Professional Documents

Culture Documents

TQM Tools & Tech

Uploaded by

P K Senthil KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TQM Tools & Tech

Uploaded by

P K Senthil KumarCopyright:

Available Formats

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

TOTAL QUALITY MANAGEMENT TOOLS AND TECHNIQUES: THE QUEST FOR AN IMPLEMENTATION ROADMAP1 Seyed Mohammadbagher Jafari* Graduate School of Management Universiti Putra Malaysia, 43400 UPM, Selangor, Malaysia E-mail: smjafari@eng.upm.edu.my Mostafa Setak Industrial Engineering Department, K.N.Toosi University of Technology, No. 7, 4 th floor, Pardis st., Molla Sadra Ave., Vanak sq., Tehran, Iran. E-mail: Setak@kntu.ac.ir

*Corresponding Author

ABSTRACT Total Quality Management (TQM) has been recognized and used during the last decades by organizations all over the world to develop a quality focus and improve organizational performance. TQM is necessary to reach competitiveness; however, the way to achieve this is not easy. TQM consists of a wide range of concepts regarding to quality. Most of the studies in TQM implementation focus on the concept of TQM. There are few studies in the literature that directly suggest an implementation roadmap of TQM tools and techniques and TQM implementation is still problematic for many organizations. In order to respond to the quest for a clear implementation methodology, this study tries to suggest an implementation roadmap for TQM tools and techniques based on DMAIC methodology. The proposed roadmap includes 6 steps and its developmental sequences start with steps that begin from process documentation and lead to accomplishment of more complex and modern quality tools and techniques that guide organization to a high level of institutionalized quality.

Keywords: Total Quality Management, TQM, Implementation Roadmap, TQM Tools, TQM Techniques, DMAIC methodology

INTRODUCTION Quality management has long been recognized as a source of competitive advantage and one of the most important drivers of global competition (Prajogo & Sohal, 2003). A few researchers tried to identify the impact of TQM implementation on firms performances in both industrialized (Ahire, Waller, & Golhar, 1996; Prabhu, Appleby, & Yarrow, 2000; Prajogo & Sohal, 2003) and developing countries (Arumugam, Ooi, & Fong, 2008; Das, Paul, Swierczek, & Laosirihongthong, 2006). Punnakitikashem et al. (2010) stated that the majority of these studies concluded that TQM positively impacts firm performances depending on the degree of its implementation. In spite of this, TQM implementation is still problematic for many organizations (Hansson & Klefsj, 2003) and yet firms report less than optimal results (Jayaram, Ahire, & Dreyfus, 2010)

This article financially supported by the Islamic Union of Iranian Students Association (in Malaysia).

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

Total Quality Management (TQM) is a management strategy aimed at embedding awareness of quality in all organizational processes (Siddiqui, Haleem, & Wadhwa, 2009). TQM defined by the Deming Prize Committee of the Union of Japanese Scientists and Engineers (JUSE, 2010) as: a set of systematic activities carried out by the entire organization to effectively and efficiently achieve the organizations objectives so as to provide products and services with a level of quality that satisfies customers, at the appropriate time and price. There are many proposed tools and techniques to achieve the TQM promises. Generally, a technique can be considered as a number of activities performed in a certain order to reach the values (Hellsten & Klefsj, 2000). On the other hand, tools sometimes have statistical basis to support decision making or facilitate analysis of data. Bunney and Dale (1997) reported that on the subject of quality management, there are many studies that agree on the vital role of the use and selection of quality management tools and techniques to support and develop the quality improvement process. However, they emphasized that organizations do encounter a range of difficulties in their use and application of quality management tools and techniques. It is hardly surprising that research and theory in TQM implementation are still at a very early stage in the West (Dale, Y.-Wu, Zairi, Williams, & Van Der Wiele, 2001; Sitkin, Sutcliffe, & Schroeder, 1994) and the gap in the TQM implementation literature is obvious. Most of the studies in TQM implementation focus on the concept of TQM. There are very few studies in the literature that directly suggest an implementation roadmap of TQM tools and techniques and usually they are not a complete roadmap. Therefore, in this research, firstly, the literature on the current proposed tools and techniques for TQM implementation reviewed and then based on the result of this review, a comprehensive roadmap for TQM implementation proposed that covers all the cited tools and techniques. LITERATURE REVIEW Researchers and practitioners have acknowledged the need to understand causal relationships among various elements of total quality management (Ahire & Ravichandran, 2002). Bunney and Dale (1997) stated that the introduction of the quality management tools and techniques depend, to a certain extent, on the phase of the improvement process. The introduction of TQM can take place in three phases (I) diagnosis and preparation, (II) management focus and commitment, and (III) intensive improvement. The diagnostic and preparation phase of TQM requires the introduction of a number of fact finding tools, some of which are cost of quality and Departmental Purpose Analysis (DPA). The management focus and commitment phase requires the use of data analysis tools (e.g. cause & effect analysis, flow charts and Pareto analysis) to identify problem areas, quantify their effects and prioritize the need for solution. During the intensive improvement phase the introduction of more complex tools (e.g. statistical process control (SPC) and failure mode and effects analysis (FMEA)) help to facilitate company-wide improvement. Bunney and Dale (1997)also categorized TQM tools and techniques in two different ways, first in five categories regarding to their application and second in seven categories regarding to the function that they can be used. Table 1 shows the TQM tools regarding to their application.

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

Table 1: Analysis of Application of Tools and Techniques (Bunney & Dale, 1997)

The following table shows TQM tools and techniques within each function of a company operation. Table 2: Analysis of Tools and Techniques Used within each Function (Bunney & Dale, 1997)

In another study, Hellsten and Klefsj (2000) suggested a new definition for TQM. Their study indicates that TQM can be defined as a management system, which consists of three interdependent units, namely core values, techniques and tools. The idea is that the core values must be supported by techniques, such as process management, benchmarking, and customer focused planning, or improvement teams, and tools, such as control charts, the quality house or Ishikawa diagrams, in order to be part of a culture. They emphasized that this systematic definition will facilitate for organizations the understanding and implementation of TQM. Therefore, the implementation work should begin with the acceptance of the core values that characterizing the culture of organization. The next step is to continuously choose

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

techniques that are suitable for supporting the selected values. Ultimately, suitable tools have to be identified and used in an efficient way in order to support the chosen techniques. Figure 1 illustrates this definition (The techniques and tools in the figure are just examples and not a complete list).

Figure 1: TQM as a Management System Consists of Values, Techniques and Tools (Hellsten & Klefsj, 2000) According to Hellsten and Klefsj (2000) the basis for the culture of the organization are the core values. Another component is techniques, i.e. ways to work within the organization to reach the values. A technique consists of a number of activities performed in a certain order. The important concept here is that TQM really should be looked on as a system. The values are supported by techniques and tools to form a whole. We have to start with the core values and ask: Which core values should characterize our organization? When this is decided, we have to identify techniques that are suitable for our organization to use and support our values. Finally, from that decision the suitable tools have to be identified and used in an efficient way to support the techniques (see Figure 2).

Figure 2: TQM Implementation Steps (Hellsten & Klefsj, 2000) Hellsten & Klefsj (2000) indicated, as an example, Benchmarking should not be used without seeing the reason for using that technique and an organization should not use just control charts without seeing the core value behind the choice and a systematic implementation roadmap of the techniques and tools. It is, of course, important to note that a particular technique can support different core values and the same tool can be useful within many techniques.

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

In another work, Scheuermann, Zhu, & Scheuermann (1997) looked at 15 frequently used TQM tools and classified them according to qualitative TQM tools and quantitative TQM tools. Qualitative tools consist mainly of subjective inputs, which often do not intend to measure something of a numerical nature. Quantitative tools, on the other hand, involve either the extension of historical data or the analysis of objective data, which usually avoid personal biases that sometimes contaminate qualitative tools. They categorized TQM tools as below: Qualitative tools: flow charts; cause-and-effect diagrams; multi-voting; affinity diagram; process action teams; brainstorming; election grids; task lists. Quantitative tools: Shewart cycle (PDCA); control charts; scatter diagrams; Pareto charts; sampling; run charts; histograms.

In another study, Ahmed and Hassan (2003) introduced a different method. They indicated that from the point of presentation of data on a process, tools can be classified as graphical tools and flow diagrams. In the graphical tools class there are histogram, stem-and-leaf diagrams, line charts, bar charts, pie charts, run or time series charts, control charts, and Pareto diagrams, and in the flow diagrams class there are flow diagrams, process flow charts, cause-and-effect diagrams, and tree diagrams. Tools like check sheets, location plots, and data tables can be used to facilitate data collection and summarization. For analyzing quality management aspects, these basic quality control tools are powerful and acceptable. Force-field analysis, nominal group technique, affinity diagram, interrelationship diagram, tree diagram, matrix diagram, prioritization matrices, process decision program chart (PDPC), and activity network diagram (PERT, CPM, arrow diagram, AoN) are some of the relevant management tools associated with quality management that can be applied to generate and treat soft data. Dale (2003) listed these tools under seven management tools M7, including affinity diagrams, relation diagrams, systematic diagrams, matrix data analysis, PDPCs, and arrow diagrams. Rao et al. (1996) categorized brainstorming, affinity diagrams (or structured brainstorming), process potential index Cp, process performance index Cpk, Taguchi's loss function, and design of experiment (DoE) as advanced tools. Ahmed and Hassan (2003)indicated that a systematic approach can produce very significant benefits in the long run. Deming's plan-do-study/check-act (PDSA/PDCA) is an excellent technique in monitoring and problem solving for continuous quality improvement where any brilliant ideas of individuals can be accommodated. However, a good number of other tools and techniques have to be invited to apply this properly. In other words, it integrates a few essential tools and techniques. In fact, without a strategic disposition, any tool or technique should not be taken in isolation for use. Figure 3 depicts the systematic use of various tools in different operational stages.

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

Figure 3: Steps in Application of Deming's PDCA Technique and Associated Tools (Ahmed & Hassan, 2003) In another study in this area, Fazel & Salegna (1996) tried to group major TQM tools and techniques into six major categories as determined by their primary area of implementation focus: 1) customer-based; 2) management-based; 3) employee-based; 4) supplier-based; 5) process-based; and 6) product-based. Table 3 shows this classification. The above mentioned categories are described below (Salegna & Fazel, 1996): 1) Customer-based strategies should be the focal point of every TQM programme, around which all other strategies are formulated. Customer satisfaction is only likely to be achieved and maintained when the customer plays an active role in the organizations process of quality improvement. Major techniques used to accomplish this are customer needs analysis, customer surveys and quality function deployment. 2) Management-based strategies are also extremely important for the successful implementation of TQM. TQM initiatives are not likely to succeed without strong leadership and support from top management. The goals and the benefits of

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

implementing TQM must clearly be communicated by top management to the workforce. The alignment of the reward structure with the goals of the organization is also vital to the organizations success in achieving these goals. Table 3: TQM Tools and Techniques Categories (Salegna & Fazel, 1996) Implementation Strategy 1) Customer-based Tools and Techniques Customer survey Customer need analysis Quality function deployment Communication Leadership Empowerment Cross-training Quality circles Quality teams Brainstorming Nominal group technique Supplier training Supplier documentation Supplier certification Quality improvement process Just-in-time Lead time reduction Benchmarking Quality cost analysis Quality audits Quality assessment Process documentation ISO 9000 Work flow analysis Benchmarking Design of experiments Concurrent engineering Product flow analysis

2) Management-based reward structure 3) Employee-based teamwork

4) Supplier-based supplier research

5) Process-based statistical process control

6) Product-based standardization

3) Employee-based strategies provide a means of increasing the participatory role of workers. Strategies such as empowerment, teamwork and cross-training may result in employees having increased decision making authority, greater job responsibilities, and increased motivation and sense of pride in their work. Quality programmes may also benefit from employee suggestions resulting from other group activities including quality teams, quality circles, the nominal group technique and brainstorming. 4) Supplier-based strategies provide a means of increasing an organizations likelihood of having suppliers who are reliable and willing to work towards the organizations goals of providing a quality product. Given the trend towards companies reducing the number of suppliers and cultivating long-term relationships with the remaining ones, these strategies are particularly important today.

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

5) Process-based strategies focus on improving processes by reducing waste, defect rates, cycle time, and providing feedback on the performance of the process. Benchmarking, SPC and JIT are some of the most popular techniques employed by companies to achieve these goals. 6) Product-based strategies are directly focused on the quality of the product, its physical characteristics and its manufacturability. THE PROPOSED ROADMAP FOR TQM IMPLEMENTATION According to Hammer & Goding (2001) DMAIC methodology provides a structured framework for solving business problems by assuring correct and effective process execution. This methodology has 6 phases in which, in the case of Six Sigma, teams take total employee involvement approaches to complete the cycle of process management and use self-diagnosis skills to fulfill the goals of each phase. The business will naturally reach the Six Sigma quality, when all key processes within a business are completed for each of these five each phases (Byrne, 2003). Figure 4 shows the DMAIC methodology.

Figure 4: DMAIC Methodology (Hammer & Goding, 2001) However, in the case of TQM, the factors that affecting TQM tools selection are many and it should be considered before any implementation plan. These factors are: the availability of resources within the company to facilitate tools successful introduction; the objective of using quality management tools such as solving a simple problem or reaching to a high level in quality; the product characteristics; and current product and process improvement or new product introduction. Some tools or techniques appear simple over others in their development and interpretation. The purpose of each of them is distinct and problem specific. Certainly, not all tools or techniques are required in one firm. SPC tools are very basic and can be applied for both short and long term goals. Some of the tools and techniques are commonly (even frequently) used, for example Pareto chart, cause & effect diagram, histogram or quality control charts for quality performance monitoring and improvement, and some others can be used less frequently (such as Benchmarking, QFD). Some of the techniques are used, for example, QFD, FMEA, and design for manufacturability (DfM), in the design and development

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

processes. Different control charts and process capability indices are used in controlling manufacturing processes (Ahmed & Hassan, 2003). The fundamental slogan of TQM is "Do-it-right-the-first-time (DIRFT)". For this, quality is required to be introduced at the design level. The tools that have direct linkage with the introduction of new products are DoE, QFD, FMEA, and fault tree analysis (Spring, McQuater, Swift, Dale, & Booker, 1998). Regarding to functions and activities of a manufacturing firm the following tools and techniques are suitable for implementing TQM (Ahmed & Hassan, 2003): a) in new product introduction - DoE, brainstorming, cause & effect diagram, QFD, fault tree analysis; b) in stage of production - process flow diagrams, Pareto chart, control chart; c) in assessing the process or product - histogram, pie chart, scatter diagram, bar chart, etc; and d) in every stage of data collection - capability indices, check sheet or check list, etc. Therefore, need for a systematic approach in selection stage of tools and techniques and then in implementation phases, calls for a more comprehensive methodology. In order to respond to this, an extended model proposed here based on the DMAIC methodology. This model is called TQM implementation roadmap to show its developmental sequences toward TQM tools and techniques implementation. Figure 5 shows the proposed roadmap. Documenting Process

Data Collection and Process Measurement

Problem Finding and Solving

Quality Stabilization Take Action to a High Level of Quality

Continuous Quality Improvement

Figure 5: TQM Tools and Techniques Implementation Roadmap Each step of this roadmap is described here. The first step is documenting process. A key reason for documenting a process is to allow it to be analyzed for improvement opportunities. The key step in understanding a process is to be able to document it by listing the steps involved. According to Ehresman (1995) the best tools for documenting are process flow diagrams: operating process flow diagram, functional process flow diagrams and layout process flow diagrams. Process flow diagrams are excellent process documentation tools. The diagrams allow everyone involved to view the process in the same way.

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

The next step is to collect the required data and measuring the process. Collecting and analyzing data are key steps in process improvement. Collecting process performance data help answering questions such as (Ehresman, 1995): What is happening? How is the process performing? Is the process improving? Is the process satisfying customer requirements? The best tools for this purpose is check sheet, Pareto chart, histogram, scatter diagram, run chart and statistical process control (SPC). The data collected by these tools can be used to measure the process. According to Ehresman (1995) process measurements serve as a means to listen to a process. When appropriately analyzed and interpreted, the measurements provide accurate, meaningful and timely process performance feedback. The measurements can tell you a lot about the process. Process measurements are useful for many purposes including those listed below: understanding what is happening; provide objective performance feedback; evaluate the need for improvement; evaluate the impact of changes; and set schedules and performance targets. The third step in the proposed roadmap is to use problem finding and solving tools. Problem solving requires a structured approach. Without such an approach, efforts often are random and/or misguided. The five steps listed below can be applied to any type of problem, regardless of its complexity (Ehresman, 1995): 1) define a problem; 2) identify the root cause; 3) select the best solution; 4) develop an action plan; and 5) verify plan results. The proper techniques for this goal are cause & effect diagram, relationship diagram, brainstorming, reversal and characteristic changing. These techniques can be applied to determine and eliminate the root cause of a problem. Key element of any problem-solving effort are identifying the root cause and generating a list of possible solution ideas. Continuous quality improvement is the next step. In this step all the above mentioned steps will be repeated and more tools and techniques will be used to ensure continuous improvement. The most common tools and techniques in this step are control charts, FMEA, and fault tree analysis. After the above steps quality stabilization within company and making quality everyones job is necessary. Quality is not a part of everyones job. Everyone doesnt do quality for a while and then get back to his/her real job. Quality is everyones job (Ehresman, 1995). The best tool that can assist every organization in its effort to make quality everyones job is ISO9000 series. A key aim of TQM is customer satisfaction. The focus of customer satisfaction, in turn, is to understand and meet or exceed customer requirements. A system is required to ensure that the requirements are continually and consistently adhered to. This system contains documentation so requires that anyone assigned to perform a job can be trained in the same precise manner as the previous person on that job. There can be no decline in quality just because the person performing the process has changed. The existence or need for quality

10

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

systems certainly is not new; companies around the world have been developing their own quality systems for years. ISO9000 is series of international quality standards that widely accepted and is the best tools for ensuring that quality is everyones job (Martnez-Costa, Choi, Martnez, & Martnez-Lorente, 2009; Van der Wiele, Dale, & Williams, 1997). However, in addition to the above mentioned tools and techniques, there are numerous techniques which are technical and engineering related and have specific applications to product design and development. Usually these tools and techniques cover all functions within the organization and need more effort to implement and to lead organization to a high level of quality. Six Sigma, 5Ss housekeeping, total productive maintenance (TPM), reward system, suggestion system, electronic data exchange (EDI), computer aided (product/process) design (CAD), computer aided manufacturing (CAM), design for manufacture and assembly (DFMA), finite element analysis (FEA), computer numerical control (CNC), computer integrated manufacturing (CIM) and just-in-time (JIT) are within this category. CONCLUSION The correct selection and use of tools and techniques is a vital component of any successful TQM implementation plan. The TQM tools and techniques can be divided into simple tools for solving a special problem and complex one that cover all functions within the company. Before any implementation the availability of resources within the company, the usage and scope of each tools and techniques and the product characteristics should be considered carefully. In order to response to the quest for a comprehensive methodology for TQM tools and techniques implementation, a roadmap with 6 steps proposed in this research. The developmental sequences of this roadmap start with steps that begin from process documentation and lead to accomplishment of more complex and modern quality tools and techniques that guide organization to a high level of quality. This roadmap can help all organizations intending to reach to a high level of institutionalized quality.

References Ahire, S., & Ravichandran, T. (2002). An innovation diffusion model of TQM implementation. Engineering Management, IEEE Transactions on, 48(4), 445-464. Ahire, S., Waller, M., & Golhar, D. (1996). Quality management in TQM versus non-TQM firms: an empirical investigation. International Journal of Quality & Reliability Management, 13 (8), 8-27. Ahmed, S., & Hassan, M. (2003). Survey and case investigations on application of quality management tools and techniques in SMIs. International Journal of Quality & Reliability Management, 20(7), 795-826. Arumugam, V., Ooi, K., & Fong, T. (2008). TQM practices and quality management performance: An investigation of their relationship using data from ISO 9001: 2000 firms in Malaysia. The TQM Journal, 20(6), 636-650. Bunney, H., & Dale, B. (1997). The implementation of quality management tools and techniques: a study. The TQM Magazine, 9(3), 183-189. Byrne, G. (2003). Ensuring optimal success with Six Sigma implementations. Journal of Organizational Excellence, 22(2), 43-50. Dale, B. G. (2003). Managing Quality (4th ed.). Oxford: Wiley-Blackwell. Dale, B. G., Y.-Wu, P., Zairi, M., Williams, A., & Van Der Wiele, T. (2001). Total quality management and theory: An exploratory study of contribution. Total Quality Management & Business Excellence, 12(4), 439-449.

11

Proceedings of the AGBA 7th World Congress, Malaysia 13 Dec 2010

Das, A., Paul, H., Swierczek, F., & Laosirihongthong, T. (2006). A measurement instrument for TQM implementation in the Thai manufacturing industry. International Journal of Innovation and Technology Management, 3(4), 117. Ehresman, T. (1995). Small Business Success Through TQM: ASQC Quality Press, Milwaukee, WI. Hammer, M., & Goding, J. (2001). Putting six sigma in perspective. Quality, 40(10), 58-62. Hansson, J., & Klefsj, B. (2003). A core value model for implementing total quality management in small organisations. The TQM Magazine, 15(2), 71-81. Hellsten, U., & Klefsj, B. (2000). TQM as a management system consisting of values, techniques and tools. The TQM Magazine, 12(4), 238-244. Jayaram, J., Ahire, S., & Dreyfus, P. (2010). Contingency relationships of firm size, TQM duration, unionization, and industry context on TQM implementation--A focus on total effects. Journal of Operations Management, 28(4), 345-356. JUSE (2010). THE DEMING PRIZE GUIDE 2010 : Union of Japanese Scientists and Engineers Martnez-Costa, M., Choi, T. Y., Martnez, J. A., & Martnez-Lorente, A. R. (2009). ISO 9000/1994, ISO 9001/2000 and TQM: the performance debate revisited. Journal of Operations Management, 27(6), 495-511. Prabhu, V., Appleby, A., & Yarrow, D. (2000). The impact of ISO 9000 and TQM on best practice/performance. The TQM Magazine, 12(2), 84-92. Prajogo, D., & Sohal, A. (2003). The relationship between TQM practices, quality performance, and innovation performance: An empirical examination. International Journal of Quality & Reliability Management, 20(8), 901-918. Punnakitikashem, P., Laosirihongthong, T., Adebanjo, D., & McLean, M. (2010). A study of quality management practices in TQM and non-TQM firms: Findings from the ASEAN automotive industry. International Journal of Quality & Reliability Management, 27 (9), 1021-1035. Rao, A., Carr, L. P., Dambolena, I., Kopp, R. J., Martin, J., Rafii, F., et al. (1996). Total Quality Management: Cross Functional Perspective. New York: Wiley. Salegna, G., & Fazel, F. (1996). An integrative approach for selecting a TQM/BPR implementation plan. International Journal of Quality Science, 1(3), 6-23. Scheuermann, L., Zhu, Z., & Scheuermann, S. (1997). TQM success efforts: use more quantitative or qualitative tools? Industrial Management & Data Systems, 97(7), 264270. Siddiqui, F., Haleem, A., & Wadhwa, L. (2009). Role of Supply Chain Management in Context of Total Quality Management in Flexible Systems: A State-of the-Art Literature Review. Global Journal of Flexible Systems Management, 10(3), 1-10. Sitkin, S., Sutcliffe, K., & Schroeder, R. (1994). Distinguishing control from learning in total quality management: a contingency perspective. Academy of Management Review, 19 (3), 537-564. Spring, M., McQuater, R., Swift, K., Dale, B., & Booker, J. (1998). The use of quality tools and techniques in product introduction: an assessment methodology. The TQM Magazine, 10(1), 45-50. Van der Wiele, A., Dale, B., & Williams, A. (1997). ISO 9000 series registration to total quality management: the transformation journey. International Journal of Quality Science, 2(4), 236-252.

12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Spiro ChemicalsDocument4 pagesSpiro ChemicalsGopal KrishnanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Bharathiar University Practical Examination - October 2017: B.SC (Apparel Fashion Designing) - V SemesterDocument1 pageBharathiar University Practical Examination - October 2017: B.SC (Apparel Fashion Designing) - V SemesterGopal KrishnanNo ratings yet

- NIFT-TEA College of Knitwear Fashion: UG Third Year Apparel Fashion DesigningDocument2 pagesNIFT-TEA College of Knitwear Fashion: UG Third Year Apparel Fashion DesigningGopal KrishnanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

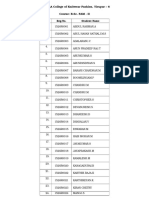

- Students List 2016-17Document30 pagesStudents List 2016-17Gopal KrishnanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Statement On The Status of Tamil As A Classical LanguageDocument3 pagesStatement On The Status of Tamil As A Classical LanguageGopal KrishnanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Filament SpinningDocument31 pagesFilament SpinningGopal KrishnanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- PillingDocument3 pagesPillingGopal KrishnanNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Contribution of Fabric Characteristics and Laundering To Shrinkage of Weft Knitted FabricsDocument9 pagesContribution of Fabric Characteristics and Laundering To Shrinkage of Weft Knitted FabricsGopal KrishnanNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Statement On The Status of Tamil As A Classical LanguageDocument3 pagesStatement On The Status of Tamil As A Classical LanguageGopal KrishnanNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Fabrics Faults or DefectsDocument13 pagesFabrics Faults or DefectsGopal KrishnanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Filament SpinningDocument31 pagesFilament SpinningGopal KrishnanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Reactive DyesDocument1 pageReactive DyesGopal KrishnanNo ratings yet

- Kfs - I M.SC CT II QPDocument1 pageKfs - I M.SC CT II QPGopal KrishnanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Fabrics Faults or DefectsDocument13 pagesFabrics Faults or DefectsGopal KrishnanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Aqm QPDocument2 pagesAqm QPGopal KrishnanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Model Exam QP AQM 13Document2 pagesModel Exam QP AQM 13Gopal KrishnanNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Aqm QPDocument2 pagesAqm QPGopal KrishnanNo ratings yet

- Antimicrobial Textile Prepared by Silver Deposition On Dielectric Barrier Discharge Treated Cotton/Polyester FabricDocument3 pagesAntimicrobial Textile Prepared by Silver Deposition On Dielectric Barrier Discharge Treated Cotton/Polyester FabricGopal KrishnanNo ratings yet

- Tfy & KFS CT I QPDocument2 pagesTfy & KFS CT I QPGopal KrishnanNo ratings yet

- Common Problems in DesizingDocument4 pagesCommon Problems in DesizingGopal Krishnan100% (1)

- Common Problems in DesizingDocument4 pagesCommon Problems in DesizingGopal Krishnan100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)