Professional Documents

Culture Documents

Havc Underground Piping Mos

Uploaded by

Yusuf Ziya DilbazOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Havc Underground Piping Mos

Uploaded by

Yusuf Ziya DilbazCopyright:

Available Formats

Date: Revision:

12.12.2009 0 37

METHOD STATEMENTS

MS No:

AL FATEH UNI ERSIT! "RO#E$T %FU"& $AM"US ' A TRI"OLI( LI)!A MATH. * STAT. FA$ULT! + $39,2009 -ENERAL * $HEMI$AL STORA-ES +$.0,2009 METHOD STATEMENTS H A$ UNDER-ROUND "I"INSUMMAR!:

The work covered by this Method Statement consists of providing all tools, labour, equipment, accessories, scaffolding and materials and performing all operations in connection with the pipe joining method and inspection of Hvac underground piping installation as detailed.

$ONTENTS:

. !ntroduction ". Materials and Tools ". #Materials "."#Tools $. %uality &ontrol '. (pplication '. # )elding process '."# *oint Set installation method +. &ooling system e,ternal lines testing

1. INTRODU$TION

This method statement is written to appropriate (l -ateh .niversity /roject 0-./1 &onstruction Specifications for Mathematics and Statistics -aculty and 2eneral and &hemical Storage 3uildings. This method statement includes all technical specifications of Hvac underground piping works in accordance with the requirements of (l -ateh .niversity /roject 0-./1 standards.

Page 1 of 5

Date: Revision:

12.12.2009 0 37

METHOD STATEMENTS

MS No:

2. MATERIALS AND TOOLS

2.1 Mate/ia0s:

-or the scope of this procedure, material is pre#insulated underground steel pipes as defined specs. The pipe material approved by 4ngineer shall be used. # 5imka underground preinsulated pipe shall be used cooling system e,ternal lines.. "# *oints on pipes and fittings shall be welded. -abricated fittings shall be used. 2.2 Too0s: -iller material 0/oliol and isocyonate1 )elding machine Metal 3rush -lame gun

3. 1UALIT! $ONTROL

&ontractor6s %uality &ontrol 4ngineer shall check the conditions of materials and components of each delivery, in particular to ensure that7 # # # # # # # Materials and components are clean, undamaged and dry. /lants and tools are in a clean and serviceable condition at least every week. Suitability of background provided for the roof isolation to be applied prior to first application. &orrect storage of materials at least every week is being checked regularly. (ll packaged materials shall be delivered in factory#sealed, unopened, and unbroken bags, packages, containers or bundles. 3ulk materials shall be delivered in clean transport vessels, free of contaminates. (ll application shall be done in accordance with manufacturer6s requirements.

.. A""LI$ATION

..1 2e03in4 5/o6ess The pipe ends shall be beveled properly and cleaned foreign particulars . The pipes that will be joining together shall be welded according to previously submitted method of statement for welding. ..2 #oint Set insta00ation 7et8o3 Ste5 1:

Page 2 of 5

Date: Revision:

12.12.2009 0 37

METHOD STATEMENTS

MS No:

Suitable *oint set shall be provided for each diameter of pre#insulated pipes.That sets were delivered site for each required diameter . Ste5 2: 8equired equipment shall be provided. These are flame gun0torch1,tools for surface abrasion, googles and etc.

Ste5 3: 4,posed steel and protective sleeve shall be cleaned and pre heated.

Ste5 .: /rotective sleeve shall be fi,ed over casing pipe. The hole thet on the sleeve shall be located upward.

Ste5 9: )rap the shrink sleeve around the casing pipe, ensuring the appropriate overlap.

Ste5 :: The sleeve shall be fi,ed with band.

Page 3 of 5

Date: Revision:

12.12.2009 0 37

METHOD STATEMENTS

MS No:

Ste5 7: .sing the appropriate flame gun, begin at the centre of the sleeve and heat around the pipe.

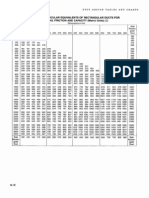

Ste5 ;: T8e 5o0<=/et8ane >oa7 s8a00 ?e =se3 to ins=0ate t8e 5i5e. T@o 3i>>e/ent 68e7i6a0 s8a00 ?e s=550ie3 in 0iA=i3 >o/7 in Ba/s. T8e a7o=nts a/e 4iven in t8e ?e0o@ ta?0e a66o/3in4 to 5i5e 3ia7ete/.

pipe diameter <5 + <5"> <5"+ <5$" <5'> <5+> <5=+ <5@> <5 >> <5 "+ <5 +> <5">> <5"+> <5$>> <5$+> <5'>>

#OINT SETS /9:;9:0whi !S9&;(5(T408 te1 ed1 =' >" ?$ '? ? '= ' @" > A= $> ">@ =" "+? ">" $"$ $ '?@ $++ +=@ ' > =+= =$+ > = >'' =A> A$ @AA '?A "$?+ @A= $>>"

9. $OOLIN- S!STEM ECTERNAL LINES TESTIN&ooling system operation pressure is $ bar. Subject piping system to a hydrostatic

test pressure, which at every point in the system is not less than .+ times the design Page 4 of 5

Date: Revision:

12.12.2009 0 37

METHOD STATEMENTS

MS No:

pressure. The cooling system e,ternal line shall be tested '.+#+ bars as per

specification for duration of " hours. (ny leakage shall be eliminated.

Page 5 of 5

You might also like

- Sample Report Dilapidation CommercialDocument12 pagesSample Report Dilapidation CommercialhfzhnNo ratings yet

- Differences Between ASTM A706 and A615Document4 pagesDifferences Between ASTM A706 and A615อภิรักษ์ มานะกิจศิริสุทธิ100% (6)

- HVAC Duct Leakage Testing and Sealing Best PracticesDocument68 pagesHVAC Duct Leakage Testing and Sealing Best PracticesRyte EchanoNo ratings yet

- Instructions For Welding The Cat Advansys™ Adapters On Excavator and Wheel Loader S (0679, 6001, 6800)Document1 pageInstructions For Welding The Cat Advansys™ Adapters On Excavator and Wheel Loader S (0679, 6001, 6800)arfa ujiantoNo ratings yet

- Work Methodology For Installation of Service Water Piping Under GroundDocument2 pagesWork Methodology For Installation of Service Water Piping Under GroundKomputershengalNo ratings yet

- Dasco 19-26Document8 pagesDasco 19-26Ahmed AzadNo ratings yet

- External Building DrainageDocument11 pagesExternal Building Drainagevelayuthan_s9168No ratings yet

- A Comparison of Modern Methods of Bathroom ConstruDocument11 pagesA Comparison of Modern Methods of Bathroom Construel wahabi omarNo ratings yet

- Bilt Middle East LLC: Inspections and Testing PlanDocument1 pageBilt Middle East LLC: Inspections and Testing Plansarmad009No ratings yet

- Refrigerant Piping Work1Document13 pagesRefrigerant Piping Work1Le Manh HieuNo ratings yet

- TS-02 Ventilation Fans - Toilet & BasementDocument11 pagesTS-02 Ventilation Fans - Toilet & BasementPraveen KumarNo ratings yet

- LP Gas CalculationDocument4 pagesLP Gas Calculationlutfi awnNo ratings yet

- York - AHU - Selection PDFDocument172 pagesYork - AHU - Selection PDFAhmed NabilNo ratings yet

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- Acoustic Calculation of Ventilation SystemsDocument49 pagesAcoustic Calculation of Ventilation SystemsHari Babu DharmavarapuNo ratings yet

- مشروع توزيع الكهرباء لمستشفى كاملDocument280 pagesمشروع توزيع الكهرباء لمستشفى كاملhunkbsrNo ratings yet

- MEP Testing and Commissioning ManagementDocument6 pagesMEP Testing and Commissioning ManagementJon TyackeNo ratings yet

- Installation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreDocument25 pagesInstallation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreScherraine Khrys CastillonNo ratings yet

- Domestic - MTD SilentDocument6 pagesDomestic - MTD SilentVan Vinh NguyenNo ratings yet

- Method Statement For HoistingDocument5 pagesMethod Statement For HoistingKAY UNANo ratings yet

- Regulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainDocument10 pagesRegulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainSarathNo ratings yet

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlNo ratings yet

- Drain Pump DaikinDocument2 pagesDrain Pump DaikinJonathan GanNo ratings yet

- Bin DR C4 MS 000 0 MS0001 PDFDocument126 pagesBin DR C4 MS 000 0 MS0001 PDFniteen_mnnitNo ratings yet

- Mr. Slim System Pre-Commissioning and Installation Check ListDocument4 pagesMr. Slim System Pre-Commissioning and Installation Check Listamerico zambrano contrerasNo ratings yet

- 230313-MEP Client RequirementDocument19 pages230313-MEP Client RequirementSelcen yeniçeriNo ratings yet

- DCC T&C Ms-PlumbingDocument11 pagesDCC T&C Ms-Plumbing721917114 47100% (1)

- Cooling Tower Makeup Water EstimationDocument3 pagesCooling Tower Makeup Water EstimationMuhammad NaeemNo ratings yet

- Final Training Manual - SYSTEMDocument3 pagesFinal Training Manual - SYSTEMsarmad009No ratings yet

- Duct Specifications TableDocument16 pagesDuct Specifications Tablehasanadel88100% (1)

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document7 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- A. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasDocument4 pagesA. Load Values, in Water Supply Fixture Units (Wsfu) For All AreasIbrahim A. HameedNo ratings yet

- Dasco 1-9Document9 pagesDasco 1-9Ahmed AzadNo ratings yet

- Preparation of HVAC Ducting LayoutDocument6 pagesPreparation of HVAC Ducting Layoutarunima04No ratings yet

- FI NotesDocument1,069 pagesFI NotesparadoxendazzlingNo ratings yet

- Part E - 2 - (HVAC) Engineering DesignDocument69 pagesPart E - 2 - (HVAC) Engineering Designkeya2020No ratings yet

- Air Volumes in Ducts in Cubic Feet Per Minute (CFM)Document1 pageAir Volumes in Ducts in Cubic Feet Per Minute (CFM)mahaveenNo ratings yet

- AHU - Pre-Commissioning Checklist FormDocument5 pagesAHU - Pre-Commissioning Checklist FormMarvin ArinueloNo ratings yet

- DD Electric Driven Fire Pump SpecificationDocument16 pagesDD Electric Driven Fire Pump SpecificationNurcahyo Djati WNo ratings yet

- Installation, Testing - Flushing of Firefighting SystemDocument7 pagesInstallation, Testing - Flushing of Firefighting SystemWahid Husain100% (1)

- Cleaning and Passivation of Chilled Water PipingDocument13 pagesCleaning and Passivation of Chilled Water PipingtonylyfNo ratings yet

- Green Oasis Mall Water Pump CalculationsDocument19 pagesGreen Oasis Mall Water Pump CalculationsKashif SiddiquiNo ratings yet

- DESCRIPTIONS Garbage ChuteDocument12 pagesDESCRIPTIONS Garbage ChuteYasser Fathy AlyNo ratings yet

- Chilled Water Piping Schematic DetailsDocument1 pageChilled Water Piping Schematic DetailsShabab AnwerNo ratings yet

- Check List For Installation of Ahus, Fcus and FansDocument2 pagesCheck List For Installation of Ahus, Fcus and FansUmair LiaqatNo ratings yet

- Vinod Desu: Work ExperienceDocument3 pagesVinod Desu: Work ExperienceNEB MEPNo ratings yet

- Method of Statement For Precommissioning & Commissioning of Chiller Plant ManagerDocument3 pagesMethod of Statement For Precommissioning & Commissioning of Chiller Plant Managervin ssNo ratings yet

- ASHRAE 90.1 Lighting Power Allowance UpdatesDocument2 pagesASHRAE 90.1 Lighting Power Allowance UpdatesMohammad UmairNo ratings yet

- Diffuser Sizing GuidelinesDocument1 pageDiffuser Sizing Guidelinessyed mustafa aliNo ratings yet

- Ventilation Design Guide for Electrical RoomsDocument8 pagesVentilation Design Guide for Electrical RoomsphilipyongNo ratings yet

- Design Calculation Sheet: Project No. DateDocument14 pagesDesign Calculation Sheet: Project No. DatePhanhai KakaNo ratings yet

- Project Name: Al Ruwais Housing Complex 663 Villas: ElectricalDocument3 pagesProject Name: Al Ruwais Housing Complex 663 Villas: Electricalabdallah salama100% (1)

- Particular HVACDocument49 pagesParticular HVACAdnan Khan100% (1)

- FAHU SubmittalDocument62 pagesFAHU SubmittalEngr.MmosaadNo ratings yet

- AHU ChecklistDocument11 pagesAHU ChecklistRavi SharmaNo ratings yet

- Pressure Drop Calculation Combined Steel and Mesonery Duct PDFDocument3 pagesPressure Drop Calculation Combined Steel and Mesonery Duct PDFsmcsamindaNo ratings yet

- AHU CHW Coil ConnectionDocument1 pageAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- Phenolic Duct SpecificationDocument2 pagesPhenolic Duct Specificationpsn_kylmNo ratings yet

- HVAC Installation Bill of QuantitiesDocument5 pagesHVAC Installation Bill of QuantitiesRajeshNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDocument6 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusNo ratings yet

- SmartTank Master SpecDocument13 pagesSmartTank Master Speccarlos030476No ratings yet

- Method Statement For Laboratory Compressed Air and Vacuum SystemDocument8 pagesMethod Statement For Laboratory Compressed Air and Vacuum SystemAhmed SherifNo ratings yet

- E2 IELTS - 20 Speaking TopicsDocument10 pagesE2 IELTS - 20 Speaking TopicsYusuf Ziya DilbazNo ratings yet

- Louver Material Submittal ReviewDocument42 pagesLouver Material Submittal ReviewYusuf Ziya DilbazNo ratings yet

- Ielts Task 2 RyanDocument89 pagesIelts Task 2 RyanBuddhi Ekanayaka100% (3)

- Phrasal Verbs for Understanding Complex SentencesDocument7 pagesPhrasal Verbs for Understanding Complex SentencesYusuf Ziya DilbazNo ratings yet

- Colt Fire CurtainDocument8 pagesColt Fire CurtainYusuf Ziya DilbazNo ratings yet

- Fire Fighting Equipment Sample SubmittalDocument6 pagesFire Fighting Equipment Sample SubmittalYusuf Ziya DilbazNo ratings yet

- A Mechanical Engineer S Handbook by ONGC PDFDocument303 pagesA Mechanical Engineer S Handbook by ONGC PDFshujad77No ratings yet

- Sprinkler SizingDocument4 pagesSprinkler SizingYusuf Ziya DilbazNo ratings yet

- Expansion Joints, r1 (11!11!2018)Document3 pagesExpansion Joints, r1 (11!11!2018)Yusuf Ziya DilbazNo ratings yet

- TROX TVR Terminal UnitsDocument31 pagesTROX TVR Terminal UnitsYusuf Ziya DilbazNo ratings yet

- MOS Pipe WeldingDocument3 pagesMOS Pipe WeldingYusuf Ziya DilbazNo ratings yet

- External Corner Pipe Chamber DetailsDocument1 pageExternal Corner Pipe Chamber DetailsYusuf Ziya DilbazNo ratings yet

- General Specification For Main Laying Contracts-2005 PDFDocument40 pagesGeneral Specification For Main Laying Contracts-2005 PDFYusuf Ziya Dilbaz100% (2)

- Mertes Round DuctDocument80 pagesMertes Round DuctYusuf Ziya DilbazNo ratings yet

- HVAC Systems Duct Design (Circular Equivalents)Document2 pagesHVAC Systems Duct Design (Circular Equivalents)Yusuf Ziya Dilbaz100% (2)

- Smacna LeakageDocument10 pagesSmacna Leakagekothat82No ratings yet

- Roof Terracing: Construction and Materials-Iii (Rar - 302)Document24 pagesRoof Terracing: Construction and Materials-Iii (Rar - 302)jashndeep100% (1)

- Gearbox DN500-600 PN10Document1 pageGearbox DN500-600 PN10Victor Hugo Urrieta MoraNo ratings yet

- Narrative ReportDocument4 pagesNarrative ReportMichael Adrian Magbanua100% (1)

- PengaruhPenambahanSeratPolypropylenepadaKuat PDFDocument10 pagesPengaruhPenambahanSeratPolypropylenepadaKuat PDFNick YogaNo ratings yet

- Midterm ExamDocument2 pagesMidterm ExamNissan UyNo ratings yet

- Materials and Methodology 3.1 Materials Used 3.1.1 Sisal FiberDocument13 pagesMaterials and Methodology 3.1 Materials Used 3.1.1 Sisal FiberFortune FireNo ratings yet

- Astm B209-06Document29 pagesAstm B209-06tuongNo ratings yet

- Metals and AlloysDocument45 pagesMetals and AlloysStephen SimanjuntakNo ratings yet

- Modeling Slump Flow of Concrete Using Second-Order Regressions and Artificial Neural NetworksDocument7 pagesModeling Slump Flow of Concrete Using Second-Order Regressions and Artificial Neural NetworksLiliana ForzaniNo ratings yet

- All About CanningDocument12 pagesAll About CanningGayathri Fernando100% (1)

- Is 2269.2006-Hex Soc Hd. Cap ScrewDocument20 pagesIs 2269.2006-Hex Soc Hd. Cap ScrewdombipinNo ratings yet

- Chemical Composition AluminiumDocument3 pagesChemical Composition AluminiumEmreNo ratings yet

- Plastic Manufacturing ProcessesDocument6 pagesPlastic Manufacturing ProcessesHimanshu TiwariNo ratings yet

- Copper Tube HandbookDocument96 pagesCopper Tube HandbookAnonymous S9qBDVkyNo ratings yet

- Unistryt Pipe Supports CatalogueDocument14 pagesUnistryt Pipe Supports CatalogueMehedi ChowdhuryNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 35291 396040301Document135 pagesT Proc Notices Notices 040 K Notice Doc 35291 396040301Engr Nissar KakarNo ratings yet

- Masterair 721 v1Document2 pagesMasterair 721 v1tally3tallyNo ratings yet

- Basic Civil and Mechanical Engineering Unit 1 Construction Materials Support NotesDocument9 pagesBasic Civil and Mechanical Engineering Unit 1 Construction Materials Support NotesA.R. Pradeep KumarNo ratings yet

- Polyflor Global Approved AdhesivesDocument24 pagesPolyflor Global Approved AdhesivesRatna Ayu K 201102No ratings yet

- Guide to Prestressed Concrete DesignDocument140 pagesGuide to Prestressed Concrete Designindian royalNo ratings yet

- Polymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeDocument26 pagesPolymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeJim LivingstonNo ratings yet

- PPG AtlanticaDocument2 pagesPPG AtlanticaVincent BrassierNo ratings yet

- Assessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012Document39 pagesAssessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012abhi_luvme03100% (1)

- Scrapzone Price ListDocument2 pagesScrapzone Price Listshantanukulkarni007No ratings yet

- Thermal & Moisture ProtectionDocument14 pagesThermal & Moisture Protectionmarc naganoNo ratings yet

- Katalog KarbosanDocument224 pagesKatalog KarbosanTonggo R ManikNo ratings yet

- QuikTrak Design and Installation ManualDocument26 pagesQuikTrak Design and Installation ManualPeter KimbelNo ratings yet