Professional Documents

Culture Documents

Cesar Lcpcv5 Intro v10 GB

Uploaded by

David RemaudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cesar Lcpcv5 Intro v10 GB

Uploaded by

David RemaudCopyright:

Available Formats

- 1 -

12-16 Rue de Vincennes

93100 Montreuil

France

Tel : +33 1 48 70 47 41

Fax : +33 1 48 59 12 24

cesar-lcpc@itech-soft.com

www.cesar-lcpc.com

itech - 2011

Getting started with CESAR-LCPC version 5

Table of contents

1. INTRODUCTION ...................................................................................................................................................... 5

1.1. About CESAR .............................................................................................................................................. 5

1.2. History ....................................................................................................................................................... 5

1.3. Installation ................................................................................................................................................ 6

2. CESAR-LCPC V5 CONTENT ..................................................................................................................................... 7

2.1. Work sequence .......................................................................................................................................... 7

2.2. Modelling process ..................................................................................................................................... 8

2.2.1 CAD tools ............................................................................................................................................... 8

2.2.2. Meshing procedures ............................................................................................................................ 10

2.3. Analysis features ..................................................................................................................................... 13

2.3.1. Elements library .................................................................................................................................. 13

2.3.2. Constitutive models ............................................................................................................................ 14

2.3.3. Computation modules ........................................................................................................................ 16

2.4. Tools for results analysis ......................................................................................................................... 17

3. GENERAL ORGANIZATION AND FEATURES .................................................................................................................. 19

3.1. Organization of the window and menu system....................................................................................... 19

3.2. Views, Selections and manipulations ...................................................................................................... 20

3.2.1. Selections ............................................................................................................................................ 20

3.2.2. Views and manipulations ................................................................................................................... 21

3.3. Work sequence of CESAR ......................................................................................................................... 22

4. GENERAL PRINCIPLES............................................................................................................................................. 27

4.1. Construction stages ................................................................................................................................. 27

4.1.1. Management and recovery of stress states ........................................................................................ 27

4.1.2. Operations on group of elements during phases of construction ....................................................... 28

4.2. Initial stress field ..................................................................................................................................... 30

4.2.1. Geostatic stress field in horizontal layers: the K0 procedure .......................................................... 30

4.2.2. The Self-weight procedure ............................................................................................................... 31

4.3. Automatic generation of excavation forces ............................................................................................ 32

5. APPENDIX 1: FILES MANAGEMENT ........................................................................................................................... 34

5.1. Files names .............................................................................................................................................. 34

5.2. Files generated by CESAR-LCPC v5 .......................................................................................................... 34

Getting started with CESAR-LCPC version 5

- 5 -

1. INTRODUCTION

1.1. About CESAR

CESAR-LCPC is an all-purpose software package based on the finite element method and adapted to

resolving civil engineering and environmental problems: soil and rock mechanics, heat-related

problems, hydrogeology, structural computation, etc.

With version 5 of CESAR-LCPC, user takes benefits of a highly interactive graphical user interface,

powerful meshing capabilities, a wide variety of constitutive models and an extensive element library.

Civil engineering-based models assist the engineer in better understanding and mastering complex

phenomena (explanatory models), as well as in designing and sizing structures (predictive decision-

making models). Such models rely upon: an analysis of the phenomena under examination and their

physical-mathematical representation, the numerical resolution of the corresponding set of equations,

and comparisons with experimental results.

The main applications for CESAR-LCPC in geotechnical engineering are:

- Design of underground structures: tunnels, mines, storage facilities, deep excavations

- Design of embankments, shallow and deep foundations (settlements and soil failure analysis),

- Design of pavement structures,

- Slope stability analysis: cut or fill for highways, reinforced slopes, earth retaining structures

- Seepage, dewatering and consolidation analyses.

The main applications for CESAR-LCPC in structural engineering are:

- High buildings and industrial facilities,

- Massive concrete structures (phenomena associated with young hardening concrete),

- Design of steel, concrete or composite bridges.

1.2. History

The IFFSTAR, former LCPC (Laboratoire Central des Ponts et Chausses / Road and Public Works

Research Institute), civil engineering research facility has been involved with these model-building

efforts since the end of the 1960's and over the past thirty years has been concentrating on the

development of its CESAR-LCPC software package.

Development of the CESAR-LCPC product got underway towards the beginning of the 1980's as a

definitive successor to the ROSALIE system (developed and revised by the LCPC between 1968 and

1983); Version 2.0 was initially released in 1986. CESAR-LCPC has been designed for continual revision

and updating by virtue of its status as a research and development tool.

Getting started with CESAR-LCPC version 5

- 6 -

Examples of models designed and analysed with previous versions of CESAR-LCPC

1.3. Installation

System requirement

CESAR-LCPC operates on IBM compatible Personal Computer (PC) in Windows environment.

In addition, CESAR-LCPC requires the following minimum configuration.

Operating system Microsoft Windows XP / Vista / 7, 32 bits or 64 bits.

(Microsoft Windows 7, 64 bits or later recommended)

CPU Pentium Core Duo 2,5 GHZ recommended

Memory (RAM) 512 MB (4 Go or greater recommended)

HDD space 8 Go

Video Card Nvidia GeForce Type video card recommended

Video Memory 32 Mo (252 Mo or greater recommended)

Installation sequence

Follow the steps below to install CESAR-LCPC.

1. Insert the CESAR-LCPCv5 CD in the CD-ROM drive.

2. Installation will proceed automatically.

- Define the setup directory

- Setup Ghostscript and Ghostview for the postsript files (needed for prints)

3. Reboot the computer to initialize the program environment.

As a result of the setup, 3 programs are installed on the computer:

- CLEO2D.exe, pre- and post-processor for 2D FE models, with icon ,

- CLEO3D.exe, pre- and post-processor for 3D FE models, with icon ,

- CESARv4.exe, Finite Element kernel.

Getting started with CESAR-LCPC version 5

- 7 -

2. CESAR-LCPC V5 CONTENT

2.1. Work sequence

CESAR-LCPC proposes 2D and 3D post and pre-processors, Cleo2D and Cleo3D. Use of both will follow

the same work sequence:

- Geometry modelling,

- Mesh generation,

- Model properties (materials, boundary conditions, loadings...),

- Computation of the solution,

- Results analysis.

Example: analysis of a footing on a 2-slope embankment

1. Geometry: lines

2. Geometry: volumes

2. Mesh densities

4. Mesh

5. Model properties: uniform pressure

6. Results

Getting started with CESAR-LCPC version 5

- 8 -

2.2. Modelling process

2.2.1 CAD tools

Using CESAR-LCPC, user will access

advanced geometry modelling features.

These are necessary to achieve 2D as well

as 3D complex analysis.

Data exchange is also possible with other

CAD software (dxf import for example).

Standard tools enable the user the easy

definition and edition of the geometry of

the structure.

- Definition of lines, circles, ellipses,

splines, predefined structures,

- Definition of surfaces type plane,

cylindrical, Coons,

- Translation, rotation and symmetry

operations,

- Intersection of lines, surfaces

In version 5 of CESAR-LCPC, new features

have been added. Among them are:

- NURBS,

- Volumes of any shape,

- Intersections.

NURBS Surfaces

Non-uniform rational basis spline (NURBS) is a mathematical model commonly used in computer

graphics for generating and representing curves and surfaces which offers great flexibility and precision

for handling both analytic and freeform shapes.

In CESAR-LCPC, NURBS are controlled by an external boundary and inner points.

Using these NURBS is useful for modelling of complex geotechnical or structural problems.

Cloud of points (terrain) and resulting NURBS

Getting started with CESAR-LCPC version 5

- 9 -

Volumes of any shape

With the same objectives of the NURBS, volumes of any shapes are fundamental for complex

geotechnical or structural models.

CESAR-LCPC enables the generation of volumes closed by surfaces on any shape.

Example of volumes

Intersections

- Volume/volume

- Volume/surface

- Surface/surface

- Surface/line

- Line/line

- Line/surface

Toolbox for intersections

Getting started with CESAR-LCPC version 5

- 10 -

2.2.2. Meshing procedures

Surface meshing

Surface meshing is the common procedure for 2D models as well for shell elements generation. Surface

meshes are quadrangular or triangular, depending of the geometry of the supporting surface.

CESAR-LCPC proposes 3 levels of mesh algorithms. These levels are useful to generate transition

meshes from refined areas to loose areas.

These algorithms are also used for surface mesh generation in 3D (shell and plates elements).

Examples of 2D mesh evolutions in function of the algorithm: linear, quadratic or cubic.

3D Surface meshes

Getting started with CESAR-LCPC version 5

- 11 -

3D mesh - Tetrahedron mesh generator

A major evolution of CESAR-LCPC v5 is to propose the user to get free of geometrical constraints. This

is made possible by using automatic tetrahedron mesh generators. Those fill the volume from its

external surface mesh.

CESAR-LCPC v5 offers 2 types of mesh generators:

- An integrated one, with option to define a mesh coarseness;

- An external one, TETMESH-GHS3D, developed by INRIA and SIMULOG.

3D mesh - Super-element procedure

This robust method is used when the model can be decomposed in volumes with standard shape:

hexahedron, pentahedron or tetrahedron.

It has as advantages that the mesh is regular. However, this kind of mesh imposes that densities on

edges are the same on opposite sides of the volume.

Getting started with CESAR-LCPC version 5

- 12 -

The mesh generator fills the volumes with corresponding elements: hexahedrons, pentahedrons or

tetrahedrons.

Example of mesh with super-elements

3D mesh - Extrusion procedure

This procedure is useful when a 2D mesh exists and can be used for a 3D model. This is the case of

models with a principal direction.

Example 1: tunnel 2D mesh and the resulting 3D mesh

Example 2: embankment 2D mesh and the resulting 3D mesh

Getting started with CESAR-LCPC version 5

- 13 -

2.3. Analysis features

2.3.1. Elements library

All the elements in CESAR are grouped in families. The following table describes the available

element families in the current version of the software.

Mechanics

Family 1 Two-dimensional isoparametric displacement-type elements

Family 2 Three-dimensional isoparametric displacement-type elements

Family 3 Two-dimensional beam element

Family 4 Three-dimensional beam element

Family 5 Shell elements

Family 6 (2D, 3D) Contact elements

Family 7 Two-dimensional truss elements

Family 8 Three-dimensional truss elements

Family 11 Axisymmetrical isoparametric displacement-type elements for the computation of structures

with a revolution-based geometry submitted to any loading

Diffusion

Family 21 Two-dimensional isoparametric diffusion-type elements

Family 22 Three-dimensional isoparametric diffusion-type elements

Family 23 Two-dimensional exchange elements

Family 24 Three-dimensional exchange elements

Family 25 Discontinuous elements for identifying a free surface (plane problems)

Coupling

Family 41 Two-dimensional isoparametric elements with three degrees of freedom per node (two

displacements, hydraulic load) for consolidation problems

Family 42 Three-dimensional isoparametric elements with four degrees of freedom per node (three

displacements, hydraulic load) for consolidation problems

Family 45 Two-dimensional isoparametric elements with four degrees of freedom per node (two

displacements, pore pressure, temperature) for thermomechanical problems in porous media

Family 46 Three-dimensional isoparametric elements with five degrees of freedom per node (three

displacements, pore pressure, temperature) for thermomechanical problems in porous media

Getting started with CESAR-LCPC version 5

- 14 -

2.3.2. Constitutive models

Constitutive laws for the element families used in Mechanics and Geomechanics.

Family Constitutive model Type of material

Family 1 Elasticity:

isotropic linear

orthotropic linear

with isotropic dilatancy

Elastoplasticity, criterion:

Mohr-Coulomb (with or without strain

hardening, with or without orthotropic elasticity)

Tresca

Von Mises (with or without strain hardening)

Drcker-Prager (with or without strain

hardening)

parabolic

Vermeer

Nova

modified Cam-Clay

Prevost and Hog

oriented

Melanie

Willam - Warnke

Hoek - Brown

Other:

early-age concrete

sand, clay, rock

clay

metals

sand, clay, rock

concrete

sand

sand

clay

rock

stratified medium

clay

concrete

rock

concrete

Family 2 Elasticity:

isotropic linear

orthotropic linear

with isotropic dilatancy

Elastoplasticity, criterion:

Mohr-Coulomb

Von Mises (with or without strain hardening)

Drcker-Prager (with or without strain

hardening)

parabolic

Vermeer

Nova

modified Cam-Clay

Prevost and Hog

oriented

Willam - Warnke

Hoek - Brown

Other:

early-age concrete

sand, clay, rock

metals

sand, clay, rock

concrete

sand

sand

clay

rock

stratified medium

concrete

rock

concrete

Families 3, 4,

5, 7, 8 and 11

Linear isotropic elasticity

Family 6 Contact laws:

bonding

Coulomb friction

perfect slippage

Getting started with CESAR-LCPC version 5

- 15 -

Constitutive laws for the element families used in Coupled analysis.

Family Constitutive model

Family 41

Mechanics:

linear isotropic elasticity

linear orthotropic elasticity

Hydraulics:

anisotropic behavior

Family 42 Mechanics:

linear isotropic elasticity

Hydraulics:

anisotropic behavior

Family 45 Thermo-poro-elasticity:

isotropic linear

orthotropic linear

with isotropic dilatancy

Thermo-poro-elastoplasticity, criterion:

Mohr-Coulomb

Tresca

Von Mises (with or without strain hardening)

Drcker-Prager (with or without strain hardening)

parabolic

Vermeer

Nova

modified Cam-Clay

Prevost and Hog

oriented

Family 46 Thermo-poro-elasticity:

isotropic linear

orthotropic linear

with isotropic dilatancy

Thermo-poro-elastoplasticity, criterion:

Von Mises (with or without strain hardening)

Drcker-Prager (with or without strain hardening)

parabolic

Vermeer

Nova

modified Cam-Clay

Prevost and Hog

oriented

Getting started with CESAR-LCPC version 5

- 16 -

2.3.3. Computation modules

We list here the computation modules, which are available in the present version of CESAR. Every

module is characterized by a key word based on acronyms.

Mechanics or Diffusion

LINE Resolution of a linear problem

LIGC Resolution of a linear problem by means of the preconditioned conjugate gradient method, associated

with a morse storage system

Statics

MCNL Mechanics problem exhibiting non-linear behaviour

- C-phi reduction procedure

- Safety factor procedure

TCNL Contact problem between elastoplastic solids

TACT Ccontact problem between elastic solids

AXIF Computation of an axisymmetrical elastic structure (revolution-based geometry), submitted to any load

MEXO Evolution of stresses in early-age concrete

Dynamics

DYNI Determination of the response to a dynamic load by means of direct integration

MODE Determination of Eigen modes: eigenvalues and eigenvectors

SUMO Determination of the response to a dynamic load by means of modal superposition

LINC Response to a harmonic load with damping (resolution of a linear problem in complex variables)

LINH Determination of the response to a harmonic load without damping

Diffusion

SURF Resolution of a plane flow problem in porous media with free surfaces

DTLI Resolution of a linear transient diffusion problem by means of direct integration

DTNL Resolution of a non-linear transient diffusion problem

NSAT Resolution of a flow problem in unsaturated porous media

TEXO Evolution of the temperature in early-age concrete

Coupling

CSLI Consolidation problem for saturated linear elastic materials

MPLI Linear evolution problem in porous media with thermal coupling (thermo-poro-elasticity)

MPNL Non-linear evolution problem in porous media with thermal coupling (thermo-poro-plasticity)

Getting started with CESAR-LCPC version 5

- 17 -

2.4. Tools for results analysis

CESAR-LCPC v5 is a modelization tool for use in Civil engineering offices. Therefore results have to be

easily displayed, analysable and printable in order to assist the user in a better understanding of the

phenomena and the edition of the calculation report.

Display of results

Graphical analysis of results is useful in the case of 3D models. CESAR-LCPC v5 offers tools for a

detailed analysis of the finite element results. Display of results can be global or differentiated by type

of elements: volumes, shells or beams.

We present here some of these features:

- Scalar plots

- Scalar plots surfaces

Getting started with CESAR-LCPC version 5

- 18 -

- Cut planes

Each of these views can be captured and stored for illustration in the calculation report.

Graphs of results

Graphs give complementary information of the evolution of a parameter. In CESAR-LCPC v5, graphs

can be plotted for a group of points, a segment or along a cut line.

For mechanical problems, results are displacements, stresses or strains. En mcanique, les scalaires

exploitables sont les rsultats en dplacements, contraintes et dformations. They are also

combinations of stresses allowing the drawing of the evolution of a criterion.

Listing of results

CESAR-LCPC v5 creates a listing file reporting all or part of the information and results of the model.

This listing file enables the access of a maximum of information per group of elements and/or per type

of results. Thus the user can capitalize and analyse the results of his model in the most detailed way.

The listing file is also the best way to check the good progress of the calculations as all the iteration

process is written there.

Getting started with CESAR-LCPC version 5

- 19 -

3. GENERAL ORGANIZATION AND FEATURES

3.1. Organization of the window and menu system

The user interface is organized as follows:

- Main menu: provide access to main features through listed menus.

- General toolbar: the icons provide quick access to frequent actions listed in the Main menu.

- Project flow toolbar: access from one step to the other in the current project, from geometry

definition up to result visualization.

- Step toolbar: contextual bar providing access to all the actions available within the current project

stage.

- Work window: it is the area where the model is visualized.

Work window

Project flow toolbar

General toolbar

Step toolbar

Main menu

Selection toolbar

Color palette toolbar

Getting started with CESAR-LCPC version 5

- 20 -

3.2. Views, Selections and manipulations

All the views, selections and manipulations features of CESAR-LCPC helps the user in a better handling

of the model from geometry design to results analysis.

3.2.1. Selections

Selection toolbar

On the "Selection toolbar", user will specify the selectable entities. The list of entities varies from one

step to the other.

Hence, in Geometry:

- Points

- Edges

- Surfaces

- Volumes

And in Mesh:

- Edges

- Surfaces

- Volumes

- Nodes

- Segments

- Facets

- Finite elements

3D Views and manipulations

Entities display

Isoparametric views

Zooms

Selection toolbar

(updated at each project step)

Selection types

Getting started with CESAR-LCPC version 5

- 21 -

The type of finite elements is specified using Selection options.

Selection tools

Selection Direct selection by left-click on an item.

Multiple selections are possible using SHIFT or CTRL key.

Broken-line selection Select the entities by successively clicking the corners of a

polygon containing the relevant entities with the mouse cursor.

Selection of items by name Select an item by its type and its name defined in this toolbox

among those listed.

Selection of groups by name Select a group in the list of group displayed by this toolbox

(Active when a mesh is generated)

Selection by colour using the colour palette

toolbar

Selection of a colored item by right-click on its colour on the

palette toolbar

3.2.2. Views and manipulations

Zooms

Zoom Enlarge the entities contained in a window defined with the

mouse cursor

Zoom + Uniform growth of the model view in the work space

Zoom - Uniform reduction of the model view in the work space

Autoscale Fit the window to the limits of the model

Zoom and focus Fit the window to the model and adjust the camera direction

and distance

Getting started with CESAR-LCPC version 5

- 22 -

Views

Show all Show all entities of the model

Show selection only Show only the selected entities

Hide selection Hide the selected entities from view

Dynamic pan By dragging the mouse (or pushing on the mouse-roller), move

the model view

Dynamic rotation By dragging the mouse, rotation of the model view

Dynamic zoom By dragging the mouse (or using the mouse roller), zoom in/out

the model view

Isoparametric views

Front view Display the model as viewed from the +X direction

Back view Display the model as viewed from the -X direction

Left view Display the model as viewed from the -Y direction

Right view Display the model as viewed from the +Y direction

Top view Display the model as viewed from the +Z direction

Bottom view Display the model as viewed from the -Z direction

Isoparametric view Display the model in three-dimensional space

User-defined view

Storage of current view

User view

3.3. Work sequence of CESAR

The key for the use of the GUI is the project flow bar. It will guide the user in the model generation

steps:

- Definition of geometrical entities (points, lines, surfaces, volumes...),

- Finite element mesh generation (2D or 3D meshes, line elements, interface elements...),

- Model state (material properties, boundary conditions, loads, construction phases),

- Calculation launcher,

- Results analysis.

Each button of this toolbar corresponds to a project step. It is activated with the progression of the

study; thus the user is guided and protected during its work.

From the left to the right, the user will find the following groups of buttons: model building, model

initialization, definition of boundary condition, load definition, calculation, post-processing.

We describe these steps / groups of actions.

Getting started with CESAR-LCPC version 5

- 23 -

Start End

Step 1: Mesh generation from geometry to mesh

In this step, user will:

- create the geometry of the Finite Element model,

- define the mesh density,

- generate the Finite Elements for the final mesh.

Step 2: Model type and Property assignment

In this stage, the user specifies the current active model.

When a new model is defined, the user must specify the type of analysis the model is intended to. For

instance, two models may be specified based on the same mesh. One is intended to carry out a heat

flow analysis while the other is intended to carry out a structural analysis. The base mesh is termed

neutral mesh since it is independent from the element type (flow, mechanical axisymmetric,

mechanical plane strain).

The properties button enables the user to assign material or geometrical properties to element

groups.

Step 3: Initial values

For many analysis types, the user must specify the initial values of some variable fields. Such variables

are for instance the in situ stresses for non-linear static analysis of geotechnical problems, initial

velocity fields for dynamic analysis, etc

Step 3

Step 2

Step 1

Getting started with CESAR-LCPC version 5

- 24 -

Step 4: Boundary conditions edition

The boundary conditions define the state on the model boundaries (displacements, water level,

temperature).

In several cases, these boundary conditions define symmetry plans, thus it reduces the size and number

of nodes of the model.

Loading set edition

In order to unbalance the Finite Element model, loads must be defined and applied to the model. These

loads are of various kinds. They are defined in loading sets that are independent (calculations with

LINE) or combined (MCNL calculations and others).

Step 6: Analysis parameters

Before launching the calculation, several parameters have to be defined depending of the physics of

the problem.

Especially, the iteration process must be properly defined for staged or non-linear calculations.

Step 7: Calculation

All the problem data being properly defined, we call here the kernel. The user can follow the analysis

progress monitored in a DOS box.

Step 8: Result post-processing

Through this step, CESAR-LCPC v5 proposes several tools for the analysis of the calculation results. 3

actions:

Step 8

Step 7

Step 6

Step 5

Step 4

Getting started with CESAR-LCPC version 5

- 25 -

- Display of results on the global or partial mesh,

- Definition of entities (groups of nodes, cut lines),

- Drawing of curves on for the entities previously defined.

Example of toolbars for a coupled problem (initial conditions, boundary conditions, loadings)

Mechanics:

Boundary conditions on

displacements

Hydrogeology:

Boundary conditions on hydraulics,

seepage and exchanges

Diffusion:

Boundary conditions

on temperatures

Mechanics:

Initial displacements

Mechanics:

Initial stresses

Diffusion:

Initial temperatures

Hydrogeology:

Initial pressure

Mechanical loadings

Hydrogeology:

exchanges, flows

Temperature :

exchanges, flows

Getting started with CESAR-LCPC version 5

- 27 -

4. GENERAL PRINCIPLES

This document is completed with a suite of tutorials. These examples will guide the user in the

discovery of the main features of CESAR-LCPC v5 in 2D and 3D.

In this chapter are described the main principles for a good use of CESAR-LCPC v5. The scope of

application is mainly the geotechnical engineering; however structural analysis follows some of these

points. These principles concern:

- Stages of construction,

- Initial stress fields,

- Excavation forces.

4.1. Construction stages

The simulation of the constructions stages is important for a correct representation of the phenomena

and a good analysis of the stresses and strains in the structures. Each stage of construction will be

defined as a new model in CESAR-LCPC (tool , Model definition).

4.1.1. Management and recovery of stress states

In order to link the stages of construction, calculations will be initialized with the stress field calculated

at previous stage. Hence, the following process:

Stage 1 o

0

AF

1

o

1

Stage 2 o

1

AF

2

o

2

Stage n o

n-1

AF

n

o

n

will be defined in CESAR-LCPC through the following operations:

Name = Phase 1

Initialization type =

Initialization

parameters

Choice between:

Uniform stress per

group

Geostatic stresses

Stresses from file

Name =

Load set 1

Storage for restart =

file, Phase1.rst

Name = Phase 2

Initialization type =

Simple restart

Name of the file =

Phase1.rst

Name =

Load set 2

Storage for restart =

file, Phase2.rst

Name = Phase n

Initialization type =

Simple restart

Name of the file =

Phase(n-1).rst

Name =

Load set n

Storage for restart =

file, Phase(n).rst

Getting started with CESAR-LCPC version 5

- 28 -

Or, user chose the initialization type Phased analysis and the process will be automatically done:

Name = Phase 1

Initialization type =

Phased analysis

Choice between :

Uniform stress per group

Geostatic stresses

Stresses from file

Name =

Load set 1

Automatic storage of the

stress field

Name = Phase 2

Initialization type =

Phased analysis

Automatic initialization of

the stress field from Phase 1

Name =

Load set 2

Automatic storage of the

stress field

Name = Phase n

Initialization type =

Phased analysis

Automatic initialization of

the stress field from Phase

n-1

Name =

Load set n

Automatic storage of

the stress field

4.1.2. Operations on group of elements during phases of construction

In CESAR-LCPC, user will a) mesh all elements, b) affect them a given set of properties and c) pilot their

status, active or non active.

Sets of elements having same properties and status during the calculation process will be a group of

elements.

Example: 2D tunnel excavation and lining setup.

Phase 0 : Initial stress field Phase 1 : Excavation of the

tunnel section.

Phase 2 : Setup of the lining

elements.

Groups 1, 2 & 3 are active. Deactivation of groups 2 & 3. Activation of group 2.

Properties of groups 1, 2 & 3:

soil parameters.

Properties of group 1:

soil parameters.

Properties of group 1:

soil parameters.

Properties of group 2:

concrete parameters.

Initial stress field: Initial stress field: {o0} Initial stress field: {o1}

1

2

3

1

2

3

1

2

3

Getting started with CESAR-LCPC version 5

- 29 -

geostatic stresses

Tool Initial conditions

Load set: none. Load set 1:

Excavation forces on the limits of

the tunnel section.

Tool Excavation forces

Load set 2:

Self-weight of lining elements

Tool Gravity forces

Results: {o0}, {c0}, {F0} Results: {o1}, {c1}, {F1} Results: {o2}, {c2}, {o2}

Getting started with CESAR-LCPC version 5

- 30 -

4.2. Initial stress field

In previous section, the initial stress field is initialized in the first calculation, set as Phase 1. In given

cases, it is necessary to isolate the initial stress field:

- control of the computed initial stresses,

- generation of initial stresses with the self-weight of the soil layers.

Therefore we isolate 2 distinct procedures for initial stress field computation:

- geostatic stress field in horizontal layers,

- self-weight procedure.

4.2.1. Geostatic stress field in horizontal layers: the K0 procedure

The self-weight procedure is to be used in following cases:

- the soil layers are horizontal,

- the soil layers materials are homogeneous,

- interface elements are not activated.

The parameters used for the self-weight procedure are input in the Parameters initializations toolbox

( ), Geostatic stresses definition:

where Ko_x and Ko_y are the earth pressure coefficients in the x and y directions respectively.

Hence in a uniform homogeneous layer, we get:

- Vertical stress

- Horizontal stress

The process in CESAR-LCPC is described in the following table.

Name = Phase 0

Initialization type =

Phased analysis

Geostatic stresses

Name = No load Automatic storage of

the stress field

Name = Phase 1

Initialization type =

Phased analysis

Automatic initialization

of the stress field from

Phase 0

Name = Load set

1

Automatic storage of

the stress field

...

Note that this procedure generated with the Phased analysis, is also fully compatible with the

Initialization/restart one, where the stress fields are handled by the user (see previous chapter).

Getting started with CESAR-LCPC version 5

- 31 -

4.2.2. The Self-weight procedure

The self-weight procedure is to be used in following cases:

- the soil layers are not horizontal,

- the soil layers materials are not homogeneous,

- interface elements are activated.

The parameters used for the self-weight procedure are the elastic ones input in the Property

assignment toolbox ( ): density, Poissons ratio

Hence in a uniform homogeneous layer, we get:

- Vertical stress

- Horizontal stress

The process in CESAR-LCPC is described in the following table.

Name = Phase 0

Initialization type =

Phased analysis

No definition

Name =

Self-weight of the

soil layers

Tool Gravity

forces

Automatic storage of the

stress field

Name = Phase 1

Initialization type =

Phased analysis

Automatic

initialization of the

stress field from

Phase 0

Name = Load set

1

Automatic storage of the

stress field

Note that this procedure generated with the Phased analysis, is also fully compatible with the

Initialization/restart one, where the stress fields are handled by the user (see previous chapter).

Getting started with CESAR-LCPC version 5

- 32 -

4.3. Automatic generation of excavation forces

For excavation problems, the stresses initially present in the excavated block of soil are replaced by

balancing external forces on the wall of the excavation. These confinement forces are removed

gradually during the excavation phase(s). These forces have the following expression:

o + o

o + o

=

)

`

y yy x yx

y xy x xx

y

x

n n

n n

T

T

. .

. .

0 0

0 0

with

-

y x

T T , vector of the confinement forces

- o

ij

0

tensor of the initial stresses

-

y x

n n , unit vector normal to the excavation wall

- ratio between 0 and 1 representing the loss of confinement to be applied in the

considered phase.

The initial stresses used in the formula can be defined either from the field of geostatic in situ stresses

or from the stress results obtained from a previous analysis phase.

For 2D models, the ratio enables considering partial loss of confinement due to the arching effect in

the vicinity of the tunnel face.

For 3D models, the advance of the tunnel face and the arching effects are generally modelled. The ratio

can therefore be set to 1.

Evolution of the ratio in the vicinity of the tunnel face

Getting started with CESAR-LCPC version 5

- 33 -

2D visualization of excavation forces

Dialog box for the definition of excavation forces

3D visualization of excavation forces.

Getting started with CESAR-LCPC version 5

- 34 -

5. APPENDIX 1: FILES MANAGEMENT

5.1. Files names

The name of the study shall not:

- start with a number (but can contain one);

- contain one of these figures: "_", " ", "/", "\;

- exceed a given number of characters (default value is 20, set in the file SOLVES.MTRL).

5.2. Files generated by CESAR-LCPC v5

All along the process of generation and analysis of the model, CESAR-LCPC will generate several types

of files.

We take as example a study named TEST.

Files of the study:

- TEST.cleo25 for CLEO2D.

- TEST.cleo35 for CLEO3D.

This file contains all the information about the model (mesh, properties and results). It is the link

between the other files described hereafter.

Data file for the kernel:

This ASCII file is automatically generated by the 2D or 3D GUI. It is the translation of all the model

information requested for the calculation. As one study file can contain several calculation models Mi,

the generated file will be named: TEST_Mi.data.

Results files

- TEST_Mi.rsv4, binary file. It contains the results of model Mi ;

- TEST_Mi.list, ASCII file. It contains the model data, the results and the calculation process.

- TEST_mail.resu, binary file. It contains the mesh data.

Storage files:

During staged construction, the restart/initialisations are linked to stored stress fields. These are stored

in file with rst as extension. Thus the calculation of the file TEST_Mi.data will generate the file

TEST_Mi.rst.

It is important for the user to store these files as they may be useful in further calculations.

Edit par :

12-16 rue de Vincennes

F-93100 MONTREUIL

Tl. : +33 1 48 70 47 41

Fax : +33 1 48 59 12 24

cesar-lcpc@itech-soft.com

www.cesar-lcpc.com

itech - 2011

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elements of Art: Arta Midterms ReviewerDocument5 pagesElements of Art: Arta Midterms ReviewerJendeuk KimNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elements of ArtDocument3 pagesElements of ArtSerendipity FelicityNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Math 6 Q3 Week 2 Visualizing Solid FiguresDocument25 pagesMath 6 Q3 Week 2 Visualizing Solid FiguresRochelle UbaldoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Activity No. 1.2 Synthesis. Nature's NumberDocument4 pagesActivity No. 1.2 Synthesis. Nature's NumberKenneth Herrera0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Computer Graphics Lab ManualDocument11 pagesComputer Graphics Lab ManualMisbah ArshadNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Ap Art History FFCCDocument3 pagesAp Art History FFCCapi-421245207100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Arts6 - q1 - Mod2 - Elements and Principles Applied in Commercial Art - v2Document30 pagesArts6 - q1 - Mod2 - Elements and Principles Applied in Commercial Art - v2Minato Namizake0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- GuggenheimDocument28 pagesGuggenheimAnusha IvaturiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

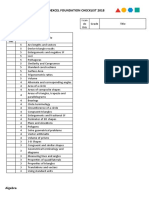

- Edexcel Maths Foundation ChecklistDocument4 pagesEdexcel Maths Foundation ChecklistRottero AbrarNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- PAT Maths - Strands and Achievement Band DescriptionsDocument15 pagesPAT Maths - Strands and Achievement Band Descriptionsjessica.vo003No ratings yet

- Date: - Prepared By: BEBELYN L. ARINGO Kindergarten TeacherDocument3 pagesDate: - Prepared By: BEBELYN L. ARINGO Kindergarten TeacherAshly SerozaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Lectures 9-10: Imaging Geometry and Camera Model: Dr. V MasilamaniDocument37 pagesLectures 9-10: Imaging Geometry and Camera Model: Dr. V MasilamaniPrateek Agrawal100% (1)

- Project Ideas and LinksDocument5 pagesProject Ideas and LinksKeston Winston Jr Mikaelson50% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Edited SCIENCE 3eng. Module 4 Week 4 v.01 CC 1Document24 pagesEdited SCIENCE 3eng. Module 4 Week 4 v.01 CC 1Junaliza Mansalay Daquio100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Matematik: Tingkatan 1Document38 pagesMatematik: Tingkatan 1Andrew MarkNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Building Blocks Learning TrajectoriesDocument16 pagesBuilding Blocks Learning TrajectoriesMega NPNo ratings yet

- Caie Igcse Maths 0580 Theory v2Document16 pagesCaie Igcse Maths 0580 Theory v2Melis Doğu BayazıtNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Maths Lesson Plan 2d ShapesDocument3 pagesMaths Lesson Plan 2d Shapesapi-298376433No ratings yet

- Fuzzy Logic Sun Tracking ControlDocument10 pagesFuzzy Logic Sun Tracking ControltheoroticaNo ratings yet

- Spheres Lesson PlanDocument4 pagesSpheres Lesson PlanvinsdvdsNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kindergarten Model Curriculum For Mathematics PDF 1Document18 pagesKindergarten Model Curriculum For Mathematics PDF 1Zizo ZizoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Lower Secondary Checkpoint 2024 - DraftDocument24 pagesLower Secondary Checkpoint 2024 - Draftdevdan03No ratings yet

- Dance 3. SocialDocument3 pagesDance 3. SocialpiaNo ratings yet

- Siop Lesson PlanDocument2 pagesSiop Lesson Planapi-3951610910% (1)

- Paper 3 Past Questions 230503 175030Document59 pagesPaper 3 Past Questions 230503 175030Nadia VellaNo ratings yet

- Mathematics in The Modern World - ModuleDocument147 pagesMathematics in The Modern World - ModuleRichard BacharNo ratings yet

- Ge 4 MMW Practice Set 5, A - FDocument6 pagesGe 4 MMW Practice Set 5, A - FAllysa Galang100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Scheme of Work Maths Stage 9Document16 pagesScheme of Work Maths Stage 9Sue Adames de Velasco50% (2)

- Preschool Math Scope & Sequence: 1st Quarter 2nd Quarter 3rd Quarter 4th QuarterDocument4 pagesPreschool Math Scope & Sequence: 1st Quarter 2nd Quarter 3rd Quarter 4th QuarterRalitsa BogdanovaNo ratings yet

- The MPEG-7 Visual Standard For Content Description-An OverviewDocument30 pagesThe MPEG-7 Visual Standard For Content Description-An OverviewAnushree TembeNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)