Professional Documents

Culture Documents

Dispersed Systems Consist of Two Phase

Uploaded by

Meera PatelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dispersed Systems Consist of Two Phase

Uploaded by

Meera PatelCopyright:

Available Formats

Pharmaceutical Process Design I: Synthesis, Separations and Sterile Processing Project PHARMACEUTICAL DOSAGE FORM- SUSPENSIONS PATEL MEERA

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

Table of Contents 1. Introduction 2. Reasons for the Pharmaceutical Suspensions 3. Classification of the Pharmaceutical Suspensions 4. Features of an Ideal Suspension 5. Important factors to be considered in formulation of the Suspensions 6. Aerosols 7. Advantages of the aerosols 8. Pharmaceutical Aerosols 9. Meter-dosed Inhaler (MDI) 10.Proper administration and usage of the aerosol 11. Summary 12.References

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

INTRODUCTION Dispersed systems consist of two phase: the substance that is dispersed known as the dispersed (or) internal phase and a continuous (or) external phase. Based on the particle size of the dispersed phase, dispersion are generally classifies as molecular dispersion, colloidal dispersion and coarse dispersion. Suspensions are the class of dispersed system in which a finely divided solid is dispersed uniformly in a liquid dispersion medium. When one or more type of solid particles that constitute the internal phase are pharmaceutically useful and there therapeutically active the suspensions is known as pharmaceutical suspensions (Herbert A. Lieberman, 1996).

REASONS FOR SUSPENSIONS

There are several reasons for preparing suspensions ((Loyd V. Allen Jr., 2010) & (Alok K. Kulshreshtha, 2009)): Certain drugs are chemically unstable in solution but stable when suspended. In this instance, the suspension ensures chemical stability while permitting liquid therapy. For many patients, the liquid form is preferred to the solid form of the same drug because of the ease of swallowing liquids and the flexibility in administration of a range of doses. This is particularly advantageous for infants, children, and the elderly. To overcome the instability of certain drug in aqueous solution: o Insoluble derivative formulated as suspension An example is ox tetracycline HCL calcium salt (Instable) (Stable) o Reduce the contact time between solid drug particles and dispersion media increase the stability of drug like Ampicillin by making it as reconstituted powder. o A drug that degraded in the presence of water suspended in non-aqueous vehicles. Examples are phenoxymethypencillin/ coconut oil and tetracycline HCL/ oil The disadvantage of a disagreeable taste of certain drugs in solution form is overcome when the drug is administered as undissolved particles of an oral suspension. In fact, chemical forms of certain poor-tasting drugs have been specifically developed for their insolubility in a desired vehicle for the sole purpose of preparing a palatable liquid dosage form. For example, erythromycin estolate is a less water-soluble ester form of erythromycin and is used to prepare a palatable liquid dosage form of erythromycin, the result being Erythromycin Estolate Oral Suspension, USP. Use of insoluble forms of drugs in suspensions greatly reduces the difficult taste-masking problems of developmental pharmacists, and selection of the flavorants to be used in a given suspension may be based on taste preference rather than on a particular flavorants ability to mask an unpleasant taste. For the most part, oral suspensions are aqueous preparations with the vehicle flavored and sweetened to suit the anticipated taste preferences of the intended patient.

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

CLASSIFICATION OF SUSPENSIONS

Suspensions can be classifies based on the characteristics of the dispersed phase or the dispersion medium (Ram I. Mahato, 2007) Based on the particle size of the dispersed phase: Coarse Suspensions: Suspensions with the particle size greater than 1m. Colloidal Suspension: Suspensions with the particle size below 1m Nano Suspensions: Suspensions with the particle size 10-100 nm

Based on concentration of the dispersed phase:

Dilute suspension (2 to10%w/v solid) Concentrated suspension ( > 50%w/v solid): Highly concentrated suspensions are termed as slurries

Based on the routes of administration: Suspensions as drug dosage forms can be prepared for oral, topical, ophthalmic, otic, and nasal route of administration. These are briefly described as follows (Leon Lachman, 1986): Oral Suspensions: Suspensions meant for peroral route of administrations (in which the drug is swallowed and enters the systemic circulation primarily through the membranes of the small intestine) are usually liquid preparations in which solid particles of the active drugs are dispersed in a sweetened, flavored and usually. For example, amoxicillin oral suspension contains 125-500 mg/5ml of suspension.

Topical suspensions: Lotions are externally applied suspensions. These

Source: http://www.drugs.com/pro/amoxicillin.html

are designed for dermatologic, cosmetic, and protective purposes. For example topical suspension Calamine lotion USP, contains 118ml of suspension.

Source : http://newbuy.ca/antiseptic-ointments/95-swan-calamine-topical-suspension-usp-118ml.html

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

Injected Suspensions: Parental suspensions may contain from 0.5% to 30% of solid particles. Viscosity and particle size are significant factors because they affect the ease of injection and the availability of the drug in the therapy. Most parenteral suspensions are designed for intramuscular or subcutaneous administration. For example, procaine penicillin G suspension is intended for the intramuscular administration.

Source: http://dailymed.nlm.nih.gov/dailymed/archives/fdaDrugInfo.cfm?archiveid=15447

Rectal suspensions: These are exemplified by the anti-inflammatory 5-acetyl salicylic acid (5ASA) rectal suspension enema for ulcerative colitis.

Source : http://www.drugs.com/pro/mesalamine-rectal-suspension.html

Liposomes and micro-/nano-particles: Suspensions of liposomes, microspheres, microcapsules, nanospheres and nanocapsules are formed from a variety of polymers or proteins. These suspensions formulations are used for targeted and controlled delivery of drugs.

Several drug delivery systems using liposomes such as Doxil and Daunome are in market.

Source : http://dailymed.nlm.nih.gov/dailymed/archives/fdaDrugInfo.cfm?archiveid=53683

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

Otic Suspensions: These ate intended for administration into ear. Most otic suspensions are antibiotics for the treatment of ear infections and may also be corticosteroids for minimizing inflammation and analgesics for pain relief. and hydrocortisone for antibiotic and anti-inflammatory effect Based on the type of the dispersed system Aqueous suspensions Nonaqueous suspensions: Although most pharmaceutical suspensions have primarily aqueous

continuous phase, formulation of a drug in a nonaqueous continuous phase, is occasionally required. Suspensions of a water-soluble drug in a nonaqueous vehicle may provide a means to prepare a liquid formulation of a drug that has poor long-term stability in aqueous solution. Aerosols represent important class of nonaqueous suspensions. The physical stability of suspended drugs in non-aqueous propellants for aerosols products can have a significant impact on the uniformity of dose and operation of the aerosol system.

FEAUTRES OF AN IDEAL SUSPENSION In contrast to the formulations of the liquid dosage form such as solutions and solid dosage forms such as tablets and capsules, the development and preparation of the suspensions dosage form involves a great challenge. Pharmaceutical formulations are thermodynamically unstable. Formulation of such suspension is difficult because often these systems faces the problems of physical stability, content uniformity, sedimentation, caking, redispersion and crystal growth. Moreover, in formulating the pharmaceutical suspension factors such as palatable for improving the taste and undesirable odor of the drug is also taken into consideration. Following are some desired attributes of a perfect and elegant pharmaceutical suspension (Alok K. Kulshreshtha, 2009)& (Ram I. Mahato, 2007): 1. For a given batch of the suspension the content of drug should remain uniform from one package to another. 2. For every dose released from the container, the quantity of drug dispensed should remain consistent. 3. Physical attributes such as particle size, PSD, viscosity should remain nearly uniform throughout the shell life of the product. 4. Suspended material should settle slowly and should readily dispersed upon gentle shaking of the container such as it uniformity is maintained with each dose. 5. Particles having lower settling velocity tends to form a hard cake. In an ideal suspension, these should never happen, but those particles should be readily redispersed upon the shaking. 6. Suspension viscosity should be such that, it should pour freely form the bottle or to flow through a needle syringe (for injectable suspension) or spreads freely on the affected area (for topical suspension). 7. There should be no microbial growth. 8. The suspension should not show any unexpected change in color or any other change in physical appearance or odor. 9. The suspension should be chemically stable, it should not degrade during the shell life and storage.

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

10. The drug must not recrystallize and/or change its polymorphic form during the storage of the formulation. These main features of a suspension, which depend on the nature of the dispersed phase, the dispersion medium, sedimentations rate, viscosity and various others factors. And all the factors that are to be given a due consideration in order to attain the desired features are described briefly next.

IMPORTANT FACTORS TO BE CONSIDERED IN FORMULATION OF THE SUSPENSION There are many considerations in the development and preparation of a pharmaceutically elegant suspension. (Loyd V. Allen Jr., 2010). Selection of the API and excipients for the formulation of the suspension should be selected carefully depending on the route of administration, end application, and possible adverse effects. The following are the most important factors to be considered during the formulation of pharmaceutical suspensions (Alok K. Kulshreshtha, 2009): 1. Nature of suspended material: Among all the properties of the suspended material, the important consideration should be given to the interfacial properties during the formulations of a suspension. Material having low interfacial tension exhibits good wetting property and readily gets suspended. In contrast, the materials possessing high interfacial tensions are not easily wetted. For such materials, suspensions is aided by using surfactants. Surfactants increase wettability of the particles by reducing their surface tension. The main function of wetting agents: (1) to reduce the contact angle between surface of solid particles and wetting liquid via displace the air in the voids (2) surfactant. Excessive amounts of wetting agents can cause foaming or undesirable taste or odor. 2. Size of suspended particles: Particle size of any suspension is critical and must be reduced within the range as determined during the preformulation study. Too large or too small particles should be avoided. Larger particles will settle faster at the bottom of the container and too fine particles will easily form hard cake at the bottom of the container. The particle size can be reduced by using mortar and pastel but in large-scale preparation different milling and pulverization equipments are used. Limitation in particle size reduction (after reaching a certain particle size): Expensive and time consuming Movement of small particles due to Brownian motion cause particles to aggregate, settle, form hard cake that it is difficult to redispersed

3. Viscosity: For the suspension to be highly viscous, it is necessary that it possess the property of shear thinning. The advantage of high viscous dispersion medium is that it has lower sedimentation rate. The viscosity of the media also affects the velocity of sedimentation. It decreases as the viscosity of the vehicle increases. The viscosity and

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

density of any vehicle are related to each other, so any attempt to change one of these parameters will also change the other one.

AEROSOLS Pharmaceutical aerosols are pressurized dosage forms that upon actuation emit a fine dispersion of liquid and/or solid materials containing one or more active ingredients in a gaseous medium (ansel). Aerosols consists of the gas that may be condensed or liquefied and it has ability to bring out the API and other ingredients out of the compartment. Pharmaceutical aerosols are like other dose structures since they require the same sorts of contemplations regarding definition, item solidness, and helpful viability. On the other hand, they vary from most other dosage form in their reliance upon the capacity of the compartment, its valve assembly, including the propellant- for the physical release of the medicine in suitable form. (ansel). The presence of propellant generates the pressure inside the package. Upon the actuation of the valve, this pressure forces the ingredients in the package to expel out through the opening in the valve (Loyd V. Allen Jr., 2010). An aerosol formulation essentially consists of two components: 1. Product concentrate 2. Propellant. Aerosols generally contain an active drug in a liquid gas propellant, in a mixture of solvents with a propellant, or in a mixture with other additives and a propellant. The concentrate can be a solution, suspension, emulsion, semisolid, or powder. The force that is required to eject the product concentrate from the compartment is imparted by the propellant. Moreover, propellant is also responsible for the delivery of the formulation in the proper form (i.e., spray, foam, semisolid). The gas propellants can be formulated to provide desired vapor pressures for enhancing the delivery of the medication through the valve and actuator in accordance with the purpose of the medication. When the propellant is a liquefied gas or a mixture of liquefied gases, it can also serve as the solvent or vehicle for the product concentrate (Leon Lachman, 1986).

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

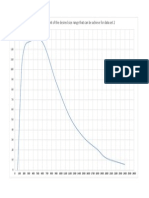

Figure: Components and Operation of Aerosol System (Loyd V. Allen Jr., 2010)

Aerosols are used as space sprays, surface sprays, aerated foams, and for oral inhalation. Aerosols used to provide an airborne mist are termed space sprays. Room disinfectants room deodorizers, and space insecticides characterize this group of aerosols. The particle size of the released product is generally quite small, usually below 50 m, and must be carefully controlled so that the dispersed droplets or particles remain airborne for a long time. Aerosols intended to carry the active drug to a surface are called surface sprays or surface coating sprays. A great many cosmetic and household aerosol products, including personal deodorant sprays, hair lacquers and Figure: Pharmaceutical Aerosol ( (Loyd V. Allen Jr., 2010) sprays, perfumes and colognes, shaving lathers, toothpaste, surface pesticide sprays, paint sprays, spray starch, waxes, polishes, cleaners, and lubricants (Loyd V. Allen Jr., 2010).

ADVANTAGES OF THE AEROSOL DOSAGE FORM

Some features of pharmaceutical aerosols that may be considered advantages over other types of dosage forms are as follows (Loyd V. Allen Jr., 2010):

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

1. Aerosols are easy to use. Medication is dispensed at the push of a button. No ancillary equipment is needed. 2. Aerosol application is a clean process which requires minimal patient "clean up" after using the product. 3. A portion of medication may be easily withdrawn without contaminating the remaining material. If the product is sterile, sterility can be maintained throughout the product's shelf life. 4. The active drug is protected from oxygen and moisture. The usual aerosol container is opaque which also protects the drug from light. 5. By proper formulation and valve control, the physical form and the particle size of the emitted product may be controlled. 6. If the dosage must be regulated, a metered dose valve can be used which will control the accuracy of the administered dose. 7. Aerosol application is a clean process, requiring little or no washup by the user.

PHARMACEUTICAL AEROSOL APPLICATIONS Pharmaceutical aerosols have been playing a crucial role in the health and wellbeing of millions of people throughout the world for many years. These devices includes: metered-dose inhalers (MDIs) dry powder inhalers (DPIs) nebulizers These devices deliver a specific quantity of drug to the lungs. For the inhalation aerosols, the particle size distribution and shape of the delivered dose is more critical than for most other conventional drug products because these factors greatly influence the deposition profile in the lungs of the patient. The optimum aerodynamic particle size distribution for most inhalation aerosols has generally been recognized as being in the range of 1-5 m (Loyd V. Allen Jr., 2010).

METERED DOSE INHALERS (MDI)

In the case of the inhalation therapy where the formulation plays a strong role, metering valves are proven to be a very useful tool. The quantity of the material to be expelled out of these metered valve systems, is controlled by an auxiliary valve chamber. The MDI device is made of a canister, and actuator, and sometimes a spacer. The canister consists of a metering dose valve with an actuating stem. The canister contains formulation and is made up of the drug, a liquefied gas propellant, and often stabilizing excipients. Actuation of the device results into evacuation of this chamber and discharges a single metered dose of liquid propellant that contains the medication. The volatile propellant breaks up into droplets which then evaporate,

Figure: Working of the Metered Dose Inhaler (http://www.horiba.com/scientific/products/particlecharacterization/applications/pharmaceutical-aerosols/)

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

creating an aerosol containing micronized drug that is inhaled into the lungs. The canister is impenetrable to the ambient conditions when the actuator valve is close and under this position the canister is packed with the formulation. The entire system is reinstated for the next dose upon the release of the actuator. The quantity of the drug released upon the actuation is measured by tests framed by the United States Pharmacopeia. The potential in delivering the medication, its local and systemic effects lies on the particle size of the inhaled drug (Ansel & link). Breathing patterns and the depth of respiration also play important roles in the deposition of inhaled aerosols to the lungs. Analysis of dose uniformity, particle size distribution patterns and the respirable fractions of Aerosol-delivered particles are areas of research in developing aerosol products for optimal oral inhalation therapy (Loyd V. Allen Jr., 2010).

EXAMPLES OF INHALATION AEROSOLS (Loyd V. Allen Jr., 2010):

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

PROPER ADMINISTRATION AND USE OF THE PHARMACEUTICAL AEROSOLS

As presented in Table a number of drug substances are administered through pressurepackaged inhalation aerosols like the type shown in Figure. For the inhaled drug substance or solution to reach the bronchial tree, the inhaled particles must be just few micron in size. (Loyd V. Allen Jr., 2010) It is the responsibility of the pharmacist to educate the patient about the aerosol dosage forms importantly for the oral and nasal administration, effectiveness of these medications lies in the proper usage. Every product package should be labelled and should contain instructions and it is the duty of the pharmacist to make sure that the patient read those instructions and warnings before they use it. In addition to this, as an assurance that the patients understands the instructions, the pharmacist should verbally convey Figure: foam for anal and perennial use (Loyd V. Allen Jr., those instructions. For better awareness on the 2010) usage of the aerosols, the pharmacist should demonstrate how the inhaler is assembled, stored and cleaned using the oral metered aerosols as a model. The patient should be instructed about shaking prior to use and the manner in which the inhaler should be hold between index finger and thumb. And this is to make sure that when the patient uses, the aerosol canister is upside down. As noted previously, the effectiveness of these dosage forms lies in the proper usage, it is important that the patient understands that there must be synchronization of the inhalation and pressing down the inhaler to release single dose. To achieve the therapeutic effect, the patient should hold the breath for several seconds or as long as possible and then remove the inhaler from the mouth and exhale slowly (Loyd V. Allen Jr., 2010). SUMMARY This report have covered the topic of the suspensions as dosage forms. Suspension dosage forms have become one of the important class of the pharmaceutical dosage form. The suspensions dosage form has been traditionally used for poorly soluble drugs for various types of the dosage formulations. These dosage form is attracting the interests of the scientist as large proportions of the new drug candidates that are emerging are mainly water insoluble and therefore, exhibits poor bioavailability in the solution dosage forms. The advantages of the suspension dosage include efficient delivery of the hydrophobic drugs; avoidance the using of cosolvents increasing the stability, masking of the unpleasant taste properties of the drug, easy administration for the children and elder person (Alok K. Kulshreshtha, 2009). This report has discussed the various types of the pharmaceutical suspensions based on the size of the particles, based on the concentration & type of the dispersed phase and based on the routes of the administration. Pharmaceutical suspensions are major the oral suspensions. Different forms of the pharmaceutical suspensions viz oral, parenteral, rectal etc. are discussed with their clinical applications. The most important challenge in developing and formulating the pharmaceutical suspension is to preparing an ideal suspension which will maintain the uniform content, remain stable both

PHARMACEUTICAL DOSAGE FORMS: SUSPENSIONS

physically and chemically, and maintain the viscosity during the storage and shell life. Therefore, development of the pharmaceutical suspension is very complex process and it is very important to have better understanding of the properties of the both the dispersed phase and continuous phase. The most important factors to be considered during the formulation have been discussed. In the context and limitation of this report only the three main factors particle size, nature of the media and viscosity have been included. Apart from these factors, there are various other factor such as sedimentation rate, charge stabilization, crystal growth, interactions of the components etc. should be thoroughly understood form the stability of the pharmaceutical suspensions. The last part of the report deals with the aerosols, one of the most important form of the nonaqueous suspensions. Aerosols is gaining importance in the pharma industry as aerosol therapy is local, rapid and intense. The inhaled drug goes directly into lungs. Different aspects of the aerosols have been briefly described and emphasis is given on the Metered dose inhaler (MDI) as it is the most common pharmaceutical aerosols. The most common challenge that the scientist is facing is developing more environmentally friendly and safer inhalers. The most common propellant used in the aerosols in the chlorofluorocarbons (CFC) since these have adverse effect on the ozone layer and also being flammable they threat the patient safety too. So, research is going on in find new and safe propellant. Further, this report can be extended to the nanosuspensions. Nanosuspensions have emerged as a promising strategy for the efficient delivery of hydrophobic drugs because of their versatile features and unique advantages. Rapid advances have been made in the delivery of nanosuspensions by oral, ocular, parenteral and pulmonary routes. Currently efforts are being made directed to extend their applications in site specific drug delivery (Alok K. Kulshreshtha, 2009). REFERENCES 1. Alok K. Kulshreshtha, O. N. (2009). Pharmaceutical Suspensions: From Formulation Development

to Manufacturing. New-York: Springer. 2. Herbert A. Lieberman, M. M. (1996). Pharmaceutical Dosage forms: Disperse Systems Volume 1. New-York: Marcel Dekker,Inc. 3. Leon Lachman, H. A. (1986). The Theory and Practice of Industrial Pharmacy . Lea & Febiger. 4. Loyd V. Allen Jr., N. G. (2010). Ansel's Pharmaceutical Dosage Forms and Drug Delivery Systems. Lippincott Williams & Wilkins. 5. Ram I. Mahato, A. S. (2007). Pharmaceutical Dosage Forms and Drug Delivery. CRC Press.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 3 Extraction, Mass Transfer OperationDocument9 pages3 Extraction, Mass Transfer OperationMeera PatelNo ratings yet

- Single Use Bioprocessing HomeworkDocument1 pageSingle Use Bioprocessing HomeworkMeera PatelNo ratings yet

- Mannose TargetedDocument37 pagesMannose TargetedMeera PatelNo ratings yet

- Paper and Board Identification of Machine and Cross Direction p2009-93Document2 pagesPaper and Board Identification of Machine and Cross Direction p2009-93Meera PatelNo ratings yet

- Comparison of The Drying Processes and EquipmentDocument2 pagesComparison of The Drying Processes and EquipmentMeera PatelNo ratings yet

- As A PolicymakerDocument1 pageAs A PolicymakerMeera PatelNo ratings yet

- A Method of Choice For Processing of Physically or Chemically Moisture Sensitive DrugsDocument1 pageA Method of Choice For Processing of Physically or Chemically Moisture Sensitive DrugsMeera PatelNo ratings yet

- Cromwell 2006Document8 pagesCromwell 2006Meera PatelNo ratings yet

- The Production of Recombinant Pharmaceutical Proteins in PlantsDocument12 pagesThe Production of Recombinant Pharmaceutical Proteins in Plantsapi-26789760No ratings yet

- Milling in The Particle TechnologyDocument1 pageMilling in The Particle TechnologyMeera PatelNo ratings yet

- Doc1-Calculation of Different DensitiesDocument1 pageDoc1-Calculation of Different DensitiesMeera PatelNo ratings yet

- Entropy 2Document10 pagesEntropy 2Meera PatelNo ratings yet

- Example-Water Flow in A PipeDocument13 pagesExample-Water Flow in A PipecristinelbNo ratings yet

- Basic Concepts of Thermo Part 1Document38 pagesBasic Concepts of Thermo Part 1Wahid AliNo ratings yet

- OrgánicaDocument11 pagesOrgánicaLuiXs GRNo ratings yet

- Introduction To Transport Phenomena From Microscopic Equations of Change To Macroscopic Design (180 Pages)Document168 pagesIntroduction To Transport Phenomena From Microscopic Equations of Change To Macroscopic Design (180 Pages)G_nd_z_G_zel_4582No ratings yet

- Pharmaceutical Emulsions and SuspensionsDocument55 pagesPharmaceutical Emulsions and SuspensionsdrugdrugNo ratings yet

- Op050109x PDF SonocrystallizationDocument10 pagesOp050109x PDF SonocrystallizationMeera PatelNo ratings yet

- OrgánicaDocument11 pagesOrgánicaLuiXs GRNo ratings yet

- Friction FactorDocument30 pagesFriction FactorSomnath JagtapNo ratings yet

- Solutions To The Advanced Transport PhenomenaDocument6 pagesSolutions To The Advanced Transport PhenomenaMeera PatelNo ratings yet

- Gennis 1 Biophyschem - PDF MechnaicsDocument68 pagesGennis 1 Biophyschem - PDF MechnaicsMeera PatelNo ratings yet

- Chapter 04 Pharmacy PracticeDocument111 pagesChapter 04 Pharmacy PracticeMeera PatelNo ratings yet

- 2.preformulation For The ScientistDocument51 pages2.preformulation For The ScientistMeera PatelNo ratings yet

- TxyDocument6 pagesTxyMeera PatelNo ratings yet

- Chapter 12.1Document19 pagesChapter 12.1Meera PatelNo ratings yet

- Friction FactorDocument30 pagesFriction FactorSomnath JagtapNo ratings yet

- Example-Water Flow in A PipeDocument13 pagesExample-Water Flow in A PipecristinelbNo ratings yet

- 3 Extraction, Mass Transfer OperationDocument9 pages3 Extraction, Mass Transfer OperationMeera PatelNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HLB Surfactant Selection PDFDocument22 pagesHLB Surfactant Selection PDFTARIQ KHAN0% (1)

- Bar SoapDocument13 pagesBar SoapMikaella ManzanoNo ratings yet

- Colonial SOSDocument2 pagesColonial SOSmndmattNo ratings yet

- Product Range - Home Care and II Asia PacificDocument19 pagesProduct Range - Home Care and II Asia PacificCarlotta C.100% (1)

- Physicochemical Principles of Pharmacy: Alexander T FlorenceDocument11 pagesPhysicochemical Principles of Pharmacy: Alexander T FlorenceNda ÂNo ratings yet

- Vesicular Drug Delivery Systems A NovelDocument10 pagesVesicular Drug Delivery Systems A NovelJERIN REJINo ratings yet

- Technology Trends in Laundry ProductsDocument25 pagesTechnology Trends in Laundry ProductsGabriela Zubieta100% (1)

- Appendix 1 List of BSI and ISO Standards Relating To Surfactant AnalysisDocument11 pagesAppendix 1 List of BSI and ISO Standards Relating To Surfactant AnalysisCouluNo ratings yet

- H Balance & Estimation of Soap & Shampoos For Skin and Hair Care Used in COVID-19 Pandemic A Review PDFDocument3 pagesH Balance & Estimation of Soap & Shampoos For Skin and Hair Care Used in COVID-19 Pandemic A Review PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sulphonation and LABS Formulation Using SO3-AIR MethodDocument3 pagesSulphonation and LABS Formulation Using SO3-AIR Methodaneece786No ratings yet

- Kao Corporation, S.A.: Disinfecting Floor Cleaner Containing Ammoniac & Pine OilDocument2 pagesKao Corporation, S.A.: Disinfecting Floor Cleaner Containing Ammoniac & Pine OilAlna Technical100% (1)

- Thms PC Emulsifiers Eu 0118 Ia PDFDocument3 pagesThms PC Emulsifiers Eu 0118 Ia PDFJuan Carlos ValverdeNo ratings yet

- Home Care 2019 RevisedDocument44 pagesHome Care 2019 RevisedYılmaz Yıldırım100% (1)

- Chap 11Document19 pagesChap 11The GantengNo ratings yet

- Comparison of Fenton and Foto-FentonDocument9 pagesComparison of Fenton and Foto-FentonNika Porubin DandelionNo ratings yet

- Emulsion ExperimentDocument5 pagesEmulsion ExperimentMARLIANANo ratings yet

- LE 2203 - LectureDocument19 pagesLE 2203 - LectureAnik AlamNo ratings yet

- Brij - CrodaDocument4 pagesBrij - Crodafgsdfgsdfg50% (2)

- Biobased Surfactants and DetergentsDocument512 pagesBiobased Surfactants and DetergentsEdgardo Ed RamirezNo ratings yet

- (NIIR) Herbal Soaps & Detergents HandbookDocument18 pages(NIIR) Herbal Soaps & Detergents HandbookHaneen MohammadNo ratings yet

- Cosmetics in The Treatment of Acne Vulgaris: Ella L. Toombs, MDDocument7 pagesCosmetics in The Treatment of Acne Vulgaris: Ella L. Toombs, MDJihanNo ratings yet

- Ganesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Document181 pagesGanesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Jesus Moreno Castillo100% (1)

- Capstone Fs 63 Technical InfoDocument2 pagesCapstone Fs 63 Technical InfoAPEX SONNo ratings yet

- Adinol: Sodium Methyl Acyl TauratesDocument3 pagesAdinol: Sodium Methyl Acyl TauratessimmiNo ratings yet

- Assignment 1 - DraftDocument24 pagesAssignment 1 - DraftAdjisetya muhammadNo ratings yet

- ConsumerChemistry9 q3 Mod1 ChemicalsFoundinCosmetics v3Document34 pagesConsumerChemistry9 q3 Mod1 ChemicalsFoundinCosmetics v3Denn Kelly PengsonNo ratings yet

- Bio-Production of Lactobionic Acid: Current Status, Applications and Future ProspectsDocument17 pagesBio-Production of Lactobionic Acid: Current Status, Applications and Future ProspectsAntonela PortaNo ratings yet

- Honeywell Performance Additives Water Based Emulsions Brochure PDFDocument12 pagesHoneywell Performance Additives Water Based Emulsions Brochure PDFyogi4yogesh100% (1)

- AkzoNobel SC CatalogDocument41 pagesAkzoNobel SC CatalogVB JazminNo ratings yet

- 2 in 1 Sahmpo y AcondicionadorDocument1 page2 in 1 Sahmpo y Acondicionadornancy seijasNo ratings yet