Professional Documents

Culture Documents

14-FSE-017-0 Rev 2.0 G8 PM Procedure

Uploaded by

Rogger RuffiniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14-FSE-017-0 Rev 2.0 G8 PM Procedure

Uploaded by

Rogger RuffiniCopyright:

Available Formats

TOSOH BIOSCIENCE, INC.

G8 PM Maintenance 14-FSE-017

Revision 1.0 Page: 1 of 6 CONTROLLED DOCUMENT NOTE: Before using this document, verify that your are using the latest revision

Revision 1.0 2.0 Release Date 12/01/2008 02/20/2012 Origin Jim Van Etten Reggie Vallotton Reason for Change(s) Initial Release Add requirement that repairs must not be part of PM process.

Change Order N/A TCO-12-016

Reviewed/Approved by:

Jim Van Etten National Service Manager Reggie Vallotton Director of Operations

Confidential For Internal Use Only

TOSOH BIOSCIENCE, INC.

G8 PM Maintenance 14-FSE-017

Revision 1.0 Page: 2 of 6 CONTROLLED DOCUMENT NOTE: Before using this document, verify that your are using the latest revision 1.0 PURPOSE To establish a procedure for performing Periodic Maintenance service on the HLC-723G8 (G8) GLYCOHEMOGLOBIN ANALYZER in accordance with Tosoh Bioscience, Inc. standards and guidelines. SCOPE This procedure is applicable for all devices manufactured or marketed by Tosoh Bioscience, Inc. This procedure applies to all employees or contracted agents involved in the refurbishment of analyzers. ASSOCIATED DOCUMENTS 14- FSE-017-1 G8 PM Check List DEFINITIONS SALESLOGIX Database containing customer activity data. Responsibilities It is the responsibility of the National Service Manager to implement this procedure. PROCEDURE NOTE: ANY part that requires replacement other than those parts identified in the G8PM kit MUST be documented on a separate TICKET with a Service Report activity type of INTERVENTION. The repair ticket must describe the reason the part(s) were replaced and that the parts replaced were failed parts and not replaced as precautionary. 6.1 Parts Required: 6.1.1 6.2 6.3 6.4 6.5 6.6 Part number = G8PM, Description: G8 PM Kit

2.0

3.0

4.0

5.0

6.0

Use FORM 14-FSE-017-1 to document the PM maintenance and testing. Verify and discuss service and repair history with customer. Review recent chromatograms for any problems. Review the condition of the analyzer. Verify system pressure below 9 Mpa

Confidential For Internal Use Only

TOSOH BIOSCIENCE, INC.

G8 PM Maintenance 14-FSE-017

Revision 1.0 Page: 3 of 6 CONTROLLED DOCUMENT NOTE: Before using this document, verify that your are using the latest revision 6.7 6.8 6.9 Review error log, section 4.10 Print out Parameter list for reference. Review all Technical Bulletins and inspect analyzer to determine if any upgrades or Technical bulletins need to be applied before PM is attempted. Sample Loader 6.10.1 Remove sample loader reverse of procedure on page 2-13 (Service Manual) 6.10.2 Remove covers. 6.10.3 Inspect x1,x2,y2,y3 belts for tension/wear 6.10.4 Clean dust/debris/corrosion/spillage. Lubricate x1, x2 bearing with Triflow. 6.10.5 Reassemble/reattach to main analyzer 6.10.6 Verify X,Y alignments @ stat and sample positions 6.10.7 Verify bar-code alignment using specimen tube with bar-code label. 6.10.8 Clean drive belts w/DH2O. If it is a 290 loader, clean the Nitflow tape that runs along the inside of the X1 loading area.

6.10

6.11

Syringe Assembly 6.11.1 Remove top cover of main unit and both syringes from mounting bracket per section 6.9.2. 6.11.2 Replace both syringe tips (019515, 018718) see sec. 6.8.1&2 (Service Manual). 6.11.3 Rinse syringe glass barrels to remove any debris from syringes with DI water. 6.11.4 Clean threaded shafts/guide rails/bearing with Triflow. 6.11.5 Inspect coupling set screws.

Confidential For Internal Use Only

TOSOH BIOSCIENCE, INC.

G8 PM Maintenance 14-FSE-017

Revision 1.0 Page: 4 of 6 CONTROLLED DOCUMENT NOTE: Before using this document, verify that your are using the latest revision 6.11.6 Re-assemble and remove any air bubble from small syringe.

6.12

Injection/Rotary Valves/Drain Valve 6.12.1 Remove 2 screws to open access door to valves. 6.12.2 Replace injection valve rotor seal (005952) per sec. 6.6.1 (Service Manual).

6.12.3 Replace the stator face (016915). 6.12.4 Tighten the two actuator arm set screws and check backlash. 6.12.5 Replace rotary valve rotor seal (019495) per sec.6.5.1 (Service Manual). 6.12.6 Tighten the coupling set screws 6.12.7 Replace the Sample Loop (021601).

6.13

Sampler Mechanism 6.13.1 Replace sample needle o-rings (220020) per sec. 6.4.2 (Service Manual) 6.13.2 Clean sample needle venting grooves. Build up on groove prevents proper venting operation. 6.13.3 Clean sampler Z axis drive screw & guide rail with Triflow. 6.13.4 Clean/lubricate Y axis guide rails with Triflow. 6.13.5 Clean dilution block surfaces w/DI water. 6.13.6 Re-install sample needle with needle opening facing toward the front for more consistent sample mixing and total areas.

6.14

Pump Assembly

Confidential For Internal Use Only

TOSOH BIOSCIENCE, INC.

G8 PM Maintenance 14-FSE-017

Revision 1.0 Page: 5 of 6 CONTROLLED DOCUMENT NOTE: Before using this document, verify that your are using the latest revision 6.14.1 Inspect pump plunger for damage (18502) replace as needed. 6.14.2 Replace pump plunger seal (18517) per sec.6.8.1(Service Manual) 6.14.3 Replace PTFE seal (019056) per sec 6.8.1 6.15 Degasser System 6.15.1 Inspect Vacuum tubing (021652) replace as needed. 6.15.2 Verify pump operation, should reach Vac. within 20 sec., See pg. 6-53 (Service Manual).

6.16

Buffer Supply 6.16.1 Replace intake ceramic filters (018723) and connector tubing (017125). 6.16.2 Inspect cap, stopper, spacer and o-rings (018806-O ring), 019881(Stopper w/oring), 019875(Spacer, buffer cap), 220163(Cap, Buffer bag) -replace as needed. 6.16.3 Replace pre-filter (021600) sec. 5.7 (Operator Manual) 6.16.4 Reset filter count.

6.17

Detector and Column Oven 6.17.1 Enter MAINTED password and turn on recorder. 6.17.2 Pump buffer #1 for 3 minutes. 6.17.3 Verify baseline noise is 0.1mV per sec. 5.3.3 of the Service Manual. 6.17.4 Record the percentage and millivolt reading from the MAINTE screen. 6.17.5 Verify Column Oven temperature is between 24.9C and 25.1C.

6.18

Other Areas

Confidential For Internal Use Only

TOSOH BIOSCIENCE, INC.

G8 PM Maintenance 14-FSE-017

Revision 1.0 Page: 6 of 6 CONTROLLED DOCUMENT NOTE: Before using this document, verify that your are using the latest revision 6.18.1 Verify Smart Media operation by inserting card and reading files. 6.18.2 Verify RS232 communication if connected to LIS.

6.18.3 Verify drain lines are draining correctly-Flush as needed. 6.18.4 Clean dust, debris, corrosion, and spillage from inside of main unit. 6.18.5 Reset test count and record life count on checklist.

6.19

Start-up Verification 6.19.1 Power-up and abort warm-up to STBY (stop key 4 times) 6.19.2 Perform prime buffers and DRAIN FLUSH. 6.19.3 Perform pump flow of buffer 1, verify system pressure 6.19.4 Power off/on, allow normal warm-up. 6.19.5 Analyze several patient samples and verify good chromatography. 6.19.6 Make adjustments to Flow parameter as necessary for proper Retention Time for current lot in use. 6.19.7 Perform analyzer calibration per operator manual. 6.19.8 Analyze Level 1&2 control material. If out of range recalibrate and re-run control material. 6.19.9 Analyze 1 normal patient sample X 10 and Calculate precision. CV should be 1% or less.

7.0

RECORDS Records will be maintained for the life of the product plus 5 years.

Confidential For Internal Use Only

You might also like

- Medical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesFrom EverandMedical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesNo ratings yet

- 1.1 Outline: HLC-723G8 Service ManualDocument8 pages1.1 Outline: HLC-723G8 Service ManualSalem Mohamad HananiNo ratings yet

- 10-Maintenance of GeneXpertDocument18 pages10-Maintenance of GeneXpertSahil ChagtiNo ratings yet

- 05 - SM-Chap4-1 - 060517Document75 pages05 - SM-Chap4-1 - 060517Salem Mohamad HananiNo ratings yet

- G8 Variant EN Rev 09072013 01Document9 pagesG8 Variant EN Rev 09072013 01Nia AmbarwatiNo ratings yet

- NIKON SMZ445 460 MicroscopeDocument2 pagesNIKON SMZ445 460 MicroscopeTedosNo ratings yet

- Abbott I-Stat 1 Analyzer - System ManualDocument454 pagesAbbott I-Stat 1 Analyzer - System ManualRastateNo ratings yet

- 10-Maintenance of GeneXpertDocument18 pages10-Maintenance of GeneXpertJ Luis Moreno LopézNo ratings yet

- HumaLyzer Primus User ManualDocument62 pagesHumaLyzer Primus User Manualansarhussain012No ratings yet

- c111 Book PDFDocument1 pagec111 Book PDFMukesh Viswanath Lingamsetty0% (1)

- Manual Completo ACL Elite InglesDocument617 pagesManual Completo ACL Elite InglesLaboratorio Emergencia100% (1)

- Operation ManualDocument50 pagesOperation ManualAhmed TawfikNo ratings yet

- AIA 360 T111 (Final Edition)Document4 pagesAIA 360 T111 (Final Edition)Rogger RuffiniNo ratings yet

- Abl90 Manual OperaçãoDocument59 pagesAbl90 Manual OperaçãoMarlos CarapetoNo ratings yet

- Abbott I-STAT 1 Operator GuideDocument20 pagesAbbott I-STAT 1 Operator Guidemarchie525No ratings yet

- Twelve-Channel ECG: Blood Gas and Chemistry AnalyzerDocument2 pagesTwelve-Channel ECG: Blood Gas and Chemistry AnalyzerWilliam LukeNo ratings yet

- Nikon E200 ManualDocument88 pagesNikon E200 ManualrosyuaNo ratings yet

- Mitsubishi p93dw Digi Monochrome PrinterDocument65 pagesMitsubishi p93dw Digi Monochrome PrinterTony KututoNo ratings yet

- BC-2800 Operation Maunal (1.8)Document283 pagesBC-2800 Operation Maunal (1.8)Tekniah GlobalNo ratings yet

- Service Manual - Selectra Pro S - 6003-500-450-01Document344 pagesService Manual - Selectra Pro S - 6003-500-450-01joseavilaNo ratings yet

- Nikon Eclipse E200 MicroscopeDocument6 pagesNikon Eclipse E200 MicroscopeTedosNo ratings yet

- pocH-100iVDiff EN PDFDocument9 pagespocH-100iVDiff EN PDFJéssica QueirozNo ratings yet

- Roche AVL9120,9130,9140,9180,9181 - Service Manual PDFDocument114 pagesRoche AVL9120,9130,9140,9180,9181 - Service Manual PDFJose Rolando Orellana Rodriguez0% (1)

- EXL Manual Ups SystemDocument68 pagesEXL Manual Ups SystemRemiel Zapata GNo ratings yet

- Bs 800 Chemistry Analyzer PDFDocument1 pageBs 800 Chemistry Analyzer PDFДимонNo ratings yet

- FUS-2000 User Manual 1011491 2017-10Document230 pagesFUS-2000 User Manual 1011491 2017-10Enkhsaikhan GereldambaNo ratings yet

- ADVIA Centaur XPT Volume Check GuideDocument7 pagesADVIA Centaur XPT Volume Check GuideAleksandar MisicNo ratings yet

- UniCel DxI and Access 2 Systems LIS Vendor InformationDocument64 pagesUniCel DxI and Access 2 Systems LIS Vendor Information朱三郎No ratings yet

- Xt1800i-Xt2000i Astm Host InterfaceDocument43 pagesXt1800i-Xt2000i Astm Host InterfaceNguyenTueNo ratings yet

- Operator Manual LIS Configuration GXDocument17 pagesOperator Manual LIS Configuration GXSowji PNo ratings yet

- YSMAN067 Anglais Rév.1 (Hema Star II Service)Document33 pagesYSMAN067 Anglais Rév.1 (Hema Star II Service)Eslam Maher100% (1)

- ABX Pentra 80 - Service Manual PDFDocument333 pagesABX Pentra 80 - Service Manual PDFFrepa_ALNo ratings yet

- CD-Ruby Preventive Maintenance ChecklistDocument6 pagesCD-Ruby Preventive Maintenance ChecklistLuis Felipe Fuentes LNo ratings yet

- 3.8 HDSD NeoChem 100Document117 pages3.8 HDSD NeoChem 100huy Lê xuan Thanh100% (1)

- 110748-GC1 RP500 Quick Reference Guide FINAL 94552391 1Document1 page110748-GC1 RP500 Quick Reference Guide FINAL 94552391 1Neamtu2No ratings yet

- Service Manual I A Me RexDocument31 pagesService Manual I A Me Rexgabo2516100% (2)

- ACL EliteDocument8 pagesACL EliteAnonymous Zy36HK100% (1)

- Service Manual: For Blood Glucose Analysers of The Eco-SeriesDocument31 pagesService Manual: For Blood Glucose Analysers of The Eco-SeriesАлександр БлаговNo ratings yet

- Technical Specifications: A New Era in Cell CountingDocument2 pagesTechnical Specifications: A New Era in Cell CountingDinil KannurNo ratings yet

- 05 BSC Fumigation FinDocument6 pages05 BSC Fumigation FinRaj KumarNo ratings yet

- 5010 Serial MonitorDocument17 pages5010 Serial Monitormohamed abdelzaherNo ratings yet

- GE Cardioserv - User ManualDocument126 pagesGE Cardioserv - User ManualJavier Martinez Zamora100% (1)

- User Manual Urine Analyzer U-AQ - Smart - MANUALDocument28 pagesUser Manual Urine Analyzer U-AQ - Smart - MANUALDouglasRuizNo ratings yet

- DS2 Elisa Processing System: Perts in LysDocument2 pagesDS2 Elisa Processing System: Perts in LysmagdecitaNo ratings yet

- ABX Pentra: Clinical Chemistry SystemDocument6 pagesABX Pentra: Clinical Chemistry SystemThys MoutonNo ratings yet

- Humastar 180 Service ManualDocument102 pagesHumastar 180 Service ManualZeljko TomicNo ratings yet

- Tosoh Bio Science - G8 ChromatogramsDocument1 pageTosoh Bio Science - G8 ChromatogramsimrecoNo ratings yet

- MSLIF08 Quantitative Immunofluorescence AnalyzerDocument2 pagesMSLIF08 Quantitative Immunofluorescence AnalyzerVictoria AnnaNo ratings yet

- ILab 300 PDFDocument42 pagesILab 300 PDFS MNo ratings yet

- PDFDocument526 pagesPDFjairodiaz88No ratings yet

- Acl9000 PDFDocument391 pagesAcl9000 PDFRENE ALEJANDRO ILLESCA NEIRANo ratings yet

- XS-Series PM Standard Procedure (E)Document10 pagesXS-Series PM Standard Procedure (E)Armando VargasNo ratings yet

- SOP05-5002F Service Manual ProlyteDocument41 pagesSOP05-5002F Service Manual ProlyteRogger Ruffini100% (1)

- Milli Q Operator Manual MSB250Document173 pagesMilli Q Operator Manual MSB250gvargasmNo ratings yet

- UrometerDocument29 pagesUrometersiva rajNo ratings yet

- Orphee Mythic 22-CT Hematology Analyzer - User ManualDocument102 pagesOrphee Mythic 22-CT Hematology Analyzer - User ManualAna Laura Ochoa ZepedaNo ratings yet

- DYNEX - DSX Manual de OperadorDocument170 pagesDYNEX - DSX Manual de OperadorEsneiderNo ratings yet

- Service Manual Coulter GEN S PDFDocument1,192 pagesService Manual Coulter GEN S PDFReynaldo MacarioNo ratings yet

- Boeco Autoclave Bte-23D: FeaturesDocument1 pageBoeco Autoclave Bte-23D: FeaturesAdrian Gomez BaldeonNo ratings yet

- Instrument Softwaret Upgrading Instruction V1.1eDocument5 pagesInstrument Softwaret Upgrading Instruction V1.1eRogger RuffiniNo ratings yet

- RT 7300 Analyzer Technical DetailsDocument13 pagesRT 7300 Analyzer Technical DetailsRogger RuffiniNo ratings yet

- 2014 06 18 - Medite M630 - SignOnDocument1 page2014 06 18 - Medite M630 - SignOnRogger RuffiniNo ratings yet

- 12-CSS-030 Rev 8.0 360 Installation ProtocolDocument12 pages12-CSS-030 Rev 8.0 360 Installation ProtocolRogger Ruffini100% (1)

- Aia 360 T123 (E)Document2 pagesAia 360 T123 (E)Rogger RuffiniNo ratings yet

- 12-CSS-030 Rev 8.0 360 Installation ProtocolDocument12 pages12-CSS-030 Rev 8.0 360 Installation ProtocolRogger Ruffini100% (1)

- TUV Certificate XL SeriesDocument1 pageTUV Certificate XL SeriesRogger RuffiniNo ratings yet

- AIA 360 T111 (Final Edition)Document4 pagesAIA 360 T111 (Final Edition)Rogger RuffiniNo ratings yet

- CE Conformity XL18Document1 pageCE Conformity XL18Rogger RuffiniNo ratings yet

- STERILAB Ns en 0810 MMM V1.07 WebDocument31 pagesSTERILAB Ns en 0810 MMM V1.07 WebRogger RuffiniNo ratings yet

- SOP05-5002F Service Manual ProlyteDocument41 pagesSOP05-5002F Service Manual ProlyteRogger Ruffini100% (1)

- Manual de ProlyteDocument82 pagesManual de ProlyteRogger Ruffini83% (6)

- AP1050BDocument2 pagesAP1050BAlex San TanaNo ratings yet

- High Resolution Indoor & Outdoor LED Display Screens - Di ImpexDocument11 pagesHigh Resolution Indoor & Outdoor LED Display Screens - Di Impexsmit4diimpexNo ratings yet

- ECU Pin-Out 90-93 MTDocument1 pageECU Pin-Out 90-93 MTAkis AlmasidisNo ratings yet

- Fluid-Manual Transmission 48-25859 A: ScopeDocument1 pageFluid-Manual Transmission 48-25859 A: ScopeJOSE MIGUELNo ratings yet

- Manual PLC ZelioDocument16 pagesManual PLC ZelioAlexander FelizNo ratings yet

- General Engine Info Aircraft Information Limiting Part InformationDocument1 pageGeneral Engine Info Aircraft Information Limiting Part InformationAHAMEDNo ratings yet

- Uni Lift InstructionsDocument2 pagesUni Lift InstructionsMarcosPauloGrilloNo ratings yet

- Attent PR 3005 TDocument4 pagesAttent PR 3005 TJuan CorreaNo ratings yet

- Microprocessors and Microcontroller System-Prelim Lab Quiz 2-20-20Document6 pagesMicroprocessors and Microcontroller System-Prelim Lab Quiz 2-20-20Dr.DokieNo ratings yet

- Physics Investigatory Project On Joule ThiefDocument5 pagesPhysics Investigatory Project On Joule ThiefathuNo ratings yet

- Boca Semiconductor Corp. BSC: Continental Device India LimitedDocument3 pagesBoca Semiconductor Corp. BSC: Continental Device India LimitedNadia Ayelen GonzalezNo ratings yet

- 04 Maintenance PDFDocument60 pages04 Maintenance PDFFabo BarajasNo ratings yet

- 26148-220-V1B-EVC0-00088 (003) Patio StatcomDocument5 pages26148-220-V1B-EVC0-00088 (003) Patio StatcomDomingo esteban perez ceballoNo ratings yet

- 20ft Steel Pole DatasheetDocument3 pages20ft Steel Pole DatasheetDVTech EngineeringNo ratings yet

- HP Pavilion Dv6000 Dv6500 Dv6600 Dv6700 Dv9000 Dv9500 - DA0AT3MB8F0 - QUANTA AT3 - SC (Intel) - Rev 1ADocument48 pagesHP Pavilion Dv6000 Dv6500 Dv6600 Dv6700 Dv9000 Dv9500 - DA0AT3MB8F0 - QUANTA AT3 - SC (Intel) - Rev 1Agbouret0% (1)

- Sperre HL2 90Document1 pageSperre HL2 90Eslam MamdouhNo ratings yet

- Figure 1. Schematic - Ev-100Zx SCR Control For Traction MotorDocument43 pagesFigure 1. Schematic - Ev-100Zx SCR Control For Traction MotorMario AguirreNo ratings yet

- Swapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTDocument5 pagesSwapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTGogyNo ratings yet

- Technical Specification Simba S7 D Atlas CopcopDocument4 pagesTechnical Specification Simba S7 D Atlas CopcopPedro Espinoza HuahuacondoriNo ratings yet

- Manual D12RDocument179 pagesManual D12RHennis Alfonzo100% (1)

- 1359 5-2004 PDFDocument33 pages1359 5-2004 PDFMark Aspinall - Good Price Cambodia0% (1)

- Iecre We TC 19 0043-R0Document9 pagesIecre We TC 19 0043-R0AvijitSinharoyNo ratings yet

- Contact Resistance Micro-Ohm Meter - Contact Resistance Tester Manufacturer From PuneDocument7 pagesContact Resistance Micro-Ohm Meter - Contact Resistance Tester Manufacturer From PuneAtanu PanNo ratings yet

- HVAC Design SourcebookDocument398 pagesHVAC Design SourcebookMahmoud Gwaily96% (55)

- 03 - Statron Technical Datasheet - Item 3.0-DikonversiDocument16 pages03 - Statron Technical Datasheet - Item 3.0-DikonversiteleangNo ratings yet

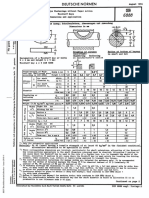

- DIN-6888-Wood Ruff Key Dim and ApplicatioinDocument2 pagesDIN-6888-Wood Ruff Key Dim and ApplicatioinManikandan Veerasekaran100% (3)

- Testing, Design For Testability: Mah, Aen EE271 Lecture 16 1Document28 pagesTesting, Design For Testability: Mah, Aen EE271 Lecture 16 1suyog kalaniNo ratings yet

- Boxster 987.2 2010 01 EN 1Document62 pagesBoxster 987.2 2010 01 EN 1Carlos MovillaNo ratings yet

- Daytona CockpitDocument1 pageDaytona Cockpitxavierr190% (1)