Professional Documents

Culture Documents

C 8

Uploaded by

Marshall BravestarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C 8

Uploaded by

Marshall BravestarCopyright:

Available Formats

EM 1110-2-2607 31 Jul 95

Chapter 8 Channel Protection

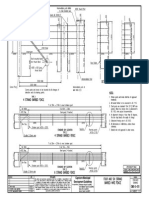

8-1. General Stabilization of banks and protection of the stream bed will usually be required for the channel at the dam site. In addition, channel realignment and/or training structures may be required. The specific types of channel protection and stabilization will depend on water velocities, wash from waves, water level fluctuations, soil characteristics, stream alignment, sediment transport, wind velocities, and navigation approach conditions. This chapter will outline, in general terms, the overall requirements for channel protection. More details and guidance are contained in EM 1110-2-1611. 8-2. Erodible Slopes and Stream Bed a. Erodible slopes. When geotechnical investigations and studies indicate that the stream banks at the dam site will not be stable under project operating conditions, it will be necessary to protect and stabilize these slopes so that they will not erode and displace into the stream or fail internally. b. Stream bed. The stream bed immediately upstream and downstream of a concrete dam will require protection to prevent displacement of bed material that could undermine the structures and result in failure of the dam and/or appurtenant structures. c. Scour protection during construction. Each construction scheme must be carefully analyzed to ensure that scour protection is provided where necessary. Successful protection has consisted of timber (lumber) mattresses or riprap, both with and without filter blankets, depending on the soil types and flow conditions. Physical and numerical models have been useful in developing scour protection designs. For cofferdams within the river channel, the riverward corner of the cofferdam is usually the critical point of scour potential. Wing extensions are sometimes provided to minimize the scour potential. 8-3. Typical Materials a. Slope protection materials. For channel slope protection, the following materials are used most often: riprap stone placed on either a sand-and-gravel filter blanket or a filter cloth, soil-cement paving, concrete paving, steel pile cells filled with stone, and articulated concrete mattresses. To be effective, the slope protection system

material must be sized with a designed thickness and must be provided with drainage blankets or pipes so that water can pass through the protection without displacing the underlying support material. In most cases, the type of material chosen for slope protection will depend on the availability of suitable natural material in the project area, which is likely to be least costly. b. Streambed protection materials. For streambed protection, the following materials are used: graded stone, derrick stone, concrete paving, trench-filled (stone) revetment, and lumber mattress. The materials chosen for streambed protection will depend on their availability and on specific design and maintenance requirements during the life of the project. 8-4. Dikes Dikes for bank protection and stabilization can consist of stone, timber pile clusters, or piling with stone fill. These dikes are designed to divert currents away from the bank or improve the alignment and velocity of the currents along the bank. Training dikes can be very beneficial in controlling sediment deposition in the upstream and downstream lock approaches and in diverting spillway discharges away from the lower lock approach. See Plate 7. Wing dikes (also referred to as wing dams or spur dikes) placed approximately normal to the channel or lock approach have proven to be suitable for these purposes. Various types of dikes are described in EM 1110-2-1611. 8-5. Upstream Channel a. Channel slopes. Just as the bank slope must be designed for stability, so the slope surfaces must be protected. Stone riprap on a sand-and-gravel blanket or on filter cloth can be used. Other forms of slope protection, such as articulated concrete mats, concrete paving, and soil-cement blankets, have also been used. The type of protection material chosen will depend on economy of usage and the ability of the material to satisfy design requirements for the life of the project with minimum maintenance costs. b. Streambed. A low-head navigation dam will usually require streambed protection upstream of the spillway for a minimum distance equal to the head on the spillway crest. The protection is usually stone; however, concrete aprons have been used. Refer to EM 1110-21605 for details. High-head dams will not usually require upstream streambed protection because of the height of the spillway crest above the streambed. The upstream

8-1

EM 1110-2-2607 31 Jul 95 streambed of a navigation dam with a ported upper guide wall adjacent to the dam spillway will require stone protection at the ported openings to prevent scour of the bed material due to water velocities caused by spillway discharges. This bed protection is especially important for soil-supported, pile-supported, or caisson-supported guide walls. Refer to Plates 3, 5, and 17. 8-6. Downstream Channel a. Channel slopes. Treatment and protection of downstream channel slopes will be similar to that for upstream channel slopes. However, the thicknesses and the extent of this protection will usually be determined by using the results of the hydraulic model test. Refer to Plates 3 and 5 for more details. b. Design conditions for streambed downstream of gated spillway. The streambed area immediately downstream of the stilling basin will require a special hydraulic investigation to determine the amount and extent of streambed scour protection needed to counteract the forces created by the spillway discharges. The spillway gate operation design conditions are outlined in ER 1110-2-1458. For a streambed composed of sound rock, no protection may be needed. However, for a readily erodible streambed, several extensive layers of graded rock may be required. Gradation layers, size of stones, and extent of protection are usually designed by hydraulic engineers using guidance contained in EM 1110-2-1605. EM 1110-2-1605 covers scour protection experiences at existing Corps projects and repair recommendations for these projects. EM 1110-2-1601 and EM 1110-2-1901 contain further design information relative to riprap and filter designs.

8-2

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Carbon Capture TechnologyDocument17 pagesCarbon Capture TechnologyNadya AmaliaNo ratings yet

- The Essential Guide To Eurocodes Transition Part-1Document33 pagesThe Essential Guide To Eurocodes Transition Part-1limegreens100% (4)

- Subdivision Project ProcessDocument16 pagesSubdivision Project Processal bentulanNo ratings yet

- Volume-3 Technical Specification and Geological Report Part-1Document344 pagesVolume-3 Technical Specification and Geological Report Part-1Kinzang Dendup100% (1)

- Environmental Studies MicroprojectDocument26 pagesEnvironmental Studies Microproject224 Shinde Ketan80% (5)

- Swimming PoolsDocument19 pagesSwimming PoolsRoshni George100% (2)

- Engtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceDocument32 pagesEngtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceMuhammad ArshadNo ratings yet

- 5 Tests That Could Save Your Life: 30 Worst Foods in AmericaDocument2 pages5 Tests That Could Save Your Life: 30 Worst Foods in AmericaMarshall BravestarNo ratings yet

- Cork Expansion Joint Filler Astm-D 1752 Type Ii: DescriptionDocument2 pagesCork Expansion Joint Filler Astm-D 1752 Type Ii: DescriptionMarshall BravestarNo ratings yet

- BestPracticeGuide4 Issue3 ElectricalDocument20 pagesBestPracticeGuide4 Issue3 ElectricalMarshall BravestarNo ratings yet

- Train Like You Mean It: The Ultimate Performance TreadmillDocument2 pagesTrain Like You Mean It: The Ultimate Performance TreadmillMarshall BravestarNo ratings yet

- CMDG General AllDocument9 pagesCMDG General AllMarshall BravestarNo ratings yet

- Ltu Ex 07239 SeDocument97 pagesLtu Ex 07239 SeMarshall BravestarNo ratings yet

- Diesel Be Stupid CatalogueDocument15 pagesDiesel Be Stupid CatalogueSaberAYarNo ratings yet

- 04 MomentDistribution PDFDocument88 pages04 MomentDistribution PDFSimran Radheshyam SoniNo ratings yet

- Foreword The Need For Land EvaluationDocument74 pagesForeword The Need For Land EvaluationMarshall BravestarNo ratings yet

- 1foundationsDocument10 pages1foundationsMarshall BravestarNo ratings yet

- 2 Design of Reinforce Concrete BeamsDocument60 pages2 Design of Reinforce Concrete BeamsTshepiso NthiteNo ratings yet

- Evolution Magazine May 2010Document20 pagesEvolution Magazine May 2010Marshall BravestarNo ratings yet

- Structural Engineers: The Institution ofDocument1 pageStructural Engineers: The Institution ofMarshall BravestarNo ratings yet

- NMTPFDocument19 pagesNMTPFMarshall BravestarNo ratings yet

- Welcome To TrinidadRealtor - ComkkDocument1 pageWelcome To TrinidadRealtor - ComkkMarshall BravestarNo ratings yet

- Portal FramesDocument31 pagesPortal FramesMarshall BravestarNo ratings yet

- DocDocument20 pagesDocMarshall BravestarNo ratings yet

- Digester FrontDocument1 pageDigester FrontMarshall BravestarNo ratings yet

- Structural Engineers: The Institution ofDocument4 pagesStructural Engineers: The Institution ofMarshall BravestarNo ratings yet

- Structural Engineers: The Institution ofDocument2 pagesStructural Engineers: The Institution ofMarshall BravestarNo ratings yet

- ReadmeDocument2 pagesReadmeMarshall BravestarNo ratings yet

- Structural Engineers: The Institution ofDocument1 pageStructural Engineers: The Institution ofMarshall BravestarNo ratings yet

- STDocument12 pagesSTMarshall BravestarNo ratings yet

- STDocument3 pagesSTMarshall BravestarNo ratings yet

- STDocument22 pagesSTMarshall BravestarNo ratings yet

- STDocument2 pagesSTMarshall BravestarNo ratings yet

- STDocument6 pagesSTMarshall BravestarNo ratings yet

- STDocument11 pagesSTMarshall BravestarNo ratings yet

- Treatment of Drilling Fluids Wastewater by ElectrocoagulationDocument7 pagesTreatment of Drilling Fluids Wastewater by ElectrocoagulationEko Ariyanto Wong PlembangNo ratings yet

- Trichy GROUND WATER PDFDocument23 pagesTrichy GROUND WATER PDFDharani NachiyarNo ratings yet

- 4 Yr PDFDocument98 pages4 Yr PDFAbinash MandalNo ratings yet

- APPENDIX B - Pump Station Design GuidelinesDocument7 pagesAPPENDIX B - Pump Station Design GuidelinesLe DucNo ratings yet

- SmartCityPlan Patna PDFDocument92 pagesSmartCityPlan Patna PDFAvi AchyutNo ratings yet

- Additel ADT927 BrochureDocument1 pageAdditel ADT927 BrochureAgus Be PeNo ratings yet

- To Civil Engineering: Dr. S. K. Prasad Assistant Professor in Civil Engineering S. J. College of Engineering MysoreDocument98 pagesTo Civil Engineering: Dr. S. K. Prasad Assistant Professor in Civil Engineering S. J. College of Engineering Mysoresanthosh55555No ratings yet

- Water (H2O)Document22 pagesWater (H2O)Julio CortezNo ratings yet

- Brady Reed Issues Management Report Everglades Restoration AEC 4031Document10 pagesBrady Reed Issues Management Report Everglades Restoration AEC 4031api-302891763No ratings yet

- NCERT Notes Types of Clouds Geography Notes For UPSCDocument4 pagesNCERT Notes Types of Clouds Geography Notes For UPSCSHUEAB MUJAWARNo ratings yet

- Fujipress - JDR 7 5 9 - PreviewDocument2 pagesFujipress - JDR 7 5 9 - Previewgivazahara0% (1)

- AR Architecture and Planning: Part A: CommonDocument2 pagesAR Architecture and Planning: Part A: Commonrajat charayaNo ratings yet

- Julita P1Document1 pageJulita P1Lhyenmar HipolNo ratings yet

- Ginasul46n Msds PDFDocument4 pagesGinasul46n Msds PDFhuiNo ratings yet

- Wedeco Portfolio Appl O3 UVDocument72 pagesWedeco Portfolio Appl O3 UVadmin DeptNo ratings yet

- Ce353 Part 3 HydrologyDocument24 pagesCe353 Part 3 HydrologyAnnie TheExplorerNo ratings yet

- Establishment and Operational Management of The Slaughterhouse-Abattoir PDFDocument15 pagesEstablishment and Operational Management of The Slaughterhouse-Abattoir PDFSalman ZafarNo ratings yet

- Annex V Discharge Requirements For Website 3 PDFDocument1 pageAnnex V Discharge Requirements For Website 3 PDFMehmet AliNo ratings yet

- Household Water Treatment MethodsDocument2 pagesHousehold Water Treatment Methodstony frankNo ratings yet

- CBSE Class 4 Science Question Paper Set ADocument3 pagesCBSE Class 4 Science Question Paper Set APreetiNo ratings yet

- SalakamcheruvuDocument3 pagesSalakamcheruvuVijay AnandNo ratings yet

- MIWC 2019 - Brochure 1.2Document9 pagesMIWC 2019 - Brochure 1.2Sim Khoon AunNo ratings yet

- Tecline Catalog - EnglishDocument27 pagesTecline Catalog - EnglishMTNo ratings yet

- CVEN4705 Lec Week8 T32020Document57 pagesCVEN4705 Lec Week8 T32020Cynthia OuyangNo ratings yet

- Earth Subsystem-Earth ScienceDocument29 pagesEarth Subsystem-Earth Sciencekenneth lo67% (3)