Professional Documents

Culture Documents

Local Stress Sample Calc

Uploaded by

qweqwe7502Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Local Stress Sample Calc

Uploaded by

qweqwe7502Copyright:

Available Formats

1

LOCAL STRESSES IN CYLINDRICAL SHELL DUE TO EXTERNAL LOADINGS OF NOZZLE

ACCORDING TO WRC Bulletin 107:rev.1987

(Page :5/1)

Dwg. No.:

02021-G0E3M-100

SHELL SIDE

External diameter of cylindrical shell

wall thickness

corrosion allowance

mill tolerance

total allowance

Input Data

Dk

s

c1

c2

c=c1+c2

= 5944.00 mm

=

22.00 mm

=

3.00 mm

=

0.30 mm

=

3.30 mm

External diameter of nozzle

wall thickness

internal protrusion

d1 = 1800.00 mm

s1 =

22.00 mm

l1 =

0.00 mm

Design pressures

Design temperature

p

t

Summ of thermal stresses

Number of cycle of loads

Nozzle loads:

- radial force

- circumferential force

- longitudinal force

- circumferential bending moment

- logitudinal bending moment

- torsion moment

ft =

N =

Material of shell:

Allowable stress at

F

Fk

Fh

Mk

Mh

Mc

=

=

0.48 MPa

450

C

0.00 N/mm

1000

=

60530 N

=

22258 N

=

89497 N

= 257235008 Nmm

= 227360000 Nmm

= 124969000 Nmm

P355GH

450 C

Welding efficiency at the opening

fm =

v

93.00

N/mm

1.00

Shell IS REINFORCED by pad around the nozzle.

External diameter of reinforcing pad

Thickness of reinforcing pad

d1'= 3200.00 mm

s1'=

22.00 mm

LOCAL STRESSES IN CYLINDRICAL SHELL DUE TO EXTERNAL LOADINGS OF NOZZLE

ACCORDING TO WRC Bulletin 107:rev.1987

(Page :5/2)

CONCLUSIONS OF CALCULATION

Since

fm * v =

93.0 N/mm

fR1

84.9 N/mm

1.5 * fm * v = 139.5 N/mm

fR2A

fR2B

fR2C

fR2D

=

=

=

=

75.6

97.3

80.7

92.2

fR3A1

fR3A2

fR3B1

fR3B2

fR3C1

fR3C2

fR3D1

fR3D2

= 69.3 N/mm

= 81.9 N/mm

= 118.8 N/mm

= 75.7 N/mm

= 19.7 N/mm

= 141.8 N/mm

= 171.7 N/mm

= 30.4 N/mm

3 * fm * v = 279.0 N/mm

[N] = 149405

N =

N/mm

N/mm

N/mm

N/mm

1000

Cylindrical shell in vicinity of nozzle

to shell junction IS SATISFACTORY.

Since

fm * v =

93.0 N/mm

1.5 * fm * v = 139.5 N/mm

3 * fm * v = 279.0 N/mm

[N]' =

14755

fR1' =

fR2A'

fR2B'

fR2C'

fR2D'

76.4 N/mm

=

=

=

=

70.3

85.4

72.8

83.0

N/mm

N/mm

N/mm

N/mm

fR3A1'=

fR3A2'=

fR3B1'=

fR3B2'=

fR3C1'=

fR3C2'=

fR3D1'=

fR3D2'=

65.8

74.7

100.2

70.6

63.7

209.3

266.3

103.3

N/mm

N/mm

N/mm

N/mm

N/mm

N/mm

N/mm

N/mm

N =

1000

Cylindrical shell at the edge of reinforcing pad IS SATISFACTORY.

LOCAL STRESSES IN CYLINDRICAL SHELL DUE TO EXTERNAL LOADINGS OF NOZZLE

ACCORDING TO WRC Bulletin 107:rev.1987

(Page :5/3)

Stresses in the cylindrical shell near to the nozzle

Joint efficiency

Stress concentration factor

Typical radius

Typical thickness

Parameters :

ro

so

= 0.2669

=

=

=

=

0.413

4.947

900.000 mm

44.000 mm

= 67.05

Internal loads on unit length due to unit external loads:

My

-----Mk/R*

Mx

-----Mk/R*

Ny

Nx

My *

------- ------- ----Mk/R* Mk/R* Mh/R*

My **

----Mh/R*

Mx *

----Mh/R*

Mx **

----Mh/R*

0.0594

0.0245

2.0925

0.0217

6.3513

0.0105

0.0133

0.0158

Ny

Nx

My *

------ ------ ----Mh/R* Mh/R*

F

My **

----F

Mx *

----F

Mx **

----F

Ny

----F/R

4.5030

0.0347

0.0188

0.0148

2.9725

2.2927

0.0423

Nx

----F/R

6.7956

Principal stresses of category 2 and 3

in the point considered, [N/mm] :

fR1

fR2

fR3

fa

A1

A2

B1

B2

C1

C2

D1

D2

84.9

75.6

69.3

34.7

84.9

75.6

81.9

41.0

84.9

97.3

118.8

59.4

84.9

97.3

75.7

37.9

84.9

80.7

19.7

9.9

84.9

80.7

141.8

70.9

84.9

92.2

171.7

85.9

84.9

92.2

30.4

15.2

Stresses due to each loads

in the points considered, [N/mm] :

fxp

fyp

fxpk

fypk

fhyMk

fhxMk

fyMk

fxMk

fhyMh

fhxMh

fyMh

fxMh

fhyF

fhyF

fhxF

fhxF

fyF

fxF

Mc

Fk

Fh

42.2

84.5

86.3

172.7

0.0

0.0

0.0

0.0

0.0

-13.9

0.0

-22.7

-10.8

-5.5

0.0

7.6

0.0

3.2

1.5

3.4

0.6

0.2

0.0

42.2

84.5

86.3

172.7

0.0

0.0

0.0

0.0

0.0

13.9

0.0

22.7

-10.8

-5.5

0.0

-7.6

0.0

-3.2

1.5

3.4

0.6

0.2

0.0

42.2

84.5

86.3

172.7

0.0

0.0

0.0

0.0

0.0

13.9

0.0

22.7

10.8

5.5

0.0

7.6

0.0

3.2

1.5

3.4

0.6

-0.2

0.0

42.2

84.5

86.3

172.7

0.0

0.0

0.0

0.0

0.0

-13.9

0.0

-22.7

10.8

5.5

0.0

-7.6

0.0

-3.2

1.5

3.4

0.6

-0.2

0.0

42.2

84.5

86.3

172.7

-70.3

-29.0

-5.7

-17.3

0.0

0.0

0.0

0.0

0.0

0.0

9.3

0.0

4.1

0.0

1.5

3.4

0.6

0.0

-0.8

42.2

84.5

86.3

172.7

70.3

29.0

-5.7

-17.3

0.0

0.0

0.0

0.0

0.0

0.0

-9.3

0.0

-4.1

0.0

1.5

3.4

0.6

0.0

-0.8

42.2

84.5

86.3

172.7

70.3

29.0

5.7

17.3

0.0

0.0

0.0

0.0

0.0

0.0

9.3

0.0

4.1

0.0

1.5

3.4

0.6

0.0

0.8

42.2

84.5

86.3

172.7

-70.3

-29.0

5.7

17.3

0.0

0.0

0.0

0.0

0.0

0.0

-9.3

0.0

-4.1

0.0

1.5

3.4

0.6

0.0

0.8

LOCAL STRESSES IN CYLINDRICAL SHELL DUE TO EXTERNAL LOADINGS OF NOZZLE

ACCORDING TO WRC Bulletin 107:rev.1987

(Page :5/4)

Stresses in the cylindrical shell at the edge of reinforcing pad

Joint efficiency

Stress concentration factor

Typical radius

Typical thickness

Parameters :

'

'

ro'

so'

= 0.4728

=

1.000

=

1.000

= 1600.000 mm

=

22.000 mm

=134.59

Internal loads on unit length due to unit external loads:

My

-----Mk/R*

Mx

-----Mk/R*

Ny

Nx

My *

------- ------- ----Mk/R* Mk/R* Mh/R*

My **

----Mh/R*

Mx *

----Mh/R*

Mx **

----Mh/R*

0.0508

0.0192

1.5105

0.0096

7.9878

0.0016

0.0035

0.0025

Ny

Nx

My *

------ ------ ----Mh/R* Mh/R*

F

My **

----F

Mx *

----F

Mx **

----F

Ny

----F/R

2.5838

0.0050

0.0068

0.0021

1.2524

1.2181

0.0226

Nx

----F/R

4.6834

Principal stresses of category 2 and 3

in the point considered, [N/mm] :

fR1'

fR2'

fR3'

fa'

A1

A2

B1

B2

C1

C2

D1

D2

76.4

70.3

65.8

32.9

76.4

70.3

74.7

37.4

76.4

85.4

100.2

50.1

76.4

85.4

70.6

35.3

76.4

72.8

63.7

31.9

76.4

72.8

209.3

104.7

76.4

83.0

266.3

133.2

76.4

83.0

103.3

51.6

Stresses due to each loads

in the points considered, [N/mm] :

fxp'

fyp'

fxpk'

fypk'

fhyMk'

fhxMk'

fyMk'

fxMk'

fhyMh'

fhxMh'

fyMh'

fxMh'

fhyF'

fhyF'

fhxF'

fhxF'

fyF'

fxF'

Mc'

Fk'

Fh'

38.0

76.0

38.0

76.0

0.0

0.0

0.0

0.0

0.0

-9.6

0.0

-26.8

-7.6

-3.6

0.0

5.2

0.0

2.2

1.4

5.1

0.4

0.2

0.0

38.0

76.0

38.0

76.0

0.0

0.0

0.0

0.0

0.0

9.6

0.0

26.8

-7.6

-3.6

0.0

-5.2

0.0

-2.2

1.4

5.1

0.4

0.2

0.0

38.0

76.0

38.0

76.0

0.0

0.0

0.0

0.0

0.0

9.6

0.0

26.8

7.6

3.6

0.0

5.2

0.0

2.2

1.4

5.1

0.4

-0.2

0.0

38.0

38.0

76.0

76.0

38.0

38.0

76.0

76.0

0.0 -160.0

0.0 -60.4

0.0

-5.0

0.0 -26.5

0.0

0.0

-9.6

0.0

0.0

0.0

-26.8

0.0

7.6

0.0

3.6

0.0

0.0

23.5

-5.2

0.0

0.0

7.1

-2.2

0.0

1.4

1.4

5.1

5.1

0.4

0.4

-0.2

0.0

0.0

-1.0

38.0

76.0

38.0

76.0

160.0

60.4

-5.0

-26.5

0.0

0.0

0.0

0.0

0.0

0.0

-23.5

0.0

-7.1

0.0

1.4

5.1

0.4

0.0

-1.0

38.0

38.0

76.0

76.0

38.0

38.0

76.0

76.0

160.0 -160.0

60.4 -60.4

5.0

5.0

26.5

26.5

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

23.5 -23.5

0.0

0.0

7.1

-7.1

0.0

0.0

1.4

1.4

5.1

5.1

0.4

0.4

0.0

0.0

1.0

1.0

LOCAL STRESSES IN CYLINDRICAL SHELL DUE TO EXTERNAL LOADINGS OF NOZZLE

ACCORDING TO WRC Bulletin 107:rev.1987

(Page :5/5)

Description of values in tables:

fhyMk [N/mm]

- circumferential bending stress in the point

considered due to moment Mk

- meridional bending stress in the point

considered due to moment Mk

- circumferential membrane stress in the point

considered due to moment Mk

- meridional membrane stress in the point

considered due to moment Mk

- circumferential bending stress in the point

considered due to moment Mh

- meridional bending stress in the point

considered due to moment Mh

- circumferential membrane stress in the point

considered due to moment Mh

- meridional membrane stress in the point

considered due to moment Mh

- circumferential bending stress in the point

considered due to force F

- meridional bending stress in the point

considered due to force F

- circumferential membrane stress in the point

considered due to force F

- meridional membrane stress in the point

considered due to force F

- shear stress in the point

considered due to torsion moment Mc

- shear stress in the point

considered due to force Fk

- shear stress in the point

considered due to force Fh

fhxMk [N/mm]

fyMk

[N/mm]

fxMk

[N/mm]

fhyMh [N/mm]

fhxMh [N/mm]

fyMh

[N/mm]

fxMh

[N/mm]

fhyF

[N/mm]

fhxF

[N/mm]

fyF

[N/mm]

fxF

[N/mm]

Mc

[N/mm]

Fk

[N/mm]

Fh

[N/mm]

fR1

[N/mm]

fR2

[N/mm]

- Mohr's principal stress

calculated from stress components

fxpk, fypk, , fxMk, fyMk, fxMh, fyMh, fxF, fyF

fR3

[N/mm]

- Mohr's principal stress

calculated from stress components

fxpk, fypk, , fxMk, fyMk, fxMh, fyMh, fxF, fyF,

fhxMk, fhyMk, fhxMh, fhyMh, fhxF, fhyF and ft

fR3' [N/mm]

Mohr's principal stress

calculated from stress components

fxp, fyp

- Mohr's principal stress

calculated from stress components

fxpc, fypc, , fxMk, fyMk, fxMh, fyMh, fxF, fyF

fhxMk, fhyMk, fhxMh, fhyMh, fhxF, fhyF and ft

REFERENCES

[1] - Wichmann, K.R., A.G. Hopper and J.L. Hershon:

Local Stresses in Spherical and Cylindrical

Shells due to External Loadings

Welding Research Council Bulletin 107, Rev.3.79.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Solved PROBLEMS PDFDocument127 pagesSolved PROBLEMS PDFprasanthNo ratings yet

- REF Calculations Output Code of PracticeDocument8 pagesREF Calculations Output Code of Practicekushal JeebodhunNo ratings yet

- Piping Stress Handbook - by Victor Helguero - Part 2Document121 pagesPiping Stress Handbook - by Victor Helguero - Part 2namdq-1No ratings yet

- Fabrication and Characterization of Aa6061/Cnts Surface Nanocomposite by Friction Stir ProcessingDocument1 pageFabrication and Characterization of Aa6061/Cnts Surface Nanocomposite by Friction Stir ProcessingAli RazaNo ratings yet

- Inspection Report: V'Groove DetailsDocument4 pagesInspection Report: V'Groove DetailsVijay Makwana VishwakarmaNo ratings yet

- 4.1chemical Bonding HandoutDocument4 pages4.1chemical Bonding HandoutMichelle NgNo ratings yet

- Frank Girgsdies Phase Analysis and Structure Refinement 131129Document91 pagesFrank Girgsdies Phase Analysis and Structure Refinement 131129MegaTypers100% (1)

- Performance-Based Seismic Design of Shape Memory Alloy - Reinforced Concrete Bridge Piers. I: Development of Performance-Based Damage StatesDocument13 pagesPerformance-Based Seismic Design of Shape Memory Alloy - Reinforced Concrete Bridge Piers. I: Development of Performance-Based Damage StatesalokaNo ratings yet

- Surfactants Emulsion PolymersDocument2 pagesSurfactants Emulsion Polymers8612106535100% (2)

- Base Plate and Anchor Bolt EurocodeDocument45 pagesBase Plate and Anchor Bolt Eurocoderaymond0% (1)

- Rheology, Compounding and Processing of Filled ThermoplasticsDocument63 pagesRheology, Compounding and Processing of Filled Thermoplasticsjr_hernando_enal3852No ratings yet

- Helical Compression Spring DesignDocument2 pagesHelical Compression Spring DesignkarthegreNo ratings yet

- Material's FatigueDocument25 pagesMaterial's FatigueGary TeongNo ratings yet

- 2020 Solid2 2 Ch10 Superconductivity Abcdef2Document46 pages2020 Solid2 2 Ch10 Superconductivity Abcdef2Aqua BlueNo ratings yet

- Phase DiagramDocument49 pagesPhase DiagramJaber HasanNo ratings yet

- Nanotechnology Lab-Service PortfolioDocument17 pagesNanotechnology Lab-Service PortfolioSujit KumarNo ratings yet

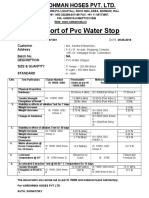

- Test Report of PVC Water Stop: Customer: Address: Batch No.: Na Description: Size & Quantity: StandardDocument1 pageTest Report of PVC Water Stop: Customer: Address: Batch No.: Na Description: Size & Quantity: StandardR.ThangarajNo ratings yet

- Tension MemDocument19 pagesTension MemNick AvisNo ratings yet

- 2 Design FactorsDocument7 pages2 Design FactorsshurookNo ratings yet

- Numerical Simulation of Seismic Slope Stability Analysis Based On Tension-Shear Failure MechanismDocument12 pagesNumerical Simulation of Seismic Slope Stability Analysis Based On Tension-Shear Failure MechanismPaul Pinedo VilcahuamánNo ratings yet

- Tensile LabDocument13 pagesTensile LabnevermoreNo ratings yet

- Design of Steel StructuresDocument2,529 pagesDesign of Steel StructuresStructural Spreadsheets75% (8)

- Applied Physics: Unit - V Dielectric and Magnetic Properties of MaterialsDocument114 pagesApplied Physics: Unit - V Dielectric and Magnetic Properties of MaterialsAķ Śhâ Yá RèddÿNo ratings yet

- Farrat Plate BrochureDocument12 pagesFarrat Plate BrochureShaneLinehanNo ratings yet

- LeHTN PDFDocument220 pagesLeHTN PDFjasimabdNo ratings yet

- Corbel PDFDocument25 pagesCorbel PDFAve Robin M. RamosNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- Stresses and Deformations of A Conveyor Power Pulley Shell Under Exponential Belt TensionsDocument9 pagesStresses and Deformations of A Conveyor Power Pulley Shell Under Exponential Belt TensionsShamik ChowdhuryNo ratings yet

- Oldroyd David Christopher. - Yielding Pillar DesignDocument93 pagesOldroyd David Christopher. - Yielding Pillar Designkatta_sridharNo ratings yet

- Heat TreatmentDocument53 pagesHeat TreatmentIqbal Muhammad HusainiNo ratings yet