Professional Documents

Culture Documents

Variable Frequency Controllers

Uploaded by

saravana3kumar3ravicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Variable Frequency Controllers

Uploaded by

saravana3kumar3ravicCopyright:

Available Formats

SECTION 16269 VARIABLE FREQUENCY CONTROLLERS PART 1 - GENERAL Read and conform to all electrical sections of these specifications,the

general instructions for electrical division, section 16010, apply to and form part of all electrical sections. These shall be read in conjunction with design drawings. 1.01 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions apply to this Section. 1.02 SUMMARY

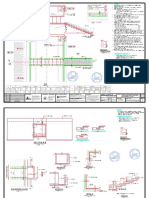

A. This Section includes solid-state, VFCs for speed control of three-phase, squirrelcage induction motors. 1.03 A. 1. Product Data: For each type of VFC, provide dimensions; mounting arrangements; location for conduit entries; shipping and operating weights; and manufacturer's technical data on features, performance, electrical ratings, characteristics, and finishes. 2. Submit relevant documents for EMI compatibility, Surge protection requirements & Harmonic filteration . All relevant data to be provided. B. Shop Drawings: For each VFC. 1. Include dimensioned plans, elevations, sections, and details, including required clearances and service space around equipment. Show tabulations of installed devices, equipment features, and ratings. Include the following: a. Each installed unit's type and details. b. Nameplate legends. c. Short-circuit current ratings of integrated unit. d. UL listing for series rating of over current protective devices in combination controllers. e. Features, characteristics, ratings, and factory settings of each motorcontrol center unit. 2. Wiring Diagrams: Power, signal, and control wiring for VFC. schematic wiring diagram for each type of VFC. Provide SUBMITTALS

WB4733 Al Ghurair City Expansion Phase II

16269 April 2008 Rev - 0

Variable Frequency Controllers. Page 1 of 10

C. Coordination Drawings: Floor plans showing dimensioned layout, required working clearances, and required area above and around VFCs where pipe and ducts are prohibited. Show VFC layout and relationships between electrical components and adjacent structural and mechanical elements. Show support locations, type of support, and weight on each support. Indicate field measurements. D. Qualification Data: For testing agency and manufacturer. E. Manufacturer's field service report. F. Operation and Maintenance Data: For VFCs, all installed devices, and components to include in emergency, operation, and maintenance manuals. In addition to items specified in Division 1 include the following: 1. Routine maintenance requirements for VFCs and all installed components. 2. Manufacturer's written instructions for testing and adjusting overcurrent protective devices. 3. Interfacing provisions for BMS. G. Load-Current and List of Settings of Adjustable Overload Relays: Compile after motors have been installed and arrange to demonstrate that dip switch settings for motor running overload protection suit actual motor to be protected. 1.04 QUALITY ASSURANCE

A. Manufacturer Qualifications: Manufacturer shall have an own office in the country of installation to provide complete product support and after sales service. B. Source Limitations: Obtain VFCs of a single type through one source from a single manufacturer. C. Comply with the following standards. 1. The VFD shall conform to international standards and meet the recommendations of the following: a. EMC Immunity: 1) IEC 1000-4-2/EN 61000-4-2 Level 3 2) IEC 1000-4-3/EN 61000-4-3 Level 3 3) IEC 1000-4-4/EN 61000-4-4 Level 4 4) IEC 1000-4-5/EN 61000-4-5 Level 3 b. EMC, conducted and radiated emissions: 1) IEC 1800-3-2/EN 61800-3, environment 1 (public sector) and 2 (industrial sector) under restricted distribution 2) EN 55011 class A (RFI filters included) 3) EN 55022 class B, with additional filters c. Vibrations: 1) IEC 68-2-6, 1.5 mm peak from 2 to 13 Hz, 1g from 13 to 200Hz 2. The VFD shall have UL and CSA , ISO 9001, ISO 14001, Stick product certification approvals. 3. The VFD shall consist of a variable Frequency Controller, a circuit breaker, a line contactor and necessary indicating lights and switch/pushbuttons.

WB4733 Al Ghurair City Expansion Phase II 16269 April 2008 Rev - 0 Variable Frequency Controllers. Page 2 of 10

4. The VFD along with associated components shall be installed in an enclosure having sufficient ventilation for heat dissipation. 1.05 DELIVERY, STORAGE, AND HANDLING

A. Deliver VFCs in shipping splits of lengths that can be moved past obstructions in delivery path as indicated. B. Store VFCs indoors in clean, dry space with uniform temperature to prevent condensation. Protect VFCs from exposure to dirt, fumes, water, corrosive substances, and physical damage. C. If stored in areas subject to weather, cover VFCs to protect them from weather, dirt, dust, corrosive substances, and physical damage. Remove loose packing and flammable materials from inside controllers; install electric heating of sufficient wattage to prevent condensation. 1.06 COORDINATION

A. Coordinate layout and installation of VFCs with other construction including conduit, piping, equipment, and adjacent surfaces. Maintain required workspace clearances and required clearances for equipment access doors and panels. B. Coordinate size and location of concrete bases. Cast anchor-bolt inserts into bases. C. Coordinate installation of roof curbs, equipment supports, and roof penetrations. D. Coordinate features of VFCs, installed units, and accessory devices with pilot devices and control circuits to which they connect. E. Coordinate features, accessories, and functions of each VFC and each installed unit with ratings and characteristics of supply circuit, motor, required control sequence, and duty cycle of motor and load. 1.07 EXTRA MATERIALS

A. Furnish extra materials described below that match products installed and that are packaged with protective covering for storage and identified with labels describing contents. 1. Spare Fuses: Furnish one spare for every five (5) installed, but not less than one set of three (3) of each type and rating. 2. Indicating Lights: two (2) of each type installed.

WB4733 Al Ghurair City Expansion Phase II

16269 April 2008 Rev - 0

Variable Frequency Controllers. Page 3 of 10

PART 2 - PRODUCTS 2.01 OUTPUT CHARACTERISTICS

A. Start-up and Permanent Operation 1. The VFC shall be capable of continuously delivering its rated output voltage to the motor in the limit of acceptable input voltage variations. 2. The VFC shall be able to control a 3-phase squirrel cage motor over a speed range of 3. 1% (minimal speed) to 100% (maximum speed), continuously and smoothly. 4. Within this speed range no derating of nominal torque value is accepted. 5. The VFC shall be adaptable to various types of applications and in particular it shall be possible to select on site, one of the three following operating modes: a. For low speed machines and heavy loading, (i.e.: high U/f ratio)* b. For machines with average loading operating at low speed (i.e.: constant torque, U/f ratio)* c. For pumps and fans (i.e.: variable torque, progressive U/f ratio)* (*): U= output voltage in Volt, f = output frequency in Hz. B. Transient Conditions: 1. For application requesting the VFC to operate in a constant torque configuration, transient over torque (for 60 sec.) shall be possible: 15% of nominal torque of motor. 2. For application requesting the VFSD to operate in a variable torque configuration, transient over torque of 120% of nominal torque shall be possible. 3. To protect the network against transient current, a current limitation function shall be used: a. For constant torque applications, limitation at 150% of motor nominal current for 60 s b. For variable torque applications, limitation at 120% of motor nominal current for 60 s. C. Inverter protections: 1. The VFC shall include the following auto protections against short-circuits: a. Between phase to phase, b. Between phase to earth, c. On internal supplies, d. On analogue and logic outputs. 2. It shall also include the following protections: a. Overheating, b. Mains over voltage and undervoltage, c. Loss of input phase. d. Underload. e. External fault.

WB4733 Al Ghurair City Expansion Phase II 16269 April 2008 Rev - 0 Variable Frequency Controllers. Page 4 of 10

D. Motor protections: 1. The VFC shall include the following motor protections: a. Protection by continuous calculation of I2t, as a function of speed b. Saving of motor thermal state when the VFC is powered off, c. Loss of output phase. d. Protection via PTC probes 2. Motor protection mode shall be adaptable to type of motor cooling, forcecooled or self-cooled. 2.02 INPUT CHARACTERISTICS

A. Input voltage 1. The VFC shall be capable of maintaining its output performances when powered under the following conditions: a. Mains voltage 400V +/- 5%, b. Mains frequency 50. 2. In case of mains undervoltage, the VFC shall operate in the following mode: 3. The VFC shall have a minimum AC undervoltage power loss ride through of 200 milliseconds (10 cycles) B. Input current 1. During start-up sequences speed shall increase smoothly and limitation current can be reached. a. All VFDs shall have built in chokes. 1) To reduce harmonic currents feedback, 2) To limit input voltage spikes. 2. In installation where harmonic current circulation may affect the operation of sensitive equipment, global or local compensation of harmonic currents shall be provided. 3. In this case only auto adaptable harmonic compensators are acceptable to cope with permanent modification of harmonic content. (e.g.: active harmonic compensators). The VFC shall have an RFI Filter. 2.03 ENVIRONMENTAL CONDITIONS

A. The VFC shall be able to operate without derating under the following conditions: 1. Ambient temperature: 0 to 40 oC, without derating 2. Altitude from see level: 1000 m, without derating 3. Relative humidity: 93% with no condensation or dripping water (IEC 68-2-3). 2.04 KEYPAD DISPLAY INTERFACE

A. The keypad display interface shall offer the modification of AC Controller adjustments via a touch keypad. All electrical values, configuration parameters, I/O assignments, application and activity function access, faults, local control, and adjustment storage, and diagnostics shall be in plain English. There will be

WB4733 Al Ghurair City Expansion Phase II

16269 April 2008 Rev - 0

Variable Frequency Controllers. Page 5 of 10

a standard selection of 2 additional languages built-in to the operating software as standard. B. The display will be a high resolution, LCD backlit screen. The keypad shall be detachable. C. The AC Drive model number, torque type, software revision number, horsepower, output current, motor frequency and motor voltage shall be listed on the controller identification portion of the LCD display. D. The keypad display shall consist of programmable function keys that allow both operating commands and programming options to be preset by the operator. A hardware selector switch and password setting shall allow the terminal keypad to be locked out from unauthorized personnel. E. A RUN key and a STOP key will command a normal starting and stopping as programmed when the AC Controller is in keypad control mode. The STOP key must be active in all control modes. Provisions for covering the RUN and STOP keys must be available for applications that do not allow starting and stopping from the keypad. F. The AC Controller shall have two LEDs mounted on the front panel to indicate functional status. A green LED will verify that the AC Controller power supply is on. A red LED indicator will indicate an AC Controller fault. G. KWH and MWH shall be indicated. 2.05 ADJUSTMENTS & CONFIGURATIONS

A. The AC Controller will be factory programmed to operate all specified optional devices. B. The output frequency of the VFC is ranging from 1 to 250 Hz, for power ratings up to 75KW, and from 1 to 250 Hz for powers between 75 kW to 630 kW. C. The acceleration and deceleration ramp times shall be variable from 0.1 to 1800 seconds. D. The memory shall retain and record run status and fault type of the past fault. The VFC will record the 16 last faults for all rating. E. The software shall have an Energy Economy function that, when selected, will reduce the voltage to the motor when selected for variable torque loads. A constant volts/Hz ratio will be maintained during acceleration. The output voltage will then automatically adjust to meet the torque requirement of the load. F. As an option the VFC shall also include facility for communication with industrial networks or PLCs, using various communication protocols.

WB4733 Al Ghurair City Expansion Phase II

16269 April 2008 Rev - 0

Variable Frequency Controllers. Page 6 of 10

2.06

REMOTE INFORMATION

A The following minimum features shall be incorporated in the VFC: 1. Analogue inputs: a. 1 analogue voltage input, 0-10 V impedance 30 k, b. 1 analogue current input X-Y mA (X and Y programmable from 0 to 20), maximum impedance 250 k, 2. Reassignment of these values shall be possible from the keypad of the VSD. 3. Frequency resolution not greater than 0.1 Hz for 100 Hz 4. Sampling time 4 or 5m 5. Logic inputs: a. 5 logic inputs, impedance 3.5 k, 6. It shall be possible to reassign all of these inputs from the keypad of the equipment. a. Analogue outputs: 1) For all VFDs, 1 analogue output 0-20 mA or 4-20 mA 2) For power rating higher than 75 kW, 2 analog outputs 0-20 mA or 4-20 mA 7. Unless differently specified, these shall be factory set up to: Output frequency 8. It shall also be possible to reassign these outputs to other functions. 9. Logic outputs: a. 1 or 2 PLC compatible logic outputs, which can be reassigned from the keypad of the equipment to different functions. 2.07 OPERATING SEQUENCES

A. Acceleration and Deceleration: 1. The VFC shall be capable of smooth motor start and stop by controlling acceleration and deceleration ramps. 2. As a minimum the VFC shall be capable of the following adjustable ramps shapes: a. Linear, S shaped, U shaped. 3. Duration of the ramps shall be factory set up at 3 s, and shall be site adjustable from 0.1 to 1800 (resolution 0.1s). 4. For precise load performance, the VFC shall include the possibility to dynamically change the ramp shape through logic input or frequency threshold. Adaptation of ramp times shall be automatic in the event of exceeding available braking torque. B. Breaking to Standstill from Low Speed 1. For all VFDs, the braking shall be automatic by DC injection for 0.5 s when frequency passes below 0.1 Hz. 2. The following shall be site adjustable from the keypad of the equipment: a. Level of current b. Frequency threshold, c. Injection time. C. Automatic current limitation: 1. The VFC shall include a feature to adapt the current limitation according to the thermal characteristics of the motor to avoid nuisance tripping.

WB4733 Al Ghurair City Expansion Phase II 16269 April 2008 Rev - 0 Variable Frequency Controllers. Page 7 of 10

D. Skip frequencies: 1. It shall be possible to program 3 preset frequency to be skipped by the VFC, so that they will not be applied to the motor (protection against mechanical resonance). E. Type 2 Co-Ordination: 1. The VFC starter panel should have a bypass starter with type 2 co-ordination as per relevant IEC standard and selection of Circuit breaker and line contactor should be accordingly. F. Enclosure : 1. The VFC shall be located inside the motor Control Center as shown with the following specification. 2. In case it has to be located outside the following details shall be followed. 3. The VFC along with associated components like Circuit breaker, semi conductor fuses, line contactor, indicating lights, push button, Auto-manual selector switch to configure with BMS system and other necessary wiring and terminations, should be enclosed in a sheet steel enclosure suitable for VFC application. The enclosure should have sufficient ventilations for proper heat dissipation.

WB4733 Al Ghurair City Expansion Phase II

16269 April 2008 Rev - 0

Variable Frequency Controllers. Page 8 of 10

PART 3 3.01

EXECUTION

EXAMINATION

A. Examine areas, surfaces, and substrates to receive VFCs for compliance with requirements, installation tolerances, and other conditions affecting performance. B. Examine roughing-in for conduit systems to verify actual locations of conduit connections before VFC installation. C. Proceed with installation only after unsatisfactory conditions have been corrected. 3.02 APPLICATIONS

A. Select features of each VFC to coordinate with ratings and characteristics of supply circuit and motor; required control sequence; and duty cycle of motor, Controller, and load. B. Select rating of controllers to suit motor controlled. 3.03 INSTALLATION

A. Anchor each VFC assembly to steel-channel sills arranged and sized according to manufacturer's written instructions. Attach by bolting. Level and grout sills flush with VFC mounting surface. B. Install VFCs on concrete bases. C. Control Fuses: Install fuses in each fusible switch. 3.04 IDENTIFICATION

A. Identify VFCs, components, and control wiring according to Section 16010. B. Operating Instructions: Frame printed operating instructions for VFCs, including control sequences and emergency procedures. Fabricate frame of finished metal, and cover instructions with clear acrylic plastic. Mount on front of VFC units. 3.05 CONTROL WIRING INSTALLATION

A. Bundle, train, and support wiring in enclosures. 3.06 CONNECTIONS

A. Ground equipment.

WB4733 Al Ghurair City Expansion Phase II

16269 April 2008 Rev - 0

Variable Frequency Controllers. Page 9 of 10

B. Tighten electrical connectors and terminals according to manufacturer's published torque-tightening values. If manufacturer's torque values are not indicated, use those specified in UL 486A and UL 486B. 3.07 FIELD QUALITY CONTROL

A. Prepare for acceptance tests as follows: 1. Test insulation resistance for each VFC element, bus, component, connecting supply, feeder, and control circuit. 2 Test continuity of each circuit. B. Testing: Perform the following field quality-control testing: 1. Perform each electrical test and visual and mechanical inspection stated in NETA ATS, Sections 7.5, 7.6, and 7.16. Certify compliance with test parameters. 2. Correct malfunctioning units on-site, where possible, and retest to demonstrate compliance; otherwise, replace with new units and retest. C. Manufacturer's Field Service: Engage a factory-authorized service representative to inspect field-assembled components and equipment installation, including pretesting and adjusting VFCs. D. Test Reports: Prepare a written report to record the following: 1. Test procedures used. 2. Test results that comply with requirements. 3. Test results that do not comply with requirements and corrective action taken to achieve compliance with requirements. 3.08 STARTUP SERVICE

A. Engage a factory-authorized service representative to perform startup service. B. Verify that electrical wiring installation complies with manufacturer's submittal and installation requirements in Division 16 Sections. C. Complete installation and startup checks according to manufacturer's written instructions. 3.09 ADJUSTING

A. Set field-adjustable switches and circuit-breaker trip ranges. 3.10 DEMONSTRATION

A. Engage a factory-authorized service representative to train Owner's maintenance personnel to adjust, operate, and maintain VFCs.

END OF SECTION

WB4733 Al Ghurair City Expansion Phase II 16269 April 2008 Rev - 0 Variable Frequency Controllers. Page 10 of 10

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- C 1197 - 04 - QzexotcDocument5 pagesC 1197 - 04 - QzexotcDipesh Chandra BaruaNo ratings yet

- Saf 113 A Daily She Inspection Report 1Document4 pagesSaf 113 A Daily She Inspection Report 1saravana3kumar3ravic100% (1)

- Motor Control CentersDocument10 pagesMotor Control Centerssaravana3kumar3ravicNo ratings yet

- 12 Samss 005 PDFDocument6 pages12 Samss 005 PDFfetihNo ratings yet

- Mechanical Design and Stress Analysis of a Distillation ColumnDocument7 pagesMechanical Design and Stress Analysis of a Distillation ColumnSumant Pilgaonkar100% (1)

- Column Design - Staad ReactionsDocument12 pagesColumn Design - Staad ReactionsNitesh SinghNo ratings yet

- Land Acquisition Act, 1894Document22 pagesLand Acquisition Act, 1894Aditya DhimanNo ratings yet

- Population Group Wise Branch ListDocument764 pagesPopulation Group Wise Branch ListrajanNo ratings yet

- HamletDocument144 pagesHamletStella NyakoaNo ratings yet

- EIA Corrections and Queries - C4Document4 pagesEIA Corrections and Queries - C4saravana3kumar3ravicNo ratings yet

- Mistake of Taking Cancer For Something ElseDocument2 pagesMistake of Taking Cancer For Something Elsesaravana3kumar3ravicNo ratings yet

- Tableof Contents I: The Water (Prevention and Control of Pollution) Cess (Amendment) Act, 2003Document4 pagesTableof Contents I: The Water (Prevention and Control of Pollution) Cess (Amendment) Act, 2003saravana3kumar3ravicNo ratings yet

- Alcohol & Drug PolicyDocument1 pageAlcohol & Drug Policysaravana3kumar3ravicNo ratings yet

- Scaffold Under Erection TagDocument1 pageScaffold Under Erection Tagsaravana3kumar3ravicNo ratings yet

- Index Al GurairDocument1 pageIndex Al Gurairsaravana3kumar3ravicNo ratings yet

- Access Control SystemDocument1 pageAccess Control Systemsaravana3kumar3ravicNo ratings yet

- Distribution BoardsDocument6 pagesDistribution Boardssaravana3kumar3ravicNo ratings yet

- Distribution BoardsDocument6 pagesDistribution Boardssaravana3kumar3ravicNo ratings yet

- Exterior LightingDocument8 pagesExterior Lightingsaravana3kumar3ravicNo ratings yet

- Interior LightingDocument11 pagesInterior Lightingsaravana3kumar3ravicNo ratings yet

- Transfer SwitchesDocument10 pagesTransfer Switchessaravana3kumar3ravicNo ratings yet

- PWR Fac Correction CapacitorsDocument8 pagesPWR Fac Correction Capacitorssaravana3kumar3ravicNo ratings yet

- Wiring DevicesDocument11 pagesWiring Devicessaravana3kumar3ravicNo ratings yet

- Earthing & Bonding SystemDocument6 pagesEarthing & Bonding Systemsaravana3kumar3ravicNo ratings yet

- Cable TraysDocument7 pagesCable Trayssaravana3kumar3ravicNo ratings yet

- Wiring DevicesDocument11 pagesWiring Devicessaravana3kumar3ravicNo ratings yet

- Static Uninterruptable PWR SplyDocument13 pagesStatic Uninterruptable PWR Splysaravana3kumar3ravicNo ratings yet

- Wiring DevicesDocument11 pagesWiring Devicessaravana3kumar3ravicNo ratings yet

- Low Voltage Lighting Control SysDocument14 pagesLow Voltage Lighting Control Syssaravana3kumar3ravicNo ratings yet

- Al Gurair City Expansion Phase Ii: Electrical SpecificationDocument2 pagesAl Gurair City Expansion Phase Ii: Electrical Specificationsaravana3kumar3ravicNo ratings yet

- Busbar Trunking System (Busways)Document6 pagesBusbar Trunking System (Busways)saravana3kumar3ravic100% (1)

- General Provisions For MEPDocument8 pagesGeneral Provisions For MEPsaravana3kumar3ravicNo ratings yet

- Public Address & Back Ground Music SystemDocument11 pagesPublic Address & Back Ground Music Systemsaravana3kumar3ravicNo ratings yet

- ReferencesDocument6 pagesReferencesKaung KhantNo ratings yet

- B Chem Engg Syllabus-Revised PDFDocument61 pagesB Chem Engg Syllabus-Revised PDFZulfansyah MuchtarNo ratings yet

- Presentation For MTR VisitDocument12 pagesPresentation For MTR VisitA. K. mauryaNo ratings yet

- MSc Structural Integrity (Asset Reliability ManagementDocument6 pagesMSc Structural Integrity (Asset Reliability ManagementEzebunwo NwoforNo ratings yet

- Flexible Pavement Design Spreadsheet ImportantDocument10 pagesFlexible Pavement Design Spreadsheet ImportantAnonymous bUtSDElMTMNo ratings yet

- Space RoboticsDocument9 pagesSpace RoboticsRushikesh WareNo ratings yet

- Elastec en 4700Document12 pagesElastec en 4700Guillermo Prada TurradoNo ratings yet

- International Student Program Fees 2019/20Document1 pageInternational Student Program Fees 2019/20Pedro barriaNo ratings yet

- ENGINEERING MANAGEMENT Part IDocument19 pagesENGINEERING MANAGEMENT Part Irtg.chrisNo ratings yet

- Culvert 1x2x2 0.50 CushionDocument22 pagesCulvert 1x2x2 0.50 CushionubiakashNo ratings yet

- PriceListHirePurchase Normal 1Document55 pagesPriceListHirePurchase Normal 1Muhammad HajiNo ratings yet

- Computer System MaintenanceDocument4 pagesComputer System MaintenanceJeruNo ratings yet

- 8a Codes and Q & CDocument35 pages8a Codes and Q & CDanem HalasNo ratings yet

- Simplified Assessment of Bending Moment Capacity For RCDocument11 pagesSimplified Assessment of Bending Moment Capacity For RCAbhishek KumarNo ratings yet

- Design and Modelling of Disaster Relief Vehicle Using Rocker Bogie MechanismDocument3 pagesDesign and Modelling of Disaster Relief Vehicle Using Rocker Bogie MechanismKanna MonishNo ratings yet

- Technical Skills List - Eng - v1.3Document2 pagesTechnical Skills List - Eng - v1.3rohitNo ratings yet

- MBM Engineering CollegeDocument3 pagesMBM Engineering CollegeDeep Raj JangidNo ratings yet

- CAT-3500 Upgrade 8-11Document2 pagesCAT-3500 Upgrade 8-11docrafiNo ratings yet

- BF2220 10 81 56130 R 56130 Virendra Behra 204853Document1 pageBF2220 10 81 56130 R 56130 Virendra Behra 204853virendra behraNo ratings yet

- Traffic Control SolutionDocument24 pagesTraffic Control Solutioncome24 dealNo ratings yet

- Plan of StudyDocument3 pagesPlan of Studyapi-384127467No ratings yet

- REMISTAR BrochureDocument6 pagesREMISTAR BrochureassurendranNo ratings yet

- Final TT-End Sem - Spring Sem2022-23 - 13.04.2023Document4 pagesFinal TT-End Sem - Spring Sem2022-23 - 13.04.2023Ritwik NandiNo ratings yet

- JNTUK II B.Tech II Sem Revised Time TableDocument2 pagesJNTUK II B.Tech II Sem Revised Time TableJayanth KanumuriNo ratings yet

- 2 Nov 15 Guidelines On Supervision of Steelworks Fabricated Overseas PDFDocument12 pages2 Nov 15 Guidelines On Supervision of Steelworks Fabricated Overseas PDFSadok KzadriNo ratings yet

- Elements of Masonry DesignDocument83 pagesElements of Masonry DesigndyetNo ratings yet