Professional Documents

Culture Documents

Advanced Wall Framing

Uploaded by

Muhammad Shakil JanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Wall Framing

Uploaded by

Muhammad Shakil JanCopyright:

Available Formats

T e c h n o l o g y F a c t S h e e t

ADVANCED WALL FRAMING

Build efficiently, use less material, and save energy!

ADVANCED FRAMING Advanced framing refers to a variety of framing techniques designed to reduce the amount of lumber used and waste generated in the construction of a wood-framed house. These techniques include Designing homes on 2-foot modules to make the best use of common sheet good sizes and reduce waste and labor. Spacing wall studs up to 24 inches on-center. Spacing floor joists and roof rafters up to 24 inches on-center. Using two-stud corner framing and inexpensive drywall clips or scrap lumber for drywall backing instead of studs. Eliminating headers in non-load-bearing walls. Using in-line framing in which floor, wall, and roof framing members are vertically in line with one another and loads are transferred directly downward. Using single lumber headers and top plates when appropriate. BENEFITS FROM ADVANCED FRAMING Both builders and home owners can benefit from advanced framing. Advanced framing techniques create a structurally sound home that has lower material and labor costs than a conventionally framed house. Additional construction cost savings result from the generation of less waste that needs to be disposed of, which also helps the environment. Advanced framing improves energy efficiency by replacing lumber with insulation material. The whole-wall R-value is improved by reducing thermal bridging through the framing and maximizing the wall area that is insulated. Advanced framing techniques can be implemented individually or as a complete package, depending on the builder. Fully implementing advanced framing techniques can result in materials cost savings of about $500 or $1000 (for a 1,200- and 2,400-square-foot house, respectively), labor cost savings of between 3 and 5 percent, and annual heating and cooling cost savings of up to 5 percent.

Buildings for the 21st Century

Buildings that are more energy efficient, comfortable, and affordablethats the goal of DOEs Office of Building Technology, State and Community Programs (BTS). To accelerate the development and wide application of energy efficiency measures, BTS: Conducts R&D on technologies and concepts for energy efficiency, working closely with the building industry and with manufacturers of materials, equipment, and appliances Promotes energy/money saving opportunities to both builders and buyers of homes and commercial buildings Works with state and local regulatory groups to improve building codes, appliance standards, and guidelines for efficient energy use Provides support and grants to states and communities for deployment of energyefficient technologies and practices

Advanced framing techniques, sometimes called Optimum Value Engineering (OVE), have been researched extensively and proven effective. However, some techniques may not be allowed under certain circumstances (i.e., high wind or seismic potential) or in some localities. Be certain to consult local building officials early in the design phase to verify or obtain acceptance of these techniques.

OFFICE OF BUILDING TECHNOLOGY, STATE AND COMMUNITY PROGRAMS ENERGY EFFICIENCY AND RENEWABLE ENERGY U.S. DEPARTMENT OF ENERGY

ADVANCED FRAMING TECHNIQUES Stud Spacing - In many cases, it is acceptable by code to increase stud spacing from 16 inches to 24 inches on-center. The 1995 International Code Councils One- and Two-Family Dwell-

ing Code allows studs up to 10 feet long to be spaced up to 24 inches on-center. In walls supporting only a roof and ceiling, 2x4 studs can be spaced up to 24 inches on-center, except for Utility grade (No. 3) studs. For walls supporting one floor, such as non-bearing gable endwalls on the first floor of a 2-story house, 2x4s can be spaced up to 24 inches on-center when Utility grade studs are not used. Studs in walls supporting a floor and roof above can be 2x6 spaced up to 24 inches oncenter rather than 2x4 spaced up to 16 inches on-center.

Total cost (material and labor) for framing with 2x6 studs spaced 24 inches on-center is similar to that for framing with 2x4 studs spaced 16 inches on-center. The economics of 2x6 wall construction is especially favorable in areas with significant winters and in homes in which windows and doors occupy 10 percent or less of the total wall area. Walls with much more window and door area may require as much framing lumber as conventially-framed walls because each additional opening can add extra studs. In addition, the added 2-inch wall thickness requires the use of extension jambs at windows unless drywall returns are used. Headers - Structural headers are often oversized or installed where unnecessary, largely for convenience. Proper sizing of

DRYWALL RETURN Use of drywall returns for windows in walls with 2x6 stud framing eliminates the need for extension jambs in windows

Drywall return at windows in walls with 2x6 studs

headers allows better insulation and saves wood. In some cases, single-ply (single 2x6, for example) headers can be used, allowing even better insulation around windows. Headers are not required in non-bearing walls, including most interior walls and gable endwalls with only non-bearing trusses directly above. The table and accompanying text below outlines some header requirements from the 1995 International Code Councils One- and Two-Family Dwelling Code. It is possible to insulate headers by using foam sheathing as a spacer in place of plywood or oriented strand board (OSB), either between or on one side (preferably the exterior side) of doubled headers. This technique is an excellent way to make

Maximum Spans For Two-Inch Double Headers (in feet) a (Derived from Table 602.6 of the 1995 International Code Councils One- and Two-Family Dwelling Code) Header Size 2x4 2x6 2x8 2x10 2x12 Supporting Roof Only 4 6 8 10 12 Supporting One Story Above 0 4 6 8 10 Supporting Two Stories Above 0 0 0 6 8 Not Supporting Walls Or Roofs

b

10 12 16

a Also applies to nominal 4-inch single headers. Based on No. 2 lumber with 10-foot tributary loads. Not to be used where concentrated loads are supported by headers. b Load-bearing headers are not required in interior or exterior nonbearing walls. Single flat 2-inch-by-4-inch members may be used as headers in interior or exterior nonbearing walls for openings up to 8 feet in width if the vertical distance to the parallel nailing surface above is not more than 24 inches. For such nonbearing headers, no cripples or blocking are required above the header.

use of scrap foam sheathing and reduce waste. For assistance in designing headers, consult local structural engineers, code officials, lumber suppliers, or organizations such as the Western Wood Products Association (www.wwpa.org). Jacks (shoulder studs/cripples) - Jacks can be eliminated when structural headers are not used or when metal hangers support structural headers. However, elimination of jacks reduces the available nailing area for siding and trim if nailable sheathing (e.g., plywood, OSB) is not used, and may leave as little as 1 inches of nailable width next to a window. If needed, construct a modified window opening by installing a 2x2 wood nailer behind the sheathing for siding attachment.

Outside and Inside Corners - Two-stud corners decrease lumber use and increase possible insulation levels compared with typical practice. However, if nailable sheathing is not used, attachment of exterior trim and siding at corners may be more difficult. For example, vinyl-siding corners require attachment at a point several inches from the corner. Therefore, if foam or other non-nailbase sheathing is used, it may be necessary to add a wood nailer behind the sheathing. When drywall clips are used, they should be installed above the level of the interior trim so trim nails will not interfere. The noncoped trim piece should be installed first, against the drywall that bears on the clip, so that the final coped trim piece can be nailed to the stud.

STACK FRAMING DETAILS

Roof pitch/eave width designed on the 2-foot module

Roof framing/trusses line up with wall and floor framing

Foam sheathing

No headers in non-bearing wall 2x2 nailer for siding

Single top plate

d late Insuader he

24-inch stud spacing

2x2 nailer added to outside and flush to the exterior of window opening to provide nailing surface for siding and window trim

Single top plate Window aligned with studs Single stud at rough opening Point load transferred between studs by rim closure material acting as header. If rim closure material is nonstructural, support will be required under point loads. Use solid blocking between joists.

MODIFIED HEADER AND WINDOW OPENING Reduced waste and increased insulation can be achieved by supporting an insulated header with hangers and by nailing surfaces for siding scabbed toward the outside edge of studs.

No cripples under window opening Header hangers instead of jack studs

Two stud corners

Insulated header sized for actual load

Adapted from Building Science Corporation

ADVANCED WALL FRAMING

Partition Connections to Exterior Walls (T-walls) - These are often made by adding studs at each side of a partition which serve only to provide a surface for attaching drywall. In addition to wasting wood, this type of connection creates an area that is difficult to insulate. Alternatives include installing ladder blocks , drywall clips, or a full-length 2x6 or 1x6 behind the first partition stud. Intermediate Blocking - Horizontal blocks between studs are generally not required for structural strength or fire/draft stopping in platform framing, at least with standard 8-foot high walls. Therefore, intermediate blocking can be eliminated with platform framing because it is not required by the major building codes. Single Top Plates - When used in conjunction with in-line framing designs, single top plates are usually acceptable from a structural standpoint, and are accepted by model building codes such as International Code Council (ICC) and Building Officials Code Administrators (BOCA). These codes require that 3x6 inch, 20-gauge galvanized steel plates be used to tie the top plate at joints, corners, and wall intersections and that they be nailed using three 8d nails at each side.

INSIDE TWO-STUD CORNERS

Position clip support for gypsum board so that it does not interfere with trim nailing

T-WALL ALTERNATIVES The use of ladder blocking or a full-length 1x6 or 2x6 blocking allows for increased insulation in the outer wall

Backer support for gypsum board

The first drywall sheet is installed against side with clip or backer

Ladder T-wall uses less wood and allows for insulation coverage behind partition walls

SINGLE TOP PLATE

Connector plate Single top plate

ADVANCED WALL FRAMING

Because wall height is changed when single top plates are used, sheathing and drywall needs are affected. Studs that are 94 inches long (often used for interior walls) do not need to be cut for use with single top plates, but they are not always available. Ninety-six-inch lumber needs to be cut to length or requires having a strip of drywall added at the bottom of the wall. Pre-cut 925/8-inch studs will require ripping approximately 1 inch from the sheathing and drywall. If 94-inch studs are not available, use 925/8-inch studs rather than 96-inch lumber because they require less labor and generate less waste. ADVANCED FRAMING DESIGN CONSIDERATIONS Two-Foot Module - Design building length, width, and roof pitch in 2-foot increments to make the best use of common sheet good sizes. This technique will reduce material use, labor, and waste, as many products come in multiples of 2 feet. For example, with proper planning, the entire cutoff from a centercut sheet of plywood can be used elsewhere, eliminating the need for an additional cut and reducing scrap. When planning the roof, remember to allow space for a ridge vent if one is used. In-Line Framing - Align floor, wall, and roof framing members directly above or below one another so that loads are transferred directly downward. With in-line framing, double top plates can be eliminated because the load is distributed evenly through the top plate. Using this method, studs that are 24 inch on-center are placed directly below roof trusses spaced 24 inches on-center. Window and Door Layout - Align at least one side of each window and door in line with an existing stud and attach the other side with a metal hanger. Windows with rough openings of 22 inches can fit between studs that are spaced 24 inches oncenter. When this size window is used in conjunction with inline framing, headers are not necessary because no studs need to be cut. Other items - For maximum efficiency, detailed plans should show each piece of wood, cross bracing, and so on in the house and locations for all other items such as wiring, ducts, and pipes. Detailed plans will help eliminate conflicts over space, expedite installation, and eliminate the need to alter or move studs, joists, or other framing members later.

TWO-FOOT MODULE DESIGN

2 strips of plywood 4 feet wide and 1 strip 2 feet wide

24 in

" 10'-0 grid

ch

2'- 10"

9'- 7" 16'- 2" 19'- 2" 18" overhang

16"

4' 16"

16"

Plywood soffit Plywood cutting pattern

16"

8'

2" vent strip

Lay out and cut framing and sheet goods to take advantage of the full dimension of the material. This also reduces job site waste.

ADVANCED WALL FRAMING

For more information, contact: Energy Efficiency and Renewable Energy Clearinghouse (EREC) 1-800-DOE-3732 www.eren.doe.gov Or visit the BTS Web site at www.eren.doe.gov/buildings Or refer to the Builders Guide Energy Efficient Building Association, Inc. 651-268-7585 www.eeba.org Written and prepared for the U.S. Department of Energy by: NAHB Research Center 800-898-2842 www.nahbrc.org Southface Energy Institute 404-872-3549 www.southface.org U.S. Department of Energys Oak Ridge National Laboratory Buildings Technology Center 423-574-5178 www.ornl.gov/ORNL/BTC U.S. Department of Energys National Renewable Energy Laboratory 303-275-3000 www.nrel.gov/buildings_thermal The International Residential Code for One- and Two-Family Dwellings can be obtained from the International Code Council 703-931-4533 www.intlcode.org

SHEATHING Nailbase wooden structural panel sheathing OSB and plywooddominate the market. Properly installed wood structural wall panels not only provide resistance to racking (lateral loading from wind, seismic, etc.), but also improve the kickable character of many structures. Use of non-structural insulating rigid foam wall sheathing is another option. It improves energy efficiency and reduces wood use but requires that the wall assembly be adequately braced. Codes outline various bracing options, such as the following Use structural sheathing at corners and intermediate points with foam sheathing at all other locations.

Use full foam sheathing over other approved wall bracing (e.g., metal strapping, let-in wood 1xs).

Specific requirements for these and other methods depend on wind and seismic zone, as well as the number of stories in the structure. The structural implications of sheathing make it a critical wall system component. Cladding installation guidelines and warranties may also affect the choice of sheathing. Finally, newer building codes are incorporating increasingly more stringent wall bracing requirements. These should be carefully studied before selecting sheathing.

LET-IN BRACING

Metal T-bracing nailed to studs saves on the labor cost of 1x4 let-in bracing

2x4 or 2x6 stud Saw kerf for T-brace K-brace when window or door is near corner 1x4 let-in brace notched into wall studs

NOTICE: Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof.

Printed with a renewable-source ink on paper containing at least 50% wastepaper, including 20% postconsumer waste. October 2000 DOE/GO-102000-0770

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Final Evaluatio Report Testing Service Pg1Document1 pageFinal Evaluatio Report Testing Service Pg1Muhammad Shakil JanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- JP Project Manager-She Can LeadDocument8 pagesJP Project Manager-She Can LeadMuhammad Shakil JanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Challenges of FATA MergerDocument5 pagesChallenges of FATA MergerMuhammad Shakil JanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Federal Government Employees Housing FoundationDocument2 pagesFederal Government Employees Housing FoundationMuhammad Shakil JanNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- SR 421 Mainstreaming Pakistan Federally Administered Tribal AreasDocument20 pagesSR 421 Mainstreaming Pakistan Federally Administered Tribal AreasNida HammadNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 1 s2.0 S2588912518300262 MainDocument15 pages1 s2.0 S2588912518300262 MainJunaid ArshadNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- (Total Plots Allotted) : Successful Applicants Wapda Employees - 05 MarlaDocument25 pages(Total Plots Allotted) : Successful Applicants Wapda Employees - 05 MarlaMuhammad Shakil JanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Tit TocDocument7 pagesTit TocMuhammad Shakil JanNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Table With Lat Lon To Shapefile ArcGIS v10.1Document2 pagesTable With Lat Lon To Shapefile ArcGIS v10.1Muhammad Shakil JanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Invitation To Bid (For Goods, Works and Non-Consulting Services)Document1 pageInvitation To Bid (For Goods, Works and Non-Consulting Services)Muhammad Shakil JanNo ratings yet

- GM GSC For PermissionDocument1 pageGM GSC For PermissionMuhammad Shakil JanNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Programme Detail MS Management SciencesDocument2 pagesProgramme Detail MS Management SciencesMuhammad Shakil JanNo ratings yet

- Application For SWH-DataDocument2 pagesApplication For SWH-DataMuhammad Shakil JanNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Rainfall DataDocument36 pagesRainfall DataMuhammad Shakil JanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Harmonized World Soil DatabaseDocument43 pagesHarmonized World Soil DatabaseMuhammad Shakil JanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Casual Leave Form BlankDocument1 pageCasual Leave Form BlankMuhammad Shakil JanNo ratings yet

- Sen 1968 Sen's Slope MethodDocument12 pagesSen 1968 Sen's Slope MethodMuhammad Shakil JanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Specifications For BeadingDocument1 pageSpecifications For BeadingMuhammad Shakil JanNo ratings yet

- Application Form Enlistment DrillerDocument3 pagesApplication Form Enlistment DrillerMuhammad Shakil JanNo ratings yet

- Mann KendallDocument4 pagesMann KendallOm Prakash SahuNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bisma NazDocument2 pagesBisma NazMuhammad Shakil JanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mann 1945Document16 pagesMann 1945Muhammad Shakil JanNo ratings yet

- Boq AliaDocument126 pagesBoq AliaMuhammad Shakil JanNo ratings yet

- 58D6D3 Storm Water Inlet Design Curb Inlets Us UnitsDocument2 pages58D6D3 Storm Water Inlet Design Curb Inlets Us UnitsMuhammad Shakil JanNo ratings yet

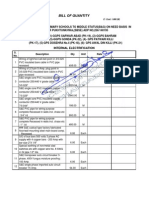

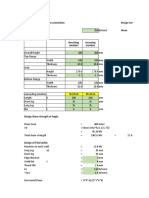

- Bill of QuantityDocument2 pagesBill of QuantityMuhammad Shakil JanNo ratings yet

- BoqDocument37 pagesBoqMuhammad Shakil JanNo ratings yet

- Curriculum Vita Amber NewDocument8 pagesCurriculum Vita Amber NewMuhammad Shakil JanNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 5FEAF3 Storm Water Inlet Design Gutter Inlets Si UnitsDocument2 pages5FEAF3 Storm Water Inlet Design Gutter Inlets Si UnitsMuhammad Shakil JanNo ratings yet

- Bill of Quantity: Internal ElectrificationDocument2 pagesBill of Quantity: Internal ElectrificationMuhammad Shakil JanNo ratings yet

- Inspection Checklist: Concrete Floor: Summary Card)Document2 pagesInspection Checklist: Concrete Floor: Summary Card)MaestroColicusNo ratings yet

- BASEPLT9Document5 pagesBASEPLT9Bunkun15No ratings yet

- Pipe Line CalculationDocument14 pagesPipe Line Calculationsamirbendre1No ratings yet

- Jntuh SA II March-2021 PyqpDocument2 pagesJntuh SA II March-2021 PyqpPradeepkumarKatgiNo ratings yet

- Sofistik ManualDocument129 pagesSofistik ManualPanagiotis Stamatis100% (1)

- LT WT Mix Design 3 000 PsiDocument20 pagesLT WT Mix Design 3 000 Psid584cnNo ratings yet

- IMPORTANT!!!Document130 pagesIMPORTANT!!!adivldsvNo ratings yet

- SRBDocument43 pagesSRBsandeepNo ratings yet

- AISC LRFD Moment Connections BoltedDocument531 pagesAISC LRFD Moment Connections BoltedManoj JaiswalNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 07 Rhs TrussesDocument24 pages07 Rhs TrussesbobbynebaNo ratings yet

- Ce 312 PDFDocument110 pagesCe 312 PDFMd RubelNo ratings yet

- Inventory Inspection and Load Rating of A Complex Segmental Concrete BridgeDocument48 pagesInventory Inspection and Load Rating of A Complex Segmental Concrete BridgeKY PengNo ratings yet

- 0331 Brick and Block ConstructionDocument17 pages0331 Brick and Block ConstructionHebatallah Reda El-desouqiNo ratings yet

- Poster For Jin Mao TowerDocument1 pagePoster For Jin Mao Towerkiri shimaNo ratings yet

- Front View Elevation Right Side Elevation: A B C D E F 10 9 8 7 6 5 4 3 2 1Document1 pageFront View Elevation Right Side Elevation: A B C D E F 10 9 8 7 6 5 4 3 2 1AYSON N. DELA CRUZNo ratings yet

- Presentation-Case Study of Shanghai Tower 12-04-14Document48 pagesPresentation-Case Study of Shanghai Tower 12-04-14shreyashNo ratings yet

- Foreva - Historic BuildingsDocument4 pagesForeva - Historic BuildingsHuy Nguyen VanNo ratings yet

- Two Storey General SpecificationsDocument7 pagesTwo Storey General SpecificationsJayson Hernandez75% (32)

- Rainas Municipality Office of The Municipal Executive AOC: Tinpiple, Lamjung, Gandaki Province, NepalDocument10 pagesRainas Municipality Office of The Municipal Executive AOC: Tinpiple, Lamjung, Gandaki Province, NepalLaxu KhanalNo ratings yet

- Swimming Pool LoadingDocument4 pagesSwimming Pool LoadingAnn GertrudeNo ratings yet

- Tufail MaboodDocument3 pagesTufail MaboodMickey DalbeheraNo ratings yet

- Study On Prefabricated Concrete Beam and Column ConnectionsDocument6 pagesStudy On Prefabricated Concrete Beam and Column ConnectionsreenaNo ratings yet

- Design Guide 7 - Pinned Based Plate Connections - Design Guide 7 - Pinned Base Plate Connections For Columns 43Document2 pagesDesign Guide 7 - Pinned Based Plate Connections - Design Guide 7 - Pinned Base Plate Connections For Columns 43Neil WayneNo ratings yet

- Battered Pile Load CalculationDocument5 pagesBattered Pile Load Calculationovikbasu100% (1)

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Document1 pageDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanNo ratings yet

- Different Types of Precast Concrete Products - Constro FacilitatorDocument6 pagesDifferent Types of Precast Concrete Products - Constro FacilitatorsreenivasiitNo ratings yet

- Exercise No. 5Document7 pagesExercise No. 5Stanly Mark SantosNo ratings yet

- Case Study On Raised FlooringDocument10 pagesCase Study On Raised FlooringAkanksha BhakareNo ratings yet

- Civil MTODocument6 pagesCivil MTOOmar DhiebNo ratings yet

- Shear Conection Design - IS 800-2007Document4 pagesShear Conection Design - IS 800-2007Swapnil ToraskarNo ratings yet