braking couple Kt = Motor constant Q = Angular speed Q" = Angular acceleration and by disregarding the term D", one obtains: KT I M T f = ----------------------------J where from it can be seen that | " | is greater if IM is negative. Figure 12. Pulse response.

14/16

AN241

Revision history

Revision history

Table 1.

Date 24-Jan-2006 13-Nov-2006

Document revision history

Revision 1 2 Initial release. Layout change, text modifications Changes

15/16

AN241

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (ST) reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any time, without notice. All ST products are sold pursuant to STs terms and conditions of sale. Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN STS TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USERS OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries. Information in this document supersedes and replaces all information previously supplied. The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

2006 STMicroelectronics - All rights reserved STMicroelectronics group of companies Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America www.st.com

16/16

You might also like

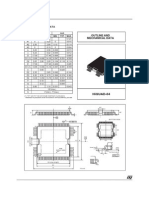

- Powerso16: Outline and Mechanical DataDocument1 pagePowerso16: Outline and Mechanical DataDan EsentherNo ratings yet

- Powerso-20 Mechanical Data: Dim. Mm. Inch Min. TYP Max. Min. Typ. MaxDocument1 pagePowerso-20 Mechanical Data: Dim. Mm. Inch Min. TYP Max. Min. Typ. MaxDan EsentherNo ratings yet

- PSSO-12 Mechanical Data: Dim. Mm. Min. TYP MaxDocument1 pagePSSO-12 Mechanical Data: Dim. Mm. Min. TYP MaxDan EsentherNo ratings yet

- L9929Document3 pagesL9929Dan EsentherNo ratings yet

- 10833Document18 pages10833Dan EsentherNo ratings yet

- Powersso-24 Mechanical Data: Dim. Mm. Min. Typ MaxDocument1 pagePowersso-24 Mechanical Data: Dim. Mm. Min. Typ MaxDan EsentherNo ratings yet

- Pso 36Document1 pagePso 36Dan EsentherNo ratings yet

- Ppak Mechanical Data: Dim. Min. TYP MaxDocument1 pagePpak Mechanical Data: Dim. Min. TYP MaxDan EsentherNo ratings yet

- Hiquad 64Document1 pageHiquad 64Dan EsentherNo ratings yet

- Powerso-10 Mechanical Data: Dim. Mm. Inch Min. Typ Max. Min. Typ. MaxDocument1 pagePowerso-10 Mechanical Data: Dim. Mm. Inch Min. Typ Max. Min. Typ. MaxDan EsentherNo ratings yet

- Multipowerso-30 Mechanical Data: Dim. Mm. Min. Typ MaxDocument1 pageMultipowerso-30 Mechanical Data: Dim. Mm. Min. Typ MaxDan EsentherNo ratings yet

- 10832Document26 pages10832Dan EsentherNo ratings yet

- 10311Document23 pages10311Dan Esenther100% (1)

- VNQ830A-E: Quad Channel High Side DriverDocument17 pagesVNQ830A-E: Quad Channel High Side DriverDan EsentherNo ratings yet

- 10831Document21 pages10831Dan EsentherNo ratings yet

- 10261Document10 pages10261Dan EsentherNo ratings yet

- Fully Integrated H-Bridge Motor Driver: VNH3SP30Document26 pagesFully Integrated H-Bridge Motor Driver: VNH3SP30Dan EsentherNo ratings yet

- 10830Document21 pages10830Dan EsentherNo ratings yet

- 10303Document5 pages10303Dan EsentherNo ratings yet

- 10683Document19 pages10683Dan EsentherNo ratings yet

- 10640Document22 pages10640Dan EsentherNo ratings yet

- VND830PEP-E: Double Channel High Side DriverDocument13 pagesVND830PEP-E: Double Channel High Side DriverDan EsentherNo ratings yet

- Uh 30Document10 pagesUh 30Dan EsentherNo ratings yet

- 9696Document17 pages9696Dan EsentherNo ratings yet

- 10302Document4 pages10302Dan EsentherNo ratings yet

- 9933Document11 pages9933Dan EsentherNo ratings yet

- 10022Document262 pages10022Dan EsentherNo ratings yet

- 9792Document21 pages9792Dan EsentherNo ratings yet

- 9927Document11 pages9927Dan EsentherNo ratings yet

- 9926Document10 pages9926Dan EsentherNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wks Mar09 Zscore ProblemsDocument1 pageWks Mar09 Zscore ProblemsKennyNo ratings yet

- Meshing 2Document26 pagesMeshing 2sb aliNo ratings yet

- 105-s29 Control of Flexural Cracking in Reinforced ConcreteDocument7 pages105-s29 Control of Flexural Cracking in Reinforced ConcreteThomas Crowe100% (1)

- FYP Report Template and GuidelinesDocument21 pagesFYP Report Template and GuidelinesTalhaNo ratings yet

- B.tech Syllabus 3rd Semester For CSE IPUDocument8 pagesB.tech Syllabus 3rd Semester For CSE IPUykr007No ratings yet

- Seismic Analysis of Multi-Story RC BuildingsDocument15 pagesSeismic Analysis of Multi-Story RC BuildingsPrakash Channappagoudar100% (1)

- YLAC-1808 应力分析报告(Stress Analysis-1808)Document19 pagesYLAC-1808 应力分析报告(Stress Analysis-1808)arisandiyusufNo ratings yet

- Understanding Hooke's Law and Modulus of ElasticityDocument18 pagesUnderstanding Hooke's Law and Modulus of ElasticityIznifaiznur Faiznur0% (1)

- IGODocument30 pagesIGOMayukh MaityNo ratings yet

- Piping Elbows and Bends PDFDocument4 pagesPiping Elbows and Bends PDFaap1100% (2)

- Simulation of Crack Propagation in API 5L X52 Pressurized Pipes Using XFEM-Based Cohesive Segment ApproachDocument15 pagesSimulation of Crack Propagation in API 5L X52 Pressurized Pipes Using XFEM-Based Cohesive Segment ApproachAmmarul NafikNo ratings yet

- Managing Six SigmaDocument286 pagesManaging Six SigmaSharandeep100% (1)

- Amc 14 QsDocument6 pagesAmc 14 Qsjoebloggs_comNo ratings yet

- Introduction To Survival Analysis: Lecture NotesDocument28 pagesIntroduction To Survival Analysis: Lecture NotesMadhu MaddyNo ratings yet

- Very Hard Circle TheoremsDocument6 pagesVery Hard Circle TheoremsSasha MalikNo ratings yet

- Experimental Investigation and Process Parameter Optimization of Sheet Metal Bending by Line Heating MethodDocument12 pagesExperimental Investigation and Process Parameter Optimization of Sheet Metal Bending by Line Heating MethodJoel AbateNo ratings yet

- F 002Document25 pagesF 002Pampa MondalNo ratings yet

- Bollinger Bands: Standard DeviationDocument9 pagesBollinger Bands: Standard DeviationSwetha ReddyNo ratings yet

- Engineering Mathematics For Gate Chapter1Document1 pageEngineering Mathematics For Gate Chapter1Sai VeerendraNo ratings yet

- Forecasting Mortality Trends in The 1980 Cohort - A Comparative Analysis of Cairns Blake Dowd (CBD) and Lee-Carter ModelsDocument34 pagesForecasting Mortality Trends in The 1980 Cohort - A Comparative Analysis of Cairns Blake Dowd (CBD) and Lee-Carter Modelsngahuemily76No ratings yet

- EEE I & IV Year R09Document107 pagesEEE I & IV Year R09Sravan GuptaNo ratings yet

- AD and DA ConversionDocument15 pagesAD and DA ConversionmumamaduraiNo ratings yet

- Practice Assignment Solutions PDFDocument34 pagesPractice Assignment Solutions PDFJoseph SebastianNo ratings yet

- Dm2 Ch4 AutomataDocument38 pagesDm2 Ch4 AutomataPham Hoai VanNo ratings yet

- Pert CPMDocument42 pagesPert CPMNaveed Iqbal Salman86% (7)

- Litpack ManuelDocument66 pagesLitpack ManuelMoussaab BerkaniNo ratings yet

- Modeling and SimulationDocument29 pagesModeling and SimulationMiloradNo ratings yet

- c3 DDocument6 pagesc3 DMiracleNo ratings yet

- Need To Check If N 0Document4 pagesNeed To Check If N 0Sameerdaboss DabossNo ratings yet

- RDD Stata 1Document23 pagesRDD Stata 1Denis Lima E AlvesNo ratings yet