Professional Documents

Culture Documents

Ferrocement Joints

Uploaded by

Sulaiman Mohsin AbdulAzizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ferrocement Joints

Uploaded by

Sulaiman Mohsin AbdulAzizCopyright:

Available Formats

INTERNATIONAL JOURNAL OF CIVIL AND STRUCTURAL ENGINEERING Volume 3, No 2, 2012

Copyright 2010 All rights reserved Integrated Publishing services

Research article

ISSN 0976 4399

Naveen G.M1, Suresh G.S2 1- Assistant professor, Department of Civil Engineering, Government Engineering college, Chamarajanagara 2- Professor and Head, Department of Civil Engineering, NIE, Mysore naveengm.gowda@gmail.com doi:10.6088/ijcser.201203013028 ABSTRACT Light weight ferrocement is a composite material consisting of cement-sand mortar (matrix) along with light weight fine aggregate ( In this work foamed blast furnace slag is employed as light weight fine aggregate ) as a replacement of sand in some quantity reinforced with layers of small diameter wire meshes The present work is concentrated on two major aspects, Effect of blast furnace slag on first crack and ultimate strength and Behavior of light weight ferrocement element under monotonic & repeated flexural loading. The first part of the present study has been focused on the effect of blast furnace slag (BFS) on ultimate strength with replacement of slag by 0%, 10%, 20% and 30% and second part of the work focusing the behavior of Light weight ferrocement beam under monotonic load and repeated load with increased load. The results obtained from this work is expected to be useful in determining the strength and ductility of light weight ferrocement beam subjected to similar types of forces and thus will help toward designing ferrocement elements to withstand monotonic and repeated flexural loading. Keywords: Light weight ferrocement, blast furnace slag (BFS), wire mesh. 1. Introduction Light weight Ferrocement is a composite material consisting of cement-sand mortar (matrix) reinforced with layers of small diameter wire meshes and BFS. It consists of closely spaced, multiple layers of mesh or fine rods completely embedded in cement mortar. Usually steel bars are used in addition, to form a steel skeleton, which helps in retaining the required shape of the ferrocement components until the cement mortar hardens. It differs from conventional reinforced concrete primarily by the manner in which the reinforcement is arranged within the brittle matrix. Since its behavior is quite different from that of conventional reinforced concrete in performance, strength and potential applications, it is classed as a separate material. Light weight ferrocement has high resistance against cracking; also many of its engineering properties such as toughness, fatigue against resistance, and impermeability etc. are improved when compared to reinforced concrete. In India, light weight ferrocement is used often because the constructions made from it are better resistant against earthquakes. Earthquake-resistance is dependent on good construction technique and additional reinforcement of the cement. 1.1 Earlier works Investigations related to mechanical properties of ferrocement elements under monotonically with increased loading (Desayi P et. al and Naaman A.E et. al) and fatigues have been 294

Experimental study on light weight ferrocement beam under monotonic and repeated flexural loading

Received on September, 2012 Published on November 2012

Experimental Study on light weight Ferrocement beam under monotonic and repeated flexural loading Naveen G.M, Suresh G.S

reported (Balaguru P. et. al., 1951) and some design procedure has been suggested based on the results of such studies. Both first crack and ultimate moment increases with increasing matrix grade (decreasing w/c ratio)( Walkus B.R,1986) and increasing volume fraction of reinforcement have been reported(Suresh G.S et. al., 2007 ), No information has been available on the response of light weight ferrocement structure subjected to monotonic and repeated loading. In this work matrix grade increase and volume fraction is increasing by taken as 6 layer wire mesh and study the behaviour of light weight ferrocement beam. 2. Objectives of the present work Specific objectives of this paper are as follows: 1. Basic materials testing i.e. Cement, Sand, Blast furnace slag(BFS) and wire mesh. 2. Effect of blast furnace slag on first crack and ultimate strength of the light weight ferrocement beams. 3. Behavior of light weight ferrocement beams under monotonic and repeated flexural loading. 2.1 Materials used and its properties Cement Ordinary Portland cement of grade 43 conforming to IS: 8112-1989, which was stored in a cool and dry place before used. Physical properties of cement is found given in the table1. Table 1: Properties of cement

Physical property Compressive strength 28-days Results obtained 44.10 N/mm2

Sand Fine aggregate used in the light weight ferrocement is taken from Narsipura river bed near Kudala sangama. This river sand is totally free from all impurity and organic matters. Experiment physical properties are obtained is shown in table 2. Table 2: Properties of sand

Fineness modulus Density (kN/m3) Water content (%) Specific gravity 2.85 1.53 0.5 2.61

Blast Furnace Slag (BFS) The blast furnace slag used to replace sand was obtained from Visvesvaraya Iron and Steel Plant, Bhadravathi. It is non-metallic by product of steel manufacturing, consisting essentially of silicates and aluminum silicates of calcium that are developed in a molten condition simultaneously with iron in a blast furnace. It is mixed in different proportions in mortar. The chemical composition of this BFS given by the supplier and the physical properties are found by experiment as shown in table 3 and table 4. 295

International Journal of Civil and Structural Engineering Volume 3 Issue 2 2012

Experimental Study on light weight Ferrocement beam under monotonic and repeated flexural loading Naveen G.M, Suresh G.S

Table 3: Properties of BFS

Fineness modulus Density (kN/m3) Water content (%) Specific gravity Grading zone 3.58 1.12 0.05 2.41 I

Table 4: Chemical Properties of BFS

Constituents SiO2 Al2O3 CaO MgO S Others Compositions (%) 30-33 20-22 33-35 9-10 Traces 3-5

Water Ordinary potable drinking water free from organic matter, silt, oil,sugar,chloride and acidic material was used for mixing. Wire mesh Galvanised woven square meshes of 6 x 20 guage size (0.55 mm average wire diameter at 4.17 mm nominal spacing) have been used. The tensile strength of the mesh is found as 435 .86 N/mm2.

Figure 1: View of wire mesh 3. Casting and testing of specimens Casting specimens

296

International Journal of Civil and Structural Engineering Volume 3 Issue 2 2012

Experimental Study on light weight Ferrocement beam under monotonic and repeated flexural loading Naveen G.M, Suresh G.S

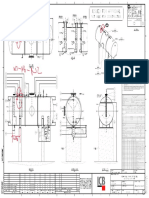

Parameters considered in this study are the percentage of sand replacement and mesh wires. Four percentage of replacing sand by light weight aggregate(L.W.A) viz.,0%,10%,20% and 30% by weight and mesh wires in terms of number of mesh layers per specimen 6 layers is selected by previous experimental study. A total of 24 ferrocement specimens have been cast. 6 specimens were cast at a time of dimension as shown in figure 2 and 4 and using of teak wood moulds as shown in figure 2.The layer of mesh was held in position at required spacing in the moulds by means of suitable aluminum spacers, which were removed while casting. In each casting about 3 mortar cubes 70.6 of mm side were also cast as control specimens.Three cubes were tested for their compressive strength after testing each set of specimens.

Figure 2: Teak wood mould Table 5: Light Weight Ferrocement Beam details and varying parameters

No. of mesh layers Percentage replacement of B.F.S. of 1:2 cement mortar 0 LMN61-0% LMN62-0% LMN63-0% LRP61-0% LRP 62-0% LRP 63-0% 10 LMN61-10% LMN62-10% LMN63-10% LRP 61-10% LRP 62-10% LRP 63-10% 20 LMN61-20% LMN62-20% LMN63-20% LRP 61-20% LRP 62-20% LRP 63-20% 30 LMN61-30% LMN62-30% LMN63-30% LRP 61-30% LRP 62-30% LRP 63-30%

Figure 3: Details of Reinforcement in Specimen 297

International Journal of Civil and Structural Engineering Volume 3 Issue 2 2012

Experimental Study on light weight Ferrocement beam under monotonic and repeated flexural loading Naveen G.M, Suresh G.S

Testing of Specimen

Figure 4: Details of Demec and Dial Gauge points specimens In each set three specimens were cast and they were tested under monotonic loading. A jack is used for testing specimens under monotonic loading as shown in figure 3. Two points loading was applied at one fourth span points, ie at 150mm from supports using a mechanical screw jack of 100kN capacity through a distribution steel high beam. Applied load was measured using a proving ring of 50 KN capacities. Deflections and strains on mortar surfaces at various levels across the depth of the specimens in pure flexure zone were recorded during testing of ferrocement elements under monotonic and repeated flexural loading. Deflections were measured at mid points. For measuring deflections at these points, dial gauges of 25mm range with least count of 0.01mm were used. During testing, these dial gauges were reset when the deflection exceeded the range of gauges. Strain on mortar surface of specimens were measured by demec (demountable mechanical) gauge over demec points fixed to the mortar surface with an adhesive. Surface strains were measured on top and bottom edges of the specimens and at other levels of specimen across the depth.Strain were measured on both the faces of specimen over gauge length of 200mm and least count of demec gauge was 1x10-5. 4. Result and discussion Behavior of average of three specimens for each percentage of slag replacement under monotonic load, represented by the load-deflection curves show in figure 5

Figure 5: Monotonic Load (N) vs Deflection (mm) 298

International Journal of Civil and Structural Engineering Volume 3 Issue 2 2012

Experimental Study on light weight Ferrocement beam under monotonic and repeated flexural loading Naveen G.M, Suresh G.S

For all the specimens under monotonic loading, the load deflection curves show generally two portions. The first portion is a rising portion up to first crack load and second is horizontal portion near ultimate showing an increase in deflection.

Figure 6: Failure of specimens in 10% replacement of BFS Behavior of average of three specimens for each percentage of slag replacement under repeated load, represented by the load deflection curves show in figure 7

Figure 7: Repeated Load (N) vs Deflection (mm) 299

International Journal of Civil and Structural Engineering Volume 3 Issue 2 2012

Experimental Study on light weight Ferrocement beam under monotonic and repeated flexural loading Naveen G.M, Suresh G.S

Form all the specimens under repeated loading, the load-deflection curves shown in figure 7, the 10 % of slag replacement specimens carry a more load compare to other replacements & it is felt that increase in stiffness in the initial cycles may be due to the closure of shrinkage cracks present in the specimens before loading. behavior of average of three specimens for each percentage of slag replacement under monotonic load & repeated loading represented by the moment curvature curves show in figure 8.

Figure 8: Moment vs Curvature

300

International Journal of Civil and Structural Engineering Volume 3 Issue 2 2012

Experimental Study on light weight Ferrocement beam under monotonic and repeated flexural loading Naveen G.M, Suresh G.S

Form all the specimens under monotonic and repeated loading, the moment curvature curves shown in figure 8, the 10 % of slag replacement specimens carry a more moment compare to other replacements. 5. Conclusion Based on the experimental investigations the following conclusions were drawn,

1. It can be observed that, the first crack and ultimate strength increases up to 10% replacement of sand, and then decreases with the increased percentage of sand replacement. 2. The light weight ferrocement specimens having increased wire mesh (Volume fraction)could sustain greater number of repetitions, compared to the plain light weight ferrocement specimens because of their greater strain carrying capacity. 3. Light weight ferrocement beams have good moment of resistant under both monotonic & repeated loading. 4. The mesh wires are found to be more effective in increasing the margin between first crack and ultimate flexural strengths. 6. References 1. Balaguru P, Naaman A.E, and Shah S.P., (1951), Analysis and Behavior of Ferrocement in Flexure, Journal of structural division, Proc.of ASCE, 103, p 1937 2. Suresh G.S, Sheshaprakash M.N and Gangadharappa B.M., (2007) Experimental studies on Blast Furnace Slag (BFS) Ferrocement under monotonic compression, ISSN-0973-1334, National journal of technology, 1(3). 3. Desayi P and Jacob K.R, Strength and behavior of Ferrocement in tension and flexure, Proceedings of the symposium, Modern trend in civil engineering, Roorkee, India, pp 274-279 4. 4.Naaman A.E. and Shah S.P, Tensile tests of ferrocement , The American concrete institute journal, 68(9), pp 693-698. 5. Walkus B.R, (1986), Testing and test methods for ferrocement Journal of ferrocement, 16(1), pp 27-37. Acknowledgement One of the author Naveen G.M wish to thanks students, Dept of Civil Engineering, GECC for his help during work. Naveen G.M also acknowledges the fortunate to have blessing and affection of my parents Made gowda.S and Mahadevamma.S, bother Mahesh and sisters Rani.M and Rajini.M support and encouragement during this project work.

301

International Journal of Civil and Structural Engineering Volume 3 Issue 2 2012

You might also like

- 03 Pipe Supports and Pipe RestraintsDocument19 pages03 Pipe Supports and Pipe RestraintsballisnothingNo ratings yet

- FOOTING STRESSESDocument6 pagesFOOTING STRESSESSulaiman Mohsin AbdulAziz100% (1)

- Design For Torsion and Shear According To ACI-318-99Document1 pageDesign For Torsion and Shear According To ACI-318-99Sulaiman Mohsin AbdulAzizNo ratings yet

- Pipelines Design CriteriaDocument16 pagesPipelines Design CriteriaAnonymous 3kDy7eNo ratings yet

- Calculating The Cost of Stone (Random Rubble) Masonry Work./rate Analysis of Random Rubble (Stone) Masonry WorkDocument3 pagesCalculating The Cost of Stone (Random Rubble) Masonry Work./rate Analysis of Random Rubble (Stone) Masonry WorkHari Prasath80% (5)

- Report On Steel Fiber Reinforced ConcreteDocument44 pagesReport On Steel Fiber Reinforced Concretevishalgore100% (1)

- Design of Monolithic Corbels and Brackets According To Aci 318 - 99Document1 pageDesign of Monolithic Corbels and Brackets According To Aci 318 - 99Sulaiman Mohsin AbdulAzizNo ratings yet

- Curing ConcreteDocument10 pagesCuring ConcreteShariq KhanNo ratings yet

- AAB - Example Problems HandoutDocument217 pagesAAB - Example Problems HandoutM Refaat Fath100% (1)

- Magoosh GRE Math Formula EbookDocument33 pagesMagoosh GRE Math Formula EbookLavina D'costa100% (1)

- Figure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2Document5 pagesFigure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2met-calcNo ratings yet

- المدخل لعمل المساحة في الطرق - Introduction to roadDocument29 pagesالمدخل لعمل المساحة في الطرق - Introduction to roadehssan8743% (7)

- Compressive Stress Strain Relationship of Steel Fibre-Reinforced Concrete at Early AgeDocument14 pagesCompressive Stress Strain Relationship of Steel Fibre-Reinforced Concrete at Early AgesonugaurNo ratings yet

- Abu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlateDocument11 pagesAbu Altemen Et Al., 2017, Punching Shear Behavior of Small SFRC Flat PlatefaridNo ratings yet

- Experimental Study of Flexure and Impact On Ferrocement SlabsDocument5 pagesExperimental Study of Flexure and Impact On Ferrocement Slabsadwaid paloliNo ratings yet

- High-Strength Flowable Mortar Reinforced by Steel Fiber: M. Ramli, E. Thanon DawoodDocument7 pagesHigh-Strength Flowable Mortar Reinforced by Steel Fiber: M. Ramli, E. Thanon DawoodvietpineNo ratings yet

- 2017 - FC2015 - Effect of The Loading Rate On Fibre Reinforced Concrete BeamsDocument7 pages2017 - FC2015 - Effect of The Loading Rate On Fibre Reinforced Concrete BeamsJuhász KPNo ratings yet

- Paper 7Document9 pagesPaper 7RakeshconclaveNo ratings yet

- Experimental Investigation of Steel Fiber Reinforced ConcetreDocument6 pagesExperimental Investigation of Steel Fiber Reinforced ConcetreJETLYNo ratings yet

- Cob03 0310Document11 pagesCob03 0310abdollahzadehNo ratings yet

- Experimental study enhances concrete flexural strength with small steel fibersDocument9 pagesExperimental study enhances concrete flexural strength with small steel fibersSal SaadNo ratings yet

- Copy ManuscriptDocument20 pagesCopy ManuscriptSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inNo ratings yet

- Fracture Energy of Steel Fiber-Reinforced ConcreteDocument18 pagesFracture Energy of Steel Fiber-Reinforced ConcreteMilanNo ratings yet

- Energy Absorption Capacity of Composite BeamsDocument6 pagesEnergy Absorption Capacity of Composite BeamsvijayapandimNo ratings yet

- Siva Kumar 2007Document6 pagesSiva Kumar 2007akaiNo ratings yet

- Effect of Steel Fiber and Glass Fiber On Mechanical Properties of ConcreteDocument6 pagesEffect of Steel Fiber and Glass Fiber On Mechanical Properties of ConcreteIJSTENo ratings yet

- Structural Faults & Repair (Masonry Walls SRG)Document12 pagesStructural Faults & Repair (Masonry Walls SRG)Kausalya AravindNo ratings yet

- Effect of Lathe Waste Review 1Document22 pagesEffect of Lathe Waste Review 1dreamboy87No ratings yet

- Ferrocement Column BehaviourDocument4 pagesFerrocement Column BehaviourPushpakaran PillaiNo ratings yet

- Biaxial Bending of SFRC Slabs Is Conventional Reinforcement NecessaryDocument15 pagesBiaxial Bending of SFRC Slabs Is Conventional Reinforcement NecessaryDan MaceNo ratings yet

- Shear Behaviour of RC BEAMDocument14 pagesShear Behaviour of RC BEAMSridhar PeriasamyNo ratings yet

- Fiber reinforced concrete beams shear strengthDocument7 pagesFiber reinforced concrete beams shear strengthChris LumyNo ratings yet

- Abaqus AnalysisDocument12 pagesAbaqus AnalysisMohan BhalmeNo ratings yet

- Flexural Behavior of ECC Hollow Beams Incorporating Different Synthetic FibersDocument13 pagesFlexural Behavior of ECC Hollow Beams Incorporating Different Synthetic Fibersnagham tariqNo ratings yet

- A Study On Steel Fiber Reinforced Normal PDFDocument5 pagesA Study On Steel Fiber Reinforced Normal PDFZindagiDeeNo ratings yet

- Seismic Behaviour of Fibre Reinforced Concrete Frames: G Campione, L La Mendola and G ZingoneDocument8 pagesSeismic Behaviour of Fibre Reinforced Concrete Frames: G Campione, L La Mendola and G Zingonecivilstructure.singhbrothersNo ratings yet

- Cement & Concrete Composites - Reduced Shear Reinforcement in Fiber Reinforced Concrete BeamsDocument9 pagesCement & Concrete Composites - Reduced Shear Reinforcement in Fiber Reinforced Concrete BeamsAdi PrasetyoNo ratings yet

- Effects of Fibre Geometry and Volume Fraction On The Flexural Behaviour of Steel-Fibre Reinforced ConcreteDocument7 pagesEffects of Fibre Geometry and Volume Fraction On The Flexural Behaviour of Steel-Fibre Reinforced ConcreteHrishav SinghNo ratings yet

- Materials Today: Proceedings: S. Sangeetha, N. Sakthieswaran, O. Ganesh BabuDocument5 pagesMaterials Today: Proceedings: S. Sangeetha, N. Sakthieswaran, O. Ganesh BabuShaik Abdul RaheemNo ratings yet

- Composites: Part B: Z.L. Wang, Z.M. Shi, J.G. WangDocument6 pagesComposites: Part B: Z.L. Wang, Z.M. Shi, J.G. WangPriyanka JainNo ratings yet

- Physical Properties of Steel Fiber Reinforced Cement Composites Made With Fly AshDocument9 pagesPhysical Properties of Steel Fiber Reinforced Cement Composites Made With Fly AshAnonymous POUAc3zNo ratings yet

- An Investigation of Steel Fiber Reinforced Concrete With Fly AshDocument5 pagesAn Investigation of Steel Fiber Reinforced Concrete With Fly AshmaheshNo ratings yet

- Strength Behavior of Bamboo Reinforced CDocument9 pagesStrength Behavior of Bamboo Reinforced CBRYLLE KYLLE OIDEMNo ratings yet

- Test 468561165465431Document6 pagesTest 468561165465431uvezfGRNo ratings yet

- Geopolymers Repair Concrete Beams REINFORCDocument6 pagesGeopolymers Repair Concrete Beams REINFORCGiordano BrunoNo ratings yet

- Argamassa 13 - 2011 - AllicheDocument10 pagesArgamassa 13 - 2011 - AllicheAmanda ZottisNo ratings yet

- Experimental Model for Steel Fibre Concrete SlabDocument24 pagesExperimental Model for Steel Fibre Concrete Slabdisha847No ratings yet

- Ferrocement ApplnsDocument7 pagesFerrocement ApplnsPushpakaran PillaiNo ratings yet

- 0125 3395 32 4 419 424 PDFDocument6 pages0125 3395 32 4 419 424 PDFRommel Dave TejanoNo ratings yet

- Analysis and Design of Ferrocement Panels An Experimental StudyDocument8 pagesAnalysis and Design of Ferrocement Panels An Experimental StudyNick CordetaNo ratings yet

- An Experimental Investigation of Steel CDocument4 pagesAn Experimental Investigation of Steel CnomadiczapatoNo ratings yet

- Fatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, GermanyDocument6 pagesFatigue Behaviour of Concrete in Tension: Institute of Concrete Structures and Building Materials, Karlsruhe, GermanyRamchandraNo ratings yet

- CconfinedDocument7 pagesCconfinedchaitanya krishnaNo ratings yet

- Toughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessDocument4 pagesToughness Study On Fly Ash Based Fiber Reinforced Concrete: Originalresearch Open AccessvitusstructuresNo ratings yet

- Study On FlexuralDocument8 pagesStudy On FlexuralRafael CuaNo ratings yet

- Crack Growth Resistance of Thin Mortar Layers With Hybrid Fiber ReinforcementDocument18 pagesCrack Growth Resistance of Thin Mortar Layers With Hybrid Fiber Reinforcementwerdubob8944No ratings yet

- Impact of Crack Width On Bond Confined and Unconfined RebarDocument10 pagesImpact of Crack Width On Bond Confined and Unconfined RebarbrahmabulNo ratings yet

- FIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanDocument8 pagesFIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanIvan KotNo ratings yet

- Performance of Steel Fiber Reinforced Self Compacting ConcreteDocument5 pagesPerformance of Steel Fiber Reinforced Self Compacting ConcreteInternational Journal of computational Engineering research (IJCER)No ratings yet

- Application of A Self-Compacting Ultra-High-Performance Fibre-Reinforced Concrete To Retrofit RC Beams Subjected To Repeated LoadingDocument13 pagesApplication of A Self-Compacting Ultra-High-Performance Fibre-Reinforced Concrete To Retrofit RC Beams Subjected To Repeated LoadingAhmad AdibNo ratings yet

- Flexural Behaviour of Reinforced Fibrous Concrete BeamsDocument10 pagesFlexural Behaviour of Reinforced Fibrous Concrete BeamsAndrade AntonioNo ratings yet

- Recron FibresDocument12 pagesRecron FibresAnonymous kRIjqBLk100% (1)

- 7th Int'l Conf on Civil Eng Strengthen thin concrete with hempDocument7 pages7th Int'l Conf on Civil Eng Strengthen thin concrete with hempKenan KajosevicNo ratings yet

- Experimental Study On The Shear Strength of Recycled Aggregate Concrete BeamsDocument12 pagesExperimental Study On The Shear Strength of Recycled Aggregate Concrete BeamsIsabela KotelakNo ratings yet

- Post-Cracking Behaviour of Steel and Macro-Synthetic Fibre-Reinforced ConcretesDocument10 pagesPost-Cracking Behaviour of Steel and Macro-Synthetic Fibre-Reinforced ConcretesDan MaceNo ratings yet

- Experimental Study of Steel Fiber Prestressed Concrete Beam For Shear, Bending and TorsionDocument16 pagesExperimental Study of Steel Fiber Prestressed Concrete Beam For Shear, Bending and TorsionChaitali patilNo ratings yet

- Experimental Investigation On Hybrid Fiber Reinforced ConcreteDocument5 pagesExperimental Investigation On Hybrid Fiber Reinforced ConcreteRakeshNo ratings yet

- Response of Ferrocement Confinement On Behavior of Square RC Short ColumnDocument10 pagesResponse of Ferrocement Confinement On Behavior of Square RC Short ColumnPANKAJ TAMBAKHENo ratings yet

- Chapter One: 1.1 GeneralDocument1 pageChapter One: 1.1 GeneralSulaiman Mohsin AbdulAzizNo ratings yet

- Lincoln Wastewater SystemDocument4 pagesLincoln Wastewater SystemSulaiman Mohsin AbdulAzizNo ratings yet

- Calculus For BeginnersDocument21 pagesCalculus For BeginnersJay LawsonNo ratings yet

- L6 FoundationsDocument10 pagesL6 FoundationsAntonio MontanaNo ratings yet

- Water For ConcreteDocument6 pagesWater For Concreteazim_malpekar303No ratings yet

- ADAPT-PT Non Prismatic DesignDocument2 pagesADAPT-PT Non Prismatic DesignMahmoud Hamdy BadawyNo ratings yet

- Ferro Cement 11Document11 pagesFerro Cement 11Cage PrabhuNo ratings yet

- Structuro W437-Formerly RXDocument2 pagesStructuro W437-Formerly RXSulaiman Mohsin AbdulAziz0% (1)

- Decentralized Wastewater Treatment Highlights BrochureDocument20 pagesDecentralized Wastewater Treatment Highlights BrochureSulaiman Mohsin AbdulAzizNo ratings yet

- World Atlas JanDocument0 pagesWorld Atlas JanMasbooksNo ratings yet

- Reinforcement WorkDocument20 pagesReinforcement WorkSulaiman Mohsin AbdulAzizNo ratings yet

- Font MapDocument5 pagesFont MapFuat ArslanNo ratings yet

- Adobe Acrobat Reader Help: Opening PDF DocumentsDocument9 pagesAdobe Acrobat Reader Help: Opening PDF Documentsanon-537450No ratings yet

- ETABSDocument5 pagesETABSSulaiman Mohsin AbdulAzizNo ratings yet

- ADAPT-PT Non Prismatic DesignDocument2 pagesADAPT-PT Non Prismatic DesignMahmoud Hamdy BadawyNo ratings yet

- ADAPT-Modeler PT Design ProcessDocument2 pagesADAPT-Modeler PT Design ProcessAnonymous ELujOV3No ratings yet

- IntroductionDocument1 pageIntroductionSulaiman Mohsin AbdulAzizNo ratings yet

- 39 TransportationDocument7 pages39 Transportationmpe1No ratings yet

- About A-PDF WatermarkDocument1 pageAbout A-PDF WatermarkSulaiman Mohsin AbdulAzizNo ratings yet

- Test Taker GRE Verbal Reasoning SamplesDocument11 pagesTest Taker GRE Verbal Reasoning SamplesShreyas GoṏnayNo ratings yet

- Reinforcement Steel SpecificationsDocument1 pageReinforcement Steel SpecificationsSulaiman Mohsin AbdulAzizNo ratings yet

- Shear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsDocument2 pagesShear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsSulaiman Mohsin AbdulAziz100% (1)

- All Sheets ConcreteDocument72 pagesAll Sheets ConcreteSulaiman Mohsin AbdulAziz100% (1)

- Soil classification and properties from geotechnical engineering problemsDocument11 pagesSoil classification and properties from geotechnical engineering problemsApple AterradoNo ratings yet

- Bridge EngineeringDocument4 pagesBridge EngineeringSudheer KumarNo ratings yet

- KNS3643 Tutorial 1 1617 1Document2 pagesKNS3643 Tutorial 1 1617 1Nur Hazirah SadonNo ratings yet

- AcousticDocument10 pagesAcousticKurnianda Dian WulandariNo ratings yet

- Natural fibers in concrete compositesDocument2 pagesNatural fibers in concrete compositesAdriane Kelly CagampanNo ratings yet

- Work Background: Site Engineer (2 Years & 2 Months)Document3 pagesWork Background: Site Engineer (2 Years & 2 Months)Manish JangidNo ratings yet

- EE2 Unit 2Document32 pagesEE2 Unit 2abel shimelesNo ratings yet

- Conduit NormsDocument275 pagesConduit NormsDinesh JounNo ratings yet

- DARSHANA TRADING CO. BILL OF MATERIALSDocument16 pagesDARSHANA TRADING CO. BILL OF MATERIALSsamyak munotNo ratings yet

- Carcd 161201130828Document21 pagesCarcd 161201130828Ganesh Peketi100% (1)

- BEARING CAPACITY OF SHALLOW FOUNDATIONS BY TERZAGHI THEORYDocument13 pagesBEARING CAPACITY OF SHALLOW FOUNDATIONS BY TERZAGHI THEORYramNo ratings yet

- Fluid Mechanics Course OverviewDocument2 pagesFluid Mechanics Course OverviewParamvir GuliaNo ratings yet

- Excavation Safety - Ver2014Document14 pagesExcavation Safety - Ver2014Loysa MataNo ratings yet

- Steel-Concrete Composite Slab Design Using ExcelDocument9 pagesSteel-Concrete Composite Slab Design Using ExcelTasnuva NazmulNo ratings yet

- Assessment of Groundwater Potential Zones Using GisDocument9 pagesAssessment of Groundwater Potential Zones Using Gisla guslandNo ratings yet

- PSL BrochureDocument10 pagesPSL BrochurekevincoperNo ratings yet

- Mechanical Behaviour of Materials 2014Document47 pagesMechanical Behaviour of Materials 2014bananaNo ratings yet

- Bending Stresses in Beams ExplainedDocument13 pagesBending Stresses in Beams ExplainedIsuru Udayanga NanayakkaraNo ratings yet

- Mec-02-3223-13-04-R03 - B (V-1324) (Adf Comments) PDFDocument1 pageMec-02-3223-13-04-R03 - B (V-1324) (Adf Comments) PDFAgustín DomínguezNo ratings yet

- Passive Solar Design BasicsDocument5 pagesPassive Solar Design Basicspsn_kylm100% (1)

- Design of Formwork for Concrete StructuresDocument30 pagesDesign of Formwork for Concrete StructuresSantosoNo ratings yet

- Piling Work Rates and MeasurementsDocument4 pagesPiling Work Rates and MeasurementsArif NofiyantoNo ratings yet

- Tufail MaboodDocument3 pagesTufail MaboodMickey DalbeheraNo ratings yet

- Rail&Rail Joint: C) IRS-52kg-SAILDocument2 pagesRail&Rail Joint: C) IRS-52kg-SAILPravanjan SahooNo ratings yet

- ApendiDocument28 pagesApendiMarvvvNo ratings yet