Professional Documents

Culture Documents

Dell Server Ordering Six Sigma Case Study

Uploaded by

Steven BonacorsiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dell Server Ordering Six Sigma Case Study

Uploaded by

Steven BonacorsiCopyright:

Available Formats

Six Sigma DMAIC Project

GEAE Account

Project Leader/Green Belt: Mike Lisenby Project Leader Title: Project Coordinator and Certified Green Belt Project Start Date: September 9, 2002

Master Black Belt: Steven Bonacorsi

Six Sigma in Action Dell Server Ordering

Customer Profile Global design & production company for Aircraft Engines Business Problem & Impact Server replacements with Dell products had come to a halt, due to an inability to correlate servers and components received with what was ordered. The required cycle time of 10 days was not being met.

Before Z_ST 1.4

Success 48%

(29 Orders)

Defect 52%

(31 Orders)

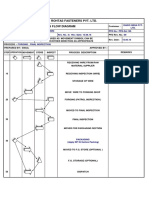

Measure & Analyze Data Collection: Cycle time was measured in days, from the date of order to the date of delivery. The existing process sigma was negative 1.2. A complete analysis of continuous data collected was performed. Upon review, the customer elected to change their CTQ, causing a shift to discrete data analysis. Root Causes: Lack of an identification methodology up-front in the ordering process was identified as the root cause. Shipping distance was a contributor.

Improve & Control Host name and/or project code of the parent server was used as a reference on each server/component order. Orders for multiple servers were separated into logical units. Results/Benefits After the 2 month project, the customer saved US$258K, and ITS saved $16K as a result of the improved process.

After Z_ST 2.76

Defect 10%

(3 Orders)

Success 90%

(26 Orders)

A Combined Savings of $275K Over 12 Months!

You might also like

- Product Order Cycle Time Six Sigma Case StudyDocument2 pagesProduct Order Cycle Time Six Sigma Case StudySteven BonacorsiNo ratings yet

- Server Backup Six Sigma Case StudyDocument2 pagesServer Backup Six Sigma Case StudySteven BonacorsiNo ratings yet

- DFSSDocument4 pagesDFSSankitrathod87No ratings yet

- 1 Six Sigma Project Review: Executive SummaryDocument6 pages1 Six Sigma Project Review: Executive Summaryanjo0225No ratings yet

- Quick Change OverDocument14 pagesQuick Change Overghaos1No ratings yet

- Green Belt Course ManualDocument34 pagesGreen Belt Course ManualKaranShinde100% (1)

- Cellular Manufacturing Flexible OperationsDocument16 pagesCellular Manufacturing Flexible OperationsAlpha Excellence consultingNo ratings yet

- 3a 2 Card Kanban System CalculationsDocument2 pages3a 2 Card Kanban System CalculationsJose OrtegaNo ratings yet

- Project Reviews and Examples: © 2001 Conceptflow 0Document36 pagesProject Reviews and Examples: © 2001 Conceptflow 0Michael WuNo ratings yet

- Chap 2Document28 pagesChap 2Keyredin SelmanNo ratings yet

- 4a Quiz StraightenDocument2 pages4a Quiz StraightenJose Ortega0% (1)

- Lean OutlineDocument2 pagesLean OutlineTee Hor ChangNo ratings yet

- Part1 Define - GBDocument38 pagesPart1 Define - GBNitesh GoyalNo ratings yet

- F M E A M S A A V: Ailure Odes & Ffects Nalysis Easurement Ystems Nalysis ND AlidationDocument20 pagesF M E A M S A A V: Ailure Odes & Ffects Nalysis Easurement Ystems Nalysis ND AlidationViswanathan SrkNo ratings yet

- 10 Commandmens of KaikakuDocument3 pages10 Commandmens of Kaikakupolypro78No ratings yet

- Tact Time StudyDocument10 pagesTact Time StudyAtul SharmaNo ratings yet

- 供应商培训资料 8D PDFDocument77 pages供应商培训资料 8D PDFFisher1987No ratings yet

- Steps of The A3 ProcessDocument14 pagesSteps of The A3 ProcessJayantRKNo ratings yet

- Cellular LayoutsDocument10 pagesCellular Layoutssidd88No ratings yet

- Payroll Remittance Six Sigma Case StudyDocument2 pagesPayroll Remittance Six Sigma Case StudySteven BonacorsiNo ratings yet

- Lean Value Stream: Mapping & AnalysisDocument34 pagesLean Value Stream: Mapping & AnalysisJose SantosNo ratings yet

- Simptww S-1105Document3 pagesSimptww S-1105Vijay RajaindranNo ratings yet

- FS 508 Installation ManualDocument8 pagesFS 508 Installation ManualleolamiaNo ratings yet

- Nested Designs: Study Vs Control SiteDocument13 pagesNested Designs: Study Vs Control SiteHasrul MuhNo ratings yet

- Week 7 - Adaptable Kanban System Maintains JIT ProductionDocument36 pagesWeek 7 - Adaptable Kanban System Maintains JIT ProductionQuynh Chau TranNo ratings yet

- The Lean Stack - Part 1Document15 pagesThe Lean Stack - Part 1iNFuT™ - Institute for Future TechnologyNo ratings yet

- Final Report TPM PartDocument16 pagesFinal Report TPM PartNikita AwasthiNo ratings yet

- HA CEDAC Workshop INDO Kaizen PartDocument16 pagesHA CEDAC Workshop INDO Kaizen PartHardi BanuareaNo ratings yet

- Six Sigma For Chemical Engineers: George LiebermannDocument39 pagesSix Sigma For Chemical Engineers: George LiebermannDave CNo ratings yet

- Measurement System Analysis: - Two Sources of Variation: 1. Part - To - Part Variation 2. Measurement System VariationDocument4 pagesMeasurement System Analysis: - Two Sources of Variation: 1. Part - To - Part Variation 2. Measurement System Variationhan seongNo ratings yet

- 3-2 Introduction To ImproveDocument11 pages3-2 Introduction To Improveanjo0225No ratings yet

- Concepts of Precision and Accuracy: Precise Process Is One With Accurate Process Is One WhichDocument27 pagesConcepts of Precision and Accuracy: Precise Process Is One With Accurate Process Is One WhichsareenaikbalNo ratings yet

- Dmaic:: The 5 Phase Method That Underlies Lean Six SigmaDocument11 pagesDmaic:: The 5 Phase Method That Underlies Lean Six SigmaSam MakNo ratings yet

- Six Sigma Quality Engineering: Week 2 Introduction To Six Sigma Macro Model of Six Sigma ManagementDocument29 pagesSix Sigma Quality Engineering: Week 2 Introduction To Six Sigma Macro Model of Six Sigma Managementkr_padmavathiNo ratings yet

- Lean Manufacturing 1Document70 pagesLean Manufacturing 1AbhiNo ratings yet

- Seven Basic Quality Tools: List / Use / InteractionDocument56 pagesSeven Basic Quality Tools: List / Use / InteractionmangofaNo ratings yet

- Om - 3M CaseDocument18 pagesOm - 3M CaseBianda Puspita Sari100% (1)

- Process Capability Analysis Using MINITAB (II) - BowerDocument8 pagesProcess Capability Analysis Using MINITAB (II) - Bowertehky63No ratings yet

- Roller (Did-428) PFDDocument1 pageRoller (Did-428) PFDVikas KashyapNo ratings yet

- 1-1 Introduction & AgendaDocument14 pages1-1 Introduction & Agendaanjo0225No ratings yet

- CHAPTER 8 Continuous Process ApproachDocument19 pagesCHAPTER 8 Continuous Process Approachloyd smithNo ratings yet

- Arrow DiagramDocument4 pagesArrow DiagramscapasNo ratings yet

- Fmea Chart 70kb PDFDocument1 pageFmea Chart 70kb PDFmike gamerNo ratings yet

- 3 - Analyze - Inferential StatisticsDocument29 pages3 - Analyze - Inferential StatisticsParaschivescu CristinaNo ratings yet

- How To Calculate Sigma Level For A ProcessDocument9 pagesHow To Calculate Sigma Level For A ProcessmaherkamelNo ratings yet

- Examples Line BalancingDocument11 pagesExamples Line BalancingTee Hor ChangNo ratings yet

- Error Proof AssemblyDocument30 pagesError Proof AssemblySergioRiveroSalcidoNo ratings yet

- Six Sigma - A Strategy For Achieving World Class PerformanceDocument31 pagesSix Sigma - A Strategy For Achieving World Class Performancedaredevil19901No ratings yet

- Cellular ManufacturingDocument25 pagesCellular ManufacturingApoorv Mathur100% (1)

- VSM 1hr PresentationDocument25 pagesVSM 1hr PresentationGilson VieiraNo ratings yet

- Process Manager WorkshopDocument58 pagesProcess Manager WorkshopHamada AhmedNo ratings yet

- Quality Improvement Through Planned Experimentation: Third EditionDocument6 pagesQuality Improvement Through Planned Experimentation: Third EditionJaiveer YadavNo ratings yet

- Unblocking BottlenecksDocument3 pagesUnblocking BottlenecksMaggie GonzalesNo ratings yet

- 3c Red Tag TemplateDocument1 page3c Red Tag TemplatehiteshcparmarNo ratings yet

- BMW IMAC Form Completeness Six Sigma Case StudyDocument2 pagesBMW IMAC Form Completeness Six Sigma Case StudySteven BonacorsiNo ratings yet

- What Is QFD?: Dr. Yoji AkaoDocument6 pagesWhat Is QFD?: Dr. Yoji AkaoANo ratings yet

- 03 - Project For QCI AwardDocument43 pages03 - Project For QCI AwardAsawari JoshiNo ratings yet

- Operations Management: Toyota Production System (TPS), Just-in-Time (JIT), and Lean Manufacturing HandoutDocument92 pagesOperations Management: Toyota Production System (TPS), Just-in-Time (JIT), and Lean Manufacturing Handoutjitendrasutar1975No ratings yet

- Statistical Process Control QPSPDocument166 pagesStatistical Process Control QPSPRAVISSAGARNo ratings yet

- Data Conversion Cycle Time Six Sigma Case StudyDocument2 pagesData Conversion Cycle Time Six Sigma Case StudySteven BonacorsiNo ratings yet

- Gage Area Deployment Six Sigma Case StudyDocument2 pagesGage Area Deployment Six Sigma Case StudySteven BonacorsiNo ratings yet

- Deploy Image Cycle Time Six Sigma Case StudyDocument2 pagesDeploy Image Cycle Time Six Sigma Case StudySteven BonacorsiNo ratings yet

- Depot Repair Cycle Time Six Sigma Case StudyDocument2 pagesDepot Repair Cycle Time Six Sigma Case StudySteven BonacorsiNo ratings yet

- Image Update Six Sigma Case StudyDocument2 pagesImage Update Six Sigma Case StudySteven Bonacorsi100% (1)

- Replacement Planning Six Sigma Case StudyDocument2 pagesReplacement Planning Six Sigma Case StudySteven BonacorsiNo ratings yet

- Certification Process Six Sigma Case StudyDocument2 pagesCertification Process Six Sigma Case StudySteven BonacorsiNo ratings yet

- Software Store Six Sigma Case StudyDocument2 pagesSoftware Store Six Sigma Case StudySteven BonacorsiNo ratings yet

- Gillette Six Sigma Case StudyDocument2 pagesGillette Six Sigma Case StudySteven BonacorsiNo ratings yet

- Backup Completeness Six Sigma Case StudyDocument2 pagesBackup Completeness Six Sigma Case StudySteven BonacorsiNo ratings yet

- Serrver Imaging Six Sigma Case StudyDocument2 pagesSerrver Imaging Six Sigma Case StudySteven BonacorsiNo ratings yet

- Workorder Error Reduction Six Sigma Case StudyDocument2 pagesWorkorder Error Reduction Six Sigma Case StudySteven BonacorsiNo ratings yet

- E-Mail Optimization Six Sigma Case StudyDocument2 pagesE-Mail Optimization Six Sigma Case StudySteven BonacorsiNo ratings yet

- Local Asset Inventory Six Sigma Case StudyDocument2 pagesLocal Asset Inventory Six Sigma Case StudySteven BonacorsiNo ratings yet

- Kaiser Permanente Six Sigma Case StudyDocument2 pagesKaiser Permanente Six Sigma Case StudySteven BonacorsiNo ratings yet

- Redeploy Diagnostics Six Sigma Case StudyDocument2 pagesRedeploy Diagnostics Six Sigma Case StudySteven BonacorsiNo ratings yet

- GEAE Tech Support Website Six Sigma Case StudyDocument2 pagesGEAE Tech Support Website Six Sigma Case StudySteven BonacorsiNo ratings yet

- SN - Model - Accuracy Six Sigma Case StudyDocument2 pagesSN - Model - Accuracy Six Sigma Case StudySteven BonacorsiNo ratings yet

- System Completeness Six Sigma Case StudyDocument2 pagesSystem Completeness Six Sigma Case StudySteven BonacorsiNo ratings yet

- Operating System Six Sigma Case StudyDocument2 pagesOperating System Six Sigma Case StudySteven BonacorsiNo ratings yet

- Lease Buyout Cost Reduction Six Sigma Case StudyDocument2 pagesLease Buyout Cost Reduction Six Sigma Case StudySteven BonacorsiNo ratings yet

- Virus Remediation Six Sigma Case StudyDocument2 pagesVirus Remediation Six Sigma Case StudySteven BonacorsiNo ratings yet

- Payroll Remittance Six Sigma Case StudyDocument2 pagesPayroll Remittance Six Sigma Case StudySteven BonacorsiNo ratings yet

- Printer Consumable Process Six Sigma Case StudyDocument2 pagesPrinter Consumable Process Six Sigma Case StudySteven BonacorsiNo ratings yet

- Repair Cycle Time Improvement Six Sigma Case StudyDocument2 pagesRepair Cycle Time Improvement Six Sigma Case StudySteven BonacorsiNo ratings yet