Professional Documents

Culture Documents

Sabp A 004

Uploaded by

philipyapOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sabp A 004

Uploaded by

philipyapCopyright:

Available Formats

Best Practice

SABP-A-004 Energy Performance Indices Document Responsibility: CSD/ESD/Energy Systems Unit 19 March 2006

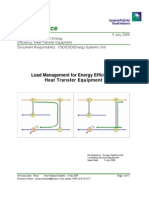

Energy Performance Indices

Electricity Steam Fuel

Energy Data

Calc engine

Prices: Feed Product Energy

Process Fluid Flows Densities

Data Recon

Balanced Model

Electricity Steam Fuel Total Energy Indices

Heat & Mass Balance Refinery Model

Developed by: Energy Systems Unit Consulting Services Department Issue Date: 19 March 2006

Previous Issue: None Next Planned Update: 19 March 2009 Page 1 of 79 Primary Contact: jimmy.kuamana@aramco.com, phone +966 (3) 874-6157

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Table of Contents

Page 3 3 3 4 4 5 6 7 9 10 11 14 14 15 20 25 26 31 36 50 52 53 55 61 65 65 68 69 74

1.

Introduction 1.1 Purpose and Scope 1.2 Definitions 1.3 Conflicts with Other Standards 1.4 References and Related Documents General 2.1 Classification 2.2 Data Availability and Quality 2.3 Calculation Strategy 2.4 Simulation models 2.5 Trend Chart Formatting Equipment EPIs 3.1 Pumps 3.2 Compressors 3.3 Fired Heaters 3.4 Fired Boilers 3.5 Unfired Boilers 3.6 Steam Turbines 3.7 Gas Turbines 3.8 Cogeneration Systems Process Unit/Area EPIs 4.1 Solomon EII for Oil Refining 4.2 Aramco Process Index for Gas Processing 4.3 Aramco Process Index for GOSPs Product EPIs 5.1 Methodology 5.2 Examples Oil Refineries 5.3 Example Juaymah Gas Plant On-line Implementation

Page 2 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

1.0

INTRODUCTION

Energy is a significant operating cost parameter for Saudi Aramco, and one that is important to management. The Companys energy conservation program is overseen by the Energy Management Steering Committee (EMSC), which determined that the potential existed to double the companys energy efficiency (i.e., to halve its energy consumption index) in the major industrial manufacturing plants. One of the key elements in the EMSCs strategy was to develop and monitor effective Energy Performance Indices (EPIs), and to report the results regularly. After conducting an exhaustive survey of industry practice, it was determined that while the indices in common industrial use were indeed of some value for competitive benchmarking, they are lacking in other important capabilities, chiefly:

Monitoring trends in energy efficiency by product, by process unit, and by major

equipment.

Serving as a diagnostic tool for process troubleshooting and operational efficiency

improvement. Ideally, the EPIs should also screen out the effect of variations in uncontrollable external factors such as feed rate, feed composition, product mix, and ambient conditions. This manual is an explanation of the methodology for calculating the new EPIs that were developed internally within Saudi Aramco to meet the EMSCs specifications.

1.1

Purpose and Scope

The purpose of this DeskTop Standard is to describe proven Best Practices, consistent with guidelines endorsed by the Companys Energy Management Steering Committee (EMSC), in developing and deploying an integrated system of EPIs. This Manual provides the theoretical basis for developing EPIs, the methodology for calculating them, and examples of final output. It is intended as an aid to engineers working in Saudi Aramco plants who are responsible for maintaining and reporting the departmental EPIs. It is important to also understand what this manual is not. It is not intended to provide a comprehensive review of all current or past practices only to describe the best ones. It focuses on practices that have been proven to be useful in the field, not on the theoretical ideal way of doing things. The Best Practices therefore incorporate necessary compromises that invariably must be made to adjust to the reality of existing instrumentation, raw data quality, available software, limited manpower resources, etc. Finally, despite the high level of detail in some sections, the manual is not intended to be a cookbook giving step by step procedures for every possible EPI for every facility. The objective is to outline the general approach and procedure for the major classes of EPIs, and to illustrate how these EPIs were implemented in their best manifestation.

Page 3 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

1.2

Definitions

Best Practice: A process or method that, when correctly executed, leads to enhanced system performance. Energy Performance Index: An operating policy that distributes the load between parallel networks of multiple machines/equipment in a way that minimizes their energy (fuel + power) consumption, without compromising safety or reliability

1.3

Conflicts with Other Standards

There are no other published Standards, Procedures, or General Instructions that address the subject of Energy Performance Indices, and therefore no conflicts are expected.

1.4

References and Related Documents

This manual is based on an unpublished course that was developed and delivered in June 2005 by the Energy Systems Unit of Consulting Services Department to energy engineers from all proponent facilities. The software referenced in this Manual was originally developed by Energy Systems Unit, and is available to all Saudi Aramco engineers upon request.

Page 4 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

2.0

GENERAL

The concept of EPIs for monitoring process and equipment efficiency is not new. In fact, many different types of EPIs are in use throughout the oil and gas industry. EPIs have two primary applications: Benchmarking o Historical o Competitive o Absolute Process Improvement (viz. energy efficiency) Historical benchmarking is when the current energy efficiency is compared to previous energy efficiency, usually at some baseline period in time. Competitive benchmarking is when the plant performance is compared against the performance of other similar plants, usually on an industry-wide basis, although it can also be applied to different plants making the same products within a single company. Absolute benchmarking is when the equipment or plant energy efficiency is compared against a theoretical target or budget. EPIs can be used to measure and monitor the efficiency of process equipment, process units, or entire process plants. The proper formulation depends upon the objective. In all cases it is imperative that the EPI should accurately reflect the efficiency of energy consumption. For equipment, the EPI is generally formulated as the thermodynamic efficiency. The higher the thermodynamic efficiency, the better. For process plants, there are several formulations, but in general they are all expressed as an energy intensity, i.e., energy consumption per unit of throughput. In general, a high numerical value for the process EPI indicates high energy intensity, whereas a small EPI indicates low energy consumption per unit of output. In short, the lower the EPI, the better. For oil refining, the most widely accepted process EPI is the Solomon Energy Intensity Index (EII), which was developed in the mid 1970s as a tool for comparing the energy efficiencies of different oil refineries. This type of index works well when the processes being used are comparable in all plants. Its primary use is in competitive benchmarking. In the gas processing industry, the most widely accepted EPI is CGEYs* Energy Efficiency Index, which is expressed as energy consumption per unit of feed per GPU (Gas Processing Unit), or $/MMscfd per GPU. The GPU is a parameter developed by CGEY to represent the complexity of a plant. Each process unit (e.g., amine treating, dehydration, NGL recovery, etc.) is characterized by a GPU value, which is determined based on its theoretical energy consumption per unit of feed flow. The GPU values of all the units in a plant are summed up to get the overall GPU. The capacity parameter is combined raw feed gas (MMscfd). CGEYs EEI was modeled after the Solomon EII, and is also designed primarily for use as a competitive benchmarking tool.

*

Cap Gemini Ernst and Young, a management consulting firm based in Canada Page 5 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Plants operating under different feedstock conditions, product specs, and process technologies are impossible to compare unless there is a mechanism for reducing them to a common basis. The artifice of creating a GPU is an attempt to partially compensate for some of the differences in feedstock compositions and pressures, product slates, and product specification. CGEY freely concedes that the GPU technique is approximate at best and cannot provide truly accurate benchmarks, but they claim it is the best available (which at the moment of writing was true). There is no comparable industry-wide energy efficiency index applicable to oil & gas exploration and production. An even more important application of EPIs than benchmarking is to serve as a diagnostic tool for process troubleshooting and identifying opportunities for process efficiency improvement. Neither the Solomon nor the CGEY indices have this capability. To fill the need for timely actionable information, CSDs Energy Systems Unit has developed a different approach to Energy Performance Indices (EPIs) with the following desired features:

Energy consumption and cost are expressed per unit of product rather than feed Different indices for different user groups managers, engineers, and operators Capable of meeting all EMSC objectives report card, accurate benchmarking, diagnostic tool for process trouble-shooting and identifying efficiency improvement opportunities, and an operator alarm generation system to flag significant deviations from target performance.

In addition the output from these EPIs can be used for accurate product pricing as well as calculating a global energy KPI for the entire company, which is of great value and interest to both the Finance Department and to senior management. The main structural difference between EMSCs overall product indices and existing industry indices is that they are formulated as output-based instead of input-based. The problem with feed-based indices is that even a reduction in energy consumption associated caused by declining process yield (something undesirable) will show up as an improved energy index, which is misleading. Product-based indices, on the other hand, would clearly show that the index has deteriorated, and reliably indicate both favorable and adverse trends.

2.1

Classification

The first thing to understand is that there is not just a single EPI but sets of EPIs, each formulated to meet a specific application. In fact, one can have as many EPIs as one would like, as long as each one provides some useful actionable information. The key here is actionable, which means the engineer or manager should be able to take some logical action to improve the index, based on its numerical value.

Page 6 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Four categories of EPIs are described in this manual, with different objectives and functions as follows: Category Equipment EPIs Process Area EPIs Individual product EPIs Corporate Energy KPI Management Intended Users Engineers x x x Operators x x

x x

The new EPIs are expected to be developed and deployed by each Department in 3 phases: Phase 1: Phase 2: Phase 3: Initial rollout, including on-line implementation, based on simplified models. Improved data conditioning and model refinement. Further improvements, e.g., comparison against dynamic targets, segregation of indices by shift, etc.

This manual covers implementation of Phase 1 only. Additional manuals will be prepared for Phases 2 and 3 after they are implemented (scheduled for 2007 and beyond).

2.2

Data Availability and Quality

A large number of flow, pressure, temperature and economic data are needed as input to the EPI models. The primary data sources are expected to be as follows:

Readings from the PI system Manual readings and logs Official raw material, product and energy prices as specified by Business Analysis Department of Corporate Planning

One of the problems with using live PI data directly in the EPI models is that even if one of the data values is bad (i.e., a non-numerical value), the model fails to complete the calculation and give a numerical result. When we have hundreds of such PI inputs, the probability of at least one input being bad is quite high. Bad data such as a textual error message or a numerical error (e.g., division by zero) are easy to recognize. Therefore, it is necessary to screen live data and substitute default values when bad readings are encountered. The second and more difficult problem we must deal with is to recognize when the numerical data that we do get are not correct, and to make necessary corrections. Two simple error detection techniques are recommended to start with. One is to set upper and lower bounds for each parameter. These limits could either be fixed values, or set as a function of some other parameter(s). If the measured data value is outside these limits, the default value is used, and an error message is transmitted to the operator and logged. The other technique is to do a consistency check on a set of inter-related parameters using material and heat balances and/or physical property correlations. For example, unless the pressure and temperature measurements of saturated steam are consistent with the Vapor-Liquid Equilibrium (VLE) equations, we would know that one or the other is incorrect. When such inter-related data cannot be reconciled, and fail the consistency checks, an error message should be automatically transmitted by the system to the operator and the engineers logs. All of this logic

Page 7 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

(see Exhibit 2-1) must be embedded within the EPI models, reviewed periodically, and revised as needed. Exhibit 2-1: Data Validation and Conditioning Logic

There are several options for selecting default values, in order of increasing accuracy and computational effort: a) b) c) d) e) Use a fixed number, based on manual input Use the last good numerical value Use an average over some reasonable period (could be hours, days, or weeks) prior to encountering the bad value Use a computed value based on statistical regressions Use a computed value derived inferentially (using simulation models) from other measured data that are known to be good.

The appropriate default value must be selected for each parameter on a case-by-case basis. For input data that do not change much over time, e.g., HHV of the fuel, a fixed number is probably the right choice. For parameters that typical vary from period to period, such as flow, temperature, and pressure, the last good value may be the right choice for the following 2-4 periods, after which we might switch to the use of an average value. In the case of power or fuel consumption readings, the correct choice would be a computed value based on statistical correlations of historical data, since the energy consumption can be expected to be a function of throughput as well as ambient temperature. And so on.

Page 8 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

2.3

Calculation Strategy

The general form for expressing energy EPIs (or any KPI for that matter) is

EPI =

Resource Consumption Throughput

Ideally, the throughput should be expressed in terms of the desired output from that process, which is the product produced. However, when one has multiple products from a single feed, as in an oil refinery or gas plant, it becomes difficult to decide how much of the resource consumed should be allocated to each product. That is why standard industry practice has been to express the indices on the basis of feedstock processed. Unfortunately, the consequent indices are not particularly helpful, and can even be misleading, as we shall demonstrate, using a simple illustrative example. Consider the simplified process model illustrated in Exhibit 2-3. Exhibit 2-3: Simplified Process Model

Waste, W

Feed, F

PROCESS

Energy, E

Product, P

FB =

E input1 = F input2

PB =

E input = P output

Note: FB = Feed-based, PB = Product-based

Suppose the yield of the process has been improved through continuous process innovation since it was started up. Suppose that a 10% increase in yield requires a 5% increase in energy consumption. In this case the feed-based index would go up by 5%, while the product based index would go down by 4.5% (= 100-105/110). The feed-based EPI would indicate to management that the plant has become less efficient, when in fact it has become more efficient. A similar argument can be made to demonstrate that a feed-based index will not change if part of the product is used as fuel (which in fact is common practice in Aramcos gas plants as well as refineries), and might even improve, if we account only for purchased fuels and power. A product-based index will highlight the revenue loss, because using product as fuel is equivalent

Page 9 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

to a loss in yield. A product-based EPI gives accurate indications of efficiency trends, while a feed-based EPI does not. More generally, they could be thought of as input-based versus output-based. As noted earlier, the CGEY indices are all input-based. The EMSC has concluded that we need something better. The type of model required depends upon the type of index being calculated. For the product indices we need a fairly sophisticated approach combining a relatively rigorous process simulation model (including heat and material balances) with a relatively sophisticated economic resource-allocation model. For the process unit (area) indices we can use a simpler approach for calculating EPIs (no economics involved), but which uses the output from the same rigorous process simulation model. For the equipment indices we do not use these models at all. Instead, we develop equipment-specific models for directly calculating energy efficiency. The general data collection and computational strategy is depicted in Exhibit 2-4. Exhibit 2-4: EPI Calculation Strategy

Live input data collection

Temporary cache, data stored as values Data validation and conditioning Archive of Good data set (input data for Model)

Run calc engine to generate EPIs for current data set

Archived database of historical EPI values Generate trend charts and Reports

2.4

Simulation Models

All EPIs require some sort of calculations based on measured process parameters. Equipment EPIs require only very simple models, most conveniently done using spreadsheets. Process and product EPI calculations, though somewhat more complex in concept, are also fairly simple to model using spreadsheets. However, to give meaningful results, process and product EPIs require relatively good (i.e., consistent and accurate) mass and energy balance data. Direct measured data from the PI system is seldom of sufficiently good quality for our purposes, and must be validated using a data reconciliation software package that goes well beyond the rudimentary data conditioning techniques described in section 2.2. Such data reconciliation soft-

Page 10 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

ware is not currently installed at any Saudi Aramco facility. Therefore it is recommended that a stop-gap approach be used on an interim basis. The proposed solution is to employ commercial software packages such as AspenPlus, Pro-II, or Hysys to develop simplified heat and mass balance simulation models for each process unit and also for the plant as a whole. These simplified models would not do detailed simulations of reactions and VLE separations (such as distillation) just the heat and mass balances. Reactors and separations would be modeled as mixers and splitters with the split ratios for the cut streams specified as manual input. The models would have to be tuned using accurate feed and product flow data (which are usually metered using very high-accuracy custodytransfer meters, and certain key temperature/pressure/composition measurements at anchor points within the process. The simulation models essentially serve as a virtual metering system for intermediate flows between process units, and thereby minimize the reliance on measured data of dubious quality. While the virtual metering approach cannot guarantee accuracy, it does guarantee consistency, which is perhaps more important. As an alternative to using commercial software, it is also possible to develop HMB simulation models of adequate accuracy using electronic spreadsheets. This has been successfully done for all five gas processing plants (by the GO Center of Excellence in Dhahran), for JGP, and for Safaniya Onshore Producing. Output from these simulation models is then used as input for the EPI models.

2.5

Trend Chart Formatting

EPI trend charts must be formatted to show time scale on the X axis and the index or indices on the Y axis. The time scale should be selected to cover the period of interest. For product and process EPIs being used within the department, a monthly or weekly EPI calculation is probably appropriate, and the recommended period is 12 months preceding the current date. If, on the other hand, the EPI trend chart is being used for a presentation to management on long-term trends, the time scale should be on an annual basis. For equipment EPIs, the index should be calculated on an hourly, shift, or daily basis, depending on the equipment and process variability for that particular application. The recommended display period could be the previous 3-10 days (for EPIs calculated frequently) or the previous 30 days (for EPIs calculated daily). The Y-axis scale should be selected to provide a balance between perspective and discrimination. Too narrow a range magnifies variations at the cost of perspective. A wide range restores perspective, but may lose discrimination. A good rule of thumb is that the Y-axis scale should be approximately 2-4 times the difference between the highest and lowest values for the parameter being displayed. Some illustrative examples are provided in Exhibits 2-5 through 2-7.

Page 11 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibits 2-5a and b: Product EPIs for Safaniya Onshore Producing

Dry Gas Fuel and Power Indices

1.0 2500

0.8

2000

MMBtu/MB

0.4

1000

0.2

Fuel Index Power Index

500

0.0 Jan03

Feb03

Mar03

Apr03

May03

Jun- Jul-03 Aug03 03

Sep03

Oct03

Nov03

0 Dec03

Dry Gas Energy Cost Index

70 60 50 40 30 20 10 0 Jan03

Energy Cost, $/MB

Feb03

Mar03

Apr03

May03

Jun03

Jul-03 Aug03

Sep03

Oct03

Nov03

Dec03

KWH/MB

0.6

1500

Page 12 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 2-6: Process EPIs for Abqaiq Plants

30 0.20

25

0.18

MMBtu/bbl crude oil feed

15

0.14

10

Overall Energy Index Steam Index P o wer Index

0.12

0.10

0 1999

2000

2001

2002

2003

2004

0.08 2005

Exhibit 2-7: Equipment EPIs for Compressors at HGP

Stabilizer OH Compr Polytropic Efficiency, HGP

100% 95% 90% 85% 80% 75% 70% 65% 60% 3/29/05 K-003A K-003B

4/3/05

4/8/05

4/13/05

4/18/05

4/23/05

4/28/05

5/3/05

kwh/bbl oil feed

20

0.16

Page 13 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

3.0

EQUIPMENT EPIs

Equipment EPIs are the first level of indices, and the simplest to implement. They are required for only the major energy consuming or conversion equipment within each process area. These EPIs are most conveniently expressed as equipment efficiencies thermodynamic or mechanical. The equipment for which energy efficiency is important can be divided into two categories:

Energy consumers e.g., pumps, compressors, furnaces, lighting, distillation columns Energy converters e.g., boilers, turbines, electric motors, generators

EPIs are generally recommended only for major energy consumers, i.e., power > 2 MW, or fuel > 15 MMBtu/h. The definitions of efficiency for these two categories are correspondingly different. For consumers, energy efficiency = useful work accomplished on the process divided by the energy that must be supplied. For converters, energy efficiency = useful energy output divided by energy input. Exhibit 3-1: Definitions of Equipment Energy Efficiency Equipment Type Pump Compressor Fired process heater Distillation column Electric motor Generator Steam Turbine Boiler Input (Denominator) Mechanical shaftwork Mechanical shaftwork Chemical (fuel) energy Thermal energy Electrical power Mechanical shaftwork Steam kinetic energy Chemical (fuel) energy Output (Numerator) Liquid kinetic energy Vapor/gas pressure energy Process enthalpy Chemical separation of mixture Mechanical shaftwork Electrical power Mechanical shaftwork Thermal energy (as steam)

Nowhere does a capacity term appear in the calculation of energy efficiency. One common mistake worth mentioning is that some people refer to condensing steam turbines as being more efficient than back-pressure steam turbines because they generally produce more shaftwork (kwh) per lb of steam; this is inconsistent with fundamental thermodynamic principles. An index expressed as kwh/lb of steam could perhaps be considered an indicator of generating capacity, but certainly not of energy efficiency.

3.1

Pumps

The mechanical efficiency of a centrifugal pump is given by Eff (fractional) = Flow x (P2 - P1) / HP / 1715 To calculate efficiency on-line it is necessary to have four measured data points the flow rate, in gpm, the suction and discharge pressures in psi, and the horsepower (or kilowatt) reading. Normally, we have instrumentation for the first three but not the last. Without all four readings, it is not possible to calculate the efficiency. Sometimes, a pump may have an ammeter instead of a kw meter. The power can then be calculated as:

HP =

I .V . 3. cos( ). M 746

Page 14 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

where

I = measured current, amperes

V = applied voltage (known) cos() = power factor, expressed as a decimal, typically 0.85-0.92

M = motor efficiency (from data sheet), typically 94-97%

Normally the mechanical efficiency of a pump does not fluctuate in the short term. Rather, it degrades slowly over a period of months or even years. Therefore on-line efficiency measurement is not especially valuable. For both of these reasons, pump efficiency monitoring is not a high priority in most cases. It could be included for selected applications in the future if desired, after the power meters have been installed. An alternative diagnostic tool on the pumps mechanical condition and performance is to plot the actual pump characteristic curve (flow rate versus P) and compare it against the design curve as in Exhibit 3-2. If the pump is delivering less TDH (total discharge head) than design at the measured flow, it means that the performance has fallen off and needs corrective action. The efficiency loss can be estimated very roughly as the ratio of actual head to design head at that particular flow rate. Exhibit 3-2: Comparison of Actual Pump Performance vs Design

Centrifugal Pump

1000

800

Head, ft

600

400

200

Design Actual

0 0 2000 4000 6000 8000 10000

Flow, gpm

3.2

Compressors

Overall Energy

Large gas compressors are good candidates for efficiency monitoring. Efficiency of an individual compressor is defined as:

o =

absorbed energy into process gas isentropic HP = delivered energy to the driver brake HP

Page 15 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Unfortunately, it is impossible to measure directly. The best we can do is calculate efficiency based on measurements of other process parameters such as flow, temperature, pressure, and estimated gas physical properties. For compressors, there are two types of efficiencies: the adiabatic efficiency and polytropic efficiency. As a practical matter, the adiabatic efficiency can be calculated from process data as

a =

where T1 T2 T2 = = =

T2' T1 T2 T1

Suction temperature, F Actual discharge temperature before any cooling, F isentropic (adiabatic) discharge temperature, F, calculated as:

P2 ' T2 = (T1 + 460 ) P1

P1 & P2 = k =

k 1 k

1 + T1

suction and discharge pressures, psia specific heat ratio Cp/Cv

The polytropic efficiency is calculated as:

p =

where

n k 1 n 1 k

n = polytropic constant, which is a function of gas properties only, and determined experimentally from the equation PVn=constant, unique to each machine.

The polytropic constant can be calculated from on-line process measurements by the equation:

n =.

ln( P2 / P 1)

{ln( P2 / P 1 ) ln(T2 / T1 )}

Adiabatic efficiency varies with compressor inlet conditions, whereas the polytropic efficiency is constant for a particular gas mixture, being a function primarily of mechanical design. The polytropic efficiency is therefore a better indicator of compressor mechanical condition and performance. The overall efficiencies are then obtained as:

oa = a . m

where

and

op = p . m

= =

mechanical efficiency of the compressor fraction of power delivered by the driver (motor) that is actually transmitted to the gas, usually 97-98%

Spreadsheet templates for calculating compressor efficiency are shown in Exhibits 3-3 and 3-4. It is recommended that compressor efficiencies should be monitored on-line (at 4 hour intervals) to detect any adverse trends in a timely manner and to take appropriate corrective action.

Page 16 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

To see a sample trend chart, refer back to Exhibit 2-7. The approximate polytropic efficiency for large compressors (suction flow >5000 acfm) in good condition is Eff = 61 + 1.31 ln (acfm). Exhibit 3-3: Efficiency Calculation Template for Single Stage Compressors

Page 17 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-4a: Efficiency Calculation Template for Two-Stage Compressors (LP section)

Page 18 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-4b: Efficiency Calculation Template for Two-Stage Compressors (HP section)

For gas mixtures, the compressibility and specific heat data are most conveniently determined off-line at average inlet/outlet conditions (using Hysis, VMGsim or other physical properties simulation software), and entered manually. For pure component gases (e.g., refrigeration), a higher level of modeling flexibility and accuracy can be obtained without too much effort by using correlations (developed off-line for the expected range of operating conditions) for the compressibility and specific heat, calculating the values separately at inlet and outlet conditions, and then taking their arithmetic average.

Page 19 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Observe that several checks are built into the EPI models to check consistency of measured vs calculated mixture temperatures (for 2-stage compressors), and measured vs calculated power. The model also checks to ensure that the measured flow rate does not exceed compressor capacity and that the calculated horse power does not exceed motor size. Three-stage compressors are not very common, but can be handled in the same manner as two stage compressors: i.e., efficiency must be calculated for each section. Under field conditions, mechanically identical machines may develop differences in polytropic efficiencies of as much as 5%. As a general rule, if they are within 3% of one another, and the trends tend to track in parallel, it is an indication that the machines are in comparable mechanical condition, and that the instruments are reading correctly. Wide discrepancies in efficiency or non-parallel trends could indicate that one machine has deteriorated significantly compared to others, the instrument readings are not accurate, or that something abnormal is going on process wise.

3.3

Fired heaters

Fired heaters or furnaces are found in oil refineries, gas plants (usually in the Sulfur Recovery Units), and GOSPs.

Losses PROCESS FLOW IN: W, T1, H1 FURNACE PROCESS FLOW OUT: W, T2, H2

Fuel, F

For fired heaters that are supplying sensible heat to the process, the fuel efficiency is most simply calculated by the heat balance method, also known as the direct method:

W .Cp.(T2 T1 ) F .HHV

where W = mass flow rate of process fluid, lb/h Cp = average specific heat, Btu/lbF (varies with composition and temperature) T1, T2 = inlet and outlet process temperatures, F F = fuel gas flow rate, scfm HHV = higher heating value, about 1050 Btu/scf on average (spec is 1080). If the lower heating value (LHV) used instead of HHV, is called thermal efficiency instead of fuel efficiency. If the process stream being heated is undergoing both sensible heating and evaporation, the equation becomes:

W .( H 2 h1 ) F .HHV

where h1, H2 = inlet and outlet enthalpies of the process stream, Btu/lb.

Page 20 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

While simple is theory, the heat balance method has a major deficiency it gives accurate results only when the data quality is extremely good (generally less than 1% error), which is hardly ever the case. A more accurate estimate of furnace efficiency can be obtained by the heat loss method (also known as the indirect method) as follows:

Absorbed duty F .HHV Losses or alternatively = Absorbed duty + Losses F .HHV

Choose the formulation according which measured value (absorbed duty of fuel input) is likely to be more accurate. A spreadsheet template for calculating furnace/heater efficiency is shown in Exhibit 3-5, with provision for calculating the efficiency for both gaseous and liquid fuels. It also has the option to calculate either single-phase or two-phase process heating duty. Exhibit 3-5a: Efficiency Calculation Template for Fired Heaters (part a)

Page 21 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Observe the messages saying OK. These represent the results of built-in consistency checks. If the consistency check failed, there would be an warning error message instead. It may appear that running a full set of calculations including consistency checks for each set of data is too much work. However, it is necessary in order to ensure that the results are as accurate and reliable as possible. Exhibit 3-5b: Efficiency Calculation Template for Fired Heaters (part b)

Furnace efficiency monitoring using the heat balance method, without any consistency checks, is illustrated in Exhibits 3-6 and 3-7. It is an acceptable first step, but ultimately the efficiency calculation method should be upgraded to the more rigorous approach.

Page 22 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-6: Heat Balance Method for Furnace Efficiency

PI DATA

Exhibit 3-7: Sample Trend Chart for Furnace Efficiency

Safaniya Furnace F-212

100 500

80

OUT

400

Thermal Eff, %

60

300

40 Efficiency Stack Temp 0 May-03 Feb-03 Mar-03 Oct-03 Jan-03 Nov-03 Aug-03 Dec-03 Jun-03 Jul-03 Sep-03 Apr-03

200

20

100

Stack Temp, F

Page 23 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

The spreadsheet templates presented in this and the following section on boilers are intended to serve as guidelines only. There could be many variations from the illustrated case, depending on the specific situation. The engineer must apply his knowledge and understanding of the basic principles to adapt the base-case EPI calculation engine. The information provided in Exhibits 3-8 to 3-10 may be useful in this effort. Exhibit 3-8: Thermo-chemical Properties of Common Fuels and Elements

Exhibit 3-9: Calculation of HHV from Ultimate Analysis (wt%)

Exhibit 3-10: Heating Value of Fuel Oils as Function of API Gravity

Heat of Combustion for Fuel Oils

21000

20000 y = -0.4303x 2 + 68.919x + 17671 Heating Value, Btu/lb 19000

18000 y = -0.3774x 2 + 57.906x + 16786

LHV

17000

HHV P o ly. (HHV) P o ly. (LHV)

16000 0 10 20 30 deg API gravity 40 50 60 70

Page 24 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

In general, the heat loss method is preferred over heat balance method because it is less sensitive to errors in measurement. For example, lets say that the true fuel firing rate is 100 MMBtu/h and the true efficiency is 85%. i.e., Absorbed duty = 85 MMBtu/h and Losses = 15 MMBtu/h. Now suppose the fuel meter reading is low by 10%, ie it measures 90 MMBtu/h instead of 100 MMBtu/h. By the heat balance method, the calculated efficiency would be 85/90, or 94.4% (error of 9.4%), whereas by the heat loss method, it would be (90-15)/90 = 83.3%, an error of only 1.7%. Clearly, the latter is more robust.

3.4

Fired Boilers

A fired boiler converts chemical energy in the fuel to thermal energy in steam. Saudi Aramco plants appear to have standardized on steam generation pressures of 600 psig, 375 psig, and 150 psig. However, there is no reason boilers could not be designed for other pressures. In fact, there are significant advantages in terms of power generation potential (employing backpressure steam turbines) to higher steam pressures, e.g., 900-1200 psig. Usually, the steam is superheated by at least 200F in order to avoid condensation inside the turbine casing.

Flue gas Water In, W Fuel, F BOILER Steam Out, S Blowdown

Air, A

As for fired heaters, boiler efficiency can be calculated by either the heat balance method or the heat loss method. The heat balance method is straightforward:

S .( H 2 h1 ) F .HHV

where the parameters are identical to those described earlier. ASME recommends the heat loss method, which though more complicated method, is far more accurate:

F .HHV (losses) S .H = F .HHV S .H + (losses)

The input data required are usually measured on-line in any case: Steam flow Steam pressure Steam temperature Fuel gas flow Fuel gas heating value Combustion air flow Air supply temp Air supply relative humidity Flue gas temperature Oxygen content of flue gas CO content of flue gas (optional) Deaerator temperature Blowdown rate Ambient temp around boiler wall Boiler skin temperature Wind velocity past boiler walls

Page 25 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

In addition, it is necessary to provide the following details about boiler geometry and design as one-time manual inputs: surface area exposed to the environment (viz. wind), total area of openings through which heat can be radiated out (e.g., peepholes), wall thickness, insulation thickness, and type of wall material whether metal or brick. A spreadsheet template for calculating boiler efficiency is shown in Exhibit 3-11, and a sample trend chart is shown in Exhibit 3-12. An iterative procedure is required. Assuming the gas flow is more accurate; the steam flow is calculated by heat balance, and compared against the measured value. Although the spreadsheet template presented is for gas-fired boilers, which are the most common type used in Saudi Aramco facilities, it can be easily adapted to other fuel types, in a manner similar to that shown for oil-fired furnaces in Exhibit 3-5.

3.5

Waste Heat Boilers

Waste heat boilers (WHBs) are similar in function to conventional boilers, except that the heat source is a hot process stream (e.g., reactor outlet or incinerator flue gas), and no fuel-firing is employed. Because they generally operate at much lower temperatures than fired boilers, the construction is quite different no refractory linings are required. In fact, they are very similar in design to shell-and-tube kettle reboilers, with steam generation either on the shell side or the tube side, depending upon process considerations.

Steam, H2 PROCESS FLOW IN: W, T1 WASTE HEAT BOILER Water, h1 PROCESS FLOW OUT: W, T2

For waste heat boilers (WHBs) where the objective is recovery of steam for process use, the thermal efficiency is given by:

S .( H 2 h1 ) W .Cp.(T2 T1 )

where W = mass flow rate of tail gas, lb/h T1, T2 = inlet and outlet process temperatures, F S = mass flow rate of steam generated, lb/h h1, H2 = enthalpies of boiler feedwater makeup and steam respectively, Btu/lb. For WHBs, we can only use the heat balance method, because the heat loss method does not apply. As the flow data are usually extremely unreliable, one has to check for consistency using material balances on the water side, i.e., to ensure steam plus blowdown flow rates add up to the boiler feedwater supply.

Page 26 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-11a: Efficiency Calculation Template for Gas-Fired Boilers (part a)

Page 27 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-11b: Efficiency Calculation Template for Gas-Fired Boilers (part b)

Page 28 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-12: Sample Trend Chart for Boiler Efficiency

Boiler Efficiency, HGP

95% 94% 93% 92% 91% 90% 89% 88% 87% 86% 85% 3/29/05 Boiler-1 Boiler-2 Boiler-3 Boiler-4

4/3/05

4/8/05

4/13/05

4/18/05

4/23/05

4/28/05

5/3/05

Exhibit 3-13: Efficiency Calculation Template for Waste Heat Boilers

Page 29 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

The calculation template and sample trend chart for WHBs are presented in Exhibits 3-13 and 3-14. The consistency checking method is illustrated in Exhibit 3-15. It should be obvious there is a metering problem from June 2004 to January 2005, as the generated steam cannot possibly exceed boiler feedwater flow. Exhibit 3-14: Sample Trend Chart for Waste Heat Boiler Efficiency

RTR Waste Heat Boiler 15-E293

120 100 80 60 40 20 0

Thermal Eff, %

Stm / BFW mass frac

Ja n0 Ja 4 n0 Fe 4 b0 M 4 ar -0 A 4 pr M 04 ay -0 Ju 4 n04 Ju lA 04 ug -0 Se 4 p0 O 4 ct -0 No 4 v0 De 4 c0 De 4 c04 Ja n0 Fe 5 b05 M ar -0 A 5 pr -0 M 5 ay -0 5

Ja n0 Ja 4 n0 Fe 4 b0 M 4 ar -0 A 4 pr M 04 ay -0 Ju 4 n04 Ju l-0 A 4 ug -0 Se 4 p0 O 4 ct -0 No 4 v0 De 4 c0 De 4 c04 Ja n0 Fe 5 b0 M 5 ar -0 A 5 pr -0 M 5 ay -0 5

Exhibit 3-15: Material balance Consistency Check for WHB

Steam - BFW mass balance

160% 140% 120% 100% 80% 60% 40% 20% 0%

Page 30 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

In case the steam is generated at saturated conditions (quite common in the case of WHBs) for use directly in a process application, there is a risk of steam hammer problems in the pipework due to condensation. To avoid this problem the steam should be blended back in to the main header or superheated, even if by only 20F, e.g., against flue gas from any nearby furnace. Examples of these two potential solutions are shown in Exhibits 3-16 and 3-17 (next page). In the worst case, some HP steam could be injected. Plant engineers should always be asking themselves if the results they see make sense, e.g., by comparing them against known industry standards. Consider, for example, the trend chart of Exhibit 3-12, which shows boiler efficiency values in excess of 90%. Examination of typical efficiency values for well operated boilers, as listed in Exhibit 3-18, should lead us to conclude that the input data are probably wrong, not that the boilers are working exceptionally well. Exhibit 3-18: Typical Boiler Efficiencies for Well-operated Boilers

Waste heat boilers, on the other hand, should have thermal efficiencies in the range of 95-99%, as the only losses are due to radiation and convection.

3.6

Steam Turbines

Steam turbines come in many different configurations: back-pressure (single exhaust pressure, > 1 atm) back-pressure (dual exhaust pressures, > 1 atm) condensing (exhaust < 1 atm) condensing (exhaust < 1 atm) with extraction (> 1 atm)

The most common steam turbine design used in industrial applications is the single-exhaust back-pressure type, because it is the most efficient thermodynamically.

Page 31 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-16: Blending Saturated Steam into Superheated Header

Exhibit 3-17: Superheating Saturated Steam against Hot Process Steam

Page 32 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

HP Steam

BPST

WORK

LP Steam

PROCESS

Two kinds of efficiency are important. One is the isentropic efficiency of the turbine, which is an indicator of how well the machine was designed to begin with, and its present mechanical condition. This machine efficiency is calculated as:

=

where H1 H2 H2 = = =

H1 H 2 H1 H 2 '

Enthalpy of HP inlet steam, Btu/lb Actual enthalpy of exhaust LP steam, Btu/lb Enthalpy of exhaust LP steam assuming isentropic expansion, Btu/lb

The other kind of efficiency is the overall or cycle energy efficiency, which is calculated as:

3413 x kw + W.H 2 W.H 1

Since enthalpy cannot be measured directly, it must be inferred from pressure and temperature measurements using a steam properties database. This is called Method 1. The recommended properties software is called SteamTab version 3, which is an Excel add-in software package, available for about $150 per copy from ChemicalLogic Corp (Woburn, Mass). It is also possible to manually read these properties off a Mollier Diagram, but this is not practical to do when calculating and trending results using a computer. Some plants have extraction steam turbines with two exhausts at medium and low pressure. The thermodynamic efficiency is calculated for each stage, and the overall efficiency is derived from the stage-efficiency results. A spreadsheet template for calculating isentropic steam turbine efficiency according to Method 1 is presented in Exhibit 3-19a. The template shown can be used for either single- or dual-exhaust turbines. Observe that there are two parallel calculation columns, entitled Approx and Exact. The Exact calculation requires the SteamTab software add-in to be installed on the computer being used. If it is not, then the Approx calculation results can be used.

Page 33 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-19a: Efficiency Calculation Template for Back-pressure Steam Turbines

Exhibit 3-19b: Overall Turbine Efficiency Calculation

Page 34 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

It may appear that there is not much difference in results between the two sets of data for the steam pressures selected, but if the pressures are significantly different, the Approx correlations may no longer be in such close agreement. The overall system (cycle) energy efficiency for this same turbine is shown in Exhibit 3-19b. Notice that the overall cycle efficiency is extremely high approaching 100%. This is typical of back-pressure steam turbines. Condensing steam turbines, by contrast, have overall cycle efficiencies in the range of 20-30%, which is why they should never be considered except in certain extreme conditions, e.g., for extremely remote locations where electrical power is either not available at all or is very expensive, or if the fuel is a waste material that requires disposal. The former condition exists only at Shaybah in Saudi Aramco facilities. The latter is unlikely to be encountered anywhere in the Kingdom within the foreseeable future. The isentropic efficiency is of more practical use from an operational viewpoint, because it provides a warning of developing mechanical problems. The cycle energy efficiency is more useful for design and decision-making purposes, such for calculating the process unit energy balance when conducting plant energy audits or choosing between project alternatives. Exhibit 3-20: Sample Trend Chart for Back-pressure Steam Turbine Efficiency

Steam Turbine Efficiency, HGP

82

80 Isentropic Efficiency, %

78

KT-361 KT-461

76

74

72 4/1/05

4/8/05

4/15/05

4/22/05

4/29/05

If the turbine is equipped with a torque meter it is possible to determine the actual power output directly, from which the overall energy efficiency can be calculated by energy balance. This is called Method 2. Most existing steam turbines in Saudi Aramco plants do not have such torque meters, but a revision to the standards is under consideration that will in the future require torque meters on all turbines larger than about 5 MW.

Page 35 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Energy efficiency for condensing type steam turbines cannot be calculated by method 1; only by method 2 (based on torque meter reading). Fortunately, the point is moot because as a matter of policy, the Company should not be using condensing turbines due to their extremely low cycle efficiency, as noted earlier.

3.7

Gas Turbines

Gas Turbines, also called Combustion Gas Turbines (CGTs) are widely used in Saudi Aramco plants, both as direct process drivers and as electrical power generators. Two kinds of energy efficiency are important the equipment efficiency, and the cycle efficiency (not the same as process efficiency, which is covered in the next section). The energy efficiency of individual components can be estimated using the methods of sections 3.2 and 3.6. This section focuses on cycle efficiency. A gas turbine is an internal combustion engine that operates on a thermodynamic cycle known as the Brayton cycle. The principal components consist of an air compressor, a combustion chamber, and a turbo-expander. Atmospheric air is drawn into the compressor and compressed to several times atmospheric pressure. The pressure of the compressed air is further increased by burning it in a confined space (the combustion chamber). The hot, pressurized combustion gases are then expanded through a series of stationary nozzles and rotating turbine wheel and blade assemblies, which results in rotation of the output shaft. The mechanical energy of the shaft rotation is used to drive the gas turbine compressor and gas turbine accessories, as well as the process load such as a generator, pump, or compressor. After giving up energy in expansion, the gases may be discharged directly to the atmosphere or to a heat recovery system. The flow of air, fuel, and combustion products through the gas turbine cycle is shown schematically in Exhibit 3-21. Exhibit 3-21: Basic Brayton Cycle Configuration

Page 36 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

The ideal Brayton cycle consists of the four processes that are shown on the pressure volume and temperature entropy diagrams in Exhibit 3-22. The points identified in Exhibit 3-22 correspond to the similarly labeled points on the turbine in Exhibit 3-21, and they indicate where the processes are occurring. Exhibit 3-22: Thermodynamic Representation of Basic Brayton Cycle

Page 37 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

There are several different variations of the Brayton cycle, and each has a different calculation procedure for determining the efficiency. Therefore a brief overview of cycle types and the governing thermodynamic equations is provided here as background. For additional details, the reader is referred to Saudi Aramcos PEDD course MEX-214. The Brayton cycle for power generation is usually employed in one of the following four configurations: Simple (or open) Regenerative Combined Cycle Steam Injection (Cheng Cycle)

Only the simple cycle and combined cycle configurations are currently used in Saudi Aramco plants. Nevertheless it is important to be aware of the other configurations in case they are used in the future. For the ideal simple cycle, the optimum pressure ratio to produce maximum net output is that for which the compressor discharge and turbine exhaust temperatures are the same. In real life, the pressure ratio at which maximum net work is produced is considerably lower, due to the effect of compressor and turbine inefficiencies and combustion section pressure drop. Consequently, the turbine exhaust temperature is considerably higher than the compressor discharge temperature. For example, the typical exhaust temperature in a heavy duty industrial turbine is about 1000F, while the compressor discharge temperature is only about 650F. Simple cycle energy efficiency can be increased by as much as 25% using a regenerator, which recovers some of the waste heat in the exhaust gas to preheat the compressor discharge air before it enters the combustor, as shown in Figure 3-23. Exhibit 3-23: Regenerative Configuration of Brayton Cycle

Page 38 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Although the regenerative cycle exhibits improved efficiency over the simple cycle, it is not widely used in industrial gas turbine applications because the recuperative heat exchanger required is invariably too large and expensive. In addition to capital cost, the large heat exchanger size offsets one of the main advantages of using a gas turbine, which is its compact size and small footprint. Pressure drops occurring through the heat exchanger further reduce the theoretical improvement in efficiency that could be obtained. The Combined Cycle is a combination of the Brayton cycle and the Rankine cycle, as illustrated schematically in Exhibit 3-24. Heat in the CGT exhaust is used to generate HP steam in a type of boiler called a Heat Recovery Steam Generator (HRSG). The HP steam is used to generate additional power in a condensing steam turbine according to the Rankine cycle. Exhibit 3-24: Combined Cycle Configuration

Because CGT exhaust usually contains about 15% oxygen, it is capable of sustaining combustion. This characteristic can be exploited to generate additional steam and power by employing supplementary firing in duct burners (not shown). Because much of the waste heat in the gas turbine exhaust is used, the efficiency of the combined cycle is considerably greater than that of the simple cycle, as follows: CC = GT + HRSGST - GTHRSGST

Page 39 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

where: GT HRSG ST = = = Gas turbine simple cycle efficiency Heat recovery steam generator efficiency Steam turbine cycle (Rankine cycle) efficiency

Thus, for example, the combined cycle efficiency of a plant that utilizes a 30% efficient gas turbine with a heat recovery steam generator that is 80% efficient and a 32% Rankine cycle efficiency will be: CC = 0.30 + (0.80)(0.32) - (0.30)(0.80)(0.32) = 0.479 = 47.9% This is typical, although advanced cycles have been reported with operating efficiencies in the range of 50-55% even under field conditions. One of the drawbacks of the combined cycle is that the efficiency drops off significantly at part load. Another is that the steam/power ratio is fixed. This makes it unsuitable for processes that have variable steam and power demands. For such applications, the Cheng cycle can be a better solution, as it has the flexibility to produce varying amounts of steam and power to match plant process loads (see Exhibit 3-25). This is accomplished by injecting a portion of the generated HP steam back into the combustion chamber, which is why it is also known as a Steam Injection Gas Turbine (or STIG). Most of the applications have been in the 2-12 MW size range, with process steam demands of 0-100 Klb/h. The drawbacks are (a) the water content of the injected steam is lost up the stack, which can becomes uneconomic when makeup water costs are high, and (b) higher maintenance costs due to increased corrosion of turbine internals. Exhibit 3-25: Schematic of Cheng (STIG) Cycle

It should be emphasized that the thermodynamic cycles described here are for power production only, whether mechanical or electrical. If the turbine exhaust gases are used for process heating, that is called cogeneration, which is covered in section 3.8. 3.7.1 Calculating Cycle Efficiency

The efficiency of the gas turbine is equal to the ratio of turbine power output to fuel heat input, as shown in the following equation:

T TA w net c p (TC TD TB + TA ) TC TD TB + TA = 1 D = = TC TB q c p (TC TB ) TC TB

Page 40 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Since the compression (A to B) and the expansion (C to D) are both isentropic in the ideal cycle of Exhibit 3-22, the pressure ratio for these two processes is the same, viz.

TB PB = TA PA

where: PB PA k = = =

k 1 k

TC TD

Compressor discharge pressure, psia or kPa abs Compressor inlet pressure, psia or kPa abs Cp/Cv = 1.4 for air (assumed to be constant)

The substitution of these variables in the efficiency equation results in the following equation:

= 1 PB TD P A

D k 1 k

T TA PB TA P A

k 1 k

= 1

1 PB P A

k 1 k

Thus, for the ideal simple cycle, the efficiency is a function only of the pressure ratio developed by the gas turbine compressor, and the performance of the compressor is extremely important in overall gas turbine efficiency. In the real simple cycle, turbine efficiency is also dependent on the turbine inlet temperature (Point C), and decreases as turbine inlet temperature increases for a given pressure ratio. Using the formula presented above for the efficiency of an ideal Brayton cycle, the calculated efficiency of an ideal cycle with a pressure ratio of 11.5 would be

= 1

1 11.5

1.4 1 1.4

= 0.5 = 50%

A real cycle that is operating at this pressure ratio might only have an efficiency of 30 32%, because of the following critical differences between the real simple cycle and the ideal cycle: In the real cycle, the compression in the compressor section and the expansion in the turbine are not isentropic due to compressor and turbine inefficiencies. Consequently the real cycle turbo-expander provides less power, and the compressor uses more. Compressor efficiency is especially important. For each 1% decrease in compressor efficiency, there is about a 1.5 to 2% reduction in net power output. Factors such as compressor fouling can rapidly reduce compressor efficiency. Because of the importance of compressor efficiency in overall CGT performance, compressor performance should be routinely monitored during operation so that corrective action, such as a compressor section water wash, can be taken in a timely manner.

Page 41 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

In the real cycle, a pressure drop through the combustion system between the compressor discharge and the turbine inlet occurs, which reduces the available pressure ratio for expansion across the turbine. Due to frictional resistance in the exhaust system ductwork, the gases do not exhaust at atmospheric pressure, but rather at a slightly higher pressure, typically about 4 to 10 inches WC (0.14 to 0.36 psi, or 1 to 2.5 kPa) above atmospheric. This exhaust pressure loss also contributes to a smaller pressure ratio that is available across the turbine. Each 4-inch WC increase in exhaust pressure results in a decrease of about 0.4% in both output power and efficiency. There are also inlet pressure losses due to the ducting and filters, and these losses are typically also about 4 inches WC (0.14 psi, or 1 kPa). Each 4 inch WC of inlet pressure drop results in a decrease of about 1.4% in output and 0.5% in efficiency. The properties of the air and combustion gases, CP and k, are not constant, but rather vary with temperature in a way that makes the real performance worse than the ideal predicted performance.

Exhibit 3-26 compares these differences on a T-S diagram. Exhibit 3-26: Comparison of Ideal and Real Brayton Cycle (Simple)

Page 42 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

The most common parameter for measuring thermal energy efficiency of a power generation cycle is the heat rate, defined as Btu of fuel input (usually HHV) per MW of net power generated. Net power is defined as the gross power output of the expander minus the parasitic power consumption of the air compressor and other essential components. The lower the heat rate, the more thermally efficient the machine.

Heat Rate =

Fuel Input, Btu/h F .HHV = Net Power Output, kw W

It is customary to measure the power output of the turbine in kilowatts (kW) if the turbine is used as a generator drive and horsepower (HP) if it is used as a direct mechanical drive for a pump or compressor. The two measures are related as follows: 1 HP = 0.7457 kW For power generation applications, the same manufacturer is generally responsible for supplying both the gas turbine and the generator as a set, and the power output is specified as the kW output at the generator terminals; therefore, the performance measured also includes the efficiency of the generator. Because large generators are generally very efficient (~ 98%), the measured performance is still mainly that of the gas turbine. For mechanical drive units, the power output is measured as the power delivered at the turbine shaft coupling to the driven piece of equipment, even if the same manufacturer is supplying the driven equipment; therefore, only the performance of the turbine is being measured. Measuring the power output of a gas turbine for a generator drive is straightforward, as the electric metering instrumentation measures electric power directly in kW. For mechanical drive turbines, SAES-K-502, Combustion Gas Turbines, requires that the load coupling be a torquemetering coupling designed for continuous operation. The shaft torque at the coupling is measured in ft-lb (Nm in SI units). The power output is then calculated as follows: HP = where: HP T N = = = shaft horsepower measured torque, ft-lb shaft rotational speed, rpm 2 NT 33,000

Since the theoretical minimum heat rate (at 100% efficiency) of any thermodynamic cycle is 3412.14 Btu/kwh, the thermal efficiency can also be expressed as:

3412.14 Heat Rate

These equations are general, and apply to all power generation cycles.

Page 43 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Industrial gas turbines normally are normally manufactured in certain standard sizes and for certain fixed design parameters, e.g.

Normally, the published design and performance parameters are for ISO conditions, defined to be: Parameter Suction air pressure Suction air temperature Suction air Relative Humidity Inlet pressure losses Exhaust pressure losses Gearbox and transmission losses Mechanical deterioration Assumption 14.7 psia 59F (15C) 60% none none none none

These conditions are almost never found in practice. Therefore the published ISO performance has to be re-rated at actual site conditions. The site ambient conditions to be used in calculating site turbine performance can be found in SAES-A-112, Meteorological and Seismic Design Data. The procedure for re-rating a turbine is described in the next section.

3.7.2

Turbine Performance Index

The recommended energy performance index for the turbine is

Cycle Efficiency Index =

Actual Heat Rate Design Heat Rate at Site Conditions

The actual heat rate over any operating period is easy to determine from measured power output and fuel consumption. The design heat rate at site conditions requires adjustment of the ISO heat rate for changing site conditions of temperature, pressure, humidity, and mechanical conditions, as described below. Since the power produced by a gas turbine is directly related to the mass flow through the machine, anything that reduces the density of the inlet air will reduce the mass flow through the machine and, as a result, the power output.

Page 44 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Inlet air temperature has the greatest impact on gas turbine performance. Gas turbine power output will decrease approximately 0.5 % for each 1F increase in inlet air temperature (0.9% for each 1C). This is because as the air temperature rises, the density of the air decreases, which results in reduced mass flow through the turbine. Also, the pressure ratio developed by the compressor will decrease, which results in a lower expansion ratio available across the turbine. The reduced pressure ratio results in lower turbine efficiency and therefore lower power output. Barometric pressure also has a significant effect on power output. At higher altitudes, the lower barometric pressure means lower air density, which results in reduced mass flow through the turbine and consequent reduction in gas turbine power output. However, there will be no net effect on overall turbine efficiency, as the benefit of lower discharge pressure (to atmosphere) will offset the penalty due lower suction pressure. Humidity variations generally have an insignificant minor effect on gas turbine performance and are usually neglected in performance calculations. For a given total atmospheric pressure, the density of the mixture decreases as the amount of water vapor in the air increases, resulting in reduced mass flow through the turbine and consequently lower power output. An increase in the amount of water vapor increases the heat capacity of the mixture also, which reduces the efficiency of the machine, but only very slightly. Turbine manufacturers provide curves, charts, or other data that show the effects of ambient conditions on gas turbine performance (see Exhibit 3-27 as an example).

Exhibit 3-27: Inlet Temperature Correction Factors (Typical)

Page 45 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Instead of charts, it may be more convenient for computerized calculations to use the following correlations that represent an acceptably accurate approximation for most industrial gas turbines: Temperature Correction factor for Power Output, TCFPWR = 1.22 0.375 (T/100) Temp Correction factor for Heat Rate, TCFHR = 0.9656 + 0.0304 (T/100) + 0.0473 (T/100)2 where T = ambient temperature, F The correction factors for changes in atmospheric pressure, generally due to altitude are more straightforward: Pressure Correction factor for Power Output, PCFPWR = PATM / 14.7 = Altitude (ft) /7500 Pressure Correction factor for Heat Rate, PCFHR = 1.0

Exhibit 3-28: Atmospheric Pressure (Altitude) Correction Factor

Page 46 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

As indicated earlier, the correction factors for humidity variations are very small, but can be estimated either from the chart or the equations given below. Humidity Correction factor for Power Output, HCFPWR = 1.008 - 0.1335 Y Humidity Correction factor for Heat Rate, HCFHR = 0.9976 + 0.373 Y where Y = absolute humidity, lb water vapor / lb dry air

Exhibit 3-29: Ambient Humidity Correction Factors

Obstructions to air flow in the inlet air path (inlet filters, silencers, and duct work) cause the total pressure at the compressor inlet to decrease, which reduces the gas turbine's power output in two ways. First, the lower density reduces the mass flow rate of the working fluid (air). Second, it causes a decrease in compressor discharge pressure, which in turn results in a lower turbine pressure ratio, and therefore power output. The decrease of the compressor inlet pressure also affects the heat rate. A lower turbine pressure ratio reduces thermal efficiency, which increases the heat rate. The magnitude of the inlet pressure correction as a percentage of machine rating will vary, generally being a larger percentage for smaller machines. Typically, a 4 in. H2O decrease in inlet air pressure will cause a 1.7% decrease in the turbine power output, a 0.7% increase in the heat rate, and a 2F increase in the exhaust temperature. Exhibit 3-30 shows the effect of inlet pressure loss on turbine power and heat rate.

Page 47 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

Exhibit 3-30: Inlet Pressure Drop Correction Factors

Page 48 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

In equation form, the correction factors for inlet pressure drop are: DPCFPWR = 1.0 P/250, and DPCFHR = 1.0 + P/625 where DP = inlet pressure losses, inches of water column Flow restrictions in the exhaust system (heat recovery equipment, silencers, and duct work) have a similar effect, for comparable reasons. Exhibit 3-31 shows the effect of outlet pressure loss on turbine power and heat rate; the corresponding equations for correction factors are: DPCFPWR = 1.0 P/600, and DPCFHR = 1.0 + P/590

Exhibit 3-31: Exhaust Pressure Drop Correction Factors

Page 49 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

SAES-K-502 requires a power correction factor for mechanical transmission losses as well, if applicable. A power correction factor will typically be a data item submitted by the turbine vendor for base load. For example, if the reduction gear has a 97.5% mechanical efficiency, the power correction factor would be 0.975. Since the mechanical transmission losses are a direct reduction of output for a given fuel flow, a heat rate correction factor can be calculated simply as the reciprocal of the power correction factor: 1/0.975 = 1.026 in the example cited. The vendors stated ratings are invariably for a brand new gas turbine. Some deterioration of performance occurs naturally with turbine operation due to mechanical wear. To account for this deterioration, SAES-K-502 requires that the following factors be applied: 0.90 for generator drive, both single shaft and multiple shaft units. 0.90 for mechanical drive - multiple shaft units. 0.85 for mechanical drive - single shaft units.

Gas turbine heat rate will also deteriorate (increase) as the turbine ages. The percentage change in efficiency or heat rate will typically be less than the percentage change in power output. No standard correction for heat rate deterioration is specified in SAES-K-502. If the engineer wants to predict future heat rate for the turbine, a percentage change equal to about one-half of the percentage change in output is a reasonable estimate. Finally, if any of the shaft-driven auxiliaries, other than those auxiliaries included in the turbine manufacturers rating, are driven by the turbine, the power they require must be subtracted from the turbine power output. Once all the correction factors have been determined, they are applied as multipliers to the ISO rated conditions, with the exception of the auxiliary power correction. The auxiliary power correction is subtracted from the turbine power output after the other corrections have been applied. Thus, the site rated power is calculated as follows: Site Rated Power = ISO Rated Power x Temperature Correction x Altitude Correction x Humidity Correction x Inlet Losses Correction x Exhaust Losses Correction x Transmission Loss Correction x Deterioration and Contingency Correction - Auxiliary Power

Site Rated Heat Rate = ISO Rated Heat x Temperature Correction x Humidity Correction x Inlet Losses Correction x Exhaust Losses Correction x Transmission Loss Correction x Deterioration and Contingency Correction

Page 50 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

3.8

Cogeneration Systems

An EPI trend chart for the cogeneration system at Abqaiq Plants is presented in Exhibit 3-32 as a sample. Observe that the heat rate is considerably lower than the typical value of 10,000 Btu/kwh for simple cycle gas turbine installations.

Exhibit 3-32: Heat rate Trend Chart for Cogeneration Facilities

Abqaiq Plants CGTs Energy Efficiency

8000 7000 6000 Heat Rate, Btu/kwh 5000 4000 3000 2000 1000 0 Jan. Feb. March April May June July Aug. Sep. Oct. Nov. Dec.

A detailed description of the methodology and instructions on how to calculate the net heat rate will be added during the next revision.

Page 51 of 79

Document Responsibility: CSD/ESD/Energy Systems Unit Issue date: 19 March 2006 Next Update: 19 March 2009

SABP-A-004 Energy Performance Indices

4.0

PROCESS AREA EPIs