Professional Documents

Culture Documents

Fermenter Sensor

Uploaded by

A.M.ACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fermenter Sensor

Uploaded by

A.M.ACopyright:

Available Formats

Usually, the following parameters are monitored and controlled in bioreactors: Temperature Temperature is an important parameter of fermentation, since,

in the cultivation of many microorganisms, the temperature deviation by a couple of degrees can diminish dramatically the growth and biosynthesis productivity. The cultivation temperature is commonly monitored with an accuracy not less than 0.5C. For temperature measurements, stainless steel Pt100 sensors are normally used. The temperature in laboratory bioreactors is controlled by one of the following ways: 1. A heater is located inside the bioreactor vessel, and cooling is ensured by thin-wall pipes located in the upper cover, which are connected with an electromagnetic valve with the cooling water. 2. Heating and cooling proceed in a thermostat, and this thermostatted water, with the help of a pump, circulates through the bioreactor jacket. Variant 1 is less complicated, and it ensures a more economic constructive solution. This variant works very well for small bioreactors with the volume up to about 5 litres. Variant 2 ensures a more even distribution of heat throughout the bioreactor volume, which is essential in microorganisms' cultivation. In the temperature regulation process, the main reason for the regulation inaccuracy are the incorrectly chosen PID parameters. This manifests itself as temperature oscillations. To regulate the temperature precisely, the main obstacle is often the too high minimal portion of the cooling water. In this connection, the valves in the cooling water supply line should be adjusted correspondingly. Another factor for the regulation accuracy is the area and density of the heat transfer surface, since the higher is inertia, the more difficult is to reach a higher accuracy. pH pH control is based on the comparison of the adjusted "set point" and pH real values. For pH measurement, practically only sterilisable electrodes (most often, "Mettler-Toledo" electrodes) are used. The control of pH values is ensured with the help of peristaltic pumps (silicone tubes are commonly used), correspondingly metering out the acid and the alkali. Normally, the "set point" adjustment consists of the lower pHmin and higher pHmax values. If pH is between these values, then no influence occurs. Such an adjustment of the pH "set point" is applied to prevent the overdose of the titration solution. On the other hand, the "narrow" regulation limits of pH are not necessary for the successful course of the cultivation process. It should be mentioned that pH measurements should be accurate ( 0.02 pH units), since the dynamics of pH values' changes provides valuable information on the process kinetics. Source:http://www.bioreactors.net/index.php/en/important-aspects-in-bioreactors/processmonitoring-and-control.html

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Introduction To Logic: Math 1 General MathematicsDocument26 pagesIntroduction To Logic: Math 1 General MathematicsA.M.ANo ratings yet

- Moisturizing Eye Cream: Product Properties: INCI Name, Trade Name Weight % FunctionDocument2 pagesMoisturizing Eye Cream: Product Properties: INCI Name, Trade Name Weight % FunctionA.M.ANo ratings yet

- SunblocklotionDocument2 pagesSunblocklotionA.M.ANo ratings yet

- LotionDocument2 pagesLotionA.M.A100% (1)

- SPF CreamDocument3 pagesSPF CreamA.M.ANo ratings yet

- Anti-Wrinkle Night Lotion: Product Properties: INCI Name, Trade Name Weight % FunctionDocument2 pagesAnti-Wrinkle Night Lotion: Product Properties: INCI Name, Trade Name Weight % FunctionA.M.ANo ratings yet

- Cos0701 For Noveon AntiAcneCream PDFDocument1 pageCos0701 For Noveon AntiAcneCream PDFA.M.ANo ratings yet

- Cos0701 For Cog IntCareGlossDocument1 pageCos0701 For Cog IntCareGlossA.M.ANo ratings yet

- Moisturizing Sun Care Lotion Approx. SPF 16: Model RecipeDocument1 pageMoisturizing Sun Care Lotion Approx. SPF 16: Model RecipeA.M.ANo ratings yet

- Sprayable Hair MilkDocument1 pageSprayable Hair MilkA.M.ANo ratings yet

- Sun SprayDocument2 pagesSun SprayA.M.ANo ratings yet

- SOP of SOPDocument3 pagesSOP of SOPA.M.ANo ratings yet

- Tri C14-15 Alkyl CitrateDocument1 pageTri C14-15 Alkyl CitrateA.M.ANo ratings yet

- Cos0701 For Floratech VariableTintLiquitFoundationwithFlorasomesDocument1 pageCos0701 For Floratech VariableTintLiquitFoundationwithFlorasomesA.M.ANo ratings yet

- ABM - Principles of Marketing CG - 2Document4 pagesABM - Principles of Marketing CG - 2GRascia Ona67% (15)

- Deped Order No. 70 S. 2012Document3 pagesDeped Order No. 70 S. 2012bicchuchuNo ratings yet

- HUMSS - Introduction To World Religions & Belief Systems CGDocument12 pagesHUMSS - Introduction To World Religions & Belief Systems CGOwen Radaza Pirante89% (44)

- Cos0701 For SLI DuschschaumAmaranthoel GBDocument2 pagesCos0701 For SLI DuschschaumAmaranthoel GBA.M.ANo ratings yet

- Week 1 Lecture 1Document4 pagesWeek 1 Lecture 1saurabh shuklaNo ratings yet

- How To Create SOPDocument3 pagesHow To Create SOPA.M.A100% (1)

- Cleaning Agents and DisinfectantsDocument2 pagesCleaning Agents and DisinfectantsA.M.ANo ratings yet

- Quality Manual TemplateDocument37 pagesQuality Manual TemplateSteve UNo ratings yet

- First Quarter June 17, 2016 Functions and Their GraphsDocument4 pagesFirst Quarter June 17, 2016 Functions and Their GraphsA.M.ANo ratings yet

- G11.M1.v3.1.3.1w Student File ADocument227 pagesG11.M1.v3.1.3.1w Student File AA.M.ANo ratings yet

- 03 Terminology Used in Iso 9000 FamilyDocument14 pages03 Terminology Used in Iso 9000 FamilyAleni AffsNo ratings yet

- SHS Core - General Math CG PDFDocument5 pagesSHS Core - General Math CG PDFAgui S. T. Pad75% (4)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LIBRO3Document43 pagesLIBRO3Camilo LacoutureNo ratings yet

- Material MatrixDocument2 pagesMaterial MatrixFred HahnNo ratings yet

- (7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFDocument9 pages(7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFMohamed Wayrah100% (1)

- Service Handleiding Hisense LC VloermodelDocument204 pagesService Handleiding Hisense LC VloermodelMichel ZreikNo ratings yet

- Fit Up ReportDocument5 pagesFit Up ReportAkash Singh Tomar100% (1)

- (1 Unread) - Umoosa@YahooDocument1 page(1 Unread) - Umoosa@YahooMuhammad Usman MoosaNo ratings yet

- Drude LorentzFreeElectronTheory PDFDocument137 pagesDrude LorentzFreeElectronTheory PDFKushalNo ratings yet

- Concrete FormsDocument11 pagesConcrete FormsmurdicksNo ratings yet

- REHAU 20UFH InstallationDocument84 pagesREHAU 20UFH InstallationngrigoreNo ratings yet

- Design of Piping SupportsDocument15 pagesDesign of Piping SupportsWaleed EzzatNo ratings yet

- Appendix 7.4 - Culverts Inventory - EPE Final 19 Aug-6Document1 pageAppendix 7.4 - Culverts Inventory - EPE Final 19 Aug-6VISHALNo ratings yet

- ASTM C 593-06 - Standard Specification For Fly Ash and Other Pozzolans For Use With LimeDocument5 pagesASTM C 593-06 - Standard Specification For Fly Ash and Other Pozzolans For Use With Limeluisenriq33100% (1)

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaNo ratings yet

- EK Series PDFDocument8 pagesEK Series PDFImpulsora DemaNo ratings yet

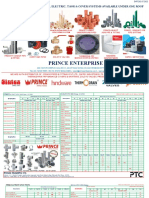

- Prince MRP List 02.07.2022Document17 pagesPrince MRP List 02.07.2022Rachit SharmaNo ratings yet

- Shear WallsDocument33 pagesShear Wallsmagdyamdb100% (1)

- Geopier Tech Paper No1Document15 pagesGeopier Tech Paper No1Maris AlexandruNo ratings yet

- Guest ListDocument6 pagesGuest ListindzarazizyNo ratings yet

- DGX and Seam SealingDocument25 pagesDGX and Seam SealingRahul KrishnetNo ratings yet

- PIPELINE PresentDocument47 pagesPIPELINE Presentromvos8469100% (1)

- Woo Yi - Frequenza Naturale CantileverDocument8 pagesWoo Yi - Frequenza Naturale CantileverOrazio GarofaloNo ratings yet

- Helical Stair - CalculationDocument5 pagesHelical Stair - CalculationSuhail Ahamed0% (1)

- Sample Pn01cs2s01Document6 pagesSample Pn01cs2s01Lynn BishopNo ratings yet

- 1-Heat & Temp - Set 1 - SolnDocument6 pages1-Heat & Temp - Set 1 - SolnBibhash SinghNo ratings yet

- ME8391-Engineering Thermodynamics PDFDocument20 pagesME8391-Engineering Thermodynamics PDFbharathNo ratings yet

- Example Calculations: Example Problems For Concentrated LoadsDocument3 pagesExample Calculations: Example Problems For Concentrated LoadsSagheer AhmedNo ratings yet

- Shree Chintamani Developers, Kadakpada (R4)Document4 pagesShree Chintamani Developers, Kadakpada (R4)Jai GaneshNo ratings yet

- Cable Wire Catalogue PDFDocument47 pagesCable Wire Catalogue PDFyoupick10No ratings yet

- Pow 17J00072Document47 pagesPow 17J00072Joseph MontalesNo ratings yet

- Daso Cooling LoadDocument31 pagesDaso Cooling LoadObakoma JosiahNo ratings yet