Professional Documents

Culture Documents

Turbosyn Sp-Antriebstechnik

Uploaded by

hyundai310Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbosyn Sp-Antriebstechnik

Uploaded by

hyundai310Copyright:

Available Formats

Simply ingenious ingenious simple: self-synchronizing hydrodynamic start-up coupling TurboSyn

Dipl.-Ing. Harald Hoffeld Head of Technology Department in the Start-up Components product group at Voith Turbo GmbH & Co. KG in Crailsheim Special print from antriebstechnik 4/2006

Figure 1: Continued development of 75 years of a proven invention: Voith Turbo uid coupling with integrated lock-up clutch, type TurboSyn.

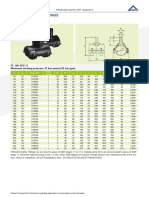

Figure 2: Motor load for different coupling types having the same size. The characteristic 2a occurs through additional emptying of the working circuit around the retaining space 1a (Figure 3) in the delay chamber 2 (Figure 3).

E-motor KL 10 / 13

1 2 2a 3

Basic requirements for uid couplings

When machines are started or stopped, a slipping transmission between the motor and the driven machine is often desired. However at rated operation a slip-less i.e. lock-up device is preferred. Up to now both of these conditions soft start and synchronous lock-up at rated operation could not be met with hydrodynamic couplings.

The Fttinger principle on which hydrodynamic couplings are based has been known for 100 years. After the invention in 1905 by Dr. Hermann Fttinger, it took 25 years before a hydrodynamic coupling called uid coupling was installed in a pumped storage power station. For the 100th anniversary of the Fttinger principle and 75 years of Voith drive technology, Voith presents a new hydrodynamic coupling which eliminates losses and slip at rated operation in an ingeniously simple way (Figure 1).

Typically a uid coupling is used to transmit power between a motor and a driven machine. The characteristic curve of the coupling can be adapted to suit the requirements. This provides a proven, easy to handle, and reliable option for optimizing the drive line. Direct on line started asynchronous motors, often preferred because of their simple construction, can only be used for a relatively brief start-up time due to their speed-dependent current consumption. Start-up is possible only of relatively small masses and always leads to loading of the drive dependent on the characteristics of the motor. To overcome these limitations uid couplings are commonly used for:

Table: Symbols used. Symbols and description DP DFriction F FG T m n nP p q Prole diameter Friction diameter Force Fill level Torque Mass Speed Pump wheel speed Contact pressure Specic friction consumption Re * P S Reynolds number Performance coefcient Coefcient of friction Relative coefcient of friction Speed ratio Density Angular velocity Angular velocity of the pump Switching angle velocity

Figure 3: Hydrodynamic coupling in different types with nozzle screws. TVV: design with delay chamber TVVS: design with delay and annular chamber Section drawing Type TVV 1b 1a 1c

Nozzle screw Section drawing Type TVVS 3

Options with conventional uid couplings

Heavy-duty start-up: Soft start of the motor and subsequent loading of the driven machine with a torque somewhat below the pull out torque of the motor. This allows the maximum possible acceleration power of the motor to be used during the entire start-up time. Soft-duty start-up: Soft start of the motor and subsequent acceleration of the driven machine with minimum acceleration torque, which is signicantly below the motor pull out torque during the entire start-up time for the driven machine. In both cases the motor is only lightly loaded during its acceleration. After it has reached its rated speed, the driven machine is accelerated up to the rated speed, and the motor is always operating above the stall speed in the stable nominal current range.

There are various parameters available to adapt the coupling function or characteristic to the drive: The coupling size, the coupling type, and the ll level, FG. In Figure 2 the load of an electric motor is shown for differing types of uid couplings using the same ll level. The different primary characteristics of the uid coupling are due to the different chambers. Figure 3: retaining space 1 (1a, 1b, 1c), delay chamber 2 and annular chamber 3. The transmission capability of uid coupling is described by the equation for torque:

5 2 T = Dp p

With this, the transmitted torque and slip can be adjusted by changing the ll level FG. For uid couplings with delay chambers, the torque build up can be further adjusted over time by changing the nozzle cross-section using removable nozzle screws (Figure 3). Based on the principle of operation of a uid coupling, a slip between pump and turbine wheel occurs during rated torque transmission. Typically slip is about 3%.

(1)

where the following applies for the performance coefcient : = f (geometry, Re, , FG) (2)

Figure 4: Geometry and applications of force on the turbine wheel segment.

Figure 5: The effect of spring relief on a centrifugal body.

Flift (FG min.) Fhydro (FG max.) a FBolt Fcent b

c F

FN

1.0

Shifting force

Fmax

[1]

0.8 0.6 0.4 0.2

Compensation m+m for the shifting force loss due to additional mass m

DP Dfriction 0 FSpring Fmax FHub (FG max.) -0.2 -0.4 0 0.1 0.2 0.3 0.4 0.5 0.53 0.6 0.7 0.8 0.9 1.0 Shifting force reduced by restoring spring s [1]

Requirements for the TurboSyn Working principle

In the following, a lock-up clutch integrated in the uid coupling is shown, which only slightly affects the essential characteristics of the uid coupling. The development goals for this lock-up clutch were specied together with the characteristics of the hydrodynamic Voith coupling: The machines connected should be protected as much as possible for both the heavy-duty start-up as well as for the soft-duty start-up. Synchronization should not reduce the masses to be accelerated. There should be no reduction of the torque transmission. A stall of the driven machine should result in load limitation by disengaging the lock-up and thus leading to a purely hydrodynamic torque transmission.

The lock-up functions close and open should be self-engaging. Lock-up should not require any additional auxiliary power source. The characteristics should be input speed independent, to simplify the engineering. The installation dimensions of the existing uid couplings are to be retained to offer a drop in replacement and still offer compact drive solutions. The interface connections to motor and driven machine side should be retained, so that the existing connecting technology (connecting coupling, anges) can be used.

Start-up and TurboSyn lock-up clutch lead to a centrifugal force controlled friction clutch, whose centrifugal bodies rotate at the output speed. To fulll the requirement for compactness, a centrifugal clutch was not just simply coupled to the uid coupling, instead, it was integrated completely. The existing mass of the turbine wheel is used as a centrifugal body (Figure 1, red and blue segments). To do this, the turbine wheel is now split into multiple segments. On the inner diameter, all segments receive a pivot bolt bearing assembly in the coupling housing. The segments are connecting with the hub so that only one angular motion is possible. This is minimal and is approximately 1 mm between free running and engaged TurboSyn position. The force is introduced into the turbine wheel segments via friction from the shell of the turbo coupling. The force is transferred to the hub via the bolt

Figure 6: Dependence of beginning of shifting on the mass ratios of a springrelieved shift coupling.

0.7 0.6 0.53 0.5 0.4 0.3 0.2 0.1 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 m m [1]

s [1]

connections (Figure 4). Because of the segmented turbine wheel design, there is now the opportunity to use the hydrodynamic peripheral forces directly to control the engagement of the clutch. The torque transmission was selected so that the turbine wheel segments are loaded in a trailing manner by the friction force, when the motor is operational. This means that the friction force supports the clutch disengaging. Therefore, it is also possible to use the hydrodynamic peripheral force for the disengaging of the clutch. The hydrodynamic force operates like the spring of a conventional centrifugal clutch, however with the advantage that the force becomes smaller with decreasing slip and does not act in the engaged state. This makes it possible to move the starting point of the engagement to higher output speeds without in-

creasing the centrifugal body mass, which would be necessary if continuously-acting springs were used. The inuence of a continuously acting spring for moving the engagement point of a rotating mass is shown in Figure 5. The spring counteracting the centrifugal force reduces the effective engaging force. To compensate for this loss of engaging power, an additional mass m is necessary. The relationship between the beginning of engagement and the mass ratios is shown in Figure 6. Geometry and masses of the turbine wheel segments were matched with the hydrodynamic peripheral force so that the reduction of the hydrodynamic spring leads to a signicant movement of the engagement point. This hydrodynamic disengagement force, as well as the trailing of the centrifugal body with the output speed, results in the

acceleration energy primarily being applied hydrodynamically, hence the loading on the friction lining is very small. The forces shown in Figure 4 correspond to the maximum occurring forces. The hydraulic force the sum of the single ow forces applied to each individual blade. The speed-dependent force ratios are shown in Figure 7. The transmittable torque of the coupling can be calculated from these force characteristics and the geometric relationships, along with knowledge of the coefcient of friction. Figure 8 shows the hydrodynamic torque transmission of the TurboSyn, and the portion of the torque transmitted by friction. The relative coefcient of friction used as the basis of this calculation is also indicated.

Figure 7: Speed-dependent force ratios on the turbine wheel segment. nP = 1,500 rpm 100,000 80,000 60,000 40,000 F [N] 20,000 0 -20,000 -40,000 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 [1] Flift FHydro (FG max) FHydro (FG min) Fcentr.

Figure 8: Torque transmission of the TurboSyn. nP = 1,500 rpm 7,000 6,000 5,000 T [Nm] *[1] * Tfriction 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 [1] 4,000 3,000 2,000 1,000 0 Ttotal THydro

Three turbine wheel versions

Characteristic curves

In order to implement the clutch characteristic for different loads optimally, three different turbine wheel versions are available: Version A: For lower loads, a design in accordance with Figure 4 is selected. The friction linings can be found on the side of the turbine wheel segments which are leading the links on the hub. Version B: For medium loads, the friction linings are applied on the center of the segments. Version C: For high loads, the friction linings are also applied on the center of the segments, however, heavier turbine wheel segments are used.

The loadings of the friction linings are similar for all turbine wheel versions, because not only the synchronous torque is modied, but the hydrodynamic torque as well. The coupling shell without annular chamber is connected to the pump wheel and encloses the turbine wheel so that the operating medium remains within the working circuit. In addition to containing the oil, the shell must accommodate the centrifugal forces of the turbine wheel segments and also serve as the contact surface for the friction linings. This requires the use of a ferrous material with sufcient surface hardness on the friction surface.

The geometric ratios of the lock-up clutch lead to the same dependence of torque on prole diameter DP and on the angular velocity of the output, which is the same as for a purely hydrodynamic coupling. Since the coupling series has a similar design, both geometrically and hydraulically, the loading of the TurboSyn can also be shown by the power coefcient as a specic characteristic. The following relationship results from equation 1 and 2: T = = f(, FG) 5 2 Dp p Figure 9 shows the calculated characteristic for the turbine wheel version C. The load on the friction linings is characterized by the contact pressure and the specic frictional force.

Figure 9: Calculated characteristic of the TurboSyn coupling for high load, as well as for friction contact load.

Figure 10: Portions of the hydrodynamic input power and centrifugal force coupling friction force dependent on the speed ratio between input and output. The effect of the synchronous coupling is implemented starting at a speed ratio of approximately 0.55.

5 4.5 103 [1]; p [N/mm2]; q [W/mm2] 4 3.5 3 2.5 2 1.5 1 0.5 0 0 p q Q [W] Hydro 103 total 103

600,000 500,000 400,000 QHydro 300,000 200,000 100,000 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 [1] 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 [1] QFriction

Example application

Summary

The power transmitted hydrodynamically and by friction are shown in Figure 10 for the start-up of a coal mill. During start-up, a part of the drive energy is transformed into heat and stored in the mass of the TurboSyn. More than 95% of this heat is generated hydrodynamically. During operation the coupling is cooled down to ambient temperature, because there are no losses due to slip. This means that after a system stop, there is a signicantly higher heat capacity available to restart, compared to a conventional slipping hydrodynamic coupling.

The use of this type of coupling is ideal for drives requiring a soft start, but which do not require the characteristics of a uid coupling under normal operation. For last 1.5 years, the drive system of a coal mill at the Frimmersdorf power plant has been successfully in operation using a TurboSyn 750 TV-X with an input power of 450 kW at a speed of 1,480 rpm. Currently a TurboSyn 562 TV is being commissioned on a coal charging conveyor with an input power of 108 kW at a speed of 1,480 rpm.

Using existing uid coupling components, a look up clutch can be integrated into the uid coupling without adding additional parts, simply by modications to both the inner wheel and shell. The turbine wheel was segmented and linked so that it fullls the function of an additional centrifugal body. Force is transmitted from the turbine wheel segments to the hub via pivot bolts which replace the previous rigid hub connection. The coupling shell is used as friction drum. The hydrodynamic force is initiated in such a way as this fullls the function of a reset spring for discharge the friction contact. All other parts of the uid coupling remain unchanged.

Voith Turbo GmbH & Co. KG Start-up Components Voithstr. 1 74564 Crailsheim, Germany Tel. +49 7951 32 -409 Fax +49 7951 32 -480 startup.components@voith.com www.startup-components.com

Cr 601 en, MSW/K&E, 05.2007, 1000. Dimensions and illustrations without obligation. Subject to modications.

You might also like

- Profit andDocument2 pagesProfit andhyundai3100% (1)

- Steam TablesDocument20 pagesSteam Tablesajitsamal456No ratings yet

- Experimental Apparatus For Thermal Shock Fatigue InvestigationsDocument10 pagesExperimental Apparatus For Thermal Shock Fatigue Investigationshyundai310No ratings yet

- 4 Conversion of Tool Angles From One System To AnotherDocument16 pages4 Conversion of Tool Angles From One System To AnotherPRASAD326100% (4)

- Voith High Performance Universal Joint ShaftsDocument72 pagesVoith High Performance Universal Joint Shaftshyundai310100% (1)

- Simulaton FurnaceDocument6 pagesSimulaton Furnacehyundai310No ratings yet

- GEAR MANUFACTURING PROCESSESDocument25 pagesGEAR MANUFACTURING PROCESSESNikhil B RamNo ratings yet

- Some Development EnggDocument16 pagesSome Development Engghyundai310No ratings yet

- ANSYS APDL - Analysis of A Truss 1 PDFDocument7 pagesANSYS APDL - Analysis of A Truss 1 PDFSamuel PintoNo ratings yet

- Screw Thread N GearsDocument71 pagesScrew Thread N Gearshyundai310100% (3)

- Precision & GyroscopeDocument53 pagesPrecision & GyroscopeVenkateswar Reddy MallepallyNo ratings yet

- Two Dimensional Truss.Document24 pagesTwo Dimensional Truss.hyundai310No ratings yet

- Voith High Performance Universal Joint ShaftsDocument72 pagesVoith High Performance Universal Joint Shaftshyundai310100% (1)

- Tutorial de Mecánica de La Fractura (Ansys APDL)Document14 pagesTutorial de Mecánica de La Fractura (Ansys APDL)omarihuanoNo ratings yet

- Lec16 Normal Modes of Vibration PDFDocument7 pagesLec16 Normal Modes of Vibration PDFhyundai310No ratings yet

- Non Linear Vibrations PDFDocument135 pagesNon Linear Vibrations PDFhyundai310100% (1)

- GEARBOXDocument16 pagesGEARBOXhyundai31050% (2)

- Ultrasonic Machining SeminarDocument11 pagesUltrasonic Machining Seminarhyundai31050% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IC Forklift X Series 4.0-Mini 5.0TDocument6 pagesIC Forklift X Series 4.0-Mini 5.0TNKG1001No ratings yet

- OlkDocument16 pagesOlkcristianNo ratings yet

- CRJ Pre - After Flight ChecklistDocument4 pagesCRJ Pre - After Flight ChecklistCHIMONo ratings yet

- CIXI GESHINI ELECTRIC APPLIANCE CO.,LTD Contact and Product SpecsDocument1 pageCIXI GESHINI ELECTRIC APPLIANCE CO.,LTD Contact and Product SpecsToni GNo ratings yet

- Epf011acd Ug V02-7302Document124 pagesEpf011acd Ug V02-7302sluz2000No ratings yet

- Modul 1 Introduction To ArduinoDocument17 pagesModul 1 Introduction To ArduinoPrima Aji AkbarNo ratings yet

- Service Manual: 17" LCD Monitor IBM L170Document54 pagesService Manual: 17" LCD Monitor IBM L170Yonny MunozNo ratings yet

- HYD3-6K-EP - IEC 62109-2 - ReportDocument30 pagesHYD3-6K-EP - IEC 62109-2 - ReportMarcus MazzeoNo ratings yet

- Check List For 3G Huawei Equipments (Outdoor Site APM+IBBS-1099)Document34 pagesCheck List For 3G Huawei Equipments (Outdoor Site APM+IBBS-1099)Mustafa IbrahimNo ratings yet

- FA87Document5 pagesFA87IFLYNo ratings yet

- RE 2558 Manual V1.0 01Document68 pagesRE 2558 Manual V1.0 01Hamilton GutierrezNo ratings yet

- Igb 0001Document15 pagesIgb 0001Дејан МркајаNo ratings yet

- Basic Circuits, Laws, and Measurements: Chapter ObjectivesDocument20 pagesBasic Circuits, Laws, and Measurements: Chapter ObjectivesSneha PavithranNo ratings yet

- Quotation - Air Fryer (AF-VS001 To VS028) - 13oct2023Document9 pagesQuotation - Air Fryer (AF-VS001 To VS028) - 13oct2023Payman GhaffArianNo ratings yet

- Mini Excavator Liugong Dressta 9035e Stage VDocument9 pagesMini Excavator Liugong Dressta 9035e Stage VRadu GălățanNo ratings yet

- Wharfedale SVP 12PMDocument13 pagesWharfedale SVP 12PMrdbasses100% (1)

- 801 Aeronca PDFDocument17 pages801 Aeronca PDFVishveshNo ratings yet

- Ficha Tecnica Siemens 6es7223-1ph32-0xb0Document3 pagesFicha Tecnica Siemens 6es7223-1ph32-0xb0ferbaq48No ratings yet

- SEAL 600 ManualDocument32 pagesSEAL 600 ManualChrister NormarkNo ratings yet

- Technical Service BulletinDocument10 pagesTechnical Service Bulletinأمجد راضي هادي /A1No ratings yet

- AN1155 Deboo IntegratorDocument4 pagesAN1155 Deboo IntegratorMichael RiveraNo ratings yet

- 1MRB520308-BEN D en Distributed Busbar Protection REB500Document58 pages1MRB520308-BEN D en Distributed Busbar Protection REB500locomaniacoNo ratings yet

- RXS J DatabookDocument39 pagesRXS J Databookjbgb3335616No ratings yet

- Kawasaki 1200 STX-R Service Manual PDFDocument289 pagesKawasaki 1200 STX-R Service Manual PDFUmar ShamsudinNo ratings yet

- Spigot Saddles: Frialen Safety FittingsDocument2 pagesSpigot Saddles: Frialen Safety FittingsAlbertoNo ratings yet

- Fire Dampers Guide PL-12, PL-13, PL-14Document4 pagesFire Dampers Guide PL-12, PL-13, PL-14Muhidin KozicaNo ratings yet

- 08 PUB171 004 00 Issue 03 20 - FP02Document28 pages08 PUB171 004 00 Issue 03 20 - FP02Tuan NguyenNo ratings yet

- 8200 8282 LCD RetrofitDocument3 pages8200 8282 LCD RetrofitDennis koophierNo ratings yet

- Safety inspection checklist for bar cutting and bending machineDocument14 pagesSafety inspection checklist for bar cutting and bending machinepartha50% (2)

- Sensor de Toner Ts0524lbDocument5 pagesSensor de Toner Ts0524lbjaag93No ratings yet