Professional Documents

Culture Documents

Application of Fuzzy Multiple

Uploaded by

Emir IkanovićCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Fuzzy Multiple

Uploaded by

Emir IkanovićCopyright:

Available Formats

Mineral Resources Engineering, Vol. 11, No.

1 (2002) 5972 c Imperial College Press

APPLICATION OF FUZZY MULTIPLE ATTRIBUTE DECISION MAKING IN MINING OPERATIONS

AYHAN KESIMAL Karadeniz Technical University, Mining Engineering Department 61080, Trabzon, Turkey ATAC BASCETIN Istanbul University, Mining Engineering Department Avcilar 34850, Istanbul, Turkey

This paper presents a fuzzy multiple attribute decision making as an innovative tool for criteria aggregation in mining decision problems. So far, various types of formulations or solution methods have been proposed with mining systems, but most of them exclusively considered linear functions as objective functions. Real world study is decision making under subjective constraints of dierent importance, after using uncertain data (linguistic variables), where compromises between competing criteria are allowed. It seems however that this technique is still very little known in mining. It is one of the aims of this case study to disseminate this technology in many mining elds. The paper is divided into four sections. The rst section provides an overview of the underlying concepts and theories of multiple attribute decision making in a fuzzy environment and the scope of this type of search. The second section introduces few applications of fuzzy set theory to mining industry problems reported in the literature. Some of these applications are briey reviewed. The third section presents two case studies which illustrate the application of the system for equipment selection in surface mining and method selection in underground mining in a fuzzy environment, and highlight the exible nature of the approach. Details of alternative systems and their criterion of each operation are given. And nally the fourth section presents the concluding remarks.

1. Introduction Over nearly the past three decades, fuzzy logic has been advanced as a formal means to deal with implicit imprecision in a wide range of problems, e.g. in industrial control, military operations, economics, engineering, medicine, reliability, and pattern recognition and classication. Among many existing references see, e.g. Maiers et al.,15 Kandel,10 Klir et al.,13 Prade,19 Dubois et al.,7 Bandopadhyay et al.,1 Bandopadhyay,2,3 Gershon et al.,8 Herzog et al.,9 Bascetin et al.5,6 and Bascetin4 for relevant applications in these and other elds. In practice, fuzzy logic synthesizes dierent solution alternatives, each of which need not be right or wrong but instead is possibly true to a certain degree (see, Zadeh26 and Yager22 ).

59

60

A. Kesimal & A. Bascetin

Decision making may be characterised as a process of choosing or selecting suciently good alternative(s), to attain, from a set of alternatives, to attain a goal or goals. Much decision making involves uncertainty. Hence, one of the most important aspects for a useful decision aid is to provide the ability to handle imprecise and vague information, such as large prots, fast speed and cheap price. A decision model should cover process for identifying, measuring and combining criteria and alternatives to build a conceptual model for decisions and evaluations in fuzzy environments. Mine planning engineers often use of their intuition and experiences in decision making. Mostly linguistic variables (the weather is raining, soil is wet, etc.) become in question and decision-makers may not know how these variables are computed. Since the advent of the fuzzy set theory, these uncertainties are easily evaluated in decision making process. By the development of computer technology and programming of colloquial language with expert systems have considerably reduced decision makers burden. 2. Fuzzy Set Theory Researchers and practitioners of equipment and method selection face diverse operational issues such as the complexity of interactive inuences, inaccuracy of measures, uncertainty of environmental forces, and subjectivity of the decision making process. Acquiring the information necessary for equipment and method selection is elaborate, to say the least, and once obtained is liable to be ambiguous, inconsistent, incomplete, or decient in quality. In addition, decision makers must often apply rules of thumb or incorporate their personal intuition and judgment when deriving performance measures based on indenite linguistic concepts, e.g. high, low, strong, weak, stable, and deteriorating. For example, if haulage level is low and then truck haulage can be used (the opportunity will be high). If coal seam is about 2.0 meters in thickness and has weak hanging wall condition then longwall method with lling can be good choice in alternatives. This terminology is a natural phenomenon caused by imperfectly dened problem attributes. Fuzzy sets25 have vague boundaries and are therefore well suited for discussing such concepts as linguistic terms (such as very or somewhat) or natural phenomena (temperatures). Fuzzy set theory has developed as an alternative to ordinary (crisp) set theory and is used to describe fuzzy sets. To clear the dierence between these two sets, let explain with an example. Supposed that a set K has various cycle times of one shovel loading same size trucks between 20 and 28 seconds. An optimum loading cycle time is considered to be 24 to 25 seconds in this mine site. K set is rstly evaluated by crisp and subsequently by fuzzy set. Figure 1(a) shows crisp set of cycle time in the 24 to 25 seconds range. In this set, 24 seconds is 100 percent a member while 23 seconds is not in the set at all; there is no in-between. The boundaries are denite and a particular loading cycle time is either in the set or not, is either 24 to 25 seconds, or is not. In contrast, a fuzzy set does not have clear boundaries. Membership in a fuzzy set is a matter of

Application of Fuzzy Multiple Attribute Decision

61

%membership

%membership

100

100

50

50

0 20 21 22 23 24 25 26 27 28 Loading cycle time (seconds)

(a) Fig. 1.

0 20 21 22 23 24 25 26 27 28 Loading cycle time (seconds)

(b) Crisp (a) and fuzzy set (b).

degree. Figure 1(b) shows 25 seconds is 100 percent a member of the set of loading cycle time, whereas 22 seconds is only 50 percent a member of the set. Additionally, the nature of fuzzy sets allows something to be a member in more than one fuzzy set. For example, a 3-year-old haulage truck might be 20 percent a member of the set of young trucks and 45 percent a member of the set of middleaged trucks. Driving the set membership function for a fuzzy set is through the use in fuzzy logic or fuzzy decision making. The problem of constructing meaningful membership functions has a lot of additional research work that will have to be done on it to achieve full satisfaction. There are a number of empirical ways to establish membership functions for fuzzy sets. Measuring of these is beyond the scope of this article. However, for more information, see Li et al.14 and Klir et al.12 2.1. Fuzzy multiple attribute decision making There are many methods of decision making. The focus of this paper is on Yagers23 method that is general enough to deal both with multiple objective and multiple attribute problems. Concentrating on multiple attribute decision making problems, only a single objective is considered, that a selecting the best from a set of alternative. All other objectives are considered criteria. The method assumes the max-min principle approach. Formally, let A = {A1 , A2 , . . . , An } be the set of alternatives, C = {C1 , C2 , . . . , Cm } be the set of criteria which can be given as fuzzy sets in the space of alternatives, and G the goal, which can also be given by a fuzzy set. Hence, the fuzzy set decision is the intersection of all criteria (and/or goals): D (A) = min(G (A), C1 (A), C2 (A), . . . , CM (A)) for all Ai A and the optimal decision D (A ) = maxA D (A) where A is the optimal decision.

62

A. Kesimal & A. Bascetin

The main dierence is that the importance of criteria is represented as exponential scalars. This is based on the idea of linguistic hedges.25 The rationale behind using weights (importance) as exponents is that the higher the importance of criteria the larger should be exponent because of the minimum rule. Conversely, the less important, the smaller the weight. This seems intuitive. Formally, D (A) = min((G (A))1 (C1 (A))2 , (C2 (A))3 , . . . , (CM (A))m ) for > 0 . Consider the problem of selecting a site from the set {A, B, C } for a new in-pit crusher in a quarry, with the goal, G, of spending the minimum investment possible and for criteria evaluation to be located near the pit and the processing plant, respectively C1 and C2 . The judgment scale used is 1-equally important, 3-weakly more important, 5-strongly more important, 7-demonstrably more important and 9-absolutely more important. The values between (2, 4, 6, 8) show compromise judgments. Yager suggests the use of Saatys21 method for pair-wise comparison of the criteria (attributes). A pair-wise comparison of attributes (criteria) could improve and facilitate the assessment of criteria importance. Saaty developed a procedure for obtaining a ratio scale for the elements compared. To obtain the importance the decision-maker is asked to judge the criteria in pair-wise comparisons and the values assigned are wij = 1/wij . Having obtained the judgments, the mxm matrix B is constructed so that: (a) bii = 1; (b) bij = wij ; (c) bji = bij . To sum up, Yager suggests that the resulting eigenvector should be used to express the decision makers empirical estimate of importance (the reciprocal matrix in which the values are given by the decision maker) for each criteria in the decision and criteria 1 and 2, respectively C1 and C2 , are three times as important as G, and the pair-wise comparison reciprocal matrix is: G G 1 3 C1 1 1 C2

C1 3 C2

1/3 1/3

1 . 1

Hence, the eigenvalues of the reciprocal matrix are = [0, 3, 0] and therefore max = 3. All values except one are zero.21 The weights of the criteria are nally achieved in the eigenvector of the matrix, eigenvector = {0.299, 0.688, 0.688} with max . The eigenvector corresponds to the weights to be associated with the memberships of each attribute/feature/goal. Thus, the exponential weighting is 1 = 0.299, 2 = 0.688, 3 = 0.688 and the nal decision (membership decision function) about the site location is given as follows:

0.688 0.688 D(A) = min(G0.299 , C1 , C2 )

G = [0.5/A1 , 0.8/A2 , 0.3/A3 ]0.299 = [0.81/A1 , 0.94/A2 , 0.70/A3 ] C1 = [0.7/A1 , 0.9/A2 , 0.5/A3 ]0.688 = [0.78/A1 , 0.93/A2 , 0.62/A3 ]

Application of Fuzzy Multiple Attribute Decision

63

C2 = [0.4/A1 , 0.2/A2 , 0.9/A3 ]0.688 = [0.53/A1 , 0.33/A2 , 0.93/A3] D(A) = (0.53/A1 , 0.33/A2, 0.62/A3 ) . And the optimal solution,20 corresponding to the maximum membership 0/63, is A3 (D (A ) = 0.62/A3 ). 3. Application of Fuzzy Set Theory in Mining In spite of many advantages of the approach, only few applications of fuzzy set theory to mining industry problems have been reported in the literature. Some of these applications are briey reviewed here: Nguyen et al.17,18 studied some fuzzy set applications in mining geomechanics and determining fuzziness of rock mass classication. Bandopadhyay et al.1,2 developed fuzzy algorithm for selection of post-mining uses of land and for decision making in mining engineering. Bandopadhyay3 indicated partial ranking of primary stripping equipment in surface mine planning and fuzzy algorithm. It deals with the process of ranking alternatives after determining their rating. Determining the optimal decision alternatives, when the results are crisp, is straightforward (just select the alternative with the highest support). It also considers that the supports for each alternative are themselves fuzzy sets. Therefore, in order to select the best alternative more sophisticated methods of comparison are needed. Gershon et al.8 studied mining method selection: a decision support system integrating multi-attribute utility theory and expert systems. Herzog et al.9 indicated ranking of optimum beneciation methods via the analytical hierarchy process. This process measures relative fuzziness by structuring the criteria and objectives of a system, hierarchically, in a multiple attribute framework. Bascetin et al.5 studied the application of fuzzy boolean linear programming technique to solve problems of selective mining. Boolean linear programming problems deal with problems of maximizing or minimizing a function of many variables subject to inequality and equality constraints and integrality restrictions on some or all of the variables (boolean variables). To have some diculties when modelling a real world problem by means of a boolean programming problem is normal. One of such diculties is either in the fact that goals and constraints are often represented by the vague linguistic form or in the fact that the parameters are not known exactly. Often in a real world problem a decision-maker or an expert gives approximate estimates about the true values of the objective coecients rather than the exact values of these, moreover those estimates can be given with some vagueness. Bascetin et al.6 handled the study of a fuzzy set theory for the selection of an optimum coal transportation system from pit to the power plant. This project has comprised variety of criteria related to the coal transportation systems.

64

A. Kesimal & A. Bascetin

BLACK SEA

merli Dam

Fig. 2.

Location of the mine site.

4. Case Studies In order to demonstrate the potential for this approach, two case studies are represented. They show how fuzzy multiple attribute decision making can be used to optimise the best system (method) among the alternatives under various sets of criteria. The work detailed in this paper has been based on the brown coal (lignite) mine situated in Black Sea coast at North-west of Arnavutkoy, Istanbul, Turkey (see Fig. 2). There two mine site are in this region: existing open pit mine and future planning underground mine. Case I: In this case study, some research has been conducted on loading-hauling systems for overburden removal of an open-pit coal mine. Technical parameters of the working site, which aect the systems, have been evaluated thoroughly and summarised below in detail. The mine site is of average size, with a pit area of 600 by 350 m and a total of 60 m of overburden being removed in six 10 m high benches. The mine will be worked over 8 years at the rate of one ten-hour shift per day, seven days a week for 300 days per year, the scheduled operating time being 3000 h/year. The average coal production is planned to be 550,000 t/year, which implies an average annual overburden removal of 2,200,000 m3 , i.e. the economic mine life is based on a 4:1 stripping ratio. The average rain and temperatures are varying between 1074-mm and 717 mm, 30 C and 4 C, respectively. The maximum daily rain fall is resulting in 76 to 101 mm/day between in August and September. Winds in the pit can exceeds 80 km/h. Snow removal obviously delays equipment movements during the winter varying between 15 and 30 days and fog can aect operations 20 to 30 days per year. Initial analysis of the loading-hauling system suggests the following alternatives: front shovel-truck (A1 ), loader-truck (A2 ), or front shovel-truck-in pit crusher-belt

Application of Fuzzy Multiple Attribute Decision Table 1. Overburden Active workday Overburden material Rock density Overburden thickness Soil property Blasting Haulage distance Average grade resistance Average rolling resistance Digging level Dump level Bucket capacity Bucket ll factor Belt conveyor In-pit crusher Operating weight Useful life Loading time Cycle time Capital cost Operating cost Technical parameters calculated for each system. 2,200,000 m3 /year 7 days/week, 300 days/year, 10 h/day (1 shift/day) Sand, sandstone, clay 1.2 ton/m3 20 to 60 m (2 to 5 benches) Moisture None 900 to 1000 m 4% 3% Front Shovel: 11 m Loader: 6.57 m Front Shovel: 7.5 m Loader: 3.72 m, Truck (Loading Height: 3.10 m). Shovel: 4 m3 , Loader: 6 m3 90% 4 m/sec speed, 370 m long total, 900 mm wide Two 400 ton/hour capacity Front Shovel: 83,800 kg Loader: 45,297 kg Truck: 31,250 kg Front Shovel: 25,000 h Loader: 20,000 h Truck: 15,000 h Conveyor: 25,000 h Front Shovel: 21 sec Loader: 30 sec Truck: 230 sec Front Shovel: $550,000, Loader: $400,000, Truck: $270 000, In-pit crusher and belt conveyor: $1,900,000 A1 = $0.67/m3 , A2 = $0.72/m3 , A3 = $0.62/m3

65

conveyor (A3 ) systems. The characteristic of the mine-site and the equipment specications are given in Table 1. The following are some of the given linguistic results produced from various solution methods (linear programming, expert systems, etc.) and therefore presented by the experts to questions posed (what if. . . ? or if. . . ?, etc.) Each system has shown its own advantages. In this case, it did not appear that an easy solution to the problem could be obtained. From the solution point of view, application of the fuzzy set theory would be a proper choice, and therefore used in this paper. The overburden thickness is thin, so A1 is better to choose. The road conditions dier from season to season. Thus the rolling resistance gives rather low point in dry season while it reaches the high in winter. Diggibility is not being dicult so the front-shovel can be selected unhesitatingly. The front-shovel as regards to the ground condition has more advantage (it is very wet and marshy especially in winter).

66

A. Kesimal & A. Bascetin

Maximum material size is about 1 m. This shows the truck haulage to good advantage from the loading point of view. The front-shovel is a much better excavator in terms of the bench planned to have a 10 m height. All combinations (systems) are suitable in regard to the height of dump but the front-shovel can make much more safe loading. The haulage distance varies between 900 and 1000 m. In this case, A3 can be considered as a better combination of loading-hauling system. A3 is the better system in terms of the working stability. A2 has the lowest capital cost. A1 and A2 are the best alternatives in terms of the mobility in the system. A3 is more suitable according to haulage capacity. The criteria of each operation is summarised in Table 2 and in the following, an optimum loading-hauling system selection procedure is given. Let A = {A1 , A2 , A3 } be the set of alternative systems and C = {C1 , C2 , C3 , . . . , Cm } be the set of criteria. The decision-maker is then asked to dene the membership grade of each criterion that is conferred with experts on this subject. Following that procedure the membership grade of each criterion is given in detail: C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 = {0.85/A1 , 0.80/A2, 0.90/A3 } = {0.90/A1 , 0.65/A2, 0.92/A3 } = {0.95/A1 , 0.80/A2, 0.95/A3 } = {0.95/A1 , 0.95/A2, 0.75/A3 } = {0.90/A1 , 0.85/A2, 0.92/A3 } = {0.85/A1 , 0.85/A2, 0.90/A3 } = {0.90/A1 , 0.70/A2, 0.90/A3 } = {0.90/A1 , 0.80/A2, 0.90/A3 } = {0.95/A1 , 0.80/A2, 0.95/A3 } = {0.87/A1 , 0.85/A2, 0.95/A3 } = {0.85/A1 , 0.95/A2, 0.75/A3 } = {0.90/A1 , 0.85/A2, 0.95/A3 } = {0.90/A1 , 0.88/A2, 0.92/A3 } C14 C15 C16 C17 C18 C19 C20 C21 C22 C23 C24 C25 C26 = = = = = = = = = = = = = {0.90/A1, 0.85/A2 , 0.95/A3 } {0.95/A1, 0.95/A2 , 0.80/A3 } {0.80/A1, 0.80/A2 , 0.95/A3 } {0.90/A1, 0.90/A2 , 0.92/A3 } {0.88/A1, 0.88/A2 , 0.95/A3 } {0.87/A1, 0.83/A2 , 0.90/A3 } {0.97/A1, 0.93/A2 , 0.85/A3 } {0.80/A1, 0.75/A2 , 0.88/A3 } {0.72/A1, 0.68/A2 , 0.80/A3 } {0.82/A1, 0.80/A2 , 0.92/A3 } {0.85/A1, 0.82/A2 , 0.79/A3 } {0.85/A1, 0.75/A2 , 0.95/A3 } {0.90/A1, 0.95/A2 , 0.80/A3 }.

Additionally, the mxm matrix (Fig. 3) was constructed to express the decisionmakers empirical estimate of importance for each criterion. Then, the maximum eigenvector was obtained using the Matlab16 (version 5.0). The judgment scale used here as: 1 equally important; 1.5 weakly more important; 2 strongly more important; 2.5 demonstrably more important; 3 absolutely more important. Hence, the maximum eigenvalue of the reciprocal matrix is = 27.2357. The weights of the criteria are nally obtained in the eigenvector of the matrix. Eigen vector = {0.1055, 0.1214, 0.1520, 0.1165, 0.1440, 0.1063, 0.1569, 0.1143, 0.1905, 0.1387, 0.2297, 0.1980, 0.2481, 0.1877, 0.1045, 0.1138, 0.1074, 0.1239, 0.1508, 0.2905, 0.2697, 0.3182, 0.2031, 0.1980, 0.2694, 0.3723} with max .

Application of Fuzzy Multiple Attribute Decision Table 2. Criterion C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 Operation Production Overburden thickness Digging Condition Material Size The Ground Condition Haul Road Condition The Height of Digging The Height of Dump Working Stability Haulage Distance Mobility Haulage Capacity Economic Life Criteria of each operation. Criterion C14 C15 C16 C17 C18 C19 C20 C21 C22 C23 C24 C25 C26 Operation Cycle Time Moisture Environment Grade Rolling Resistance Weather Conditions Flexibility Availability Utilisation Continuous Support Capital Cost Operating Cost

67

C1 C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 C14 C15 C16 C18 C19 C20 C21 C22 C23 C24 C25 C26 1 2 1 2,5 2 1 3 2 1 1,5 2,5 2,5 3 1 1 1,5 2 2,5 2 2,5 1,5 1,5 1,5 2

C2 1/2 1 1/1,5 1/2 1 1 1 2 2 2,5 3 3 3 1,5

C3 1 1,5 1 1 1,5 1/2 2 1,5 1 2,5 1,5 1,5 1

C4

C5

C6 1 1 2 2 2 1 2 2 1 2 2,5 2,5 1,5 1/2 1 1 1 2,5 2,5 2 1,5 1,5 2,5 3

C7

C8

C9

C10 C11 C12 C13 C14 C15 C16 C17 C18 C19 C20 C21 C22 C23 C24 C25 C26 1 1 1/1,5 1/2,5 1/2 1/2,5 1/1,5 1/2,5 1/3 1/2,5 1/2 1/3 1 1/3 1 2 1,5 2 2 1 1 2,5 2 2,5 1,5 2 1/1,5 1 1,5 1,5 1,5 3 2,5 2,5 2 1,5 2,5 3 1 1,5 1 1,5 1/1,5 1,5 1,5 2 1,5 2 1 2 1 1 1 1,5 1 2,5 2,5 2,5 2 2 2 2,5 1,5 1/1,5 1/2 1/2,5 1/2 1/2,5 1/1,5 1/1,5 1/1,5 1/2 1 1/2 1/2 1/3 1/1,5 1/2 1 1 1/2 1/2,5 1 1/1,5 2 1 1,5 1 1,5 2 1,5 2 1 2,5 2 1 1 1,5 1,5 2,5 2 2 2 2 2,5 3 1,5 1/1,5 1/2 1 1 1 1 1 1 2 1,5 1/2 1/2 1/1,5

1/2,5 1/2 2 1 1 1 1/2 2,5 1,5 2 3 2,5 2,5 3 1 1 1 1,5 2,5 2,5 2 2 1,5 2,5 3 1 1/1,5 1 1 1/2 1 1,5 1/1,5 1,5 1,5 1,5 2,5

1/3 1/1,5 1/2 1 1/2 1 1 1/2 1 2 2 2 2 1 1,5 2 1/2 1/1,5

1/2 1/2,5 1/3 1/2,5 1/3 1/1,5 1,5 1/1,5 1/1,5

1/2,5 1,5 1/1,5 1/2 1/2 1/1,5 1/2 1,5 1 2 1 2,5 3 3 2 1 2 1/2 1 1/2 1 1,5 1,5 2 1 1 1 2 1 2 2,5 2,5 1,5

1/1,5 1/2,5 1/2,5 1/2

1/2 1/1,5 1/2,5 1/3

1,5 1/1,5 1,5 1/1,5 1/1,5 1/2 1/2,5 1/2 1/2,5 1/2,5 1/1,5 1/2 1 1 1 1 1 1/2 1/2,5 1/2 1/1,5 1/1,5 1/2 1 1 1 1/1,5 1 1 1 1,5 1,5 1 1,5 1 1/2,5 1/3 1/2,5 1/2 1/2 1/2,5 1/2,5 1/1,5

1/2 1/2,5 1/2 1/1,5 1/2 1/2,5 1/2 1/2 1/1,5 1/2 1/2,5 1/3 1/2 1/2,5 1/3 1 1/1,5 1/2,5 1/3 1 1

1/2,5 1/2,5 1/2 1/1,5 1/1,5 1/2,5 1/3 1/2 1/2 1/2 1/2,5 1/2 1/2

1,5 1/1,5 1/2 1,5 1,5 2,5 1 2,5 1,5 1/1,5 1 1,5 2,5 2 2 2 2 2,5 3

1,5 1/1,5 1,5 1/1,5 1/1,5 1,5 1/1,5

1,5 1/1,5

1/1,5 1/1,5 1/1,5

1/2 1/1,5 1/1,5 1/2

2,5 1/1,5 1/1,5 1/2 2

1,5 1/1,5 1/2 2 1/1,5 1/2,5 1/3

1/1,5 1/2,5 1/2,5 1/2,5 1/1,5 1/2 1/1,5 1/2,5 1/2 1/1,5 1/1,5 1,5 1/2 1/2,5 1/2 1/2,5 1/1,5 1/1,5 1/2 1 1/2,5 1/2,5 1/2,5 1/2 1/2 1/2 1/2 1/2 1/2

1/1,5 1/1,5 1 1 1 2,5 2,5 2,5 2 1,5 2,5 1/2

1/2 1/1,5 1/2 1/2 1,5 2 2 1,5 1 1 1 1,5 1/1,5 1 1 2 2 2,5 2 1,5 2 2,5

1/2,5 1/2 1/2,5 1/1,5 1/2

1/1,5 1/1,5 1/1,5 1/1,5 1/3 1/2,5 1/2,5 1/2 1/1,5 1/2,5 1/3 1/2 1/2,5 1/1,5 1/1,5 1/2,5 1/2 1/1,5 1/2,5 1/2 1 2,5 2 2 2 2 2,5 1/2,5 1/2 1 1 1,5 1 1 1,5 1 1 1,5 1/2 1/2,5 1/3 1/2 1/2,5 1/3 1/2 1/2,5 1 1,5 1/1,5 1 1 2 1 2 2,5

1/1,5 1/1,5 1,5 1/1,5 1 2 2 3 1,5 2 2 2,5

1/1,5 1,5 1/1,5 1/1,5 1/2 1/1,5 1/2 1/1,5 1/1,5 1/2 1/1,5 1/2 1/1,5 1,5 1/1,5 1/1,5 1/2,5 1,5 2 2 2 1,5 2 2,5 3 1 2 2 2,5 2 2 2,5 3 1,5 1,5 1,5 1 1 1,5 2,5 2 2 2 1,5 2 3 1,5 1,5 2 1 1,5 2

C17 1/1,5 1,5

1/2,5 1/2 1/2 2 1,5 1,5 1/2 1 1,5 2 2,5 2 2,5 1,5 2 3

1/2,5 1/1,5 1,5

1/2 1/1,5 1/2,5 1,5

1/2 1/1,5 1/2 1/1,5 1,5 1/1,5 1,5 1 2 1

1,5 1/1,5 1/2 1,5 1/1,5 1/2 1/2 1/2,5 1 2 1/2 1

1,5 1/1,5 1,5

1,5 1/1,5 1/1,5 1/2

1,5 1/1,5

1/1,5 1/2 1/1,5 1,5 1/1,5 1,5 2 1 2

Fig. 3.

Criteria comparison.

The eigenvector corresponds to the weights to be associated with the memberships of each attribute/feature/goal. Thus, the exponential weighting is 1 = 0.1055, 2 = 0.1214, 3 = 0.1520, 4 = 0.1165, 5 = 0.1440, 6 = 0.1063, 7 = 0.1569, 8 = 0.1143, 9 = 0.1905, 10 = 0.1387, 11 = 0.2297, 12 = 0.1980, 13 = 0.2481, 14 = 0.1877, 15 = 0.1045, 16 = 0.1138, 17 = 0.1074, 18 =

68

A. Kesimal & A. Bascetin

0.1239, 19 = 0.1508, 20 = 0.2905, 21 = 0.2697, 22 = 0.3182, 23 = 0.2031, 24 = 0.1980, 25 = 0.2694, 26 = 0.3723 and the nal decision is obtained as follows: D (A) = min(C1 (A)1 , C2 (A)2 , . . . , Cm (Am ) for > 0 and the optimal decision D (A ) = maxA D (A) where A is the optimal decision. C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 C14 C15 C16 C17 C18 C19 C20 C21 C22 C23 C24 C25 C26 = {0.85/A1 , 0.80/A2 , 0.90/A3 }0.1055 = {0.90/A1 , 0.65/A2 , 0.92/A3 }0.1214 = {0.95/A1 , 0.80/A2 , 0.95/A3 }0.1520 = {0.95/A1 , 0.95/A2 , 0.75/A3 }0.1165 = {0.90/A1 , 0.85/A2 , 0.92/A3 }0.1440 = {0.85/A1 , 0.85/A2 , 0.90/A3 }0.1063 = {0.90/A1 , 0.70/A2 , 0.90/A3 }0.1569 = {0.90/A1 , 0.80/A2 , 0.90/A3 }0.1143 = {0.95/A1 , 0.80/A2 , 0.95/A3 }0.1905 = {0.87/A1 , 0.85/A2 , 0.95/A3 }0.1387 = {0.85/A1 , 0.95/A2 , 0.75/A3 }0.2297 = {0.90/A1 , 0.85/A2 , 0.95/A3 }0.1980 = {0.90/A1 , 0.88/A2 , 0.92/A3 }0.2481 = {0.90/A1 , 0.85/A2 , 0.95/A3 }0.1877 = {0.95/A1 , 0.95/A2 , 0.80/A3 }0.1045 = {0.80/A1 , 0.80/A2 , 0.95/A3 }0.1138 = {0.90/A1 , 0.90/A2 , 0.92/A3 }0.1074 = {0.88/A1 , 0.88/A2 , 0.95/A3 }0.1239 = {0.87/A1 , 0.83/A2 , 0.90/A3 }0.1508 = {0.97/A1 , 0.93/A2 , 0.85/A3 }0.2905 = {0.80/A1 , 0.75/A2 , 0.88/A3 }0.2697 = {0.72/A1 , 0.68/A2 , 0.80/A3 }0.3182 = {0.82/A1 , 0.80/A2 , 0.92/A3 }0.2030 = {0.85/A1 , 0.82/A2 , 0.79/A3 }0.1980 = {0.85/A1 , 0.75/A2 , 0.95/A3 }0.2694 = {0.90/A1 , 0.95/A2 , 0.80/A3 }0.3723 = = = = = = = = = = = = = = = = = = = = = = = = = = {0.98/A1, 0.98/A2 , 0.99/A3 } {0.99/A1, 0.94/A2 , 0.99/A3 } {0.99/A1, 0.97/A2 , 0.99/A3 } {0.99/A1, 0.99/A2 , 0.97/A3 } {0.98/A1, 0.98/A2 , 0.99/A3 } {0.98/A1, 0.98/A2 , 0.99/A3 } {0.98/A1, 0.94/A2 , 0.98/A3 } {0.99/A1, 0.97/A2 , 0.99/A3 } {0.99/A1, 0.96/A2 , 0.99/A3 } {0.98/A1, 0.98/A2 , 0.99/A3 } {0.96/A1, 0.98/A2 , 0.94/A3 } {0.98/A1, 0.97/A2 , 0.99/A3 } {0.97/A1, 0.97/A2 , 0.98/A3 } {0.98/A1, 0.97/A2 , 0.99/A3 } {0.99/A1, 0.99/A2 , 0.98/A3 } {0.97/A1, 0.97/A2 , 0.99/A3 } {0.99/A1, 0.99/A2 , 0.99/A3 } {0.98/A1, 0.98/A2 , 0.99/A3 } {0.98/A1, 0.97/A2 , 0.98/A3 } {0.99/A1, 0.98/A2 , 0.95/A3 } {0.94/A1, 0.92/A2 , 0.97/A3 } {0.90/A1, 0.88/A2 , 0.93/A3 } {0.96/A1, 0.95/A2 , 0.98/A3 } {0.97/A1, 0.96/A2 , 0.95/A3 } {0.96/A1, 0.93/A2 , 0.99/A3 } {0.96/A1, 0.98/A2 , 0.92/A3 }

D (A} = {0.90/A1, 0.88/A2 , 0.92/A3 } and the optimal solution is, D (A ) = 0.92/A3 . Case II: This study has been done by Karadogan et al.11 for searching the optimum underground mining method selection for the new coal seam north-west of the current mine site as mentioned in Case I. Because of the existing of a summer resort area in

Application of Fuzzy Multiple Attribute Decision Table 3. Technical parameters determined as selection criterion. Plate state (layered) 2.1 m (average) 7 50 m (average) Low strength Not clear Clay, low strength (compressive strength: 2.2 kg/cm2 ) Clay, low strength (compressive strength: 2.2 kg/cm2 ) Risky (seam is close to surface) Necessary Exist over the coal seam Combustible coal properties Exist because of the sea

69

Geometric shape of the lignite deposit Thickness of the lignite seam Seam inclination Ore depth Soundness degree of the lignite Contact state of hanging and foot wall Hanging wall Foot wall Subsidence eect Roof support Settlement area Combustion Ground water

Black Sea open pit mining may be restricted in the future. Therefore, application of one of the underground mining methods is unavoidable for producing coal. The needed physical parameters such as geologic and geotechnique properties of ore, hanging and foot wall, economic eects, environmental impacts, which are established with eld and laboratory tests together with other uncertain variables were determined. The generated parameters for the method selection are given briey in Table 3 together with related criterion. Initial analysis of the method selection system suggests the following alternatives: longwall with lling (direction of inclination rising) (A1 ), longwall with lling (direction of inclination decline) (A2 ), longwall with lling (progressed) (A3 ), longwall with lling (returned) (A4 ), or room and pillar with ling (A5 ) systems. Some of the linguistic results produced as follows: According to dimension, A3 is the best method. Seam thickness is average 2.1 meters, therefore A3 can be chosen. A5 is suitable in terms of seam inclination. A5 is more safety according to soundness degree of the hanging wall. From the viewpoint of safety of ground water A1 can be best choice.

Before underground mining method selection procedure, the following eighteen criteria of each operation have been considered in the decision making (Table 4). At the end of the evaluations (determining the membership grade of each criterion and building mxm matrix, obtaining the maximum eigenvalue of the reciprocal matrix and nally exponential weighting), the following results are obtained (for complete information of this work, see Karadogan et al.11 ).

70

A. Kesimal & A. Bascetin Table 4. Criterion C1 C2 C3 C4 C5 C6 C7 C8 C9 Operation Geometric shape of the deposit Coal thickness Seam inclination Ore depth Soundness degree of the lignite Contact state of the lignite seam Soundness degree of the hanging wall Soundness degree of the foot wall Subsidence eect Criteria of each operation. Criterion C10 C11 C12 C13 C14 C15 C16 C17 C18 Operation Roof support Settlement area Combustion Methane existence Ground water Mining cost Capital cost Production ratio Labour cost

D (A) = {0.81/A1, 0.79/A2, 0.89/A3 , 0.87/A4 , 0.92/A5 } And the optimal solution is, D (A ) = 0.92/A5 . In conclusion, room and pillar method with lling (A5 ) resulted in more suitable method with 0.92 membership degree than others. 5. Conclusions By the development of computer technology and programming of colloquial language with expert systems have considerably reduced decision makers burden. Thus, this paper has discussed decision making in a fuzzy environment for solving multiple attribute problems of optimum equipment selection in surface mining and optimum underground mining method selection. The most important approaches and basic concepts were introduced. Since the focus is on fuzzy multiple attribute problems, a detailed discussion of the most important methods for solving these problems was presented. Fuzzy multiple attribute decision making can result in nal design that is more practical and nancially ecient than conventional approaches. Inclusion of real operating constraints during the optimisation process as opposed to the normal technique of cyclic modication of optimal conditions oers potential savings in design times and costs. The method proposed can be programmed to run eectively on relatively low cost computing systems, thus providing the potential for wide spread exploitation of the technique within the mining industry worldwide. References

1. S. Bandopadhyay and A. Chattopadhyay, Selection of post-mining uses of land via fuzzy algorithm, Proc. 19th Int. Symp. Appl. Comput. Mine Planning (APCOM), ed. R. V. Ramani, SME/AIME, 1986, 321332.

Application of Fuzzy Multiple Attribute Decision

71

2. S. Bandopadhyay, Fuzzy algorithm for decision making in mining engineering, Int. J. Min. Geol. Eng. 5 (1987) 149154. 3. S. Bandopadhyay, Partial ranking of primary stripping equipment in surface mine planning, Int. J. Surf. Min. 1 (1987) 5559. 4. A. Bascetin, Optimal equipment selection in open pit mines, PhD Thesis, University of Istanbul, Faculty of Engineering Mining Engineering Department January, Istanbul, Turkey, 1999, 115 p. 5. A. Bascetin and A. Kesimal, The study of a fuzzy set theory for the selection of an optimum coal transportation system from pit to the power plant, Int. J. Surf. Min. Reclamation Env. 13 (1999) 97101. 6. A. Bascetin and A. Kesimal, The application of fuzzy Boolean linear programming technique to solve problems of selective mining, 5th Nat. Open Pit Min. Conf. Bulgaria, June 26, 1998, 322329. 7. D. Dubois, H. Prade and S. Sessa, Recent Literature in Fuzzy Sets and Systems, eds. C. V. Negoita, L. A. Zadeh and H. J. Zimmerman 51, 1 (1992) 119129. 8. M. A. Gershon, S. Bandopadhyay and V. Panchanadam, Mining method selection: A decision support system integrating multi-attribute utility theory and expert systems, Proc. 24th Int. Symp. Appl. Comput. Mine Planning (APCOM), ed. J. Elbrond, Canadian Institute of Mining and Metallurgy 3 (1993) 11-18. 9. D. Herzog and S. Bandopadhyay, Ranking of optimum benecation methods via the analytical hierarcy process, Proc. 26th Int. Symp. Appl. Comput. Mine Planning (APCOM), ed. R. V. Ramani, SME/AIME, 1996, 323329. 10. A. Kandel, Fuzzy Mathematical Techniques with Applications (Addison-Wesley, Reading, MA, 1986). 11. A. Karadogan, A. Bascetin, A. Kahriman and S. Gorgun, A new approach in selection of underground mining method, Int. Conf. Mod. Management Mine Producing Geol. Env. Protection, Varna, Bulgaria, June 39, 2001, 171183. 12. G. J. Klir and B. Yuan, Fuzy Sets and Fuzzy Logic: Theory and Applications (PrenticeHall, New York, 1995) 268. 13. G. J. Klir and T. Folger, Fuzzy Sets, Uncertainty, and Information (Prentice Hall, Englewood Clis, NI, 1988). 14. H. X. Li and V. C. Yen, Fuzzy Sets and Fuzzy Decision-Making, Chap. 4 (CRC Press, Boca Raton, FL) 1995. 15. J. Maiers and Y. S. Sherif, Applications of fuzzy set theory, IEEE Trans. Syst., Man Cybern. 15, 1 (1985) 175189. 16. Matlab, The Mathworks, Inc., version 5.0.0.4069, copyright 19841996. 17. V. U. Nguyen, Some fuzzy set applications in mining geomechanics, Int. J. Rock Mech. 22, 6 (1985) 369379. 18. V. U. Nguyen and E. Ashworth, Rock mass classication by fuzzy sets, Proc. 26th US Symp. Rock Mech., ed. E. Ashworth, 1985, 937945. 19. H. Prade, A computational approach to approximate reasoning with applications to expert systems, IEEE Trans. Pattern Anal. Mach. Intell. 713 (1985) 260283. 20. R. A. Riberio, Fuzzy multiple attribute decision making: A review and new preference elicitation techniques, Fuzzy Sets Syst. 78 (1996) 155181. 21. T. L. Saatty, Modelling unstructured decision problems The theory of analytical hierarchies, Math. Comput. Simulation 20 (1978) 147158. 22. R. R. Yager, Toward a general theory of approximate reasoning with uncertainty, Part 1: Non-specicify and fuzziness, Int. J. Intell. Syst. 1, 1 (1986) 4567. 23. R. R. Yager, A new methodology for ordinal multiobjective decisions based on fuzzy sets, Decision Sci. 12, 4 (1981) 589600.

72

A. Kesimal & A. Bascetin

24. L. A. Zadeh, Fuzzy sets, Inf. Cont. 813 (1965) 338353. 25. L. A. Zadeh, The concept of a linquistic variable and its application to approximate reasoning, Part 1, Inf. Sci. 813 (1975) 199249. 26. L. A. Zadeh, Syllogistic reasoning in fuzzy logic and its application to usuality and reasoning with dispositions, IEEE Trans. Syst. Management Cybernet. 1516 (1985) 754763.

You might also like

- Rel NotesDocument3 pagesRel NotesEmir IkanovićNo ratings yet

- GS950 Eco Series DS RevADocument2 pagesGS950 Eco Series DS RevAEmir IkanovićNo ratings yet

- Fs724l Eco DsDocument3 pagesFs724l Eco DsEmir IkanovićNo ratings yet

- Robust OnDocument9 pagesRobust OnEmir IkanovićNo ratings yet

- Outranking RelationshipsDocument12 pagesOutranking RelationshipsEmir IkanovićNo ratings yet

- Multi-Criteria Mining by Nenad MladineoDocument4 pagesMulti-Criteria Mining by Nenad MladineoEmir IkanovićNo ratings yet

- Cone CrusherDocument5 pagesCone CrusherEmir Ikanović100% (1)

- An Intelligent ClassDocument42 pagesAn Intelligent ClassEmir IkanovićNo ratings yet

- Promethee Method PDFDocument5 pagesPromethee Method PDFEmir Ikanović100% (1)

- Analysis and OptimizationDocument3 pagesAnalysis and OptimizationEmir IkanovićNo ratings yet

- Multi ObjectDocument5 pagesMulti ObjectEmir IkanovićNo ratings yet

- Alice in Wonderland, Lewis CarrollDocument67 pagesAlice in Wonderland, Lewis Carrollrobinho100% (3)

- Stohastika PDFDocument7 pagesStohastika PDFEmir IkanovićNo ratings yet

- A Comparative StudyDocument7 pagesA Comparative StudyEmir IkanovićNo ratings yet

- Fundamental of Field Bus System With S7-300Document65 pagesFundamental of Field Bus System With S7-300SamehibrahemNo ratings yet

- Mehanika DulcicDocument304 pagesMehanika DulcicFran GloblekNo ratings yet

- Osnovi MehatronikeDocument47 pagesOsnovi MehatronikeHadzalic MaidNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 31027718-HUAWEI BSC6000 System DescriptionDocument84 pages31027718-HUAWEI BSC6000 System Descriptionabkarimtc100% (1)

- Unit 5 Dive Tables and Dive ComputersDocument29 pagesUnit 5 Dive Tables and Dive ComputersnoNo ratings yet

- Declaration of XXXXXXXXX.: (Redacted) Location in The United States of AmericaDocument17 pagesDeclaration of XXXXXXXXX.: (Redacted) Location in The United States of AmericaEnwardCZorhanz94% (31)

- PETSc Manual PDFDocument272 pagesPETSc Manual PDFUtkun Erinc MalkocogluNo ratings yet

- FCBADocument5 pagesFCBATwilightNo ratings yet

- ResumeDocument4 pagesResumeSandeep LakkumdasNo ratings yet

- Certified Labview Developer Examination: InstructionsDocument8 pagesCertified Labview Developer Examination: InstructionsAugustineEsperonParondaNo ratings yet

- Group No.: 8 Section Code: B315 Group Leader: Group MembersDocument21 pagesGroup No.: 8 Section Code: B315 Group Leader: Group MembersAlfie BautistaNo ratings yet

- ROWE Scan 600 Manual PDFDocument157 pagesROWE Scan 600 Manual PDFMārtiņš DreijersNo ratings yet

- Shubham SinghalDocument1 pageShubham SinghalSahil0111No ratings yet

- Power Platform Admin and Governance WhitepaperDocument117 pagesPower Platform Admin and Governance WhitepaperJesse OliveiraNo ratings yet

- Sage ERP X3: Development Part 1 Exercises Level 1Document24 pagesSage ERP X3: Development Part 1 Exercises Level 1Yahya ChiguerNo ratings yet

- Exercise - 01: Check Your GraspDocument3 pagesExercise - 01: Check Your GraspAnkit Singh YadavNo ratings yet

- Demandware Load Test Plan - TemplateDocument4 pagesDemandware Load Test Plan - TemplateAshok JagtapNo ratings yet

- Config Item Creation Flow2Document1 pageConfig Item Creation Flow2sen2985100% (1)

- Test 4Document32 pagesTest 4Santosh JagtapNo ratings yet

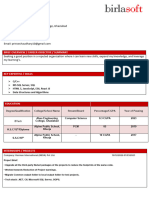

- Birlasoft Resume SampleDocument3 pagesBirlasoft Resume SamplePrince Kumar ChaudharyNo ratings yet

- Mohammed JaberDocument768 pagesMohammed JaberMohammed Omar JaberNo ratings yet

- Diagnostic Grammar Test-CopiarDocument6 pagesDiagnostic Grammar Test-CopiarJuliana PachonNo ratings yet

- Mahatma Gandhi University: NotificationDocument16 pagesMahatma Gandhi University: NotificationMukesh BishtNo ratings yet

- Semiconductor Main MemoryDocument15 pagesSemiconductor Main MemoryBereket TarikuNo ratings yet

- Arnab Dutta (Software)Document1 pageArnab Dutta (Software)Arnab DuttaNo ratings yet

- Teacher Induction Program Module 6 V1.0Document41 pagesTeacher Induction Program Module 6 V1.0Jefferson Kevin LerioNo ratings yet

- Using Clcs in Real-Time Applications: Wwwproducts/En/Pic18F47Q10Document41 pagesUsing Clcs in Real-Time Applications: Wwwproducts/En/Pic18F47Q10Bruno LeppeNo ratings yet

- Thematic Area 1: System Functionality: Issues and Challenges Solutions Taken/Highlights RecommendationsDocument3 pagesThematic Area 1: System Functionality: Issues and Challenges Solutions Taken/Highlights RecommendationsPanfilo Ferrer Dioquino Jr.No ratings yet

- Example 2:: Find The Zeroes of The Quadratic Polynomial XDocument8 pagesExample 2:: Find The Zeroes of The Quadratic Polynomial XShafeequ RahmanNo ratings yet

- SST 1700bDocument34 pagesSST 1700bDabi YannNo ratings yet

- Electronic Control System ComponentsDocument7 pagesElectronic Control System ComponentsTri WahyuningsihNo ratings yet

- E560 MPR01 DSDocument6 pagesE560 MPR01 DSSalvador FayssalNo ratings yet

- PLC Wiring Q&aDocument59 pagesPLC Wiring Q&apascal sitanggangNo ratings yet