Professional Documents

Culture Documents

CRJ Isar

Uploaded by

anshit1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRJ Isar

Uploaded by

anshit1Copyright:

Available Formats

CRJ100/200

ISAR 2005-05

ISAR ATA-Numbered Articles

123 Garratt Blvd. Downsview, Ontario, Canada M3K 1Y5 Telephone 1(416) 633-7310 http://www.aerospace.bombardier.com

IN-SERVICE ACTIVITIES REPORT

MAY 26, 2005

2005-05-0001: REMINDER : CRJ Series Operators Conference & Trade Show ......................................4 2005-05-0002: Training News - TC Acknowledgement of Same Type Rating for All CRJ Models ........5 2005-05-0003: SpotLight Awards, SpotLight First, and Other News ......................................................6 2005-05-0004: SpotLight Tip: Session Closing ......................................................................................7 2005-05-0005: Supplier Performance Metrics Now Available on RACS ................................................8 2005-05-0006: Vendor Backstop Claims - Process Information .............................................................8 2005-05-2210: Autopilot System Operation - Clarification ....................................................................10 2005-05-2720: Rudder Control System Front Pivot - Different Configurations.....................................11 2005-05-2811: Fuel Collector Tank Check Valve Functional Check ....................................................12 2005-05-3830: Toilet Fill/Rinse Shutoff Valve - STC Availability ..........................................................13

Quality Corner

.......................................................................................................................................................................13

Technical Publications News

Maintenance & Flight Manual Revision Schedule .................................................................................14

Maintenance Engineering News

2005-05-0007: Continuing Maintenance Requirements for Aging Aircraft - Part III .............................15 2005-05-0008: DREAM File Now Available on RACS Website ...........................................................17 2005-05-0009: Maintenance Task Optimization Initiatives ..................................................................18

All Operator Messages (AOM) Recently Issued ........................................................................... 19 Service Letters (SL) Recently Issued ........................................................................................... 19 Generic Reference Instruction Letter (RIL) Update ...................................................................... 19 Generic Repair Engineering Orders (REO) Recently Issued........................................................ 19 Generic In-Service Modsums Recently Issued............................................................................. 19 Bombardier Contacts (FSR/CSAM/Fleet Services) ..................................................................... 20

Readers are requested to please distribute this newsletter within their organizations.

THIS REPORT SUMMARIZES IN-SERVICE ACTIVITIES AND IS FOR BOMBARDIER AEROSPACE REGIONAL AIRCRAFT CUSTOMER INFORMATION ONLY

The ISAR is published by Customer Support. Please address inquiries to the Editor (1-416-373-7887; e-mail: lorne.bromley@aero.bombardier.com).

All published ISARs are available in the Technical Help Desk Library section of the RACS website: www.racs.bombardier.com

CRJ100/200 ISAR 2005-05

INTENT OF ISAR

The In-Service Activities Report is a technical newsletter which provides a forum for sharing in-service experiences. The document includes reports of problems and resolutions, as well as other noteworthy maintenance tips. It also provides a periodic update of customer support initiatives within Bombardier. The ISAR is intended to be read by all in the Operators organization who are concerned with maintenance support of the aircraft. In-Service Activities Reports are intended to provide routine notification of: Major items of interest and significance which have occurred during a specified period (e.g., since the previous edition of the ISAR). Discrepancies that have been experienced and reported by Operators. Action being taken to rectify discrepancies. Important Note: Material appearing in this ISAR is to be considered valid as of the date of publication. Operators concerned with the current validity and possible implications of a specific article in the ISAR should contact the Technical Help Desk (e-mail: thd.crj@aero.bombardier.com ; telephone: 1-514-855-8500).

HOW TO FIND ISARs ON RACS WEBSITE - http://www.racs.bombardier.com/ - Customer Login (enter username and password) - select Technical Help Desk Library - select CRJ - select CRJ 100/200/440 - select In-Service Activities Report (ISAR)

PROPRIETARY NOTICE This document is for information purposes only and is not part of any proposal and creates no contractual commitment. Information in this report is Proprietary to Bombardier Inc. and Bombardier Aerospace Regional Aircraft. This report must not be reproduced or distributed in whole or in part to a third party without prior express permission in writing from Bombardier Inc.

TECHNICAL CONTACT GUIDE TCG2005A, the latest edition of the Bombardier/Operator contact booklet, was

published on February 24, 2004. Available in PDF format only, TCG copies can be obtained by contacting lorne.bromley@aero.bombardier.com . The TCG can also be viewed on RACS (www.racs.bombardier.com ): select Technical Help Desk Library, select the appropriate aircraft category, click on FAD Most Frequently Accessed Documents, then click on Technical Contact Guide (this will take you to the PDF file).

For additional information on any of the in-service items covered in the ISAR, please contact your local Bombardier Aerospace Regional Aircraft Field Service Representative or the appropriate staff member noted below: Bob Duffield Martin Elliott Simon Heaton Jeffrey MacDavid Andy Nureddin Maurice Clark Dave Grant Dario Leone Robert Jacques Andrew Jones Tracy Lloyd Vasil Rambi Emily Holding Lorne Bromley Director, Maintenance Engineering Director, In-Service Engineering & Technical Support Director, Customer Support Director, Technical Publications Director, Customer Services Chief, Structures, Regional Aircraft Manager, In-Service Systems Engineering (Hydro-Mechanical/GSE) Manager, Field & Fleet Services Manager, Technical Help Desk Manager, In-Service Structures Engineering Manager, In-Service Systems Engineering (Avionics/Electrical/Propulsion) Manager, Maintenance Engineering Event & Conference Coordinator Customer Support Documentation Editor 1-416-375-3538 1-416-375-3177 1-416-373-3034 1-514-855-7308 1-416-373-5138 1-416-375-3092 1-514-855-7789 1-416-373-5295 1-514-855-7837 1-514-855-7054 1-450-476-7633 1-416-373-5529 1-514-855-8296 1-416-373-7887

CRJ100/200 ISAR 2005-05

From the Editor

Pinnacle Airlines, Inc. of Memphis, Tennessee is the featured Operator for this edition of the ISAR. Pinnacle flies in the colours of Northwest AIRLINK .

Pinnacle Airlines, formerly Express Airlines I, was founded in 1985 with the intent of offering regional airline passenger feed to a code sharing, major airlines hub. It began flying as Republic Express in August of the same year. Over the next decade, Express I provided safe, comfortable, and convenient airline service to 56 cities in the southeast and upper mid-west USA. In 1997, Northwest Airlines, Express Is new code share partner, elected to make changes in the structure of the company, which, until then, had been privately held. Effective April 1, 1997, Express I became a wholly-owned subsidiary of Northwest Airlines. In order to concentrate on flying from the Memphis Hub, Express I moved its headquarters to Memphis, Tennessee, creating many job opportunities and relocating several people to the area. Shortly after relocating to Memphis, the company was awarded 42 CRJs designated to operate as Northwest Jet Airlink. Delivery of the CRJs began in April 2000. The first Northwest CRJ lifted into the sky on June 1, 2001, flying from Memphis to Greenville-Spartanburg, S.C. As of May 9, 2005, Pinnacle operates 123 CRJs and 712 daily flights in the U.S. and Canada from its hubs in Detroit, Memphis, and Minneapolis. After the CRJ deliveries are completed, Pinnacle will operate 139 CRJs. In addition to its hubs, Pinnacle Airlines maintains Maintenance, Repair, and Overhaul (MRO) facilities located in Knoxville, Tennessee, Tulsa, Oklahoma, and South Bend and Fort Wayne in Indiana. These locations are designed to perform preventative maintenance on the CRJs. To more accurately reflect our objectives as an airline, Express Airlines I, Inc. officially changed its name to Pinnacle Airlines, Inc. on May 8, 2002. Pinnacle is now a publicly held company. Stock is traded on the NASDAQ Market as PNCL. The airline currently employs approximately 3,400 people.

Bombardier staff assigned to support Pinnacle includes Sandra Tymchuk, Customer Support Account Manager, and Gilles Potvin and Mike Dornenburg, Field Service Representatives.

Our thanks to Kristen Loughman, Manager, Internal Communications at Pinnacle and Gilles Potvin for the material for this feature.

For more information on this Operator, visit the website: www.nwairlink.com

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability

2005-05-0001

CRJ100/200/440/700/900

contributed by Emily Holding, Customer Services

REMINDER: CRJ Series Operators Conference and Trade Show

We would like to encourage you to attend the 1st CRJ Series Operators Conference & Trade Show to be held June 20-24, 2005 in Montral, Qubec, Canada. This year, we have combined the CRJ products into one conference which we hope will appeal to both our Operators and suppliers. The meetings will be held at the Palais de Congrs, a versatile conference centre in the heart of Montrals international district. It is near our preferred hotel, the Delta Centre-Ville, connected to the metro (subway), and linked to the worlds largest indoor/underground pedestrian network. If you are planning on exploring the city, see the helpful website: http://www.stcum.qc.ca/english/metro/a-mapmet.htm . The main conference forum will provide Operators with the latest updates from In-Service Engineering, Technical Publications, Spares, and Programs. In addition, we have added several workshops on Wednesday, June 22nd. The workshops include Avionics, SFAR88, Lightning Strike, Aging Aircraft, Aircraft Economics, a PPG session, and a Flight Operations Performance Review. Join us on Tuesday, June 21st to open the Trade Show with a Cocktail Reception starting at 7 p.m. The Trade Show runs from Tuesday evening until 5 p.m. on Wednesday. Dont forget your passport to the show and visit all our suppliers for the chance to win a prize. Enjoy Montrals world-famous joie de vivre at Delta Centre-Ville, our preferred hotel for the conference. Ideally situated where Old Montral and the new international business district meet near the Montral World Trade Centre, Delta Centre-Ville is the perfect base from which to explore North Americas largest French-speaking city during your free time. The following link will provide direct access to the Bombardier rate reservations at the Delta Centre-Ville: http://www.deltacentreville.ca/CRJO . The Delta Centre-Ville boasts Montrals only revolving rooftop restaurant. All week long, you can enjoy the view as you indulge in the Chefs inspired breakfasts, provided just for Bombardier guests. To register for the conference and find further information, visit our website at www.racs.bombardier.com , Shows & Events, or contact Emily Holding, Event & Conference Coordinator (emily.holding@aero.bombardier.com ; phone: 1-514-855-8296).

ATTENTION !

Deadline for registration and to book hotel accommodations:

MAY 27

CRJ100/200 ISAR 2005-05

ISAR Article Subject

2005-05-0002 contributed by Edgar Guntermann, Mgr., Instructional Systems; Training Centre Site Mgr. Training News: Transport Canada Acknowledgement of Same Type Rating for All CRJ Models

CRJ100/200/700/705/900

Applicability

On May 3, 2005, Transport Canada formally acknowledged the same type rating between the CL600-2D15, CL-600-2B19, CL-600-2C10, and the CL-600-2D24 (i.e., CRJ100/200, CRJ700, CRJ900, and CRJ705) variants of the CRJ. The latest operational evaluation determined that the earlier training, checking, and currency requirements are unchanged, and those between the CRJ900 and CRJ705 are A/A/A - in other words, only a handout is required for training. The FAA and EASA are in accord with the TC findings, however, their results will only be published towards the end of June 2005. Same type rating allows pilots to fly all variants of the CRJ with minimal additional training. The Operational Evaluation / Flight Standards Board activities determine the training/checking and currency requirements for an aircraft variant in comparison to the base aircraft. In the case of the CRJ705, no formal training program is required for a CRJ900 pilot to fly the CRJ705; only a handout describing the differences between the two variants is needed. A three-day differences course is sufficient for a CRJ200 pilot to become qualified on the CRJ900 or CRJ705. The benefits of same type rating for an Operator flying a mixed fleet are obvious in terms of reducing training and operating costs by having pilots qualified to fly multiple variants. The CRJ705/900 is the third successful CRJ Operational Evaluation / Flight Standards Board managed by the Montral-based Aircraft Services Instructional Systems department.

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability

2005-04-0003

contributed by Robin Clark & Dena Porter, CaseBank Technologies

- Awards, SpotLight First, and Other News

CRJ100/200/700/900; Q400

Monthly Awards

We are proud to announce that our monthly SpotLight awards are back, and are pleased to recognize the following individuals for their use of SpotLight during April: CRJ200: CRJ700: Q400: Bombardier: Sam Otero Christopher Kohr Maurice Takahashi (Tak) Bruce Chown SkyWest Airlines SkyWest Airlines Horizon Air FSR (at American Eagle)

Awards Program

Remember, our seasonal SpotLight First awards program that was announced in last months ISAR is running until midnight July 31, 2005. SpotLight users will be eligible to win based on the following criteria: Highest Number of Closed Sessions: This category is open to Operators and their registered SpotLight users. Note that Practice Sessions will not be considered in this contest. Highest Number of New Valid Sessions: Open to all registered Bombardier FSRs and THD SpotLight users. Note that Practice Sessions will not be considered in this contest. Best Suggestion to Enhance SpotLight: Open to all registered SpotLight users (Operators and Bombardier staff) across all three Bombardier knowledgebases (CRJ100/200/440, CRJ700/900, Q400).

Prizes Winners will have their choice from the following prize list: Apple iPod 20; Palm 32 MG Handheld; Canon 3.2MP Digital Camera; Amazon Gift Certificate (valued at $300 US or equivalent local currency). [NOTE: PRIZE MODEL NUMBERS MAY CHANGE DEPENDING ON CURRENT PRODUCT AVAILABILITY AT CLOSE OF CONTEST]

Apple iPod 20

Palm 32 MG Handheld

Canon 3.2MP Camera

Amazon Gift Certificate

For more contest information, please log onto SpotLight and click the SpotLight First link on your homepage. (Note: the SpotLight login can be accessed through the Bombardier RACS website.)

CRJ100/200 ISAR 2005-05

Other News

An Analysis of Current Troubleshooting Practices in the Regional Airline Community has recently been published. This white paper is a collaborative effort between CaseBank and Bombardier. Its intent is to inform Operators of their opportunity to save $34,800 to $52,500 US per aircraft per year, and to improve their first-time-fix rate by properly implementing and using SpotLight. We invite you to stop by the CaseBank booth at the upcoming CRJ Series Operators Conference & Trade Show and let SpotLight shine some light on the potential effect on your bottom line.

ISAR Article Subject Applicability

2005-04-0004

contributed by Robin Clark, CaseBank Technologies

User Tip: Session Closing

CRJ100/200/700/900; Q400

User feedback suggests that there is a perception that SpotLight places an extra workload on anyone creating a session. Many users believe they should leave their SpotLight sessions open until they know for sure that the action they performed was the correct fix. This places a burden on users when they return to work after vacation or days off, trying to close-out SpotLight sessions on aircraft with which they are no longer working. The goal of SpotLight is to ease your workload by sharing information. If you initiate a session on a particular aircraft and are signing off the defect in the log book, then you should also close-out the SpotLight session, indicating what the corrective action was. Any SpotLight session may be reopened and troubleshooting continued, if the problem repeats or new information becomes available, by anyone, anywhere in your organization. Also, if you worked on a SpotLight session and the aircraft is flying to another station with a deferred maintenance item, your session can be forwarded to that station for any continued action that might be required. SpotLight sessions should follow the aircraft, not the users. Open sessions should reflect what is open in the aircraft logs. Users should always review recent problems before starting a new session, and reopen existing sessions if a problem repeats. From your problem notes, you can recall what was done previously. If the problem repeats on the same aircraft, you have a record of previous activities thereby continuing the troubleshooting, rather than starting all over and repeating past fix attempts.

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability

2005-05-0005 contributed by Denis Murphy, Supplier Liaison, Customer Services Supplier Performance Metrics Now Available on RACS

CRJ100/200/700/900; Q100/200/300/400

As part of a continuing effort to increase Bombardier Aerospaces awareness and to monitor the performance of suppliers, the Supplier Liaison group is currently measuring supplier performance (i.e., on-time delivery performance and repair turnaround times) in regard to Operator purchase and repair orders. To assist in the measurement of supplier performance, a sample of certain Key Performance Indicators from specific suppliers has been posted on the Regional Aircraft Customer Services website (www.racs.bombardier.com ). Operator feedback on the suitability of these metrics is encouraged. To view the Key Performance Indicators sample, Operators should login to RACS and go to the News Update section. The title of the release is Supplier Performance and the subject is identified as Suppliers Key Performance Indicators.

ISAR Article Subject Applicability

2005-05-0006 contributed by Denis Murphy, Supplier Liaison, Customer Services Vendor Backstop Claims - Process Information

CRJ100/200/700/900; Q100/200/300/400

Supplier Liaison and Warranty have revised the Vendor BackStop (VBS) process to reflect the relaunch of the Supplier Liaison department and to provide further clarification of the process.

Important Note: VBS claims must be submitted to the Bombardier Aerospace Warranty Administrator within contractual terms and conditions in order to be accepted for consideration by Bombardier. The attached template is to be used for all VBS claim submittals, along with all related documents.

VBS provides the means by which customers of Bombardier Aerospace may claim warranty for vendor parts. Contractually, Bombardier covers warranty on Bombardier proprietary and manufactured parts only for Regional Aircraft customers. For vendor part warranty, it is expected that the customer will contact the vendor for coverage. The VBS process is used when customers do not receive the expected warranty coverage from the vendor. True vendor backstops are: 1. 2. 3. 4. 5. 6. Non-support from the vendor for warranty consideration, and the customer is forced to contact the Bombardier AOG team for support. The vendor part does not have PMA approval. Part repair turn-around time does not meet contractual agreements and the vendor does not or will not provide a free-of-charge exchange or loaner. Interface issues between the aircraft and a vendor part. The vendor does not offer warranty. The aircraft was delivered with a component that has a significant portion of its warranty period expired at the time of delivery.

Customers must submit claims to Bombardier when vendors deny warranty coverage within the contractually stipulated time period. The Warranty group will work with Supplier Liaison to research and negotiate a resolution with the vendor. When VBS claims are submitted after the contracted time limits, neither Bombardier or its vendors will be able to accept these claims. The attachment on the following page shows the specific requirements and obligations for the VBS process.

CRJ100/200 ISAR 2005-05

To: SUPPLIER LIAISON ISSUE CENTER Telephone: 416 375 3100 Fax: 416 375 4551 Email: sm@aero.bombardier.com

DATE: ______________________________

VENDOR BACKSTOP REQUEST FORM SUPPLIER LIAISON DEPARTMENT

Name of Operator Name of Contact at Operator: Aircraft Serial Number of AOG: Date of AOG: PO Number (AOG Order with Bombardier): Supplier Name: Date and Time Operator Contacted for AOG Support: Supplier Telephone Number Dialed: Supplier Response to AOG Request: PO Placed with Supplier (if applicable): Part Number of AOG: Part Description: Number of Spares Owned for AOG Part Number: Number of Repairs at Supplier for AOG Part Number: Number of Repairs at Supplier for AOG Part Number over 30 Days:

PLEASE INCLUDE ANY ADDITIONAL NOTES WHICH MAY BE RELEVANT TO YOUR VENDOR BACKSTOP REQUEST: ______________________________________________________________________________________ ______________________________________________________________________________________ ______________________________________________________________________________________ ______________________________________________________________________________________ ______________________________________________________________________________________ ______________________________________________________________________________________ ____________________________________________ PLEASE NOTE: ALL VENDOR BACKSTOP REQUESTS SHOULD BE SUBMITTED TO THE SUPPLIER LIAISON CALL CENTER WITHIN 24 HOURS.

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability Reference

2005-05-2210 contributed by Allen Firth, Technical Help Desk Autopilot System Operation - Clarification

CRJ100/200/700/900 AMM Chapter 22

The flight crew can engage the autopilot system of the CRJ aircraft by pressing the AP ENG button on the Flight Control Panel (FCP). When engaged without selecting any other lateral or vertical mode on the FCP, the autopilot enters into what is referred to as the basic pitch and roll mode. In basic pitch and roll mode, the Flight Control Computers (FCC) use the pitch and roll information transmitted by the Attitude/Heading Reference System (AHRS) or the Inertial Reference System (IRS), whichever option is installed, to control the aircraft. When the basic pitch and roll mode is active, the primary function of the autopilot is to keep the aircraft flying perfectly level, using the pitch and roll data from the AHRS/IRS. Depending on the attitude of the aircraft, the pitch and roll servos will move the flight controls (elevators and ailerons) in order to make the appropriate corrections to maintain level flight. On the ground, when maintenance personnel engage the autopilot in basic pitch and roll mode, the same logic applies to the system operation. However, if the aircraft is standing on the ramp or hangar floor that is not exactly level, the servos will command the flight controls to move towards a resolution of the error that exists between the present attitude of the aircraft and the perfectly level state. As the aircraft is on the ground and will not move as expected towards a resolution of the attitude error, an EICAS caution message (see below) will appear after a certain time delay to warn the crew that the aircraft is not responding to a pitch or roll change commanded by the autopilot. The caution messages can be one of the following, depending on the position of the aircraft: Message AP AP AP AP TRIM TRIM TRIM TRIM IS IS IS IS LWD RWD NU ND Meaning - autopilot trim is left wing down - autopilot trim is right wing down - autopilot trim is nose up - autopilot trim is nose down

For example, in a case where the aircraft is sitting on the ground with the right wing slightly higher than the left. Upon engagement of the autopilot, in basic pitch and roll mode, the handwheel will slowly rotate clockwise. After a while, the EICAS caution message AP TRIM IS RWD will be displayed. This situation is normal, as the autopilot seeks to bring the aircraft back to level even though it is on the ground and not in motion. In summary, whenever the autopilot is engaged on the ground, in basic pitch and roll mode, maintenance personnel should expect such EICAS messages and not interpret them as system malfunctions. If any ambiguity exists in the mechanics mind, the Aircraft Maintenance Manual should always be the first point of reference for complete system tests.

10

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability Reference

2005-05-2720 contributed by Jean-Francois Tremblay, Technical Help Desk Rudder Control System Front Pivot - Different Configurations

CRJ100/200 AIPC; AMM; NIEO 1000

An Operator reported a different configuration for the left-hand rudder control system front pivot installation. The Bombardier Technical Help Desk researched this issue and found different configurations in the Aircraft Illustrated Parts Catalogue (AIPC), Aircraft Maintenance Manual (AMM), and the engineering drawings. After this investigation, it was determined that the rudder control system front pivot installation p/n 600-90202-955 (L/H) and p/n 600-90202-956 (R/H) were created the same as p/n 600-90202-7 (L/H) and p/n 600-90202-10 (R/H), except for the following exceptions: Assembly -955 and -956 Modifications of assembly -7 and -10 were provided under Non-Incorporated Engineering Order (NIEO) 1000 to create the -955 and -956 assemblies. Spacer p/n 600-90265-1 (0.100 in. thickness) was added aft of washer p/n 600-90221-1 (0.080/0.081 in. thickness) to eliminate fouling on the assembly and to create a total thickness of 0.180 to 0.0181 in. Bolt p/n NAS1204-21D was replaced by bolt p/n NAS1204-23D to permit installation of the spacer on the assembly. Assembly -7 and -10 Washer p/n 600-90221-1 (0.080/0.081 in. thickness) was replaced by washer p/n 600-90221-3 (0.180/0.0181 in. thickness). This new washer permitted the removal of spacer p/n 600-90265-1. Bolt p/n NAS1204-23D was replaced by NAS1204-21D.

11

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability Reference

2005-05-2811 contributed by Andrew Field, Technical Help Desk Fuel Collector Tank Check Valve Functional Check

CRJ100/200 AMM Task 28-11-05-720-801; AIPC 28-11-03 (Fig.1, Item 60)

An Operator reported that both fuel collector tank check valves (p/n 1111-548393 - see illustration below, left side shown) were found faulty while performing the functional test. These valves prevent fuel from flowing out of the collector tank, up the gravity inlet lines, and into the wing tanks.

CHECK VALVE P/N 111-548393

COLLECTOR TANK

As the valves are not spring-loaded (flapper type) and are closed by fuel pressure only, it was suggested that the Operator should block all collector tank exits, fill it with fuel, and then see if the valves stopped the outflow. Using this method, the valves operated satisfactorily. It was determined that the dihedral of the wing results in the flapper valves resting partly open with no fuel in the collector tank. When performing AMM Task 28-11-05-720-801, if fuel is not poured into the tank quickly enough, there will not be sufficient pressure to close the valves. In this particular case, as the collector tank removal was almost complete and, in the Operators opinion, pouring fuel into the collector tank outside the wingbox required less protective gear, the Operator elected to remove the remaining tank and test it off-wing.

12

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability

2005-05-3830 contributed by Christian Holzl, In-Service Engineering (Hydro-Mechanical) Toilet Fill/Rinse Shutoff Valve - STC Availability

CRJ100/200/440/700/900

Shaw Aero Devices has developed a toilet fill/rinse ShutOff Valve (SOV) kit that provides automatic shut-off capability during the servicing of p/n 14350 toilets installed in Bombardier aircraft models CRJ100/200/440/700/900. The SOV kit assembly p/n 307-0103-02 is identified by FAA Supplemental Type Certificate number ST02638AT. The new Shaw SOV will prevent overflowing of the toilet tank after the desired pre-charge fluid level is reached. The system is entirely mechanical. It is also designed to be easily installed in the existing toilet system and requires no wiring, cables or other controls for its operation. Bombardier Aerospace makes no representations as to the suitability of the Shaw SOV for use in service and will not be stocking the part in Spares or incorporating the part in Production. Operators must directly contact the supplier for technical discussion, purchase, repair, and warranty issues: M. Richard Crouse Director of Aftermarket Sales & Customer Support Shaw Aero Devices, Inc. 3580 Shaw Boulevard, Naples, Florida, 34117 USA telephone: 1-239-304-1000 fax: 1-239-304-1088 website: www.shawaero.com

QUALITY CORNER

contributed by Danny St-Onge, Technical Help Desk (e-mail: danny.st-onge@aero.bombardier.com )

CORRECTIVE ACTIONS

No corrective actions were implemented on the production line relative to the QIRs closed in April. The investigations concluded that the issues were either considered isolated cases, and the affected employees were debriefed, or the issues were considered invalid.

To report a Quality nonconformance, Operators should e-mail all information to: ra.quality@notes.canadair.ca

13

CRJ100/200 ISAR 2005-05

TECHNICAL PUBLICATIONS NEWS

Maintenance & Flight Manual Revision Schedule

DOCUMENT Digital ManualsDVD AMM AIPC WDM SSM SRM SGREOM FIM CMM MRM Part 1 MRM Part 2 MTCM MPM NDT ITEM WBM APM MFEPM PPGRM PPBM DDG - FAA DDG - TC AFM FCOM QRH SDIR

LEGEND: *NOTES: F JAN ISS.18 ---R20 --R33* ---R26 R14 -----------FEB RELEASE G MAR APR ISS.20 R34 R32* -----------R14 -R5 --R5 R5 ---ISS.21 ---R21 R23 R9 R34 ----------------MAY ------------------------R24 ----R24 ------R27 R15 ----R26 ---R57 R57 R57 RELEASE H JUN JUL ISS.22 -R33* ------R9 -ISS.23 R35 -R31 -----AUG Antonia Iagallo & Gina Badanac RELEASE I SEP OCT ISS.25 ---R22 --R35 ----------------ISS.26 -R23 ----------R25 -R8 ------------R27 ------RELEASE J NOV DEC ISS.27 R36 ------R20 R10 R6 R28 R16 -----R25 -----ISS.28 --R32 -R25 R11 ---

ISS.19 --R30* ---------R23 -----------

ISS.24 ----R24 R10 ---------------

DEPENDENT ON AIRCRAFT DELIVERIES

BUILT TO SPECIFIC AIRCRAFT S/N (DELIVERED WITH AIRCRAFT) SHIPPED: R PLANNED: R

AIPC R32* FOR S/N 8038; WDM R30* FOR S/N 8034; FIM R33* FOR S/N 8023; REV.33 FOR S/N 8051 (LATEST AIRCRAFT S/N COVERAGE FOR MANUAL REVISION) ABBREVIATIONS

AFM AIPC AMM APM CMM DDG FCOM FIM ITEM MPM MRM MTCM

Airplane Flight Manual Aircraft Illustrated Parts Catalogue Aircraft Maintenance Manual Airport Planning Manual Component Maintenance Manual Dispatch Deviation Guide Flight Crew Operating Manual Fault Isolation Manual Illustrated Tools & Equipment Manual Maintenance Planning Manual Maintenance Requirements Manual Maintenance Task Card Manual

MFEPM NDT PPBM PPGRM QRH SDIR SGREOM SRM SSM WBM WDM

Maintenance Facilities Equipment Planning Manual Non-Destructive Testing (Manual) PowerPlant Buildup Manual PowerPlant Ground Run Manual Quick Reference Handbook Structural Deviation Inspection Repair Structural Generic Repair Engineering Order Manual Structural Repair Manual Systems Schematic Manual Weight & Balance Manual Wiring Diagram Manual

14

CRJ100/200 ISAR 2005-05

MAINTENANCE ENGINEERING NEWS

Maintenance Engineering News items originate from Bombardiers Maintenance Programs & Planning, Maintenance Data Analysis, and Aircraft Economics groups. Inquiries regarding this information should be addressed to Alex Brytak, Senior Technical Specialist (telephone: 1-416-373-5210; e-mail: alex.brytak@aero.bombardier.com ). The latest Maintenance Engineering initiatives can be viewed on: http://mainteng.aero.bombardier.com .

ISAR Article Subject

2005-05-0007 contributed by Alex Brytak, Maintenance Engineering (MPP) Continuing Maintenance Requirements for Aging Aircraft Part III

CRJ100/200/700/900; Q100/200/300/400 Ray Raoux, Corrective Action Support, Continuing Airworthiness, Aircraft Certification, Transport Canada; ISAR 2005-03-0002 (Continuing Maintenance Requirements for Aging Aircraft - Part I); ISAR 2005-040003 (Part II)

Applicability Reference

Editorial Note: This article does not imply any direct relationship to Bombardier Aerospace products, and is provided solely for technical information purposes.

Background

Briefly described in previous editions of the ISAR were the rationale for, the workings of, and recommendations made by the Aging Transport Systems Rulemaking Advisory Committee (ATSRAC) to address aircraft wiring concerns. It was not surprising that perhaps the most important finding, which has been noticed by the various investigations under the auspices of ATSRAC, was the need to recognize wire systems as a system that requires periodic inspection and cleaning. Implementation of the recommendations, particularly those related to the rationale for an Enhanced Zonal Analysis Procedure (EZAP), can potentially reduce the number of fire-related incidents and nuisance circuit breaker trips. It should also reduce the number of frustrating maintenance actions whereby replacing an electrical component returns a system to a serviceable state, but no fault is subsequently found with the removed electrical component when sent for repair or overhaul.

Aircraft Zones

Transport category aircraft can be defined by a common series of zones that can be used to assist in maintenance planning and work-card production by specifying work areas and components. A zone can be defined by physical boundaries such as wing ribs, fuselage frames, control surfaces, and areas accessible at access panels. Hence, a zonal inspection typically could entail a visual inspection for corrosion, missing/loose fasteners, and other physical damage over an internal area of the fuselage defined as being between two adjacent frames (usually 20 inches apart) and between specified stringers. An "Enhanced" Zonal Inspection (EZI) would include inspecting for the structural concerns just mentioned, but also include inspecting any system components such as wires and hydraulic lines in the same area, plus a cleaning task to remove any combustible material such as lint or chemical contaminants. The rationale for developing the EZI concept is that each wire or wire bundle or connector (i.e., wire system) in the zone is treated as a potential ignition source, and the other contents of the zone are considered as being potentially combustible material (lint, spilled fluids, etc.) or potentially contributing to combustion (fuel/oxygen/hot air lines).

15

CRJ100/200 ISAR 2005-05

Wiring Concerns

Perhaps the most important finding, which has been noticed by the various investigations under the auspices of ATSRAC, is the need to recognize wire systems as a system that requires periodic cleaning and inspection. Contaminants such as lint and grease are flammable and need to be removed to eliminate a potential combustion source. Swarf and metal filings can become lodged in a wire bundle and eventually cut or wear through the insulation; not only will the bare metal underneath be exposed and create a potential ignition source, but the conductive metallic residue can bridge the gap between the wire surface and an adjacent metal surface. The presence of any sticky fluids on the wire will help to ensure that these metallic residues do not fall off the wire into a benign location. The rear side of circuit breaker panels are seldom accessed, yet they can accumulate a significant build-up of flammable lint. Some of the following wiring concerns to inspect for, as the inspection portion of an EZI would include:

Wire clearance from fuel and oxygen lines, hydraulic lines, bleed air ducts, and flight controls. Wire bundle breakout joints. Missing or broken bonding jumper cables. Sharp bend radius causing mechanical strain. Localized heat damage. Fluid stains. Missing or damaged heat or drip shields. Absence of drip loops. Loss of wire segregation. Broken, missing, and incorrect sized clamps and missing ties. Missing sleeving and grommets, and damage where wires enter or exit a metal conduit. Chafing of wires on structure, particularly in transition zones such as engine nacelle-tofuselage, fuselage-to-wing and fuselage-to-wheel well etc. Damage to and contamination of wiring caused by maintenance activity or by cargo and baggage handling. Presence of combustible material including lint, paper, and fluid residue.

The benefits of a clean wiring system are applicable to all sizes of aircraft, whether it be the largest multi-engine transport category or the smallest single-engine general aviation category aircraft.

Clean as You Go

In an initial step towards addressing wiring systems, the concept of "Clean as You Go" is being promoted. This means that before any planned maintenance action is started, the area affected should be inspected, and any wiring in the area should be protected to ensure it does not become damaged or contaminated by the planned work. If electrical connectors have to be removed to facilitate access, they should be blanked-off. After completing the work, the area should be thoroughly cleaned. A cultural change such as the "Clean as You Go" concept can be implemented and the benefits enjoyed today; it is not necessary to wait for regulatory action to address concerns with wiring systems.

16

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability

2005-05-0008 contributed by Chris Kostakis, Maintenance Analyst DREAM File Now Available on RACS Website

CRJ100/200

The Aircraft Economics section of Maintenance Engineering has recently posted a new document on the Regional Aircraft Customer Services website (www.racs.bombardier.com ) that allows Operators to view and compare their Dispatch Reliability Rate (DIR), both to the fleet and to other Operators. The data is displayed in three ways: For the latest 12-month period. For the latest 3-month period. For a similar 3-month period, but from last year to see if there are any significant improvements or degradations.

Additionally, the file has been structured to place more emphasis, not just on the DIR, but also on the cost effect of such disruptions. This is accomplished by allowing Operators to enter an average cost of a delay and an average cost of a cancellation to determine which ATA subsystems are drivers in terms of cost, as well as in terms of DIR. The file will be updated on a regular basis. Operators are encouraged to take a moment to review the new posting on RACS. To access the file: Click on the Maintenance Cost Working Group link. Click on the category RACS TO RICHES. Click on the CRJ100/200 DREAM link to view the latest CRJ100/200 Dispatch Reliability Economic Assessment Model (DREAM). An icon will appear while downloading the file. Click on Enable Macros. Note: Allow some time for the file to download. Any questions or comments regarding the DREAM file in specific, or the subject of aircraft economics in general, should be addressed to: Chris Kostakis

Maintenance Analyst Maintenance Engineering Bombardier Aerospace Regional Aircraft telephone: 1-416-373-7768 e-mail: chris.kostakis@aero.bombardier.com

17

CRJ100/200 ISAR 2005-05

ISAR Article Subject Applicability

2005-05-0009 contributed by Alex Lazaro, Maintenance Engineering (Planning) Maintenance Task Optimization Initiatives

CRJ100/200

In an effort to pursue the goal to further escalate some of the remaining C Check Tasks that stayed at their current interval, Operator support is requested in providing Bombardier with any further information on any of the following Tasks that were accomplished on aircraft during 2004 or 2005. If any of these Tasks will be performed anytime during the remaining months of 2005, Operators are asked to forward the information to Maintenance Planning as soon as the Task is completed. MRB Task 49-14-19-01 Interval 12,000 flt-hrs Task Description detailed inspection of APU air intake assembly door mechanism for cracks, corrosion, integrity and security of installation of attaching hardware zonal inspection of internal tailcone discard of hydraulic system No.1 and No.2 reservoirmounted check valves discard of hydraulic system No.1 and No.2 return check valve discard of hydraulic system No.3 return manifold check valve discard of hydraulic system No.3 return manifold return fitting check valve operational check of each individual thermal switch in wing leading edge zonal inspection of internal left-hand pylon trailing edge zonal inspection of internal right-hand pylon trailing edge zonal inspection of internal left and right-hand horizontal stabilizer tips

53-300-06 29-11-30-01 29-11-30-03 29-12-30-01 29-12-30-03 36-21-07-01 54-400-04 54-400-08 55-300-10

16,000 flt-hrs 24,000 flt-hrs 24,000 flt-hrs 24,000 flt-hrs 24,000 flt-hrs 24,000 flt-hrs 24,000 flt-hrs 24,000 flt-hrs 24,000 flt-hrs

The following information also needs to be provided to Maintenance Planning: Manufacturers serial number (S/N) Airframe time (flight-hours) when the Task was completed and the last compliance of this Task, if applicable. The date the Task was completed and the last compliance date, if applicable. Maintenance findings, if any.

Maintenance Planning will again attempt to present these Task escalations at the next CRJ100/200 ISC/MRB meeting to be held in 1Q06. Operator assistance is highly appreciated. All information and questions regarding the subject Tasks should be addressed to: Alex Lazaro telephone: 1-416-375-3221; e-mail: alexander.lazaro@aero.bombardier.com

18

CRJ100/200 ISAR 2005-05

ALL OPERATOR MESSAGES (AOM) RECENTLY ISSUED

All AOMs are available on the RACS website (www.racs.bombardier.com ).

AOM 885 886 887 888 889 890

ATA 2800 4900 2423 7800 3210 5361

SUBJECT ASB A601R-28-064, Fuel System FAA AD 2005-07-15, APU Cooling Air Exhaust ASB A601R-24-120, Emergency AC Power Generation System - Special Detailed Inspection of ADG Strut Bombardier Aerospace (Shorts) Service Information Letters Available on RACS Website Main Landing Gear - Main Fitting Inspections TC AD CF-2005-13, Cracking of Aft Pressure Bulkhead Web

ISSUED 2005-04-18 2005-04-19 2005-04-19 2005-04-25 2005-05-03 2005-03-09

SERVICE LETTERS (SL) RECENTLY ISSUED

All SLs are available on the RACS website (www.racs.bombardier.com ).

SL No. REV 71-005 --

ATA 7130 Engine Fuel Manifold Chafing

SUBJECT

ISSUED 2005-04-25

GENERIC REFERENCE INSTRUCTION LETTER (RIL) UPDATE

Generic RILs are posted on the RACS website (www.racs.bombardier.com ). A RIL remains valid until it is either incorporated into the appropriate manual or cancelled. RILs are cancelled within 3 months after being added to technical publications. Cancelled RILs are kept on the RACS website. The RILs in the table below have been issued/closed subsequent to the list published in the previous ISAR. The CLOSED BY TR or Rev. number refers to the AMM (unless otherwise specified).

RIL ISS 348 -358 -359 366 367 370 373 377 379 --------

ATA 3443 3341 7110 4981 3041 5270 3411 2400 5211

ISSUED SUBJECT 2005-04-13 AIPC Effectivity for TCAS 622-8971-022 2005-04-21 Adjustment of Wing Landing and Taxi/Recognition Lights Using Production Tool S6003008TFIX-1A 2005-04-21 Removal of Bracket CVC496-261-3 From Right-Hand Fixed Core Cowl 2005-05-01 Interchangeability of APU Shield 601R35261-3 and -3A 2005-05-02 AIPC Effectivity for Left-Hand Window 2005-05-06 Operational Test of Passenger Door Warning System 2005-05-10 Alternate Procedure to Plug Standby Pitot Head Drain Hole at Base of Head 2005-05-13 Instructions for Removal, Installation, and Operational Test of Relay K10PA in Junction Box 5 2005-05-16 Passenger Door Lock Pawl Rework (as per RNIEO 606)

CLOSED BY

----------

GENERIC REPAIR ENGINEERING ORDERS (REO) RECENTLY ISSUED

All generic REOs are available on the RACS website (www.racs.bombardier.com ).

REO No. REV SUBJECT 601R-25-50-0001 -- Allowable Damage for Cargo Net 601R45310-5 601R-51-23-0010 -- Cabin Window Sealant 09-027 601R-52-11-0702 -- Repair for Passenger Door Forward and Aft Side Panel 601R-52-11-0722 -- Alternate Fasteners for Handrail Installation 601R-71-61-2862 -- Application of Ceram-Kote 54 to Prevent Further Erosion to Leading Edge of Nose Cowl Outer Skin 601R-78-11-2520 A Crack Damage to Exhaust Nozzle Fairing Skin Splice Plates 601R-78-30-2504 -- Blocker Door Hinge Support Brackets on Thrust Reverser - Fastener Replacement 601R-78-34-2491 -- Blocker Doors, Hinge Support, and Link Arms - Bond Repair for Migrated Bushings

ISSUED 2005-05-11 2005-04-22 2005-03-30 2005-05-02 2005-04-20 2005-05-11 2005-05-11 2005-04-27

19

CRJ100/200 ISAR 2005-05

BOMBARDIER CONTACTS

INFORMATION CURRENT AS OF: MAY 26, 2005

Note Regarding e-mail Addresses: Addresses for all Bombardier Aerospace personnel are as such:

firstname.lastname@aero.bombardier.com

FIELD SERVICE ADMINISTRATION

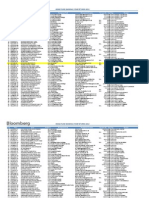

POSITION NAME TELEPHONE CELL PHONE C

Field & Fleet Services Manager Business Aircraft FSR Manager Field Service Administration Manager Field Service Coordinator FS Regional Manager - America East FS Regional Manager - America West FS Regional Manager - Asia/Pacific FS Regional Manager - Europe/Intl FS Area Representative - Americas FS Area Representative - Asia/Pacific FS Area Representative - Asia/Pacific FS Area Representative - Europe/Intl FSR - Training FSR - Training

Leone, Dario Ritchie, Michael Taylor, Maureen Nicolucci, Carol Basile, Joe Godon, Ray Davey, Chris Davies, Robin Schweiger, Tom McHale, Tim Knox, John Davies, Robin Hutchins, Mark Prokopenko, Dmitri

1-416-373-5295 1-514-855-7446 1-416-375-3089 1-416-375-3982 1-703-650-1629 1-407-825-3863 61-2-9531-6009 44-1758-535767 -86-6276-8888 81-56-839-2391 44-1758-535767 1-416-375-3982 1-905-676-4762

---Dept. Fax: 1-416-373-5308

1-703-906-7889 1-407-873-3309 61-418-987-153 44-777-199-3866 1-520-471-3771 86-1391-1190-8632 81-90-4695-1582 44-777-199-3866 -1-416-951-8404

Notes: C indicates cell phone; 24-hr Technical Help Desk (THD): Q Series thd.qseries@aero.bombardier.com / CRJ thd.crj@aero.bombardier.com

OPERATOR AIRCRAFT TYPE FSR TELEPHONE CSAM

FIELD SERVICE REPRESENTATIVES & CUSTOMER SUPPORT ACCOUNT MANAGERS

TELEPHONE

Abu Dhabi Aviation Adria Airways Aerographics Air Canada Air Canada Jazz

Q200 CRJ200 Q100 CRJ200 Q100/200 CRJ100/200

Air Creebec Air Dolomiti Lufthansa Regional Air Inuit Air Jamaica Express Air Labrador Air Marshall Islands Air National Air Nelson Air New Zealand Link Air Niugini Air Nostrum Air Senegal International Air Service Gabon Air Southwest

Q100 CRJ200 Q100 Q100 Q100 Q100 Q100/200 Q300 Q200 Q300, CRJ200 Q300 Q100/300 Q300

Davies, Robin REG.MGR. Davies, Robin REG.MGR. * contact THD * contact THD Hitchins, Ross Dorrans, Spencer Fernandez, Christophe Hughes, Hal Gagnon, Michel Savard, Roger * contact THD Davies, Robin REG.MGR. * contact THD * contact THD * contact THD Davey, Chris REG.MGR. Davey, Chris REG.MGR. Jelley, Kevin Davey, Chris REG.MGR. Rosa, Serge Davies, Robin REG.MGR. Davies, Robin REG.MGR. Davies, Robin REG.MGR.

44-777-199-3866 C 44-777-199-3866 C 1-416-375-4000 1-514-855-8500 1-905-330-0587 1-403-607-2860 C 1-416-357-7129 C 1-514-705-9174 C 1-778-233-2765 C 1-630-639-2495 C 1-416-375-4000 44-777-199-3866 C 1-416-375-4000 1-416-375-4000 1-416-375-4000 61-418-987-153 C 61-418-987-153 C 64-21-99-44-10 C 61-418-987-153 C 34-60-056-1237 C 44-777-199-3866 C 44-777-199-3866 C 44-777-199-3866 C

Derso, Haile Dumbrille, Hal Healey, Barbara Lee, Lori Lee, Lori

1-416-373-7767 1-514-855-9452 1-416-375-3028 1-416-375-3139 1-416-375-3139

Panasiuk, Mike Dumbrille, Hal Panasiuk, Mike Mitchell, Robert Anderson, Chris Mitchell, Robert Mitchell, Robert Mitchell, Robert Mitchell, Robert Lyndsay Lentine Derso, Haile Derso, Haile Derso, Haile

1-514-855-7857 1-514-855-9452 1-514-855-7857 1-416-375-4552 1-416-373-7783 1-416-375-4552 1-416-375-4552 1-416-375-4552 1-416-375-4552 1-416-375-3833 1-416-373-7767 1-416-373-7767 1-416-373-7767

20

CRJ100/200 ISAR 2005-05

OPERATOR AIRCRAFT TYPE FSR TELEPHONE CSAM TELEPHONE

Air Wisconsin United Express AIRES Airlines PNG Alberta Government Amakusa Airlines American Eagle Airlines ANA (A-net) ANA (Nakanihon Airlines) Arctic Sunwest Charters Atlantic Coast Airlines flyI Atlantic Southeast A/L Delta Atlantic Southeast Airlines Atlantic Southeast Airlines Atlasjet International Airways Augsburg Airways Lufthansa Reg. Austrian arrows Bahamasair Banco de Mexico / SETRA BP Exploration BritAir Air France British Airways CitiExpress Burrell Aviation BWIA West Indies Airways Caribbean Star Airlines Caribbean Sun Airlines CASC ChangAn Airlines Hainan China Eastern Yunnan A/L China Ocean Aviation PTI China United Airlines PTI China United Airlines PTI Cimber Air Cirrus Airlines Citelynx Eurolynx Club Challenger / Skyservice Comair Delta Comair Delta Comair Delta Comair Delta Consolidated Contractors CR Airways Denim Air DND 402 Squadron Era Aviation Eurowings Lufthansa Regional Flybaboo flybe British European Gaughan Flying Global Jet Luxembourg GMG Airlines GoJet Airlines Hawaii Island Air Hawkair Aviation Services Horizon Air

Godon, Ray REG.MGR. LeBlanc, Maurice * contact THD Q100/300 Q100 Davey, Chris REG.MGR. * contact THD Q100 Q100 Knox, John AREA REP CRJ700 Chown, Bruce Q300/400 de Graaf, Peter Q400 de Graaf, Peter * contact THD Q100 CRJ200 Basile, Joe REG.MGR. CRJ200/700 Reynolds, John CRJ200/700 Barr, Kevin CRJ200/700 Chalmers, Don CRJ700 Davies, Robin REG.MGR. Q300/400 Davies, Robin REG.MGR. CRJ100/200 Davies, Robin REG.MGR. * contact THD Q300 * contact THD Q200 * contact THD Q200 CRJ100/700 Davies, Robin REG.MGR. Q300 Davies, Robin REG.MGR. CORP. CRJ200 Letter, Dick * contact THD Q300 * contact THD Q100/300 * contact THD Q100/300 CRJ700 Kirstuik, David Q400 McHale, Tim AREA REP CRJ200 McHale, Tim AREA REP CORP. CRJ200 Roy, Ren CRJ100/200 CORP Roy, Ren CRJ700 CORP Kirstuik, David CRJ200 Davies, Robin REG.MGR. Q100/300 Davies, Robin REG.MGR. CORP. CRJ100/200 Rutherford, Peter * contact THD Q200 CRJ200/700 Godon, Ray REG.MGR. CRJ200/700 DeAbreu, Dwayne CRJ200/700 Robinson, Mike CRJ200/700 Rosso, Mike CRJ200 CORP. Rutherford, Peter CRJ100/200 Knox, John AREA REP * contact THD Q300 * contact THD Q100 CT142 * contact THD Q100 CRJ200 Davies, Robin REG.MGR. Q300 Davies, Robin REG.MGR. Q300/400 Armstrong, Dan CRJ200 CORP. Merz, Matthew CRJ100 CORP. Rutherford, Peter Q100 McHale, Tim AREA REP CRJ700 Karlovcec, Peter * contact THD Q100/200 * contact THD Q100 Q100/200/400, CRJ700 Godon, Ray REG.MGR.

CRJ200

1-407-873-3309 C 1-847-636-9280 C 1-416-375-4000 61-418-987-153 C 1-416-375-4000 81-90-4695-1582 C 1-972-877-2590 C 81-80-5676-1953 C 81-80-5676-1953 C 1-416-375-4000 1-703-906-7889 C 1-678-438-4311 C 1-678-938-0071 C 1-503-784-2984 C 44-777-199-3866 C 44-777-199-3866 C 44-777-199-3866 C 1-416-375-4000 1-416-375-4000 1-416-375-4000 44-777-199-3866 C 44-777-199-3866 C 1-847-840-8865 C 1-416-375-4000 1-416-375-4000 1-416-375-4000 86-139-1082-5753 C 86-139-1190-8632 C 86-139-1190-8632 C 86-139-0102-2466 C 86-139-0102-2466 C 86-139-1082-5753 C 44-777-199-3866 C 44-777-199-3866 C 44-7770-312385 C 1-416-375-4000 1-407-873-3309 C 1-859-801-9554 C 1-859-380-1328 C 1-407-460-2246 C 44-7770-312385 C 81-90-4695-1582 C 1-416-375-4000 1-416-375-4000 1-416-375-4000 44-777-199-3866 C 44-777-199-3866 C 44-07785-317754 C 1-408-483-8433 C 44-7770-312385 C 86-139-1190-8632 C 1-314-707-1377 C 1-416-375-4000 1-416-375-4000 1-407-873-3309 C

Panasiuk, Mike

1-514-855-7857

Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Anderson, Chris 1-416-373-7783 DeBrusk, Ryan 1-416-375-3234 Healey, Barbara 1-416-375-3028 DeBrusk, Ryan 1-416-375-3234 DeBrusk, Ryan 1-416-375-3234 Derso, Haile 1-416-373-7767 Tymchuk, Sandra 1-514-855-6543 Anderson, Chris 1-416-373-7783 Anderson, Chris 1-416-373-7783 Anderson, Chris 1-416-373-7783 Dumbrille, Hal 1-514-855-9452 Lee, Lori 1-416-375-3139 Lee, Lori 1-416-375-3139 Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Dumbrille, Hal 1-514-855-9452 Derso, Haile 1-416-373-7767 Anderson, Chris 1-416-373-7783 Mitchell, Robert 1-416-375-4552 Derso, Haile 1-416-373-7767 Derso, Haile 1-416-373-7767 Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Lu, Yong Yi 86-1391-736-7221C Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Dumbrille, Hal 1-514-855-9452 Lee, Lori 1-416-375-3139 Anderson, Chris 1-416-373-7783 Panasiuk, Mike 1-514-855-7857 Panasiuk, Mike 1-514-855-7857 Panasiuk, Mike 1-514-855-7857 Panasiuk, Mike 1-514-855-7857 Panasiuk, Mike 1-514-855-7857 Anderson, Chris 1-416-373-7783 Mitchell, Robert 1-416-375-4552 Lentine, Lyndsay 1-416-375-3833 Anderson, Chris 1-416-373-7783 Anderson, Chris 1-416-373-7783 Dumbrille, Hal 1-514-855-9452 Lentine, Lyndsay 1-416-375-3833 Derso, Haile 1-416-373-7767 Anderson, Chris 1-416-373-7783 Anderson, Chris 1-416-373-7783 DeBrusk, Ryan 1-416-375-3234 Healey, Barbara 1-416-375-3028 Mitchell, Robert 1-416-375-4552 Anderson, Chris 1-416-373-7783 Anderson, Chris 1-416-373-7783

21

CRJ100/200 ISAR 2005-05

OPERATOR AIRCRAFT TYPE FSR TELEPHONE CSAM TELEPHONE

Hydro-Qubec IBEX Airlines ANA Connection (Fair) IndyCar Aviation InterSky Island Aviation Services J-AIR JAL Japan Air Commuter JAL Kahama Mining Kenya Air Force LIAT Limited Brands Lufthansa CityLine Malv Hungarian Airlines Mesa Airlines Mesaba Airlines Northwest Airlink Mexican Navy National Jet Systems NAV Canada Olympic Aviation Oriental Air Bridge Palestinian Airlines Pegasus Technologies Inc. Penske Jet Petroleum Air Services Piedmont Airlines Inc. US Airways Pinnacle Airlines Northwest Airlink Pinnacle Airlines Northwest Airlink Provincial Airlines Limited PSA Airlines US Airways PSA Airlines QANTASLink Eastern Australia A/L QANTASLink Sunstate Airlines Quebec Government Regional 1 Airlines Ltd. Royal Wings Arab Wings Ryukyu Air Commuter Sahara Airlines Air Sahara Sakhalinskie Aviatrassy SAT SAS Saudi Aramco Schreiner Airways Shandong Airlines Shanghai Airlines Skippers Aviation SkyWest Airlines Delta/United SkyWest Airlines Delta/United South African Express Styrian Airways Styrian Spirit TAG Aviation TAG Aviation USA Tenix LADS Tobago Express Limited Trans Nation Airways (Midroc) Transport Canada

Q300/400 CRJ200 CRJ700 CORP. Q300 Q200 CRJ200 Q400 Q100 Q100 Q100/300 CRJ100 CORP. CRJ100/200/700 CRJ200 Q200,CRJ200/700/900 CRJ200 Q200 Q100/200/300 Q100 Q100/200 Q200 Q300 Q300 CRJ200 CORP. Q300 Q100/200/300 CRJ200 CRJ200 Q100 CRJ200/700 CRJ200/700 Q100/200/300 Q100/200/300 Q100 Q100 Q300 Q100 CRJ200 Q100 Q400 Q200 Q100/300 CRJ200/700 CRJ200 Q100 CRJ200/700 CRJ200/700 CRJ200, Q300 CRJ200/700 CRJ100 CORP. CRJ100 CORP. Q200 Q300 Q200 Q100

contact THD Knox, John AREA REP Webb, Mark Davies, Robin REG.MGR. McHale, Tim AREA REP Knox, John AREA REP Doles, Kelly Davies, Robin REG.MGR. Davies, Robin REG.MGR. * contact THD Block, Steve Perron, Claude Davies, Robin REG.MGR. Carruthers, Scott Conley, John * contact THD * contact THD Davey, Chris REG.MGR. * contact THD Davies, Robin REG.MGR. Knox, John AREA REP * contact THD * contact THD Kermode, Tom Davies, Robin REG.MGR. * contact THD Dornenburg, Mike Potvin, Gilles * contact THD DelVecchio, Nick Tremblay, Martin Davey, Chris REG.MGR. Davey, Chris REG.MGR. * contact THD * contact THD Davies, Robin REG.MGR. Knox, John AREA REP Foo, WahLiang Knox, John AREA REP Davies, Robin REG.MGR. Davies, Robin REG.MGR. Davies, Robin REG.MGR. McHale, Tim AREA REP McHale, Tim AREA REP Davey, Chris REG.MGR. Baker, Peter Buth, Otto Davies, Robin REG.MGR. Davies, Robin REG.MGR. Burrowes, Douglas Sciscoe, William Davey, Chris REG.MGR. * contact THD Davies, Robin REG.MGR. * contact THD

*

1-416-375-4000 81-90-4695-1582 C 1-812-459-7428 C 44-777-199-3866 C 86-139-1190-8632 C 81-90-4695-1582 C 81-90-5742-7080 C 44-777-199-3866 C 44-777-199-3866 C 1-416-375-4000 1-513-260-2688 C 49-171-4648-153 C 44-777-199-3866 C 1-480-227-6226 C 1-602-614-2072 C 1-514-855-8500 1-416-375-4000 61-418-987-153 C 1-416-375-4000 44-777-199-3866 C 81-90-4695-1582 C 1-416-375-4000 1-416-375-4000 1-443-553-9871 C 44-777-199-3866 C 1-416-375-4000 1-734-564-3651 C 1-901-508-2667 C 1-416-375-4000 1-610-664-2007 C 1-937-681-5304 C 61-418-987-153 C 61-418-987-153 C 1-416-375-4000 1-416-375-4000 44-777-199-3866 C 81-90-4695-1582 C 91-98-990-03811 C 81-90-4695-1582 C 44-777-199-3866 C 44-777-199-3866 C 44-777-199-3866 C 86-139-1190-8632 C 86-139-1190-8632 C 61-418-987-153 C 1-801-870-4784 C 1-303-829-1958 C 44-777-199-3866 C 44-777-199-3866 C 49-171-320-8870 C 1-940-206-0345 C 61-418-987-153 C 1-416-375-4000 44-777-199-3866 C 1-416-375-4000

Panasiuk, Mike 1-514-855-7857 DeBrusk, Ryan 1-416-375-3234 Anderson, Chris 1-416-373-7783 Lee, Lori 1-416-375-3139 DeBrusk, Ryan 1-416-375-3234 DeBrusk, Ryan 1-416-375-3234 DeBrusk, Ryan 1-416-375-3234 Derso, Haile 1-416-373-7767 Derso, Haile 1-416-373-7767 Mitchell, Robert 1-416-375-4552 Anderson, Chris 1-416-373-7783 Dumbrille, Hal 1-514-855-9452 Dumbrille, Hal 1-514-855-9452 Tymchuk, Sandra 1-514-855-6543 Tymchuk, Sandra 1-514-855-6543 Tymchuk, Sandra 1-514-855-6543 Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Healey, Barbara 1-416-375-3028 Lee, Lori 1-416-375-3139 DeBrusk, Ryan 1-416-375-3234 Derso, Haile 1-416-373-7767 Healey, Barbara 1-416-375-3028 Anderson, Chris 1-416-373-7783 Derso, Haile 1-416-373-7767 Healey, Barbara 1-416-375-3028 Tymchuk, Sandra 1-514-855-6543 Glover, Chris 1-514-855-7297 Anderson, Chris 1-416-373-7783 Healey, Barbara 1-416-375-3028 Healey, Barbara 1-416-375-3028 Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Panasiuk, Mike 1-514-855-7857 Anderson, Chris 1-416-373-7783 Derso, Haile 1-416-373-7767 DeBrusk, Ryan 1-416-375-3234 DeBrusk, Ryan 1-416-375-3234 DeBrusk, Ryan 1-416-375-3234 Lentine, Lyndsay 1-416-375-3833 Derso, Haile 1-416-373-7767 Lee, Lori 1-416-375-3139 Lu, Yong Yi 86-1391-736-7221C Lu, Yong Yi 86-1391-736-7221C Mitchell, Robert 1-416-375-4552 Tymchuk, Sandra 1-514-855-6543 Tymchuk, Sandra 1-514-855-6543 Derso, Haile 1-416-373-7767 Dumbrille, Hal 1-514-855-9452 Anderson, Chris 1-416-373-7783 Anderson, Chris 1-416-373-7783 Mitchell, Robert 1-416-375-4552 Mitchell, Robert 1-416-375-4552 Derso, Haile 1-416-373-7767 Healey, Barbara 1-416-375-3028

22

CRJ100/200 ISAR 2005-05

OPERATOR AIRCRAFT TYPE FSR TELEPHONE CSAM TELEPHONE

Tyrolean Airways Austrian arrows UNI Airways USAF / King Aerospace USCBP Voyageur Airways Wideres Flyveselskap Wings Air Lion Airlines

Q300/400, CRJ200 Q300 Q100 E-9A Q200 Q300 Q100/300/400 Q300

Caldwell, Doug Knox, John AREA REP * contact THD Irvine, Andy * contact THD Davies, Robin REG.MGR. McHale, Tim AREA REP

43-664-641-1207 C 81-90-4695-1582 C 1-416-375-4000 1-586-202-7339 C 1-416-375-4000 44-777-199-3866 C 86-139-1190-8632 C

Lee, Lori Mitchell, Robert Healey, Barbara Derso, Haile Anderson, Chris Lentine, Lyndsay Mitchell, Robert

1-416-375-3139 1-416-375-4552 1-416-375-3028 1-416-373-7767 1-416-373-7783 1-416-375-3833 1-416-375-4552

FLEET SERVICES

CONTACT POSITION TELEPHONE E-MAIL

Leone, Dario Tibbles, Tim Burns, Andrew De Mello, Trevor Kassoulides, John Lapointe, Marc Lukacs, Clare Vassilakis, Mike

Manager, Field & Fleet Services Supervisor, Fleet Services Customer Request Transmittal (CRT) Project Manager, Fleet Services TORONTO Project Manager, Fleet Services TORONTO Project Manager, Fleet Services MONTREAL Project Manager, Fleet Services TORONTO Project Manager, Fleet Services MONTREAL

1-416-373-5295 1-416-373-5307 1-416-373-5151 1-416-375-3601 1-416-373-5296 1-514-855-8273 1-416-375-3638 1-514-855-7869

dario.leone@aero.bombardier.com timothy.tibbles@aero.bombardier.com andrew.burns@aero.bombardier.com trevor.demello@aero.bombardier.com john.kassoulides@aero.bombardier.com marc.lapointe@aero.bombardier.com clare.lukacs@aero.bombardier.com mike.vassilakis@aero.bombardier.com

FLEET SERVICES FAX NUMBERS: 1-416-375-4512 & 1-416-375-4445 TORONTO, 1-514-855-7708 MONTREAL

23

You might also like

- Aviation Maintenance Technician: PowerplantFrom EverandAviation Maintenance Technician: PowerplantRating: 3.5 out of 5 stars3.5/5 (3)

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument21 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument20 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument33 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument27 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument22 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument14 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument18 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument19 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument25 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument18 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument18 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- Dash 8-Q Series Flight Deck Issue 2 2014Document31 pagesDash 8-Q Series Flight Deck Issue 2 2014hsotilg100% (3)

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument38 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- Aircraft Commerce MK 13Document6 pagesAircraft Commerce MK 13romixrayzenNo ratings yet

- Leaflet MPDDocument6 pagesLeaflet MPDerstrtgfd3254No ratings yet

- Aircraft Technology - Engeering and MaintenanceDocument60 pagesAircraft Technology - Engeering and MaintenanceSebastian Ionut VintilaNo ratings yet

- v28n2 PDFDocument15 pagesv28n2 PDFandualemNo ratings yet

- Boeing Magazine Aero - 19Document35 pagesBoeing Magazine Aero - 19Harry Nuryanto100% (1)

- American Airlines 2004Document47 pagesAmerican Airlines 2004edyta182100% (1)

- Business Jet Model/Market Summary: 1Q 2016 Quick Reference GuideDocument7 pagesBusiness Jet Model/Market Summary: 1Q 2016 Quick Reference GuideChandru SNo ratings yet

- Research Papers Aircraft Maintenance ManagementDocument8 pagesResearch Papers Aircraft Maintenance Managementwihefik1t0j3No ratings yet

- Service Letter: In-Service Engineering and Technical SupportDocument44 pagesService Letter: In-Service Engineering and Technical SupportDanielNo ratings yet

- Aircraft Maintenance, Repair, & Overhaul IndustryDocument36 pagesAircraft Maintenance, Repair, & Overhaul IndustrylostkinNo ratings yet

- Operator E-Jets News Rel 114Document24 pagesOperator E-Jets News Rel 114Jai DeepNo ratings yet

- Aircraft Equipment Maker Business PlanDocument25 pagesAircraft Equipment Maker Business PlanAarthi SivarajNo ratings yet

- Lockheed Martin Service News Vol28 No2Document15 pagesLockheed Martin Service News Vol28 No2Bobby ChippingNo ratings yet

- Continantal AirlineDocument25 pagesContinantal AirlineMohd Bunyamin Abd RahmanNo ratings yet

- Internship ReportDocument23 pagesInternship ReportHarshad BhoyeNo ratings yet

- American Airlines Case Study1Document25 pagesAmerican Airlines Case Study1niveditadaga11No ratings yet

- Final Exam-Rawda Sayed-Continental AirlinesDocument37 pagesFinal Exam-Rawda Sayed-Continental AirlinesRoro HassanNo ratings yet

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument17 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- Aircraft Manufacturing: Airbus A380 - First Flight - FLVDocument45 pagesAircraft Manufacturing: Airbus A380 - First Flight - FLVamk2009No ratings yet

- Airlines IndustryDocument45 pagesAirlines IndustrySahilNo ratings yet

- Hindustan Aeronautics LimitedDocument9 pagesHindustan Aeronautics LimitedIshaan SoodNo ratings yet

- Nyse Air 2016Document16 pagesNyse Air 2016gaja babaNo ratings yet

- A Cost-Effective Automated Weather Reporting System AWRS For The Canadian Remote Northern Air OperatorsDocument13 pagesA Cost-Effective Automated Weather Reporting System AWRS For The Canadian Remote Northern Air OperatorsAI Coordinator - CSC JournalsNo ratings yet

- Inear Ir Case Memo: Customer Value Proposition (CVP)Document3 pagesInear Ir Case Memo: Customer Value Proposition (CVP)Venkata VineethNo ratings yet

- Flyht Case SolutionDocument2 pagesFlyht Case SolutionkarthikawarrierNo ratings yet

- KF Airline PESTEL AnalysisDocument16 pagesKF Airline PESTEL Analysisbrij_jeshNo ratings yet

- T2cas News Letter PDFDocument12 pagesT2cas News Letter PDFPRASADNo ratings yet

- AirTran Airways Case StudyDocument18 pagesAirTran Airways Case StudySaima Ali50% (2)

- AirTran Airways Case StudyDocument16 pagesAirTran Airways Case StudyslipperinoNo ratings yet

- Bailey Helicopter GA New 2Document10 pagesBailey Helicopter GA New 2RafaNo ratings yet

- X FmeaDocument91 pagesX FmeaAngel Rustrián0% (1)

- August - September 2008 Issue 95Document116 pagesAugust - September 2008 Issue 95cf34No ratings yet

- And Then There Were..Document68 pagesAnd Then There Were..robertas negudinasNo ratings yet

- Kingfisher Airlines .T He King of Good Times: by Shruti Bhatia, IILM Lodhi RoadDocument16 pagesKingfisher Airlines .T He King of Good Times: by Shruti Bhatia, IILM Lodhi RoadSurbhi MehtaNo ratings yet

- Guide For The Presentation of Helicopter Operating Cost EstimatesDocument73 pagesGuide For The Presentation of Helicopter Operating Cost Estimatesshabgard021No ratings yet

- Freightliner Heavy Duty Trucks Service ManualDocument20 pagesFreightliner Heavy Duty Trucks Service Manualjamie100% (28)

- Mro 2022 11Document36 pagesMro 2022 11PAULO SOUZANo ratings yet

- Feasible Study of MRODocument24 pagesFeasible Study of MROrathneshkumar100% (4)

- Brochure Moteurs Civils 2015 enDocument40 pagesBrochure Moteurs Civils 2015 enShawliniNo ratings yet

- Emran Continental AirlinesDocument12 pagesEmran Continental AirlinesEmran Khan RifatNo ratings yet

- 1 List The Types of Information That Club Car Division SDocument1 page1 List The Types of Information That Club Car Division SLet's Talk With HassanNo ratings yet

- New Microsoft Word DocumentDocument4 pagesNew Microsoft Word DocumentDivyanshu AgnihotriNo ratings yet

- Operator E-Jets News 1Document13 pagesOperator E-Jets News 1PDDELUCANo ratings yet

- DPS 450 ManualDocument3 pagesDPS 450 Manualanshit10% (1)

- Mumbai Add.Document1 pageMumbai Add.anshit1No ratings yet

- CRJ IsarDocument23 pagesCRJ Isaranshit1No ratings yet

- Start The Year Fast and FocusedDocument13 pagesStart The Year Fast and Focusedanshit10% (1)

- Ifr 4000 Ops ManualDocument139 pagesIfr 4000 Ops Manualanshit1No ratings yet

- B406-4 Rev. DDocument86 pagesB406-4 Rev. Danshit1No ratings yet

- Proper Landing TechniqueDocument2 pagesProper Landing Techniqueanshit1No ratings yet

- WFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)Document2 pagesWFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)elias semagnNo ratings yet

- Leander Geisinger DissertationDocument7 pagesLeander Geisinger DissertationOrderPapersOnlineUK100% (1)

- Wilferd Madelung, The Sufyānī Between Tradition and HistoryDocument45 pagesWilferd Madelung, The Sufyānī Between Tradition and HistoryLien Iffah Naf'atu FinaNo ratings yet

- Gifts Under Islamic Law 2Document24 pagesGifts Under Islamic Law 2Utkarsh SinghNo ratings yet

- RamadanDocument12 pagesRamadanMishkat MohsinNo ratings yet

- Procure To Pay (p2p) R12 - ErpSchoolsDocument20 pagesProcure To Pay (p2p) R12 - ErpSchoolsMadhusudhan Reddy VangaNo ratings yet

- EA FRM HR 01 03 JobApplicationDocument6 pagesEA FRM HR 01 03 JobApplicationBatyNo ratings yet

- Dawah Course Syllabus - NDocument7 pagesDawah Course Syllabus - NMahmudul AminNo ratings yet

- INFJ SummaryDocument3 pagesINFJ SummarydisbuliaNo ratings yet

- Noah Horwitz - Reality in The Name of God, or Divine Insistence - An Essay On Creation, Infinity, and The Ontological Implications of Kabbalah-Punctum Books (2012) PDFDocument358 pagesNoah Horwitz - Reality in The Name of God, or Divine Insistence - An Essay On Creation, Infinity, and The Ontological Implications of Kabbalah-Punctum Books (2012) PDFGabriel Reis100% (1)

- Managing A Person With ADHD - Team Skills FromDocument7 pagesManaging A Person With ADHD - Team Skills FromHieu PhanNo ratings yet

- Upsc 1 Year Study Plan 12Document3 pagesUpsc 1 Year Study Plan 12siboNo ratings yet

- Ice Cream CaseDocument7 pagesIce Cream Casesardar hussainNo ratings yet

- Individual Paper Proposal For Biochar Literature ReviewDocument2 pagesIndividual Paper Proposal For Biochar Literature ReviewraiiinydaysNo ratings yet

- Hedge Fund Ranking 1yr 2012Document53 pagesHedge Fund Ranking 1yr 2012Finser GroupNo ratings yet

- 8299 PDF EngDocument45 pages8299 PDF Engandrea carolina suarez munevarNo ratings yet

- Fare Matrix: "No Face Mask, No Ride" "Two Passengers Only"Document4 pagesFare Matrix: "No Face Mask, No Ride" "Two Passengers Only"Joshua G NacarioNo ratings yet

- Lecture 1Document12 pagesLecture 1asiaNo ratings yet

- Technical AnalysisDocument4 pagesTechnical AnalysisShaira Ellyxa Mae VergaraNo ratings yet

- Types of Love in Othello by ShakespeareDocument2 pagesTypes of Love in Othello by ShakespeareMahdi EnglishNo ratings yet

- Shareholder Activism in India - Practical LawDocument10 pagesShareholder Activism in India - Practical LawSommya KhandelwalNo ratings yet

- IJHSS - A Penetrating Evaluation of Jibanananda Das' Sensibilities A Calm Anguished Vision - 3Document10 pagesIJHSS - A Penetrating Evaluation of Jibanananda Das' Sensibilities A Calm Anguished Vision - 3iaset123No ratings yet

- Engineering Management Past, Present, and FutureDocument4 pagesEngineering Management Past, Present, and Futuremonty4president100% (1)

- 175 Mendoza V GomezDocument2 pages175 Mendoza V GomezAnonymous bOncqbp8yiNo ratings yet

- Human Resource ManagementDocument39 pagesHuman Resource ManagementKIPNGENO EMMANUEL100% (1)

- Notice: Native American Human Remains, Funerary Objects Inventory, Repatriation, Etc.: Cosumnes River College, Sacramento, CADocument2 pagesNotice: Native American Human Remains, Funerary Objects Inventory, Repatriation, Etc.: Cosumnes River College, Sacramento, CAJustia.comNo ratings yet

- 1 Introduction Strategic Project Management (Compatibility Mode)Document39 pages1 Introduction Strategic Project Management (Compatibility Mode)Pratik TagwaleNo ratings yet

- GS Mains PYQ Compilation 2013-19Document159 pagesGS Mains PYQ Compilation 2013-19Xman ManNo ratings yet

- Calendar of ActivitiesDocument2 pagesCalendar of ActivitiesAJB Art and Perception100% (3)

- Projections GuideDocument28 pagesProjections GuidemkmattaNo ratings yet