Professional Documents

Culture Documents

Me1302 Dme

Uploaded by

sumikannuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me1302 Dme

Uploaded by

sumikannuCopyright:

Available Formats

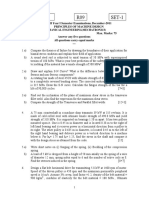

B.E./B.Tech. DEGREE EXAMINATION, NOVEMBERIDECEMBER 2008.

Fifth Semester (Regulation 2004) Mechanical Engineering ME 1302 - DESIGN OF MACHINE ELEMENTS (Common to B.E. (Part-Time) Fourth Semester - Regulation 2005) Time: Three hours Answer ALL questions. Use of approved design data book is permitted. Assumptions and assumed data have to be stated clearly. PART A - (10 x 2 = 20 marks) 1. 2. 3. 4. 5. 6. Mention some standard codes of specification of steels. What are the methods to reduce stress concentration? What is the significance of slenderness ratio in shaft design? Under what circumstances flexible couplings are used. Name the possible modes of failure of riveted joint. What is the minimum size for fillet weld? If the required weld size from strength consideration is too mall how will you fulfill the condition of minimum weld size? 7. Give some of the materials used for springs. Maximum: 100 marks

8. 9. 10.

Why are levers usually tapered? Why a brass sleeve is used in lever fulcrum? What is meant by life of anti-friction bearings? Define coefficient of fluctuation of speed and energy. PART B - (5 x 16 = 80 marks)

11.

(a)

(i)

A flat bar 32 mm wide and 12 mm thick is loaded by a steady tensile load of 85 kN. The material is mild steel with yield point stress of 315 Nzmm-. Find the factor of safety based on the yield point. (8) A flat plate of width 60 mm has a central hole of 10 mm diameter. If the plate is subjected to an axial tensile load of 10 kN, determine the thickness of plate. Assume yield point stress 300 MPa and factor of safety as 2.5. (8) Or

(ii)

(b)

A hot rolled steel shaft of 40 mm diameter is subjected to a torsional moment that varies from 330 Nm to - 110 Nm and an applied bending moment which rises from 440 Nm to - 220 Nm. The material of the shaft has an ultimate strength of 550 MN/m2 and yield strength of 410 MN/m2. Find the approximate factor of safety using Soderberg equation allowing endurance limit to be half the ultimate strength and size factor and surface finish factor to be 0.85 and 0.62 respectively. Design a hollow shaft to transmit 25 hp at 300 rpm. The loading is such that the maximum bending moment is 1000 Nm the maximum torsional moment is 500 Nm and axial thrust is 15 kN. The shaft is supported on rigid bearings 1500 mm apart. The inside diameter of the shaft is 0.8 times the outside diameter. The load is cyclic in nature and applied with shocks. The values of shock factors are Ci = 1.5 and Cm = 1.6. Or

12.

(a)

(b)

Design a protective type of cast iron flange coupling for a steel shaft transmitting 15 kW at 200 rpm and having an allowable shear stress of 40 Nzmm-. The working stress in the bolt should not exceed 30 Nzmm-. Assume that the same material is used for shaft and key that the crushing stress is twice the value of its shear stress. The maximum torque is 25% greater than the full load torque. The shear stress for cast iron is 14 Nzrnm-.

C 3378

13.

(a)

The structural connection shown in fig. 1 is subjected to an eccentric force P of 10 kN with an eccentricity of 500 mm. The centre distance between bolts 1 and 2 is 200 mm and 1 and 3 is 150 mm. All the bolts are identical. Assume t bolts.

= 80

Nzmm-for bolt material. Design the size of the

~1 -.~.-.-

i~ _,,..'_ ..'_.

~CG

Fig. 1 Or (b) A shaft of rectangular cross section is welded to a support by means of fillet welds as shown in fig. 2. Determine the size of the weld, if the permissible shear stress in the weld is limited to 75 Nzrnm-.

..SOO

25kN

~~ ~

._ ......J.._._._

, , ,

,

~ 100

!-(

-~

Fig. 2 . 3 C 3378

14.

(a)

Design a leaf spring for a truck to the following specifications: Maximum load on the spring Number of spring Material Permissible tensile stress Maximum number of leaves Span of spring Permissible deflection

= 140kN

=4

= Chromium vanadium

= 600 Nzrnm= 10 = 1000 mm

steel

= 80 mm

Or

Young's modulus of the spring = 2 x 105 Nzmm''

(b)

A hand lever is 1 m from centre of shaft to the point of application of 200 N calculate (i)

(ii)

Diameter of solid shaft allowable shear stress is 25 NzmmWhat is the twist of shaft per meter length? Determine the section of the lever near the boss, if the permissible stress is limited to 75 Nzrnm''. Distance moved by the point of application of the load due to elasticity of the shaft. Modulus of rigidity is 0.84 x 105 Nzmm". Take length of the shaft is 3 m.

(iii)

(iv)

15.

(a)

A full journal bearing of 50 mm diameter and 10 mm long has a bearing pressure of 1.4 Nzmm-. The speed of the journal is 900 rpm and the ratio of journal diameter to the diametral clearance is 1000. The bearing is lubricated with oil whose absolute viscosity of the operating temperature of 75C may be taken as O.Ollkg/msec. The room temperature is 35C. Find .

(i) (ii)

the amount of artificial cooling required and the mass of lubricating oil required if the difference between the outlet and inlet temperature of oil is 10C. Take specific heat of oil as 1850 J/kg/C. Or

(b)

A single cylinder double acting steam engine delivers 187.5 kW at 100 rpm. The maximum fluctuation of energy per revolution is 15%. The speed variation is limited to 1% either way from the mean. The mean diameter of the rim is 2.4 m. Design a cast iron flywheel for the engine.

C 3378

You might also like

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Design of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsDocument3 pagesDesign of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsHariharanAutoNo ratings yet

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyNo ratings yet

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- Dme Lab Sheets Ii Iii IvDocument4 pagesDme Lab Sheets Ii Iii IvA58Vikas UbovejaNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- 08 r05310305 Design of Machine Members IDocument9 pages08 r05310305 Design of Machine Members IKrupanandareddyYarragudiNo ratings yet

- B.Tech Exam Design of Machine Members QuestionsDocument8 pagesB.Tech Exam Design of Machine Members Questionsprk74No ratings yet

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadNo ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RNo ratings yet

- 34412501-Design of MC ElementDocument8 pages34412501-Design of MC Elementsmg26thmayNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- MDDocument5 pagesMDYogesh DanekarNo ratings yet

- Machine Elements Design QuestionsDocument5 pagesMachine Elements Design QuestionsbalameckNo ratings yet

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- Machine Members Design AssignmentDocument13 pagesMachine Members Design AssignmentHafiz Mahar28No ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajNo ratings yet

- KINGS COLLEGE MECHANICAL ENGINEERING QUESTION BANKDocument11 pagesKINGS COLLEGE MECHANICAL ENGINEERING QUESTION BANKVenkat RajaNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- VMKV Engineering College Question Bank on Machine Design ElementsDocument14 pagesVMKV Engineering College Question Bank on Machine Design ElementsSatwik PriyadarshiNo ratings yet

- Instructions:: No of Pages Course CodeDocument2 pagesInstructions:: No of Pages Course CodeCRAZY PIANO PLAYERNo ratings yet

- TUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignDocument8 pagesTUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignCharles OndiekiNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Macine Element I Worksheet for Final ExamDocument4 pagesMacine Element I Worksheet for Final Examdagimawgchew777No ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 pagesME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rNo ratings yet

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- M.D-I Final Tutorial and AssignmentDocument16 pagesM.D-I Final Tutorial and AssignmentnageshNo ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- Dme Home Assignment 2019-20Document4 pagesDme Home Assignment 2019-20VenkateshNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Register Number NIT Mechanical Design Machine Elements ExamDocument2 pagesRegister Number NIT Mechanical Design Machine Elements ExamdharaniventhanNo ratings yet

- DME Question BankDocument4 pagesDME Question BankILAYAPERUMAL KNo ratings yet

- Design of machine elements exam questions and solutionsDocument3 pagesDesign of machine elements exam questions and solutionsvikaskumar1986No ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- MTP 5Document4 pagesMTP 5tinku singhNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- Machine DesignDocument6 pagesMachine DesignRishi SinghNo ratings yet

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786No ratings yet

- R7310305-Design of Machine Members-I2Document4 pagesR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- Assignment 02Document2 pagesAssignment 02adhnan_rasheed0% (1)

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- 1 - 8th BoG Agenda NotesDocument20 pages1 - 8th BoG Agenda NotessumikannuNo ratings yet

- WWW WWW WWWWDocument1 pageWWW WWW WWWWsumikannuNo ratings yet

- Integrated Product and Process Development Unit I A. IntroductionDocument19 pagesIntegrated Product and Process Development Unit I A. IntroductionsumikannuNo ratings yet

- 7541 1462 5100 1 SyllabusDocument8 pages7541 1462 5100 1 SyllabussumikannuNo ratings yet

- Apt I NumbersDocument2 pagesApt I NumberssumikannuNo ratings yet

- Hints 1Document19 pagesHints 1sumikannuNo ratings yet

- DV03PUB7 Study GuideDocument4 pagesDV03PUB7 Study GuidesumikannuNo ratings yet

- 2013 BE Mechanical Engineering A Section Student Name ListDocument6 pages2013 BE Mechanical Engineering A Section Student Name ListsumikannuNo ratings yet

- 11EC801Document1 page11EC801sumikannuNo ratings yet

- Explain Briefly How The ChipDocument4 pagesExplain Briefly How The ChipsumikannuNo ratings yet

- Dr. Mahalingam College of Engineering and Technology, Pollachi - 642 003Document1 pageDr. Mahalingam College of Engineering and Technology, Pollachi - 642 003sumikannuNo ratings yet

- Lec 28Document13 pagesLec 28sumikannuNo ratings yet

- PT II SyllabusDocument1 pagePT II SyllabussumikannuNo ratings yet

- Agenda: Team Orientation DayDocument3 pagesAgenda: Team Orientation DaysumikannuNo ratings yet

- Dr. Mahalingam College of Engineering and Technology, PollachiDocument1 pageDr. Mahalingam College of Engineering and Technology, PollachisumikannuNo ratings yet

- Ivyeara&b Hostel Stdnts DataDocument2 pagesIvyeara&b Hostel Stdnts DatasumikannuNo ratings yet

- Calendar of Activies For14-15 CTDocument1 pageCalendar of Activies For14-15 CTsumikannuNo ratings yet

- Lease Agreement or Rental Agreement FormatDocument3 pagesLease Agreement or Rental Agreement Formatyuvashreesharmi60% (5)

- DR - Mahalingam College of Engineering & Technology, Pollachi - 3Document12 pagesDR - Mahalingam College of Engineering & Technology, Pollachi - 3sumikannuNo ratings yet

- MTS Prepaid Mobile Top Up, MTS Data Card Recharge With Credit Cards & Net BankingDocument1 pageMTS Prepaid Mobile Top Up, MTS Data Card Recharge With Credit Cards & Net BankingsumikannuNo ratings yet

- BE SW EEE Opting - List 2010 2015Document5 pagesBE SW EEE Opting - List 2010 2015sumikannuNo ratings yet

- Conversion ChartDocument1 pageConversion ChartLibinNo ratings yet

- Non-Conventional Energy SystemsDocument2 pagesNon-Conventional Energy SystemsJAMESJANUSGENIUS5678No ratings yet

- 3306 7730 1 PBDocument6 pages3306 7730 1 PBsumikannuNo ratings yet

- Calendar of Activies For14-15 CTDocument1 pageCalendar of Activies For14-15 CTsumikannuNo ratings yet

- Course 9Document2 pagesCourse 9faster123No ratings yet

- Itc LTD Interview QuestionsDocument2 pagesItc LTD Interview QuestionssumikannuNo ratings yet

- Student Project Block Diagram and OutputDocument3 pagesStudent Project Block Diagram and OutputsumikannuNo ratings yet

- Student block diagram and output reportDocument3 pagesStudent block diagram and output reportsumikannuNo ratings yet

- Maximising Energy Performance and Productivity With Solar ShadingDocument28 pagesMaximising Energy Performance and Productivity With Solar ShadingsumikannuNo ratings yet

- Tugas 1 (Allowable Stress)Document5 pagesTugas 1 (Allowable Stress)WAHYU DWI LESTARINo ratings yet

- Hydrostatic EquilibriumDocument5 pagesHydrostatic EquilibriumhlvijaykumarNo ratings yet

- Fujitsu GeneralDocument51 pagesFujitsu GeneralZubair DarNo ratings yet

- The Concept of Hydroplaning of Commercial Vehicle On Wet RoadDocument3 pagesThe Concept of Hydroplaning of Commercial Vehicle On Wet RoadPrakash ShaktiNo ratings yet

- RB 4000Document24 pagesRB 4000Công PhạmNo ratings yet

- Chapter 1 Shaft (Cont'd)Document47 pagesChapter 1 Shaft (Cont'd)Rayuth KEATNo ratings yet

- ESR ST - DesignDocument33 pagesESR ST - DesignTarkeshwar Lal SrivastavaNo ratings yet

- aNALYSIS OF Partially Composite SIPDocument13 pagesaNALYSIS OF Partially Composite SIPMickey DalbeheraNo ratings yet

- STI0807 ViscoelasticityDocument19 pagesSTI0807 ViscoelasticityDaniel GómezNo ratings yet

- SBS5225 1718 Lab AC ProcessesDocument8 pagesSBS5225 1718 Lab AC ProcessesSam C M HuiNo ratings yet

- The Case Study Is About The Failure of A Phantom Flap Actuator Rod. Basically, AnDocument9 pagesThe Case Study Is About The Failure of A Phantom Flap Actuator Rod. Basically, AnnabilNo ratings yet

- Calculation of % Slip in Mill During Rolling by Ajmal (10.09.2014)Document15 pagesCalculation of % Slip in Mill During Rolling by Ajmal (10.09.2014)Rakesh Karan SinghNo ratings yet

- Thermal Conductivity and Linear ExpansionDocument21 pagesThermal Conductivity and Linear ExpansionVincent ManganaanNo ratings yet

- Strength of Materials: 50 Multiple Choice Questions For SSC JE EXAM-2020Document14 pagesStrength of Materials: 50 Multiple Choice Questions For SSC JE EXAM-2020Yogendra Kumar100% (2)

- Design of HvacDocument12 pagesDesign of HvacZankar R ParikhNo ratings yet

- Coil Selection FormatDocument3 pagesCoil Selection FormatFarzanaShaikNo ratings yet

- Fluid Mechanics Theory and DesignDocument158 pagesFluid Mechanics Theory and DesignWONG TSNo ratings yet

- Unit Ii&iiiDocument46 pagesUnit Ii&iiiGowthamNo ratings yet

- Galerkin MethodDocument12 pagesGalerkin Methodahmed namaNo ratings yet

- DIRECT SHEAR TEST TITLEDocument19 pagesDIRECT SHEAR TEST TITLESaid-Mansour MohamedNo ratings yet

- Fluid: Static DynamicDocument5 pagesFluid: Static DynamicAn MohdNo ratings yet

- Solution Manual Analysis and Design of Machine Elements by Wei JiangDocument4 pagesSolution Manual Analysis and Design of Machine Elements by Wei Jiangindustriale82No ratings yet

- Energy Loss in PipesDocument8 pagesEnergy Loss in Pipeskelechi2475% (8)

- Write The Equations For Shear and Moment Between Points D and E. Select The Origin at DDocument21 pagesWrite The Equations For Shear and Moment Between Points D and E. Select The Origin at DThomas BautistaNo ratings yet

- Lecture05e Anharmonic Effects 2Document13 pagesLecture05e Anharmonic Effects 2Shehzad AhmedNo ratings yet

- Dynamic, Absolute and Kinematic ViscosityDocument4 pagesDynamic, Absolute and Kinematic ViscosityzahoorNo ratings yet

- Geko Ansys CFD PDFDocument38 pagesGeko Ansys CFD PDFJulio Andrés Casal RamosNo ratings yet

- Science Le - Thirdquarter - HeattransferDocument4 pagesScience Le - Thirdquarter - HeattransferFatima Abacan Reyes100% (3)

- MEC4408 - (12-2pm) - Practical Test 7 - Week 9Document3 pagesMEC4408 - (12-2pm) - Practical Test 7 - Week 9soumyaNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (115)

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)