Professional Documents

Culture Documents

Ga 610 13

Uploaded by

Aneudy AlcantaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ga 610 13

Uploaded by

Aneudy AlcantaraCopyright:

Available Formats

FIRE RESISTANCE PROVIDED BY GYPSUM BOARD MEMBRANE PROTECTION

(GA-610-13)

Introduction Dividing buildings into distinct fire-protected areas is typically accomplished by providing fireresistance rated separations between those areas. This type of separation is easily achieved by the use of gypsum board applied to either wood or steel framing members. These fire-rated separations are usually provided as total assemblies, consisting of the structural member, the gypsum board and structural flooring material (if a floor/ceiling assembly). Listings of many fire-rated assemblies or Designs are found in the GA-600, UL Fire Resistance Directory, etc. However, often no fire-rated assembly exists to match a particular configuration to be built. This is often the case for retrofit work, but may also occur in new construction. In this case all of the fire resistance may be provided by a gypsum board membrane; typically several layers of fire-rated (type X) gypsum board. Fire Tests and Finish or Membrane Ratings The finish rating is derived from the same test method (ASTM E119 or CAN/ULC S101) that establishes fire-resistance ratings for systems. The finish rating is the time necessary for an average rise in temperature of 250F (139C), or a maximum rise of 325F (180C), as measured on the face of the wood (i.e., framing) nearest the fire. In a gypsum board system, this is the time required for the back (unexposed) surface of the gypsum board to reach one of the limiting conditions as defined above. Finish ratings have been established for most fire-resistance rated systems that incorporate combustible (i.e., wood) framing components. In gypsum board construction, the finish rating can be determined to be the fire-resistance rating provided by the gypsum board membrane on the fire exposed side. While the use of finish rating data is a common and generally accepted practice to validate and document the required fire resistance of a membrane, its use must be approved by the authority having jurisdiction.

Printed in U.S.A.

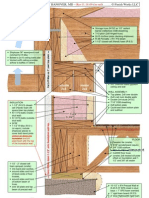

When to Use a Membrane Rating Fire tests on floor-ceiling systems are historically conducted with fully loaded solid-sawn nominal 2x10 (38x235 mm) floor framing. Hundreds of fire tests were conducted prior to the development of engineered wood trusses, wood Ijoists, and lightweight steel joists. In certain types of new construction, it may be neither practical nor economical to use the type of structural components found in tested and listed systems. In addition, engineered systems taking into account the actual loads and spans enable designers to specify systems that may not require 2x10 (38x235 mm) joists. These engineered systems often specify smaller dimension lumber, wood trusses, wood I-joists, other engineered lumber products, steel channel joists, or other materials as the structural framing. The effect of using smaller lumber sizes where shorter spans and lower loads are encountered has not been documented by full-scale tests. Due to the larger size of the test specimen required in the ASTM E119 and CAN/ULC S101 fire test method, it may not be possible to evaluate such designs by full scale tests. Retrofit construction often presents unique situations for designers, contractors, and building officials. Upgrading existing walls or floor-ceiling systems may involve limited access to the space or the presence of construction materials that may not be used in any currently available tested or listed system. When it is not possible to construct a specific tested system, the use of the finish rating of a system may be the only practical method to determine the rating. Gypsum board membranes most commonly used to meet fire-resistance requirements in unique circumstances are described and shown herein; the details and sketches are based on UL Designs U301 and L556, and on GA File Nos. FC 5406 and RC 2601.

Copyright Gypsum Association 2013. All rights reserved.

This document may be revised or withdrawn from circulation at any time. The status of the document should be verified by the user prior to following any recommendations contained herein. To verify that you have the most current edition of the document, access the Gypsum Association website at: www.gypsum.org.

One-Hour Ceiling (Based on GA File Nos. FC 5406 and RC 2601)

The ceiling membrane consists of two layers of 5/8 (15.9 mm) type X gypsum board directly applied to framing or furring. The base layer of gypsum board is applied at right angles to ceiling framing 24 (610 mm) o.c. and attached with 1 (25 mm) Type S or S12 drywall screws (for steel framing) or 1-1/4 (32 mm) Type W or S drywall screws (for wood framing) spaced 24 (610 mm) o.c. The face layer of gypsum board is applied at right angles to the framing and attached with 1-5/8 (41 mm) Type S or S-12 drywall screws (for steel framing) or 1-7/8 (48 mm) Type W or S drywall screws (for wood framing) 12 (305 mm) o.c. at end joints and intermediate joints and 1-1/2 (38 mm) Type G drywall screws 12 (305 mm) o.c. placed 2 (50 mm) back on either side of end joints. Joints of the face layer are offset 24 (610 mm) from the joints in the base layer. Face layer joints and fasteners are finished to Level 1 as specified in GA-214, Levels of Gypsum Board Finish.

Two-Hour Ceiling (Based on UL Design L556 / ULC Design M514)

The ceiling membrane consists of four layers of 5/8 (15.9 mm) type X gypsum board applied to ceiling framing spaced 24 (610 mm) o.c. with a 7/8 (22 mm) hat-shaped steel furring channel located between the third and face layers. The base layer of gypsum board is applied at right angles to the ceiling framing and attached with 1-1/4 (32 mm) type S or W drywall screws spaced 12 (305 mm) o.c. The second layer of gypsum board is applied at right angles to the ceiling framing and attached with 2 (51 mm) type S or W drywall screws spaced 12 (305 mm) o.c. The third layer of gypsum board is applied at right angles to ceiling framing and attached with 2-1/2 (64 mm) type S or W drywall screws spaced 12 (305 mm) o.c. The joints in each layer are offset a minimum of 10 (250 mm) from the previous layer. The steel hat-shaped rigid furring channels are applied at right angles to the ceiling framing and spaced 24 (610 mm) o.c. The channels are attached to the ceiling framing at each framing member/furring channel intersection with two 2-1/2 (64 mm) Type S or W drywall screws. The face layer of gypsum board is applied at right angles to the furring channels and attached with 1-1/8 (28 mm) type S drywall screws spaced 12 (305 mm) o.c. Face layer joints and fasteners are finished to Level 1 as specified in GA-214, Levels of Gypsum Board Finish.

The membrane consists of two layers of 5/8 (15.9 mm) type X gypsum board directly applied to framing or furring. The base layer of gypsum board is applied either parallel or at right angles to wall or partition framing 16 (406 mm) o.c. and attached with 1 (25 mm) Type S or S-12 drywall screws (for steel framing) or 1-7/8 (48 mm) nails or 1-1/4 (32 mm) Type W or S drywall screws (for wood framing) spaced 6 (150 mm) o.c. The face layer of gypsum board is applied either parallel or at right angles to the framing and attached with 1-5/8 (41 mm) Type S or S-12 drywall screws (for steel framing) or 2-3/8 (60 mm) nails or 1-7/8 (48 mm) Type W or S drywall screws (for wood framing) spaced 8 (203 mm) o.c. Joints of the face layer are offset 24 (610 mm) from the joints in the base layer. Face layer joints and fasteners are finished to Level 1 as specified in GA-214, Levels of Gypsum Board Finish.

Printed in U.S.A.

Copyright Gypsum Association 2013. All rights reserved.

This document may be revised or withdrawn from circulation at any time. The status of the document should be verified by the user prior to following any recommendations contained herein. To verify that you have the most current edition of the document, access the Gypsum Association website at: www.gypsum.org.

EXISTING CONSTRUCTION

One-Hour Wall Membrane (Based on UL Design U301)

You might also like

- Five Story Wood Frame Structure Over Podium Slab 2017Document80 pagesFive Story Wood Frame Structure Over Podium Slab 2017philiSCDNo ratings yet

- Build A Colonial-Style Storage Shed - Popular MechanicsDocument9 pagesBuild A Colonial-Style Storage Shed - Popular Mechanicsrockhard4wd9696No ratings yet

- Astm E1105 Water Intrusion TestDocument21 pagesAstm E1105 Water Intrusion TestCristian DandresNo ratings yet

- Astm A194 - A194m-23Document13 pagesAstm A194 - A194m-23ashrafNo ratings yet

- Astm C954Document3 pagesAstm C954Cj Elamparo100% (1)

- Use of Expanded Polystyrene in Road EmbankmentsDocument6 pagesUse of Expanded Polystyrene in Road EmbankmentsmikadituNo ratings yet

- A 954 - 96 QTK1NC05NGDocument4 pagesA 954 - 96 QTK1NC05NGsachinguptachdNo ratings yet

- A Frame CabinDocument3 pagesA Frame Cabinmondomondo75% (4)

- Nondestructive Evaluation of Wood-Based Flexural Members Using Transverse VibrationDocument8 pagesNondestructive Evaluation of Wood-Based Flexural Members Using Transverse Vibrationasma hamzaNo ratings yet

- Primavera P6 Exercise Worksheet Rev 1.04 2016-09-12Document38 pagesPrimavera P6 Exercise Worksheet Rev 1.04 2016-09-12RAKESH RANJANNo ratings yet

- Fire Resistance Ratings of Load Bearing Steel Stud Walls With Gypsum Wallboard ProtectionDocument8 pagesFire Resistance Ratings of Load Bearing Steel Stud Walls With Gypsum Wallboard Protectionjbatista_njg4152No ratings yet

- MPI Maintenance Repainting ManualDocument18 pagesMPI Maintenance Repainting ManualnzarNo ratings yet

- Ross Wood and Timber Condition Assessment Manual CH 4 PDFDocument20 pagesRoss Wood and Timber Condition Assessment Manual CH 4 PDFKen SuNo ratings yet

- E329 PDFDocument10 pagesE329 PDFINARQ1979No ratings yet

- Behavior and Capacity of Headed ReinforcementDocument9 pagesBehavior and Capacity of Headed ReinforcementjeffNo ratings yet

- Branz Slender Panel GuideDocument0 pagesBranz Slender Panel GuidesdewssNo ratings yet

- NFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsDocument5 pagesNFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsprokjongNo ratings yet

- Tips For Designers PDFDocument5 pagesTips For Designers PDFSushil DhunganaNo ratings yet

- Astm F1936-10 (2015)Document11 pagesAstm F1936-10 (2015)forbesadmin100% (1)

- Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsDocument3 pagesStyrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsLuigi HernándezNo ratings yet

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Document2 pagesSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchNo ratings yet

- Deformed and Plain Carbon-Steel Bars For Concrete ReinforcementDocument8 pagesDeformed and Plain Carbon-Steel Bars For Concrete ReinforcementmameniqNo ratings yet

- Building Construction TechnologyDocument21 pagesBuilding Construction TechnologyBCAS HND QS Assignment100% (1)

- Gypsum Board: Standard Specification ForDocument7 pagesGypsum Board: Standard Specification ForMuhammed Asraff Abdul RahmanNo ratings yet

- EG 10-101 V3-AU Uni-Rivet Application GuideDocument10 pagesEG 10-101 V3-AU Uni-Rivet Application GuideEros BellioNo ratings yet

- Wind Load Materials 3Document100 pagesWind Load Materials 3gullipalliNo ratings yet

- Application and Finishing of Gypsum Board: Standard Specification ForDocument18 pagesApplication and Finishing of Gypsum Board: Standard Specification ForINARQ1979100% (1)

- Shaftwall7.0 001Document9 pagesShaftwall7.0 001Wissam AlameddineNo ratings yet

- Astm E72 E72-15Document13 pagesAstm E72 E72-15cristobal aguilar100% (1)

- Structural Design of Residential House Case Study PDFDocument8 pagesStructural Design of Residential House Case Study PDFMac ShaikNo ratings yet

- Application of Gypsum Veneer Plaster: Standard Specification ForDocument5 pagesApplication of Gypsum Veneer Plaster: Standard Specification ForINARQ1979No ratings yet

- Ner258.pdf ICC EvaluationDocument0 pagesNer258.pdf ICC Evaluationfordy12270% (1)

- Astm C955-09Document4 pagesAstm C955-09rodrigoNo ratings yet

- Fire Resistant Timber Fire DoorsDocument2 pagesFire Resistant Timber Fire DoorsTAHER AMMARNo ratings yet

- Steel Self-Piercing Tapping Screws For The Application of Gypsum Panel Products or Metal Plaster Bases To Wood Studs or Steel StudsDocument4 pagesSteel Self-Piercing Tapping Screws For The Application of Gypsum Panel Products or Metal Plaster Bases To Wood Studs or Steel StudsMikoNo ratings yet

- Guidelines For New Foundation Design High Water Table or Surface Perched Water PDFDocument20 pagesGuidelines For New Foundation Design High Water Table or Surface Perched Water PDFMuhammad Arfan JadoonNo ratings yet

- Iapmo Ues Er493Document13 pagesIapmo Ues Er493jeffuangNo ratings yet

- SFA Framing Guide 07 PDFDocument12 pagesSFA Framing Guide 07 PDFalattar98No ratings yet

- Wood-Based Structural Panels in Compression: Standard Test Methods ForDocument7 pagesWood-Based Structural Panels in Compression: Standard Test Methods ForMarvin MoreiraNo ratings yet

- Ondura Installation GuideDocument8 pagesOndura Installation GuideiansevillaNo ratings yet

- Fiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceDocument3 pagesFiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceKevin Josue100% (1)

- By David J Hammond S.E. and Paul Decicco P.E.: Nfpa Fire Protection Manual 2003 Sect 12, CH 11Document13 pagesBy David J Hammond S.E. and Paul Decicco P.E.: Nfpa Fire Protection Manual 2003 Sect 12, CH 11fraantoineNo ratings yet

- ShotcreteDocument7 pagesShotcreteafuhcivNo ratings yet

- Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastic Lumber and Related ProductsDocument7 pagesStandard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastic Lumber and Related ProductsSyed Muneeb HaiderNo ratings yet

- 179-196 Ahmad Hamid - 18 P - PDFDocument18 pages179-196 Ahmad Hamid - 18 P - PDFeli700No ratings yet

- C1032 - 06Document2 pagesC1032 - 06Black GokuNo ratings yet

- ASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementDocument2 pagesASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementAmanda Ariesta Aprilia100% (1)

- CEVA 250-Phyzite 380Document1 pageCEVA 250-Phyzite 380hernie w. vergel de dios jrNo ratings yet

- Tek 18-01B5 PDFDocument8 pagesTek 18-01B5 PDFMohamed HNo ratings yet

- K-Series Final 030911Document54 pagesK-Series Final 030911Alvaro Alexis Mendoza PradaNo ratings yet

- Technical Data: Carbofol HDPE 406 1,0 S/s Smooth / Smooth OITDocument1 pageTechnical Data: Carbofol HDPE 406 1,0 S/s Smooth / Smooth OITAlex Lie100% (1)

- Life-365 - v2.2.3 - Users - Manual (1) - 26-53Document28 pagesLife-365 - v2.2.3 - Users - Manual (1) - 26-53Fernando RosalesNo ratings yet

- ASTM E119 - 12aDocument34 pagesASTM E119 - 12aOmer Taj-eldinNo ratings yet

- Ufgs 13 34 19Document45 pagesUfgs 13 34 19sharandeep1112No ratings yet

- Guide To ICBO Evaluation Reports For Monokote MK6Document8 pagesGuide To ICBO Evaluation Reports For Monokote MK6Eric SoNo ratings yet

- D 2527 - 83 R01 - Rdi1mjc - PDFDocument2 pagesD 2527 - 83 R01 - Rdi1mjc - PDFsabaris ksNo ratings yet

- AITC Test Methods PDFDocument45 pagesAITC Test Methods PDFMichaelYeeNo ratings yet

- Astm C-1178-1 PDFDocument3 pagesAstm C-1178-1 PDFibrahim0% (1)

- D1038-11 Standard Terminology Relating To Veneer and PlywoodDocument4 pagesD1038-11 Standard Terminology Relating To Veneer and PlywoodRony YudaNo ratings yet

- California Title 24, Part 1 Administrative Code 264pp 6x9tradeDocument264 pagesCalifornia Title 24, Part 1 Administrative Code 264pp 6x9tradeTom AstaNo ratings yet

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Document2 pagesPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelNo ratings yet

- C1568 08 (2013)Document6 pagesC1568 08 (2013)diego rodriguez100% (2)

- Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsDocument7 pagesAbuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsAlejandroNo ratings yet

- C 636 - 04 Installation of Metal Ceiling Suspension Systems ForDocument4 pagesC 636 - 04 Installation of Metal Ceiling Suspension Systems ForJavier Salinas SepúlvedaNo ratings yet

- Slip Track Design Tn-W100-08aDocument4 pagesSlip Track Design Tn-W100-08aZebNo ratings yet

- Esr 1308Document21 pagesEsr 1308dkimNo ratings yet

- Wet Setting Weld Plates in TiltUp PanelsDocument1 pageWet Setting Weld Plates in TiltUp Panelsraghuveer11No ratings yet

- Standard Specification For Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementDocument7 pagesStandard Specification For Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementJose Fernando Huayhua ApfataNo ratings yet

- Aci 211-1-91 - Standard Practice For Selecting Proportions For ConcreteDocument8 pagesAci 211-1-91 - Standard Practice For Selecting Proportions For ConcretedrfkamalodeenNo ratings yet

- Mortar Cement: Standard Specification ForDocument4 pagesMortar Cement: Standard Specification ForMaiNo ratings yet

- Jee Bommer 2002 Dsha Vs PshaDocument31 pagesJee Bommer 2002 Dsha Vs Psharyan rakhmat setiadiNo ratings yet

- Sa924 en CGCDocument24 pagesSa924 en CGCRPantelNo ratings yet

- Wall ConstructionDocument22 pagesWall ConstructionJohn Michael CastilloNo ratings yet

- Safety in FormworkDocument118 pagesSafety in FormworkvijkingNo ratings yet

- SWBL 4 PrintDocument21 pagesSWBL 4 Printmursalin S. Daham100% (1)

- PAPERDocument16 pagesPAPERjpzb1892No ratings yet

- Status MomDocument8 pagesStatus MomSunil BhatNo ratings yet

- Dry Floating y MuellesDocument63 pagesDry Floating y MuellesFarihna JoseNo ratings yet

- BNBC 2020 StructureDocument1,455 pagesBNBC 2020 StructureMd. Mominul IslamNo ratings yet

- What Impact Has Technology Had On Architecture of The 20th CenturyDocument7 pagesWhat Impact Has Technology Had On Architecture of The 20th Centurysingingman100% (1)

- PCRC Conc Lintels For Structural SupportsDocument24 pagesPCRC Conc Lintels For Structural SupportsZaky MessengerNo ratings yet

- 04 Schedule B UGSR BhathenaDocument15 pages04 Schedule B UGSR BhathenaPratik DiyoraNo ratings yet

- Bhiwadi BrochureDocument8 pagesBhiwadi Brochureharishchand2271No ratings yet

- The Strand: Marconi HouseDocument5 pagesThe Strand: Marconi HouseJohn Adam St Gang: Crown ControlNo ratings yet

- Gyan Sagar College of Engineering, Sagar: Quiz Test Exam October 2019 (Sem-Iii)Document2 pagesGyan Sagar College of Engineering, Sagar: Quiz Test Exam October 2019 (Sem-Iii)Rahul Singh PariharNo ratings yet

- GREEN BUILDING: Framing & Insulation Design DetailDocument4 pagesGREEN BUILDING: Framing & Insulation Design DetailHarris WoodwardNo ratings yet

- Edenhaus TeaserDocument16 pagesEdenhaus TeaserLeonard HartonoNo ratings yet

- CNTRLDocument26 pagesCNTRLYen DaNo ratings yet

- Structural Design Criteria For Raised Floor SystemsDocument49 pagesStructural Design Criteria For Raised Floor SystemsOmer HayatNo ratings yet

- 336138422-SP3D-Structure-S4-Tutorial-31 March PDFDocument6 pages336138422-SP3D-Structure-S4-Tutorial-31 March PDFrajendraNo ratings yet