Professional Documents

Culture Documents

MEMB 123 Semester 1 2013-2014

Uploaded by

Khairi KKamarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MEMB 123 Semester 1 2013-2014

Uploaded by

Khairi KKamarCopyright:

Available Formats

03/12/2013

MEMB 123 Semester 1 2013-2014

View the PDF version

Share on Facebook

Like

Share Be the first of your friends to like this.

MEMB 123

Semester 1

2013-2014

Project 1

Lecturer: Dr.Abreeza Noorlina Bte Abd.Manap

Student Name:

Omer Hamza Babiker

ID:

SECTION:

EP091010

03A

8 Pages

Sub Date

Project Description

A bridge having a horizontal top cord is to span between the two piers A and B

having an arbitrary height. It is required that a pin-connected truss be used,

consisting of steel members bolted together to steel gusset plates, such as the one

shown in Figure 1. The end supports are assumed to be a pin at A and a roller at B.

A vertical loading of 5 kN is to be supported within the middle 3 m of the span.

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

1/10

03/12/2013

MEMB 123 Semester 1 2013-2014

This load can be applied in part to several joints on the top cord within this region,

or to a single joint at the middle of the top cord. The weights of the members are to

be neglected. Assume the maximum tensile force in each member cannot exceed

4.25 kN; and regardless of the length of the member, the maximum compressive

force cannot exceed 3.5 kN.

Search for documents:

Report this document

Design the most economical truss that will support the loading. The members

cost $7.50/m, and the gusset plates cost $8.00 each. Submit a report on the cost

analysis as well as a complete force analysis along with the scaled drawing of the

truss, identifying on this drawing the tensile and compressive force in each member.

.

Info:

A hoist support designed specifically to hold at least 5000 Newton or 500 kilogram of loads A bridge

having a horizontal top cord is to span between the two piers A and B having an arbitrary height. It is

required that a pin-connected truss be used, consisting of steel members bolted together to steel gusset

plates. The end supports are assumed to be a pin at A and a roller at B. A vertical loading of 5 kN is to

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

2/10

03/12/2013

MEMB 123 Semester 1 2013-2014

be supported within the middle 3 m of the span. This load can be applied in part to several joints on the

top cord within this region, or to a single joint at the middle of the top cord. The weights of the members

are to be neglected. Assume the maximum tensile force in each member cannot exceed 4.25 kN; and

regardless of the length of the member, the maximum compressive force cannot exceed 3.5 kN. With

minimal usage of materials, and cost .

Goals:

1- the bridge must be able to lift a load of a specified weight and the second is

that the bridge must remain stable and not topple over when the load is lifted

and moved to another location.

2- see practical applications for trigonometry, physics, and statics.

3- must the hoist support is extremely stable and can hold the given load.

4- measuring and all the data had been recorded as we may refer to it whenever

we need to calculate and build our prototype.

5- cultivate leadership within the team. As a team, we need a leader to ensure the

effectiveness of each member.

6- The leader plays a big role and this will grant the task to complete due to

datelines given.

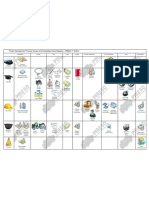

Tools :

Trusses are composed of slender bars that are assumed to carry only

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

3/10

03/12/2013

MEMB 123 Semester 1 2013-2014

axial force. Joints in large trusses are formed by welding or bolting

members to gusset plates. (see fig a ).

(a)

The members of most modern trusses are arranged in triangular patterns because

even when the joints are pinned, the triangular form is geometrically stable and will

not collapse under load (see fig b ).

Similarly, we can imagine that joint E is formed by

extending bars from joints C and D. Trusses formed in this manner are

called simple trusses. (see fig c ).

(b)

A truss is completely analyzed when the magnitude and sense (tension or

compression) of all bar forces and reactions are determined.

Because all forces acting at a joint pass through the pin, they constitute a

concurrent force system. For this type of force system, only two

equations of statics (that is, _Fx = 0 and _Fy= 0) are available to evaluate

unknown bar forces. Since only two equations of equilibrium are available, we

can only analyze joints that contain a maximum of two unknown bar forces.

(c)

Design:

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

4/10

03/12/2013

MEMB 123 Semester 1 2013-2014

Calculation:

5/10

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

03/12/2013

MEMB 123 Semester 1 2013-2014

Coast anlaysis:

Conclusion:

Based on what we learnt in MEMB 123 subject I had applied the calculation to

6/10

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

03/12/2013

MEMB 123 Semester 1 2013-2014

know receives extra force by the load to know when it may be broken by the time

and the hoist part that has to be strong enough to support the loads, Also

ensured the joining to be attached strongly and joining played their role by

supporting the force due to the load .Last I had learned that i can improve the

stability by widen the base part by applied the calculation.

References :

1-www. Wikipedia.com

2-Design of Building Trusses - James Ambrose

3-Engineering Mechanics-STATICS- R. C. Hibbeler

To find support reeactios at A B.

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

7/10

03/12/2013

MEMB 123 Semester 1 2013-2014

? ? ? = 0

-2.5*4.5 -2.5(7.5)+By*12=0

By=2.5 KN

? ?? = 0

Ax=0KN

? ?? = 0

-2.5 -2.5 =Ay+ 2.5=0

Ay=2.5KN

Let 2 = 60

Tan(60)=(h/1.5)

h=2.6 m

? ? = 0 at

jont A

A

D

2.5KN

2.5

Fac

?Fac=2

? .*=sin(60)=0

890KN

-Fad + Fac *cos(60) =0

D

A

Fad =1.44 KN

joint C

1

F

1 2.6

=50

(

)

= tan 2.25

?? = 0

-2.89 * Cos(60) Fcd * Cos (50) +Fcf = 0

?? = 0

2.5KN

2.89 * Sin(60) - Fcd * Sin(50) = 0

Fcd = 3.27 KN

Fcf = 3.54 KN

Joint D

?

D

E

?? = 0

1.44

?

Fde + 3.27 * Cos(50) + Fdf * Cos(50)=0

?? =

3.27 *Sin(50) 2.5 - Fdf * Sin(50) = 0

Fdf = 0 KN ( zero force member )

Fde = 3.5 KN

1 F

Joint E

? ?? = 0

ef

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

8/10

03/12/2013

MEMB 123 Semester 1 2013-2014

Fef

= 0 KN ( zero force member )

? ?? = 0

-3.5 +Fge = 0

Fge =3.5 KN

Joint F

By deleting previous zero force members at joints D , E . the forces at joint F looks like

G

?? = 0

C

F

Ffg = 0 KN ( zero force member )

? ?? = 0

-Fcf + Ffh = 0

Ffh = Fcf =3.54 KN

Joint G

By deleting previous zero force members at joints F . the forces at joint G looks like

2.5KN

G

E

? ?? = 0

-2.5 +Fgh * Sin (50) =0

Fgh =3.26 KN

? ?? = 0

3.5 Fgb 3.26 * Cos (50) = 0

Fgb = 1.4 KN

Joint B

B

G

1.4 Fbh * Cos(60) = 0

?? = 0

Fbh = 2.8 KN

2.5KN

Joint H

To confirm the solution . we need to do force analysis at last joint H

B

1 2

F

H

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

9/10

03/12/2013

MEMB 123 Semester 1 2013-2014

?? = 3.45 + 3.26 cos(50) + 2.8 cos(60) = 0

?? = 3.26 sin(50) + 2.8 sin(60) = 0

Member

Force (KN)

Force type

T: tension force

C: compression force

AC

2.89

T

AD CD CF DE EG

1.44 3.26 3.54 3.5 3.5

C

C

T

C

C

FH GH BH

3.54 3.26 2.8

T

C

T

GB

1.4

C

The members DF, EF, and FG are zero force members .

the design met the specification where the maximum tensile force in each member cannot exceed 4.25

kN; and regardless of the length of the member, the maximum compressive force cannot exceed 3.5

kN.

1. COAST ANALYSIS

The members cost $7.50/m, and the gusset plates cost $8.00 each. We need to find the total

length of design members and number of gussets used .

Member

AC AD

CD CF DE EG FH GH BH

GB

Length (m)

3

4.5

3.5 4.5 1.5 1.5 4.5 3.5 3

4.5

The total length is (3+4.5+3.5+4.5+1.5+1.5+4.5+3.5+3+4.5=34 m)

Number of gussets =number of joints = 8

Total cost = 34*7.5 + 8*8 =319 $.

Convert Word to PDF

share.pdfonline.com/3ad444dec5074fbc87ed5cc753f3b17e/omer.htm

10/10

You might also like

- PurlinDocument19 pagesPurlinLia Ame100% (2)

- Arch BridgesDocument20 pagesArch BridgesPankaj_Taneja_96840% (1)

- [4]14-2 LOW-RISE FRAMEDocument23 pages[4]14-2 LOW-RISE FRAMEMohamed EssamNo ratings yet

- Engr. Ernesto C. Prudenciado JRDocument36 pagesEngr. Ernesto C. Prudenciado JRGleanna NiedoNo ratings yet

- SBE SS5 SecureDocument131 pagesSBE SS5 SecureSergio ValeNo ratings yet

- Trigger 2 - Detailed Design Report - Brian MC Auliffe - 18225365 - GRDocument23 pagesTrigger 2 - Detailed Design Report - Brian MC Auliffe - 18225365 - GRapi-455351683No ratings yet

- HW 3Document2 pagesHW 3rojdaolmez0No ratings yet

- Chapter 4 StructuresDocument22 pagesChapter 4 Structuresmohamad fitri F2008No ratings yet

- Analysis of Buildings For Gravity LoadsDocument10 pagesAnalysis of Buildings For Gravity LoadsPrashant SunagarNo ratings yet

- AD 331 - Open Top Box Girders For BridgesDocument2 pagesAD 331 - Open Top Box Girders For Bridgessymon ellimacNo ratings yet

- Building Structure: Fettucine BridgeDocument35 pagesBuilding Structure: Fettucine BridgeHeng Yee TanNo ratings yet

- Types of Structures and LoadsDocument17 pagesTypes of Structures and LoadsRyan Forayo BosngonNo ratings yet

- Analysis and Design of Balanced Cantilever Prestressed Box Girder Bridge Considering Constructions Stages and Creep RedistributionDocument36 pagesAnalysis and Design of Balanced Cantilever Prestressed Box Girder Bridge Considering Constructions Stages and Creep RedistributionSitthideth Vongchanh100% (1)

- Additional Truss NotesDocument7 pagesAdditional Truss Notesmdavies20No ratings yet

- Steel Construction With TrussesDocument6 pagesSteel Construction With TrussesNero PereraNo ratings yet

- Industrial Building Truss Structure DesignDocument16 pagesIndustrial Building Truss Structure DesignRabindraUpretiNo ratings yet

- Design of Concrete Framed BuildingsDocument30 pagesDesign of Concrete Framed BuildingsRafi Mahmoud SulaimanNo ratings yet

- Balanced Cantilever BridgesDocument30 pagesBalanced Cantilever BridgesPacha Khan KhogyaniNo ratings yet

- 5 - Structural AnalysisDocument46 pages5 - Structural AnalysisHawsar Omer HamaNo ratings yet

- Unit 4s PDFDocument25 pagesUnit 4s PDFsmrutirekhaNo ratings yet

- 6.0 Beams & Shafts PDFDocument10 pages6.0 Beams & Shafts PDFLEONARD NYIRONGONo ratings yet

- Junior Design Engineer: Satyavani Projects and Consultants Pvt. LTDDocument30 pagesJunior Design Engineer: Satyavani Projects and Consultants Pvt. LTDyedida viswanadhNo ratings yet

- Structural Properties of Bolted JointsDocument5 pagesStructural Properties of Bolted JointsL095244No ratings yet

- Trusses and lattice girders design and analysisDocument17 pagesTrusses and lattice girders design and analysisMisgun Samuel50% (2)

- Models - Sme.pratt Truss BridgeDocument32 pagesModels - Sme.pratt Truss Bridgeak020202020217No ratings yet

- Full As Contoh Member AkashahDocument29 pagesFull As Contoh Member AkashahWayen Bulat100% (1)

- Anlysis of U Girder Bridge DecksDocument5 pagesAnlysis of U Girder Bridge DecksFadhilah Muslim100% (1)

- Chapter 9 - Frame Analysis (New)Document56 pagesChapter 9 - Frame Analysis (New)sorento91050% (2)

- Architectural Design (Vector) v2Document13 pagesArchitectural Design (Vector) v2Rachit AgarwalNo ratings yet

- Beams On Elastic FoundationsDocument3 pagesBeams On Elastic FoundationsIgnatius SamrajNo ratings yet

- Mobile Bridge Design for Military ApplicationsDocument7 pagesMobile Bridge Design for Military Applicationsravi vermaNo ratings yet

- Executive Summary: Figure 1: Example of Illustrated ModelDocument10 pagesExecutive Summary: Figure 1: Example of Illustrated ModelArnie FarhanaNo ratings yet

- Highway Structures: Approval Procedures and General Design Section 3 General DesignDocument18 pagesHighway Structures: Approval Procedures and General Design Section 3 General DesignΔημητρηςΣαρακυρουNo ratings yet

- Truss Design PDFDocument131 pagesTruss Design PDFmsiddiq1No ratings yet

- 1.0 TrussesDocument9 pages1.0 TrussesWilliam ManelaNo ratings yet

- Improved Large-Scale Joint Performance Using 3-D Woven Non-Crimp FabricsDocument10 pagesImproved Large-Scale Joint Performance Using 3-D Woven Non-Crimp FabricsKazi SowrovNo ratings yet

- Ridge Esign Roject: An Engineering Experience With Structural Principles and BudgetingDocument14 pagesRidge Esign Roject: An Engineering Experience With Structural Principles and BudgetingnafartityNo ratings yet

- Sultan Izmit BridgeDocument10 pagesSultan Izmit BridgeMuhammad Umar RiazNo ratings yet

- AD 283 - The Use of Discontinuous Columns in Simple ConstructionDocument3 pagesAD 283 - The Use of Discontinuous Columns in Simple Constructionsymon ellimacNo ratings yet

- 8/1/13 Beam Part 2Document50 pages8/1/13 Beam Part 2Macqui MaciasNo ratings yet

- Aula 7 - Vigas - Parte 1Document19 pagesAula 7 - Vigas - Parte 1Marcelo Zapata MuñozNo ratings yet

- Simplified Frame AnalysisDocument15 pagesSimplified Frame Analysisnaveen.m1057No ratings yet

- PLANE TRUSS ANALYSISDocument14 pagesPLANE TRUSS ANALYSISPrincess SandovalNo ratings yet

- Design Example 3 - Reinforced Strip Foundation-1Document8 pagesDesign Example 3 - Reinforced Strip Foundation-1seljak_veseljakNo ratings yet

- Beam - Stresses - P and SDocument27 pagesBeam - Stresses - P and SDianne Rose M. MadlangbayanNo ratings yet

- Section3 Unit3Document10 pagesSection3 Unit3jbsNo ratings yet

- Example - Pile Cap DesignDocument4 pagesExample - Pile Cap Designseljak_veseljak100% (1)

- 6 4uDocument7 pages6 4uElsayed Salah HamoudaNo ratings yet

- Plate GirdersDocument9 pagesPlate GirdersTapabrata2013No ratings yet

- Project Truss BridgeDocument25 pagesProject Truss BridgeMuhammad Khairuddin KassimNo ratings yet

- Statics Lab Report Group 34Document19 pagesStatics Lab Report Group 34D.DesmaanNo ratings yet

- Term Project - CIV314 Structural Analysis: OverviewDocument2 pagesTerm Project - CIV314 Structural Analysis: Overviewmohammed aburabieNo ratings yet

- Cable and ArchDocument45 pagesCable and Archabubakarsadiiq.engNo ratings yet

- Chapter 07-Unit 04 - Design of Continous Beam For Flexure PDFDocument14 pagesChapter 07-Unit 04 - Design of Continous Beam For Flexure PDFabdullahNo ratings yet

- Upgrading of Transmission Towers Using A Diaphragm Bracing SystemDocument26 pagesUpgrading of Transmission Towers Using A Diaphragm Bracing SystemthoriqNo ratings yet

- INTRO STRUCT ANALYSISDocument18 pagesINTRO STRUCT ANALYSISSagar D ShahNo ratings yet

- Analysis and Comparative Study of Composite Bridge GirdersDocument11 pagesAnalysis and Comparative Study of Composite Bridge GirdersIAEME PublicationNo ratings yet

- Multi-girder Bridge Design and Structural ConsiderationsDocument6 pagesMulti-girder Bridge Design and Structural ConsiderationsSwamy ManiNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Sediment Erosion on Francis Turbine Guide VaneDocument17 pagesSediment Erosion on Francis Turbine Guide VaneKhairi KKamarNo ratings yet

- Francis Turbine Flow Simulation Using FluentDocument47 pagesFrancis Turbine Flow Simulation Using FluentaguirretoNo ratings yet

- Measuring Elements Guide to Indicators, Recorders & DisplaysDocument9 pagesMeasuring Elements Guide to Indicators, Recorders & DisplaysKhairi KKamarNo ratings yet

- Test 2 Sem 2 08-09Document8 pagesTest 2 Sem 2 08-09Khairi KKamarNo ratings yet

- Introduction and Basic ConceptsDocument37 pagesIntroduction and Basic ConceptsKhairi KKamarNo ratings yet

- Lab 5 (Loading Effects)Document17 pagesLab 5 (Loading Effects)Khairi KKamarNo ratings yet

- Test 1 MEMB123 Sem 2 2009-2010Document9 pagesTest 1 MEMB123 Sem 2 2009-2010Mei GuanNo ratings yet

- Module 3 Project Document TemplateDocument2 pagesModule 3 Project Document TemplateqwertasdfgNo ratings yet

- The Role of Adult Attachment Style in Forgiveness Following An Interpersonal OffenseDocument10 pagesThe Role of Adult Attachment Style in Forgiveness Following An Interpersonal OffenseEsterNo ratings yet

- COE-USA Post Market DataDocument42 pagesCOE-USA Post Market DataDayaNo ratings yet

- UpatstvoenDocument2 pagesUpatstvoenRoze GaleskaNo ratings yet

- Heuristic Evaluation of PAWOON Website Portal Information SystemDocument11 pagesHeuristic Evaluation of PAWOON Website Portal Information SystemAbank AyozNo ratings yet

- 43Document5 pages43lumuxcNo ratings yet

- Pguide Completed Staff Work Calhr August 2020 VILTDocument53 pagesPguide Completed Staff Work Calhr August 2020 VILTBrigette Vilma PomarNo ratings yet

- What Are Patients Expectations of Orthodontic TreDocument9 pagesWhat Are Patients Expectations of Orthodontic TreAly OsmanNo ratings yet

- Differences between quantitative, qualitative and mixed methods researchDocument4 pagesDifferences between quantitative, qualitative and mixed methods researchrizwanooo0No ratings yet

- Validity and Reliability Issues in Educational Research: Oluwatayo, James Ayodele (PHD)Document10 pagesValidity and Reliability Issues in Educational Research: Oluwatayo, James Ayodele (PHD)Ikhled H100% (1)

- Academic Entrepreneurship in Spanish Universities An Analysis of The Determinants of Entrepreneurial IntentionDocument10 pagesAcademic Entrepreneurship in Spanish Universities An Analysis of The Determinants of Entrepreneurial IntentionGabriel CramariucNo ratings yet

- 11G Group 5 Research - Docx PR2 RESEACHDocument40 pages11G Group 5 Research - Docx PR2 RESEACHdaisyreyNo ratings yet

- Glossary For English DebateDocument4 pagesGlossary For English Debatehayati2010100% (2)

- The Predictive Index Organization Survey ChecklistDocument2 pagesThe Predictive Index Organization Survey ChecklistViktorMarkuletsNo ratings yet

- Data Analysis: Part A: Descriptive Statistics Demographic QuestionDocument7 pagesData Analysis: Part A: Descriptive Statistics Demographic QuestionShiLpa SinghNo ratings yet

- Management Engineering/ Process Improvement (ME/PI) : "Provide Value"Document30 pagesManagement Engineering/ Process Improvement (ME/PI) : "Provide Value"Naeem HussainNo ratings yet

- Week 2: Session 3: Introduction To Health and Safety (1.0)Document18 pagesWeek 2: Session 3: Introduction To Health and Safety (1.0)marymakinNo ratings yet

- Communication Studies SpeechDocument3 pagesCommunication Studies SpeechDerick TidortNo ratings yet

- 1 PB PDFDocument9 pages1 PB PDFgul shehzadNo ratings yet

- Eurobarometer 2010 - Report PDFDocument168 pagesEurobarometer 2010 - Report PDFpedroloxxxNo ratings yet

- Project Management Process Groups and Knowledge Areas MappingDocument1 pageProject Management Process Groups and Knowledge Areas Mappingacole1No ratings yet

- Testing For Measurement Invariance Testing Using AMOS Nov 2020Document67 pagesTesting For Measurement Invariance Testing Using AMOS Nov 2020GeletaNo ratings yet

- Btec HNCD Construction EabDocument16 pagesBtec HNCD Construction EabBarry StrongNo ratings yet

- The Factors of Wearing Improper Uniform of Senior High School StudentsDocument32 pagesThe Factors of Wearing Improper Uniform of Senior High School StudentsHenry Custodio IiNo ratings yet

- AAPOR Guidance on Reporting Precision for Nonprobability SamplesDocument5 pagesAAPOR Guidance on Reporting Precision for Nonprobability SamplesPatricio CamejoNo ratings yet

- 12 01Document9 pages12 01Zahid RaihanNo ratings yet

- Level of ServiceDocument5 pagesLevel of ServiceSoumya MitraNo ratings yet

- Fish Value ChainDocument79 pagesFish Value Chainziyadh4192No ratings yet

- Research Method in EducationDocument40 pagesResearch Method in EducationJonathan RavenNo ratings yet

- Geotechnical Foundation Design For Some of The WorDocument14 pagesGeotechnical Foundation Design For Some of The WorShankar PeriasamyNo ratings yet

![[4]14-2 LOW-RISE FRAME](https://imgv2-2-f.scribdassets.com/img/document/720610305/149x198/8fbed5b105/1712433771?v=1)