Professional Documents

Culture Documents

LPG Tanker 1

Uploaded by

Somayajula SuryaramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LPG Tanker 1

Uploaded by

Somayajula SuryaramCopyright:

Available Formats

'Super-cooler' - a new generation of LPG tanker

NEW generation of medium-size LPG tankers is currently being launched onto the market by Norgas, the Scandinavian company that will be operating the new series on behalf of I M Skaugen, a leading Norwegian owner. A short port turnround time is claimed as the principal benefit of the 8550m3 design, which has been drawn up by the Danish company Dwinger Marineconsult, a member of the Carl Bro group. A total of four ships of this so-called 'supercooler' class have been ordered from the Hudong-Zhonghua group in Shanghai, China; these two nearby yards amalgamated not long ago. The lead ship, Norgas Orinda, was completed in October last year. In addition, two slightly larger ships are to be constructed, and options exist for four further tankers. The benefits have been achieved by increasing tank pressure from 4.5bar to 7bar, and this - in conjunction with a daily maximum o cooling capacity of 2 C in tropical waters means that in practical terms loading time for o ambient propylene at 25 C has been cut by between two and three days, when compared

The 8550m3 Norgas Orinda is the first of a new series of so-called 'super-cooler' LPG tankers on order at the Chinese Hudong-Zhonghua yards, that are claimed to offer major benefits in shorter port turnround times.

TECHNICAL PARTICULARS NORGAS 'SUPER-COOLER' LPG TANKERS Length, oa............................... 124.90m Length, bp........................... 115.00m Breadth, moulded.......19.80m Depth, moulded to main deck............................11.50m Draught, design............6.70m Draught, scantling...................... 8.30m Gross........................8720gt Deadweight, design..... 6000dwt Deadweight, scantling.........9400dwt Capacity capacity... 8550m3 Water ballast........5000m3 Speed, service (85% MCR).... 16.70knots Main engine MAN B&W 6L48/60 Output, MCR ..6300kW Flag........ Hong Kong Classification....Det Norske Veritas 1A1 Tanker for Liquefied Gas, Ice 1C, o EO, T-MON, Ship Type 2G, -104 C, 972kg/m3, 7bar g

with similar conventional tankers. At the same time, the designer says that between four and 10 days can be saved when cooling a cargo o o from 25 C to -46 C. A shallow draught and a wide beam have been selected to allow this new class to load and discharge on an even keel, as well as giving an ability to handle a large cargo in shallow-water ports. At the same time, the specification of an Ulstein high-efficiency flap rudder and a 700kW Brunvoll bow thruster assists fast turnrounds by permitting Norgas Orinda and her sisters to turn in their own length as well as an ability to track sideways. The two cargo tanks have capacities of 5322m3 and 3139m3 and are of cylindrical shape with spherical ends, a design that is claimed to offer 30% less surface area than bi-

lobe types, thus contributing to insulation efficiency. A further tank, of 90m3, is installed on the weather deck to transport coolant. An onboard nitrogen plant allows tank purging on route, and this can be used, with coolant in the deck tank, to prepare for a different cargo grade while at sea. A MAN B&W 6L48/60 main engine develops 6300kW MCR, and drives a Alpha CP propeller to give the new class a service speed of 16.70knots. The reduction gearbox is fitted with a power take-off for a 1700kW alternator, which is equipped to double as a propulsion motor in emergencies, when it is supplied with current by four 550kW dieselalternator sets. More information on Norgas Orinda can be found in the newly published RINA annual Significant Ships of 2002.

Consultancy launches engineering service for air conditioning

NEW independent marine engineering consultancy is hoping to improve airconditioning onboard passenger ships, which, in Giles Consulting's opinion, has fallen behind the standards of land-based installations. Problems often arise because design, supply, and installation of an air-conditioning system are often vested in a single contractor. Thus the company has launched investigative engineering services to determine the cause of airconditioning failure, and then come up with the right solution. Such services may stop potential

litigation ever going to court. Giles is also in the market for original design work, which aims to prevent problems happening in the first place. Present problems are often caused, according to Giles Consulting, by a shipyard's sub-contractor agreeing to design a system for free, or at very low cost, on the condition that the same company wins the supply and installation contract. For expediency and cost, a contractor will employ methods, however antiquated, and specify products that may not be appropriate for the job. Making one company responsible for all aspects

of the work may be expedient for the shipyard, but there are often too many vested interests in such an arrangement. This consultancy, which can respond rapidly anywhere in the world, is looking to work on more cruise ships, ferries, and luxury yachts over 45m long. It believes that money saved by its corrective surgery will in the long run mitigate the cost of its services. Giles Consulting cites a number of ship systems that it already attends as a strong indication of industry demand for its services.

THE NAVAL ARCHITECT FEBRUARY 2003

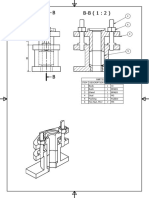

General arrangement plans of the 8550m3 LPG tanker Norgas Orinda and her sisters, ordered by I M Skaugen from Hudong-Zhonghua.

THE NAVAL ARCHITECT FEBRUARY 2003

You might also like

- Wartsila SP Technical Paper LPG Systems PDFDocument18 pagesWartsila SP Technical Paper LPG Systems PDFGhulam-ullah KhanNo ratings yet

- 10 Wartsila K Portin Performance DF Engines in LNG CarriersDocument21 pages10 Wartsila K Portin Performance DF Engines in LNG Carriersali kharalNo ratings yet

- H1827A GAS FORM B - For CSSC LEASING - R01 - 2Document11 pagesH1827A GAS FORM B - For CSSC LEASING - R01 - 2yaNo ratings yet

- Physics of Liq GasesDocument21 pagesPhysics of Liq GasesOctavianNo ratings yet

- Dstenersen Pres (Full Permission)Document38 pagesDstenersen Pres (Full Permission)Salvatore BuonoNo ratings yet

- Star Lite LNGDocument16 pagesStar Lite LNGelton100% (1)

- SUNY Maritime 8520 Teu Dual Fuel ContainershipDocument137 pagesSUNY Maritime 8520 Teu Dual Fuel Containershipntontarski100% (1)

- LNGDocument2 pagesLNGbernardinodinoNo ratings yet

- GAS TANKERS Types NOTESDocument29 pagesGAS TANKERS Types NOTESJayant Khedkar100% (1)

- LNG Tech 2Document28 pagesLNG Tech 2genergia50% (2)

- Ocimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014Document2 pagesOcimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014xingangNo ratings yet

- Air Lubrication TechnologyDocument15 pagesAir Lubrication TechnologyzaladsNo ratings yet

- Cryo StarDocument12 pagesCryo Starelenaro1234No ratings yet

- LNG Carrier 10000cbmDocument1 pageLNG Carrier 10000cbmpriyoNo ratings yet

- LNG Fueled Vessels Design Training: Lecture Notes OnDocument151 pagesLNG Fueled Vessels Design Training: Lecture Notes Onkhanh123ctmNo ratings yet

- Tanker Operator 2014 06 JuneDocument44 pagesTanker Operator 2014 06 JuneVasileios IliopoulosNo ratings yet

- Gas Ship Measurement Guidelines: 1 Gas Measure 9/99 Version 01/98 Rev 4Document40 pagesGas Ship Measurement Guidelines: 1 Gas Measure 9/99 Version 01/98 Rev 4Henry MaedaNo ratings yet

- Type Dan Jenis Kapal Tanker Gas Utk TarunaDocument25 pagesType Dan Jenis Kapal Tanker Gas Utk TarunaBebincaNo ratings yet

- Gaztransport & TechnigazDocument4 pagesGaztransport & TechnigaziuliiulianNo ratings yet

- Joint Industry Guidance On The Supply and Use of 0.50 Sulphur Marine FuelDocument64 pagesJoint Industry Guidance On The Supply and Use of 0.50 Sulphur Marine FuelharrdyNo ratings yet

- Adnan Ezzarhouni GTTChina (Revised Version)Document17 pagesAdnan Ezzarhouni GTTChina (Revised Version)ClemenNo ratings yet

- Bureau Veritas Issues FSU, FSRU Conversion GuidelinesDocument1 pageBureau Veritas Issues FSU, FSRU Conversion GuidelinesamirlngNo ratings yet

- Safety Concept - Dual Fuel EnginesDocument104 pagesSafety Concept - Dual Fuel EnginesSergei KurpishNo ratings yet

- Triality VLCCDocument20 pagesTriality VLCCLeo ThomasNo ratings yet

- A Complete Guide of Cargo Sampling On Tankers - MySeaTimeDocument17 pagesA Complete Guide of Cargo Sampling On Tankers - MySeaTimevdeviv67% (3)

- Consolidated Version of The Survey Guidelines Under HSSC of Survey and CertificateDocument182 pagesConsolidated Version of The Survey Guidelines Under HSSC of Survey and CertificatemecatronicatresNo ratings yet

- HSE-07.24 - Appendix XVI - Exhaust Gas Scrubber Management PlanDocument68 pagesHSE-07.24 - Appendix XVI - Exhaust Gas Scrubber Management PlanAndriy100% (1)

- 1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachineryDocument2 pages1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachinerysirvoltusNo ratings yet

- Difference Between Bulk and Break BulkDocument17 pagesDifference Between Bulk and Break BulkHarun Kınalı0% (1)

- DF 2005 2 PDFDocument16 pagesDF 2005 2 PDFAnonymous yRpebGJGaNo ratings yet

- 1.gas Tankers Relief Valve Setting Why Different in Sailing and PortDocument6 pages1.gas Tankers Relief Valve Setting Why Different in Sailing and PortArani ManjunathNo ratings yet

- DFDE 4 Stroke Wartsila PDFDocument60 pagesDFDE 4 Stroke Wartsila PDFpadangiringNo ratings yet

- Optimal Low Load OperationDocument6 pagesOptimal Low Load Operationpapaki2No ratings yet

- Gas Tanker ProjectDocument40 pagesGas Tanker ProjectJudson FarrayNo ratings yet

- ABS Low Carbon ShippingDocument80 pagesABS Low Carbon Shippingmsantosu000No ratings yet

- Imo 2020 Comprehensive Guide v17 PDFDocument28 pagesImo 2020 Comprehensive Guide v17 PDFTianhui HothNo ratings yet

- Sea Transport of Liquid Chemicals in Bulk PDFDocument131 pagesSea Transport of Liquid Chemicals in Bulk PDFDiana MoralesNo ratings yet

- Tugs - Developments For PDFDocument28 pagesTugs - Developments For PDFP Venkata SureshNo ratings yet

- LNG Carriers With High Pressure Gas Supply SystemDocument34 pagesLNG Carriers With High Pressure Gas Supply SystemFuchsbauNo ratings yet

- Tanker DesignDocument34 pagesTanker DesignVivekanand PatelNo ratings yet

- Ajit Vadakayil - Deepwell Pumps On Chemical Tankers - Capt Ajit VadakayilDocument24 pagesAjit Vadakayil - Deepwell Pumps On Chemical Tankers - Capt Ajit VadakayilMannMannNo ratings yet

- Fundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Document74 pagesFundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Tamunoiboumie ElijahNo ratings yet

- Propulsion Trends in Tankers - HTMDocument22 pagesPropulsion Trends in Tankers - HTMlesmosNo ratings yet

- Inert Gas On Board Tankers - All You Need To KnowDocument9 pagesInert Gas On Board Tankers - All You Need To KnowShoaib100% (1)

- Tanker Terminal and Liquid Cargo CourseDocument4 pagesTanker Terminal and Liquid Cargo CourseAnonymous yJ7VjL28iNo ratings yet

- LNG AgeingDocument13 pagesLNG AgeingBenoit PuyoNo ratings yet

- Different Types of TankersDocument23 pagesDifferent Types of TankersBhupender Ramchandani100% (2)

- Brochure Tge GasDocument13 pagesBrochure Tge GasCemGülerNo ratings yet

- 4 Study of Small Scale LNG CarrierDocument25 pages4 Study of Small Scale LNG CarrierSangeethRoshan100% (1)

- Vapour Emission Control System Onboard Chemical TankersDocument2 pagesVapour Emission Control System Onboard Chemical Tankersjish1210100% (1)

- Cargo Control RoomDocument15 pagesCargo Control RoomStamatis KaragounisNo ratings yet

- GTT CS1Document4 pagesGTT CS1iuliiulianNo ratings yet

- Types of LNG CarriersDocument11 pagesTypes of LNG CarriersAnonymous icnhaNsFNo ratings yet

- Quantum 9000Document36 pagesQuantum 9000FuchsbauNo ratings yet

- Gas and Steam Turbine For BoatsDocument49 pagesGas and Steam Turbine For BoatsAlisandro AfataNo ratings yet

- Quantum 9000 PDFDocument36 pagesQuantum 9000 PDFДмитрий ЗинченкоNo ratings yet

- New Cruise Ship ConceptDocument4 pagesNew Cruise Ship ConceptFuchsbauNo ratings yet

- QHSE Alert-024-Anchoring & MooringDocument1 pageQHSE Alert-024-Anchoring & MooringSomayajula SuryaramNo ratings yet

- Popeye The Sailor Man - Who KnewDocument2 pagesPopeye The Sailor Man - Who KnewSomayajula SuryaramNo ratings yet

- Predicting Optimal Trim For ShipsDocument79 pagesPredicting Optimal Trim For ShipsSomayajula SuryaramNo ratings yet

- India TodayDocument66 pagesIndia TodaySomayajula SuryaramNo ratings yet

- E NOIDocument3 pagesE NOISomayajula SuryaramNo ratings yet

- What Are CATZOC and How To Use It For Passage PlanningDocument30 pagesWhat Are CATZOC and How To Use It For Passage PlanningSomayajula Suryaram100% (1)

- DynaLiners Weekly 49-2015Document12 pagesDynaLiners Weekly 49-2015Somayajula SuryaramNo ratings yet

- Unified Form DBTLDocument1 pageUnified Form DBTLkayalonthewebNo ratings yet

- Steering GearDocument2 pagesSteering GearSomayajula Suryaram100% (1)

- February 2015Document8 pagesFebruary 2015Somayajula SuryaramNo ratings yet

- PAN BookDocument33 pagesPAN Bookalohia82No ratings yet

- About IIIT-H - IIIT HyderabadDocument2 pagesAbout IIIT-H - IIIT HyderabadSomayajula SuryaramNo ratings yet

- 09 BPReversingDocument93 pages09 BPReversinggmatweakNo ratings yet

- Action To Be Taken For IntermediaryDocument1 pageAction To Be Taken For IntermediarySomayajula SuryaramNo ratings yet

- CASE: 1 / Changing All Tanks To C3Document1 pageCASE: 1 / Changing All Tanks To C3Somayajula SuryaramNo ratings yet

- Mastrep NewReporting SystemDocument4 pagesMastrep NewReporting SystemSomayajula SuryaramNo ratings yet

- Js Insight Gas Form CDocument64 pagesJs Insight Gas Form CSomayajula SuryaramNo ratings yet

- ETH HandbookDocument68 pagesETH HandbookGianluca Can GenovaNo ratings yet

- CSR FormsDocument5 pagesCSR FormsSomayajula SuryaramNo ratings yet

- National Institutes of TechnologyDocument15 pagesNational Institutes of TechnologySomayajula SuryaramNo ratings yet

- Gassing-Up & Cooling Down NotesDocument7 pagesGassing-Up & Cooling Down NotesSomayajula SuryaramNo ratings yet

- SitDocument7 pagesSitSomayajula SuryaramNo ratings yet

- National Institutes of TechnologyDocument15 pagesNational Institutes of TechnologySomayajula SuryaramNo ratings yet

- Information Brochure JEE Adv 2015 Ver 2.2!29!12 2014Document76 pagesInformation Brochure JEE Adv 2015 Ver 2.2!29!12 2014Sidharth AryaNo ratings yet

- OSHAS Basic TrainingDocument36 pagesOSHAS Basic TrainingSomayajula SuryaramNo ratings yet

- Imo Wheelhouse Poster (Musashi Gloria)Document1 pageImo Wheelhouse Poster (Musashi Gloria)Somayajula Suryaram100% (1)

- IISc UG - FAQDocument4 pagesIISc UG - FAQSomayajula SuryaramNo ratings yet

- MLC GuidanceDocument2 pagesMLC GuidanceSomayajula Suryaram100% (1)

- Rescue SignalsDocument2 pagesRescue Signalssuresh25489042100% (2)

- Self Checklist For SMS 2010Document8 pagesSelf Checklist For SMS 2010Somayajula Suryaram100% (2)

- Sulzer RtaDocument24 pagesSulzer Rtafederrr86% (7)

- Pitch Control For Ships With Diesel Mechanical and Hybrid PropulsionDocument23 pagesPitch Control For Ships With Diesel Mechanical and Hybrid Propulsionjulianasange8No ratings yet

- Iami Section A - Motor EkDocument9 pagesIami Section A - Motor Ekstelios0% (1)

- Modern Technology in Ship Building IndustryDocument17 pagesModern Technology in Ship Building IndustrySwapnil Rupaye100% (2)

- Yanmar Propulsion Medium Speed 0803Document20 pagesYanmar Propulsion Medium Speed 0803Mohsen MoghadamNo ratings yet

- Naval ArchitectureDocument79 pagesNaval ArchitectureRENGANATHAN PNo ratings yet

- Sizes: Zodiac Hurricane: Critical Mission SolutionsDocument2 pagesSizes: Zodiac Hurricane: Critical Mission SolutionsEtrcilNo ratings yet

- Kanaya CompanyProfileDocument28 pagesKanaya CompanyProfileElidas SwesiNo ratings yet

- 2014 - Operational - MSC.1 Circ.1417 - Guidelines For Passenger Ship TendersDocument13 pages2014 - Operational - MSC.1 Circ.1417 - Guidelines For Passenger Ship TendersKTVNo ratings yet

- +diesel Electric Propulsion Plants Engineering GuidelineDocument27 pages+diesel Electric Propulsion Plants Engineering GuidelinelesmosNo ratings yet

- Wartsila SP PPT 2012 OSV Europe.Document25 pagesWartsila SP PPT 2012 OSV Europe.Uhrin ImreNo ratings yet

- Servogear Instruction Manual. Part III. Rev 01. 21.03.2011Document40 pagesServogear Instruction Manual. Part III. Rev 01. 21.03.2011michelNo ratings yet

- Application of GT35 Industrial Turbine For FerryDocument5 pagesApplication of GT35 Industrial Turbine For FerryFauzan PhoneNo ratings yet

- Divakar C. Menon.: Email: Mobile: +91-9487733295, 9443333295. Phone: +91-413-2272916 Career OrientationDocument5 pagesDivakar C. Menon.: Email: Mobile: +91-9487733295, 9443333295. Phone: +91-413-2272916 Career Orientationpnark02No ratings yet

- EFINORDocument21 pagesEFINORElias JarjouraNo ratings yet

- EU Standards For Boats PDFDocument11 pagesEU Standards For Boats PDFmusebladeNo ratings yet

- Engineering STEYR MOTORS DigitalDocument28 pagesEngineering STEYR MOTORS DigitalhakjinNo ratings yet

- 4 Diesel PropulsionDocument52 pages4 Diesel Propulsionsudhanshu22kumar22No ratings yet

- Data Sheet PDFDocument2 pagesData Sheet PDFRaymundo AlarconNo ratings yet

- M/T Saracena: 20.500 DWT - Twin Screw Diesel Driven Oil Chemical Tanker Ice Class 1A - Rina ClassDocument2 pagesM/T Saracena: 20.500 DWT - Twin Screw Diesel Driven Oil Chemical Tanker Ice Class 1A - Rina ClasshalimNo ratings yet

- Modern Marine Engineer Manual Volume IIDocument418 pagesModern Marine Engineer Manual Volume IIHergheligiu VasileNo ratings yet

- MEPC.1-Circ.683 - Guidance For The Development of A Ship Energy Efficiency Management PlanDocument13 pagesMEPC.1-Circ.683 - Guidance For The Development of A Ship Energy Efficiency Management PlangetnarayanaprakashNo ratings yet

- Sea 302Document6 pagesSea 302PetricaNo ratings yet

- 2018-11-13 ABC Presentation - The Power of Change, Literally-V2Document36 pages2018-11-13 ABC Presentation - The Power of Change, Literally-V2Mohamed SalemNo ratings yet

- NMIT MRI 2303 General Ship Knowledge CHDocument19 pagesNMIT MRI 2303 General Ship Knowledge CHAdrianAndyNo ratings yet

- CC1200 Parts SERIAL 10000332xxa012669Document332 pagesCC1200 Parts SERIAL 10000332xxa012669Adrian Mora100% (1)

- Caterpillar Marine Commisioning and Sea Trial Guide - CAT 3500Document54 pagesCaterpillar Marine Commisioning and Sea Trial Guide - CAT 3500nicusebp100% (1)

- Stuffing BoxDocument2 pagesStuffing BoxAnonymous hlRLVcMNo ratings yet

- 2008 Mercruiser Service Manual Index PDFDocument6 pages2008 Mercruiser Service Manual Index PDFkujawat11No ratings yet

- Horseless VehicleDocument488 pagesHorseless Vehiclevuongspkt12007No ratings yet