Professional Documents

Culture Documents

Hydrometallurgy: Cao Zhan-Fang, Zhong Hong, Qiu Zhao-Hui

Uploaded by

Pablo C. VicencioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrometallurgy: Cao Zhan-Fang, Zhong Hong, Qiu Zhao-Hui

Uploaded by

Pablo C. VicencioCopyright:

Available Formats

Hydrometallurgy 97 (2009) 153157

Contents lists available at ScienceDirect

Hydrometallurgy

j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / h yd r o m e t

Solvent extraction of rhenium from molybdenum in alkaline solution

Cao Zhan-fang , Zhong Hong, Qiu Zhao-hui

College of Chemistry and Chemical Engineering, Central South University, Changsha, Hunan, 410083, China

a r t i c l e

i n f o

a b s t r a c t

The technology of selective extraction of rhenium from alkaline solutions containing rhenium and molybdenum by solvent extraction using a mixture of tributyl phosphate and triotylamine as extractant has been investigated, complete separation of rhenium from alkaline solutions containing rhenium and molybdenum was possible after repeated extraction and repeated stripping. The results show that the mixture of 20% triotylamine and 30% tributyl phosphate diluted kerosene oil is selective extractant of rhenium with respect to molybdenum. It extracted molybdenum with extraction efciency of 1.7%, while rhenium was extracted with efciency of 96.8%, and separation coefcient Re/Mo is relatively good (1.7 103). The optimum extraction conditions have been determined experimentally as: 20% triotylamine and 30% tributyl phosphate, pH of the feed solution (9.0), room temperature, phase ratio (1:1), Stripping of rhenium to aqueous phase was efcient when 18% ammonia liquor were applied, the rhenium stripping efciencies in the examined conditions were about 99.3% under conditions of O:A ratio of 1:1 for 10 min at 40 C. 2009 Elsevier B.V. All rights reserved.

Article history: Received 4 January 2009 Received in revised form 19 February 2009 Accepted 20 February 2009 Available online 27 February 2009 Keywords: Rhenium Molybdenum Selective extraction Tributyl phosphate Triotylamine

1. Introduction Rhenium is a less common metal with special properties and is widely used in the petrochemical industry, aviation, electron, medicine and metallurgy etc. Because of the higher value of rhenium than that of molybdenum, the recovery of rhenium from rhenium bearing materials has both economic and environmental benets and received much attention in our literature (Sato and Sato, 1990; Gerhardt et al., 2000). The separation of rhenium from molybdenum in aqueous solution has always been a problem in hydrometallurgy. Their adjacent positions in the periodic table results in aqueous somewhat similar chemical behaviour but differences do exist (Gerhardt et al., 2000). The current industrial practice of recovery rhenium from rhenium bearing materials can be described as leachingextraction and leachingion exchanging resin absorbingeluting processes (Li and Zhu, 1992; Gupta, 1992; Tao, 1996; Juneja et al., 1996; Kholmogorov and Kononava, 1999; Yun et al., 2006). The aim of this paper is to improve on the former process. The resin-in-leaching solution (RIL) followed by selective elution processes is an effective process for rhenium recovery. However, the long leaching and absorbing operations, less selectivity of ion exchanging resin and lower capacity of absorption makes the process cost higher. Solvent extraction method is used especially for the recovery of many rare metal ions (Ali and Vanjara, 2001; Moriya et al., 2001; Wang et al., 2002; Cox et al., 2002; Iyer and Dhadke, 2003). In general, extraction of metal anions with amines is a common method for the recovery of molybdenum and rhenium. The common amine extractant, tri-n-octylamine, provides high extent of extraction of metal anions (Coca et al., 1990; Sato and Sato, 1990). The efciency

Corresponding author. Tel.: +86 13787288460; fax: +86 731 8879616. E-mail address: zfcao1980@163.com (C. Zhan-fang). 0304-386X/$ see front matter 2009 Elsevier B.V. All rights reserved. doi:10.1016/j.hydromet.2009.02.005

of metal extraction by amines decreases as follows: quaternary N tertiary N secondary N primary when metal ion complexes are extracted under the same conditions. Certain difculties are encountered in stripping metals using quaternary ammonium compounds; tertiary amines have found wide application in practical extraction systems. Among these is tri-n-octyl amine (TOA), which extracts metal ion complexes by an anion-exchange reaction (Qiong et al., 2006). Kerosene with added modiers of the organic phase (alcohols or ketones) is usually used in diluting TOA. Solvent extraction method is used especially for separation of rhenium from other components, such as arsenic, tungsten or molybdenum. Most frequently, for rhenium extraction tri-n-octylamine, bis-isododecylamine, pyridine, Aliquat336, tributyl phosphate, trioctylphosphine oxide, cyklohexanon, ethyl xanthate and mesityl oxide were used (Gerhardt et al., 2001). In the process of rhenium stripping from organic phase, solutions of both acids and alkalis were used, i.e. aqueous HCl, H2SO4 and ammonium solution (for ammonium perrhenate separation) or aqueous solutions of NaOH and KOH (to separate suitable rhenium salts, i.e. NaReO4 and KReO4) (Colton, 1965). The objective of this study was that the extraction and separation of rhenium from alkaline leach solutions containing rhenium and molybdenum by solvent extraction using a mixture of tributyl phosphate and triotylamine as extractant. 2. Experimental 2.1. Reagents The organic phase consists of an extractant, a modier, and a diluent. The extractant is triotylamine (N235), which is purchased from Shanghai, China. The modier is tributyl phosphate (TBP), which is

154 Table 1 Compositions of molybdenite concentrate (mass fraction, %). Component Content % Mo 47.40 S 31.40

C. Zhan-fang et al. / Hydrometallurgy 97 (2009) 153157

Cu 2.20

P 0.04

Fe 3.50

As 0.10

CaO 0.17

SiO2 4.35

Re 0.07

Sn 0.10

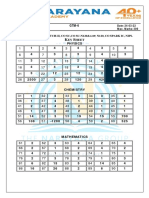

Table 2 The extraction capability of the several extractions. The composition of organics phase N235 Sec-caprylic alcohol/% Tributyl phosphate/% 10 50 20 10 10 10 20 20 20 30 30 30 20 10 30 50 10 30 50 10 30 50 Kerosene oil/% 90 50 60 80 60 40 70 50 30 60 40 20 Initial aqueous phase pH 9 9 9 9 9 9 9 9 9 9 9 9 Mo (g/L) 15 15 15 15 15 15 15 15 15 15 15 15 Re (mg/L) 100 100 100 100 100 100 100 100 100 100 100 100 Fafnate Mo (g/L) Re (mg/L) 14.99 91.5 14.98 77.7 12.94 91.9 14.88 45.8 14.86 43.3 14.89 35.1 14.79 36.2 14.85 2.4 14.77 5.9 14.71 28.1 14.74 24.6 Split phase ambiguity Percentage extraction/% Mo 0.04 0.11 13.7 0.8 0.9 0.7 1.4 1.6 1.5 1.9 1.7 Re 8.5 22.3 8.1 54.2 56.7 64.9 63.8 97.6 94.1 71.9 75.4

purchased from Langfang Longtengyu Fine Chemicals Co., Ltd, China. Commercial kerosene (China Petroleum & Chemical Corporation, China) was used as diluents. Rhenium and molybdenum synthetic alkaline solutions were prepared from reagent grade ammonium molybdate and ammonium perrhenate. Ammonia liquor, hydrochloric acid, sec-caprylic alcohol and H2SO4 were of A.R. grades (Changsha, China) that were used directly as received from the manufacturer. On the other hand, commercial kerosene is a complex mixture of aliphatic origin and also contains aromatics about 15% w/w. 2.2. Feed solution preparation The aqueous solutions were prepared by electric-oxidating the original ore sample, which came from the Dexing Copper Mine, Jiangxi Province, China; the original ore sample was analyzed by using sps8000 ICP-AES (Beijing, China), and the compositions of molybdenite concentrate are listed in Table 1. Mo and Re leaching rate can get to over 99.5% under the optimum electric-oxidation conditions that concentration of NaCl, the liquid-to-solid ratio, stirring speed, operating potential, anode ampere density, pH, leaching temperature, and leaching time are 4 mol/L, 30, 400 rpm, 3.0 V, 800 A/m2, 9, room temperature, 240 min, respectively and alkaline leach solutions containing rhenium and molybdenum were obtained, the concentration of molybdenum and rhenium are 16.5 g/L; 0.13 g/L; respectively, residual metals such as Cu, Fe, As, Sn were not investigated. Thus, the solution was not processed further before extraction; the alkaline leach solution prepared as mentioned above was used as the feed solution in the experiments. The selectivity and extraction capability of the several extractions for the Mo and Re was shown by using a molybdenum-containing synthetic alkaline solution in which the salts ammonium molybdate and ammonium perrhenate reagent grade were added. The composition of the initial synthetic solution was as follows: Mo 15 g/L, Re 0.1 g/L, and the pH value of the solution is 9. The separation efciency was taken as the ratio of the corresponding extraction percentages (EMo/ERe). The metal concentration in the organic phase was calculated by mass balance. The phase contact time was set to 10 min at room temperature, phases disengaged within 30 s after mixing. 2.3. Experimental method The phase contact time was set to 10 min. In solvent extraction experiments, 10 mL of aqueous phase were mixed with different vol-

umes of extractant of a desired concentration in different diluents at room temperature. The phase contact time was set to 10 min and the mixture was then poured into separation funnel, phases disengaged within 30 s after mixing and after several minutes delaminated phases were separated and their volume was measured. Organic phases were collected (for stripping studies), and aqueous phases were analyzed for rhenium and molybdenum content. 2.4. Analytical method The concentrations of rhenium and molybdenum were determined by colorimetry using butyl rhodamine and thiocyanate respectively. 3. Result and discussion 3.1. Selection of the extractant To compare with the selectivity and extraction capability of the several extractions, a series leaching tests were carried out under conditions of O:A ratio of 1:1 for 10 min at room temperature as shown in Table 2. Comparative tests of various extractants have shown that the highest rhenium recovery (above 97%) was reached for the mixture of 20% N235 and 30% tributyl phosphate diluted kerosene oil. Signicantly lower results were obtained when TBP in kerosene oil

Fig. 1. Effect of pH on the percentage extraction of Re and Mo (20% N235, 20% seccaprylic alcohol and 60% kerosene oil).

C. Zhan-fang et al. / Hydrometallurgy 97 (2009) 153157

155

Table 3 Extraction percentage of rhenium (VII) and molybdenum (VI) from the solution obtained from electric-oxidation solution. Extraction stage Fresh organic phasea 1st Stage 2nd Stage Regenerated organic phasec 1st Stage 2nd Stage

a b c

Rafnate content (g/L) Re Mo

Percent extracted/% Re 97.6 98.5b Mo 1.6 1.7b

96.8 98.3b

1.4 1.6b

Organic phase consisted of stock chemicals. Combined extraction percentage of metals for two stages of extraction. Organic phase regenerated as described in Section 2.

Fig. 2. Effect of pH on the percentage extraction of Re and Mo (20% N235, 30% tributyl phosphate and 50% kerosene oil).

(22.3%) and the mixture of 20% N235 and 20% sec-caprylic alcohol diluted kerosene oil (8.1%) were used. As it turned out, the most selective extractant of rhenium with respect to molybdenum is the mixture of 20% N235 and 30% tributyl phosphate diluted kerosene oil. It extracted molybdenum with extraction efciency of 1.6%, while rhenium was extracted with efciency of 97.6%, and separation coefcient Re/Mo is relatively good (2.5 103). Therefore, for further investigations the following extractants were selected: the mixture of 20% N235 and 30% tributyl phosphate diluted kerosene oil, because of relatively high rhenium extraction ef ciency and satisfying selectivity coefcients. From Fig. 1 it is found that the molybdenum extraction capacities of the mixture of 20% N235 and 20% sec-caprylic alcohol diluted kerosene oil for rhenium and molybdenum are almost the same. Whilst Fig. 2 shows that mixture of 20% N235 and 30% tributyl phosphate diluted kerosene oil has lower extraction capacities of molybdenum than that of rhenium, this shows that tributyl phosphate has better selective assist extraction capacities for Re. The recovery of metals in the organic phase in the two stages is N 98%. Excellent phase separation performance (rapid phase separation, no formation of the third phase and no generation of an emulsion) in the extraction process was observed. Molybdenum and rhenium were stripped by Ammonia liquor (18%) solution at an aqueous/organic phase ratio of 1:1. After the stripping, the organic phase was regenerated by treatment with 10% sulphuric acid and was subsequently used for the

extraction of molybdenum and rhenium. As shown in Table 3, the decrease in efciency of metal extraction using the regenerated organic phase was slight. Hence all the experiments were conducted with the mixture of 20% N235 and 30% tributyl phosphate diluted kerosene oil. Effect of parameters for maximum metal recovery was studied and is given below. 3.2. Inuence of aqueous to organic ratio of extraction For the feed solution, extractions were conducted with the 20% N235 and 30% tributyl phosphate diluted kerosene oil. The results of the studies into inuence of phase ratio on extraction efciency are presented in Fig. 3. High rhenium extraction efciencies (about 97%) were obtained when the ratio of aqueous phase to organic phase (volume) was in the range from 1:2 to 1:1. When the ratio of aqueous phase to organic phase (volume) was 2:1 rhenium extraction degree went down to 76.7%. Therefore extraction of rhenium from the solution with the 20% N235 and 30% tributyl phosphate diluted kerosene oil should be conducted at the ratio of aqueous phase volume to the volume of organic phase equal to 1:1. That guarantees maximum effectiveness of extraction process, i.e. maximum efciency and selectivity. These limitations are directly related to very high but limited capacities of the extractants for rhenium extraction. 3.3. Inuence of alkaline leach solution pH In the next investigations the most advantageous pH for conducting efcient rhenium extraction was examined. For the feed solution,

Fig. 3. Effect of the ratio of aqueous phase to organic phase on the percentage extraction of Re and Mo Operation condition: pH = 9.0, room temperature, and the phase contact time (10 min).

Fig. 4. Effect of pH on the percentage extraction of Re and Mo. Operation condition: aqueous/organic phase ratio (1:1), room temperature, and the phase contact time (10 min).

156

C. Zhan-fang et al. / Hydrometallurgy 97 (2009) 153157

Fig. 5. Effect of temperature on the percentage extraction of Re and Mo. Operation condition: aqueous/organic phase ratio (1:1), pH= 9.0, and the phase contact time (10 min).

Fig. 7. Inuence of aqueous to organic ratio of stripping. Operation condition: ammonia liquor 18%, 40 C, and the phase contact time (10 min).

results of studies into inuence of pH on efciency and selectivity of rhenium extraction with the 20% N235 and 30% tributyl phosphate diluted kerosene oil are presented in Fig. 4. The solutions were shaken for a varying pH values for 10 min, using hydrochloric acid and ammonia solution to adjust the pH value. From Fig. 4 the following information was observed: when the pH value of the solution is 9.0, high rhenium extraction recovery was reached for the 20% N235 and 30% tributyl phosphate diluted kerosene oil, which extracted rhenium at the level of 96.8% and 1.7% of molybdenum, that extractant presented also high selectivity coefcient of extraction of rhenium versus molybdenum. When the pH value of the solution greater than or equal to 7.0, the molybdenum extraction rate is always low, however, rhenium extraction efciency and, as a consequence, Re/ Mo selectivity coefcient were to some degree dependent on pH of the solution. When pH value lies in the range of pH 7 to pH 10.0, rhenium extraction efciency is essentially slightly affected by acidity, but pH N 10, rhenium extraction efciency fall down eetly. For the 20% N235 and 30% tributyl phosphate diluted kerosene oil, it was determined that high rhenium extraction recovery (96.8%) was reached and at the same time the highest selectivity coefcient of rhenium versus ammonium ions obtained (about 1.7 103) around pH 9.0. 3.4. Inuence of extraction temperature 10 mL of extractant was added to 10 mL of the feed solution, and the whole volume was intensely stirred for 10 min, phases disengaged within 30s after mixing. The effect of leaching temperature on rhe-

nium extraction was investigated in the range of 1050 C. The results in Fig. 5 show that temperature cannot obviously impact rhenium extraction rate, so the optional manipulation temperature is chosen as room temperature.

3.5. Results of stripping of rhenium The objective of this part of the study was to determine conditions for stripping of rhenium from the extractants, i.e. the 20% N235 and 30% tributyl phosphate diluted kerosene oil, to aqueous phases. The stripping operation should produce aqueous solution of the possibly highest rhenium concentration and the lowest molybdenum content. For the feed solution, the stripping of rhenium and molybdenum was investigated with respect to the effects of ammonia liquor concentration, by changing leaching temperature and aqueous to organic ratio. The results of investigations into stripping of rhenium and molybdenum with various agents to aqueous phase are presented in Figs. 68. From the obtained results it can be observed that stripping of rhenium (from the 20% N235 and 30% tributyl phosphate diluted kerosene oil) to aqueous phase was efcient when 18% ammonia liquor were applied. The rhenium stripping efciencies in the examined conditions were about 99.3% under conditions of O:A ratio of 1:1 for 10 min at 40 C. Unfortunately, in those conditions also intensive molybdenum stripping was observed, the concentration of molybdenum and rhenium in solutions after extraction and stripping are 0.279 g/L, 0.125 g/L respectively.

Fig. 6. Inuence of the concentration of ammonia liquor of stripping. Operation condition: aqueous/organic phase ratio (1:1), 40 C, and the phase contact time (10 min).

Fig. 8. Inuence of temperature of stripping. Operation condition: aqueous/organic phase ratio (1:1), ammonia liquor 18%, and the phase contact time (10 min).

C. Zhan-fang et al. / Hydrometallurgy 97 (2009) 153157

157

4. Conclusions (1) For the feed solution, the results show that the mixture of 20% N235 and 30% tributyl phosphate diluted kerosene oil is selective extractant of rhenium with respect to molybdenum. It extracted molybdenum with extraction efciency of 1.7%, while rhenium was extracted with efciency of 96.8%, and separation coefcient Re/Mo is relatively good (1.7 103). The concentration of molybdenum and rhenium in solutions after extraction are 16.2 g/L, 0.004 g/L, respectively. (2) Stripping of rhenium to aqueous phase was efcient when 18% ammonia liquor were applied. The rhenium stripping efciencies in the examined conditions were about 99.3% under conditions of O:A ratio of 1:1 for 10 min at 40 C, the concentration of molybdenum and rhenium in solutions after extraction and stripping are 0.279 g/L, 0.125 g/L respectively. Acknowledgement The authors are thankful to the 11th Five-year Plan of National Scientic and Technological Program of China (2007 BAB22B01). References

Ali, K.A., Vanjara, A.K., 2001. Solvent extraction and separation of Bi(III) and Sb(III) from HCl and HBr media using tri-n-octyl phosphine oxide (TOPO). Ind. J. Chem. Technol. 8, 239243. Coca, J., Diez, F.V., Moriz, M., 1990. Solvent extraction of molybdenum and tungsten by Alamine 336 and DEHPA. Hydrometallurgy 25, 125135.

Colton, R., 1965. The Chemistry of Rhenium and Technetium. John Wiley & Sons Ltd, LondonNew YorkSydney, p. 17. Cox, M., Flett, D.S., Velea, T., Vasiliu, C., 2002. Impurity removal from copper tankhouse liquors by solvent extraction. International Solvent Extraction Conference, Cape Town, pp. 9951000. Gerhardt, N.I., Palant, A.A., Dungan, S.R., 2000. Extraction of tungsten (VI), molybdenum (VI) and rhenium (VII) by diisododecylamine. Hydrometallurgy 55, 115. Gerhardt, N., Palant, A., Petrova, V., Tagirov, R., 2001. Solvent extraction of molybdenum (VI), tungsten (VI) and rhenium (VII) by diisododecylamine from leach liquors. Hydrometallurgy 60, 1. Gupta, C.K., 1992. Extractive Metallurgy of Molybdenum. CRC Press, Boca Raton, USA. Iyer, J.N., Dhadke, P.M., 2003. Solvent extraction and separation studies of antimony (III) and bismuth(III) by using Cyanex-925. Ind. J. Chem. Technol. 10, 665669. Juneja, J.M., Singh, S., Bose, D.K., 1996. Investigations on the extraction of molybdenum and rhenium values from low grade molybdenite concentrate. Hydrometallurgy 41, 201209. Kholmogorov, A.G., Kononava, O.N., 1999. Ion exchange recovery and concentration of rhenium from salt solutions. Hydrometallurgy 51, 1935. Li, J., Zhu, L.L.,1992. The kinetics study of ion exchange resin in pulp. Chin. J. Hydrometall. 2, 1013. Moriya, Y., Sugai, M., Nakata, S., Ogawa, N., 2001. Extraction of bismuth (III) with 2bromoalkanoic acid non-donating solvent from highly acidic aqueous solution. Anal. Sci. 17, 297300. Qiong, J., Jie, W., Ting-Ting, L., Wei, H.Z.H., 2006. Synergistic extraction of Zn(II) by mixtures of tri-butyl-phosphate and trialkyl amine extractant. Chin. J. Anal. Chem. 36, 619622. Sato, T., Sato, K., 1990. Liquidliquid extraction of rhenium (VII) from hydrochloric acid solutions by neutral organophosphorus compounds and high molecular weight amines. Hydrometallurgy 25, 281291. Tao, Z.Y., 1996. Terms of ion exchange. Ion Exch. Adsorpt. 12 (2), 184194. Wang, C., Jiang, K., Liu, D., Wang, H., 2002. Purication of copper electrolyte with Cyanex 923. International Solvent Extraction Conference, Cape Town, pp. 10391044. Yun, Ch., Qiming, F., Yanhai, Sh., Guofan, Zh., Leming, O., Yiping, L., 2006. Investigations on the extraction of molybdenum and vanadium from ammonia leaching residue of spent catalyst. Inter. J. Miner. Process. 79, 4248.

You might also like

- Eng20120900001 11566282Document6 pagesEng20120900001 11566282Uli ArthaNo ratings yet

- Quaternary Ammonium HalidesDocument5 pagesQuaternary Ammonium HalidesromeroeqNo ratings yet

- Study of Mechanisms of Manganese Removal From Leachates: G. Bazdanis, D. Zaharaki and K. KomnitsasDocument6 pagesStudy of Mechanisms of Manganese Removal From Leachates: G. Bazdanis, D. Zaharaki and K. KomnitsasIoannis KapageridisNo ratings yet

- Investigations On Humic Acid Removal From Water Using Surfactant-Modified Zeolite As Adsorbent in A Fixed-Bed ReactorDocument14 pagesInvestigations On Humic Acid Removal From Water Using Surfactant-Modified Zeolite As Adsorbent in A Fixed-Bed ReactorAnonymousNo ratings yet

- Effects of Ozonation vs. Chlorination Water Treatment Operations On Natural Organic Matter FractionsDocument16 pagesEffects of Ozonation vs. Chlorination Water Treatment Operations On Natural Organic Matter FractionsdimateaNo ratings yet

- Copper (II) Extraction From Nitric Acid Solution With 1-Phenyl-3-Methyl-4-Benzoyl-5-Pyrazolone As A Cation Carrier by Liquid Membrane EmulsionDocument8 pagesCopper (II) Extraction From Nitric Acid Solution With 1-Phenyl-3-Methyl-4-Benzoyl-5-Pyrazolone As A Cation Carrier by Liquid Membrane EmulsionSaad ShahNo ratings yet

- Separation of Rare Earths by Solvent Extraction With An Undiluted Nitrate Ionic LiquidDocument6 pagesSeparation of Rare Earths by Solvent Extraction With An Undiluted Nitrate Ionic LiquidmtanaydinNo ratings yet

- Nanofiltration Process Applied To The Tannery SolutionsDocument2 pagesNanofiltration Process Applied To The Tannery SolutionsAditya RahmatNo ratings yet

- Sdarticle 21Document13 pagesSdarticle 21Vijaykumar MarakattiNo ratings yet

- Uslu 2007Document6 pagesUslu 2007raquelNo ratings yet

- Liquid-Liquid Extraction of Metal Ions Using Aqueous Biphasic SystemsDocument10 pagesLiquid-Liquid Extraction of Metal Ions Using Aqueous Biphasic Systemskareem_opoNo ratings yet

- MSN 3549 Proceedings 192 fullpaperPACCONDocument6 pagesMSN 3549 Proceedings 192 fullpaperPACCONMaritza UreñaNo ratings yet

- Mafu 2014Document10 pagesMafu 2014korope8705No ratings yet

- PMMADocument9 pagesPMMArehanNo ratings yet

- 10.1515 - TSD 2022 2447Document20 pages10.1515 - TSD 2022 2447Fatma TaherNo ratings yet

- Minerals Engineering: J.W. An, Y.H. Lee, S.J. Kim, T. Tran, S.O. Lee, M.J. KimDocument6 pagesMinerals Engineering: J.W. An, Y.H. Lee, S.J. Kim, T. Tran, S.O. Lee, M.J. KimSebastian Andres MuñozNo ratings yet

- Art 25Document4 pagesArt 25Marcelo RoccoNo ratings yet

- Extraction of Zinc and Copper-Zinc Mixtures From Ammoniacal Solutions Into Emulsion Liquid Membranes Using LIX 84I®Document8 pagesExtraction of Zinc and Copper-Zinc Mixtures From Ammoniacal Solutions Into Emulsion Liquid Membranes Using LIX 84I®ahmad syuhaibNo ratings yet

- Solvent Extraction in Production and Processing of Uranium and ThoriumDocument44 pagesSolvent Extraction in Production and Processing of Uranium and ThoriumRubaiyat IshtiNo ratings yet

- Thiocyanate Hydrometallurgy For The Recovery of Gold Part 4Document6 pagesThiocyanate Hydrometallurgy For The Recovery of Gold Part 4Roberto ChangNo ratings yet

- Analytical &: Phosphorous Removal From Wastewater Effluent Using Electro-Coagulation by Aluminum and Iron PlatesDocument13 pagesAnalytical &: Phosphorous Removal From Wastewater Effluent Using Electro-Coagulation by Aluminum and Iron PlatesHamed8665No ratings yet

- Uranium Extraction From Yellow CakeDocument6 pagesUranium Extraction From Yellow Cakeعین الله یاسینیNo ratings yet

- The Heterogenation of Melamine and Its Catalytic Activity: Applied Catalysis A: GeneralDocument7 pagesThe Heterogenation of Melamine and Its Catalytic Activity: Applied Catalysis A: GeneralJimmy NelsonNo ratings yet

- Determination Foods eDocument7 pagesDetermination Foods eRoberta MatosNo ratings yet

- Optimization of Ammonia Removal by Ion-ExchangeDocument10 pagesOptimization of Ammonia Removal by Ion-ExchangeOssian89No ratings yet

- Studies On Diffusion Approach of MN Ions Onto Granular Activated CarbonDocument7 pagesStudies On Diffusion Approach of MN Ions Onto Granular Activated CarbonInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Extraction of Lithium by HFDocument24 pagesExtraction of Lithium by HFTalexandra PatienceNo ratings yet

- Recovery of Rare Earths From Acid Leach Solutions of Spent Nickel-Metal Hydride Batteries Using Solvent ExtractionDocument7 pagesRecovery of Rare Earths From Acid Leach Solutions of Spent Nickel-Metal Hydride Batteries Using Solvent ExtractionHoracio Piña SpeziaNo ratings yet

- Determination of Trace Metals in Waters by FAAS After Enrichment As Metal-HMDTC Complexes Using Solid Phase ExtractionDocument6 pagesDetermination of Trace Metals in Waters by FAAS After Enrichment As Metal-HMDTC Complexes Using Solid Phase ExtractionDamian DaquiNo ratings yet

- Ultrasound-Assisted Solubilization of Trace and Minor Metals From Plant Tissue Using Ethylenediaminetetraacetic Acid in Alkaline MediumDocument6 pagesUltrasound-Assisted Solubilization of Trace and Minor Metals From Plant Tissue Using Ethylenediaminetetraacetic Acid in Alkaline MediumImad AghilaNo ratings yet

- 1 s2.0 S0304386X05000733 Main PDFDocument6 pages1 s2.0 S0304386X05000733 Main PDFEmely Daniela Vera VillamizarNo ratings yet

- EL-HAZEK - Liquid-Liquid Extraction of Tantalum and Niobium by OctanolDocument9 pagesEL-HAZEK - Liquid-Liquid Extraction of Tantalum and Niobium by OctanolOscar BenimanaNo ratings yet

- Observation of Anthracene Excimer Fluorescence at Very Low Concentrations Utilizing Dendritic StructuresDocument3 pagesObservation of Anthracene Excimer Fluorescence at Very Low Concentrations Utilizing Dendritic StructuresSreedevi KrishnakumarNo ratings yet

- Narin 2000Document6 pagesNarin 2000Adnan Ahmed ChahalNo ratings yet

- IJEAS0305036Document5 pagesIJEAS0305036erpublication100% (1)

- Molecules 23 02364Document25 pagesMolecules 23 02364IbrahimNo ratings yet

- Process For The Recovery of Lithium Ion From Aqueous Solution and SeawaterDocument4 pagesProcess For The Recovery of Lithium Ion From Aqueous Solution and SeawaterGregorius Rionugroho HarviantoNo ratings yet

- Solvent Extraction Process and ApplicationsDocument4 pagesSolvent Extraction Process and ApplicationsSyedMeherAliNo ratings yet

- A Kinetic Study of The Reduction of Colloidal Manganese Dioxide by Oxalic AcidDocument10 pagesA Kinetic Study of The Reduction of Colloidal Manganese Dioxide by Oxalic AcidDarine Mahfouf Ep BoucharebNo ratings yet

- Neutron Activation Analysis of Uranium IDocument8 pagesNeutron Activation Analysis of Uranium ICeren ÖZERNo ratings yet

- 1 s2.0 S1381116905004474 MainDocument6 pages1 s2.0 S1381116905004474 MainHaileyesus HatanoNo ratings yet

- 2007 - Removal of Textile Dyes From Water by The Electro-Fenton ProcessDocument5 pages2007 - Removal of Textile Dyes From Water by The Electro-Fenton ProcessClaudio CastroNo ratings yet

- Determination of Lead in River Water by Flame Atomic Absorption SpectrometryDocument8 pagesDetermination of Lead in River Water by Flame Atomic Absorption SpectrometryputriNo ratings yet

- Adsorptive Removal of Methylene Blue Onto ZnCl2 AcDocument12 pagesAdsorptive Removal of Methylene Blue Onto ZnCl2 AcHazel Rene Gallegos MorenoNo ratings yet

- Extraction of Europium by Sodium Oleate/Pentanol/Heptane/Nacl Microemulsion SystemDocument6 pagesExtraction of Europium by Sodium Oleate/Pentanol/Heptane/Nacl Microemulsion SystemUdrescu Andreea-IrinaNo ratings yet

- CHEMCON - 2003 - Research PaperDocument4 pagesCHEMCON - 2003 - Research Paperरुद्र प्रताप सिंह ८२No ratings yet

- Ekstraksi Asam Sitrat Dan Asam Oksalat: Pengaruh Konsentrasi Solut Terhadap Koefisien DistribusiDocument7 pagesEkstraksi Asam Sitrat Dan Asam Oksalat: Pengaruh Konsentrasi Solut Terhadap Koefisien DistribusiDevi Citra RastutiNo ratings yet

- A New Trend For Preparating Polymeric CalciumDocument11 pagesA New Trend For Preparating Polymeric CalciumNicolae LucaNo ratings yet

- Comparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010Document6 pagesComparative Study of Organic Solvents For Extraction of Copper From Ammoniacal Carbonate Solution Hu2010mtanaydinNo ratings yet

- Stereospeci®c Anionic Polymerization of A - (Alkoxymethyl) Acrylate Derivatives Affording Novel Vinyl Polymers With Macrocyclic Side ChainsDocument6 pagesStereospeci®c Anionic Polymerization of A - (Alkoxymethyl) Acrylate Derivatives Affording Novel Vinyl Polymers With Macrocyclic Side ChainsWalter EduardoNo ratings yet

- A Hydrometallurgical Approach To Recover Zinc and Manganese From Spent ZN-C BatteriesDocument16 pagesA Hydrometallurgical Approach To Recover Zinc and Manganese From Spent ZN-C BatteriesFerdianDwitamaNo ratings yet

- Xiao 2017Document66 pagesXiao 2017Yuliastri DewiNo ratings yet

- Preparation and Characterization of An Ion Exchanger Based On Semi-Carbonized Polyacrylonitrile FiberDocument6 pagesPreparation and Characterization of An Ion Exchanger Based On Semi-Carbonized Polyacrylonitrile FiberNico QuisumbingNo ratings yet

- Wang 2005Document10 pagesWang 2005hellna284No ratings yet

- Mineral ProcessingDocument9 pagesMineral ProcessingEdwar Villavicencio JaimesNo ratings yet

- Application of The Solution Mining Process To The Turkish 1996 HydrometalluDocument11 pagesApplication of The Solution Mining Process To The Turkish 1996 HydrometalluYiğitcan AkyüzNo ratings yet

- Reactivity Of (Η -Allyl) Dicarbonylnitrosyl Iron Complexes With Dimethyl Malonate And Diisobutyl MalonateDocument14 pagesReactivity Of (Η -Allyl) Dicarbonylnitrosyl Iron Complexes With Dimethyl Malonate And Diisobutyl MalonateElfabilo Abi RiloNo ratings yet

- Application of The Solution Mining Process To The Turkish 1996 HydrometalluDocument11 pagesApplication of The Solution Mining Process To The Turkish 1996 HydrometalluYiğitcan AkyüzNo ratings yet

- P24 Astm D501Document10 pagesP24 Astm D501Labicer Fc-uniNo ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- Prepare Cuprammonium Rayon Threads From Filter PaperDocument5 pagesPrepare Cuprammonium Rayon Threads From Filter PaperChetan ChhalaniNo ratings yet

- Ragagep Update: Douglas Reindl, Director, IRC 2016 IRC R&T ForumDocument25 pagesRagagep Update: Douglas Reindl, Director, IRC 2016 IRC R&T ForumSergio GarciaNo ratings yet

- AirCorr PaperDocument22 pagesAirCorr Papernaren57No ratings yet

- Explanation Text ExcerciseDocument6 pagesExplanation Text ExcerciseSILVIA PRAMESTYNo ratings yet

- AMCP 706-185, Military Pyrotechnics - Theory and ApplicationDocument270 pagesAMCP 706-185, Military Pyrotechnics - Theory and ApplicationASDAFF ASADNo ratings yet

- The Equilibrium Constant QPDocument12 pagesThe Equilibrium Constant QPStuart LittleNo ratings yet

- ScreeningDocument8 pagesScreeningBijaya GiriNo ratings yet

- Additional Numerical BufferDocument2 pagesAdditional Numerical BufferPrahlad DasNo ratings yet

- Process Description of Ammonia PlantDocument12 pagesProcess Description of Ammonia PlantSridharNo ratings yet

- D3867 16Document11 pagesD3867 16Ricardo Aguirre100% (1)

- Fertilizer Warehousing 3Document6 pagesFertilizer Warehousing 3Saurabh AgarwalNo ratings yet

- KCSE Form 3 NotesDocument265 pagesKCSE Form 3 NotesN Katana100% (1)

- Acid Base and Salts EdxlDocument5 pagesAcid Base and Salts EdxlMaria adeelNo ratings yet

- Orio, Psyber Experiment 2Document12 pagesOrio, Psyber Experiment 2Chanie Baguio Pitogo100% (1)

- CH425Document35 pagesCH425Vatra ReksaNo ratings yet

- Biochemical Activities of BacteriasDocument11 pagesBiochemical Activities of BacteriasEbruAkharmanNo ratings yet

- Ag Report UreaDocument40 pagesAg Report UreaVakul AgarwalNo ratings yet

- Physico-Chemical Properties of Drinking WaterDocument12 pagesPhysico-Chemical Properties of Drinking WaterEmmanuel WinfulNo ratings yet

- EY Heet Physics 1 4 4 3 2 4 3 3 4 3 3 2 2 4 1 4 4 3 4 4 3 12 12 2 3 2500 3 120 420 4Document19 pagesEY Heet Physics 1 4 4 3 2 4 3 3 4 3 3 2 2 4 1 4 4 3 4 4 3 12 12 2 3 2500 3 120 420 4sunny meenuNo ratings yet

- Aim IiT 2017 - Class Assignment Mole Concept-2Document8 pagesAim IiT 2017 - Class Assignment Mole Concept-2RaghavJain100% (1)

- Bgcse Double Kit With Answers-1-1Document116 pagesBgcse Double Kit With Answers-1-1Gèè MøttNo ratings yet

- Stoichiometry Practice ProblemsDocument5 pagesStoichiometry Practice ProblemsDwayneNo ratings yet

- GOC PYQsDocument15 pagesGOC PYQsshafique khanNo ratings yet

- Icsce Class 10 Periodic ClassificationDocument2 pagesIcsce Class 10 Periodic ClassificationprashantNo ratings yet

- 5070 w12 QP 12Document16 pages5070 w12 QP 12mstudy123456No ratings yet

- IA and IIA Group ElementsDocument4 pagesIA and IIA Group ElementsGagan NdNo ratings yet

- Selection and Design of CondensersDocument27 pagesSelection and Design of Condensersjdgh1986No ratings yet

- Cambridge O Level: CHEMISTRY 5070/03Document10 pagesCambridge O Level: CHEMISTRY 5070/03Sandra PepesNo ratings yet

- Buletinul Ipt Iasi - 2005Document308 pagesBuletinul Ipt Iasi - 2005danmertzNo ratings yet

- Nov 2022 H2 Chemistry 9729 Paper 4 Suggested SolutionDocument20 pagesNov 2022 H2 Chemistry 9729 Paper 4 Suggested Solutionzavairling05No ratings yet