Professional Documents

Culture Documents

Process Simulation of Solvent Deasphalting Plants With PROII

Uploaded by

studyendlessOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Simulation of Solvent Deasphalting Plants With PROII

Uploaded by

studyendlessCopyright:

Available Formats

EDL Anlagenbau Gesellschaft mbH

Moscow, 28-30 March 2012

EDL Anlagenbau Gesellschaft mbH

Process Simulation of Solvent Deasphalting Plants

with PRO/II based on Thermodynamic Equilibrium Data

"VLE K -Values - Fill Options"

EDL Anlagenbau

2EDL_SDA_PRO/II_Fill-Options

Introduction

SDA, the Solvent Deasphalting technology is actually one of the

most interesting Bottom to Barrel technology for heavy residues

in modern refineries

?

Large price differences between light sweet crudes and heavy sour crudes

created strong incentives for bottom processing tecchnologies

Old fashion technology SDA in the lube oil refinery

will be more and more also applied in fuel oil refineries, too

The SDA technology is the lowest investment cost variant compared to

Gasification, Visbreaker, Hydrocracker, Coker et al

In the best case both products DAO as well as Pitch can be converted in

further process steps to valuble products, no further residues will be available

EDL Anlagenbau

3EDL_SDA_PRO/II_Fill-Options

Integration of SDA in modern Refinery

VDU

AR

Crude

SDA

ADU

VR

Bitumen plant

Asphalt (Pitch)

Bright Stock

FCC -Plant

Hydrocracker

Lube Oil Refinery

Fuel Oil Refinery

DAO

ADUAtmospheric Distillation Unit

VDUVacuum Distillation Unit

SDASolvent Deasphalting

AR..Atmospheric Residue

VR..Vacuum Residue

EDL Anlagenbau

4EDL_SDA_PRO/II_Fill-Options

Typical SDA

a typical SDA plant is a PDA, e.g.

- Propane Deasphalting Plant -

The plant normally consists of the following parts:

Propane Extraction

DAO Train

Asphalt Train

Propane Condensation and Recovery

Pressure Relieve -, Slop - and Flushing system

EDL Anlagenbau

5EDL_SDA_PRO/II_Fill-Options

SDA simulation and design

The simulation and design of a SDA , especially the

liquid liqud extraction process is a challenging task !

?

the feed, Vacuum Residue can only be simulated with pseudo

components e.g. it is impossible to use components from the data base

with a defined structure

the pseudo components have no structure to produce BIPs from the

UNIFAC Model to build activity coefficients between the components

the liquid liquid extraction process for the SDA is based on the different

solubilities between the solvent and the hydrocarbons

BIPs are necessary to calculate the equilibria in the two liquid phases,

the DAO and the Asphalt phase

BIP Binary Interaction Parameters

EDL Anlagenbau

6EDL_SDA_PRO/II_Fill-Options

Model Basis: Chueh and Prausnitz

The BIPs can be calculated based on a publication from Chueh and Prausnitz

(1967) for an EOS (Equation of State) via the partial molar volumes of the

multicomponent liquid mixture:

) (

5 . 0

b T

a

b

RT

P

+

=

u u u

Equation of State:

Partial differentiation of EOS:

with the mixing rules for a mixture and used for

) , , , , , , ( ........ , , , ,

bi ai ci ci ci i i ij i ii

T P x f a b a b a O O u e

(

+

+

+

+

2 2 2 / 1 2

2 / 1

) (

2

) (

) (

) /( ) ( 2

) 1 (

b

b

T

a

b

RT

T b

b ab a x

b

b

b

RT

i

k ki i

k

k

u u

u

u

u u

u

u u

u

0 ) ( and 0 ) (

2

2

= =

c c

T T

P P

ou

o

ou

o

0867 . 0 and 4278 . 0

a

= O = O

b

EDL Anlagenbau

7EDL_SDA_PRO/II_Fill-Options

applying the pseudocritical rules to the critical region:

93 , 0 >

R

T

) ( ) (

) ( ) (

'

'

R CM CT CM

CM

R CM CT CM

CM

T D

T D T T T T

u u u u + =

+ =

Further, with adjustments to SRK and PR applied in PRO/II we get

the BIPs between the components:

n

CMj CMi

CMj CMi

ij

k

(

(

+

=

2 / ) (

1

3 / 1

'

3 / 1

'

3 / 1

'

3 / 1

'

u u

u u

3 = n

(the best fit with experimental data)

Model Basis: Chueh and Prausnitz

EDL Anlagenbau

8EDL_SDA_PRO/II_Fill-Options

Notation

factor ..acentric ..........

EOS Kwong Redlich in parameter ess dimensionl .... ,

phase liquid in ffraction ....mole x.........

mixture of volume critical true .........

mixture of volume ical pseudocrit corrected .......

mixture of volume ical pseudocrit ........

phase liquid in k component of me molar volu partial ..........

mixture liquid or liquid of lume ..molar vo ..........

mixture liquid of volume ..total V.........

re temperatu reduced .......... T

ure ..temperat T.........

pressure ..total P.........

parameters n interactio for s BIP' ......... k

region critical the o function t correction )... D(T

EOS Kwong Redlich in nstants b.......co a,

a

CT

'

CM

R

ij

R

e

u

u

u

u

u

b

CM

k

O O

EDL Anlagenbau

9EDL_SDA_PRO/II_Fill-Options

PRO/II PFD- one stage

Typical one stage liquid liquid extraction unit:

EDL Anlagenbau

10EDL_SDA_PRO/II_Fill-Options

Pseudo component feed Vacuum Residue (VR)

kg/kg 9669 . 0

15

= d

EDL Anlagenbau

11EDL_SDA_PRO/II_Fill-Options

Pseudo component properties

EDL Anlagenbau

12EDL_SDA_PRO/II_Fill-Options

PRO/II- K-value Fill Options

EDL Anlagenbau

13EDL_SDA_PRO/II_Fill-Options

EOS for Fill Options

The following EOS are awailable for the Fill Option:

- Modified Chueh Prausnitz Hydrocarbon Fill -

Soave Redlich Kwong

SRK Panagiotopoulos-Reid

SRK Modified Panagiotopoulos-Reid

SRK SIMSCI

Peng Robinson

PR Panagiotopoulos-Reid

PR Modified Panagiotopoulos-Reid

Predictive Peng Robinson 78

Tacite

The best fit with practical results we achieved with the

SRK Modified Panagiotopoulos Reid thermodynamic !

EDL Anlagenbau

14EDL_SDA_PRO/II_Fill-Options

BIPs calculation

BIPs calculated from the output report:

EDL Anlagenbau

15EDL_SDA_PRO/II_Fill-Options

Stream list

DAO: 28.5 %, Asphalt : 71.5 %

EDL Anlagenbau

16EDL_SDA_PRO/II_Fill-Options

VR-DAO-Asphalt TBP

EDL Anlagenbau

17EDL_SDA_PRO/II_Fill-Options

VR-DAO-Asphalt distribution

EDL Anlagenbau

18EDL_SDA_PRO/II_Fill-Options

Property list

As shown in the property list special data as S, V, Ni, Fe, N and CCR

can be controlled in the DAO, Asphalt via a distribution in the feed (VR):

EDL Anlagenbau

19EDL_SDA_PRO/II_Fill-Options

Bench scale tests

The theoretical results were compared to bench scale tests in a autoclave:

Conditions: subcritical pressure from 30 to 35 bar and

temperature about 50C

Solvent: Propane (100%)

Autoclave

EDL Anlagenbau

20EDL_SDA_PRO/II_Fill-Options

Bench scale tests

Results: DAO and Asphalt from the bench scale unit

DAO..Deasphalted oil

AS..Asphalt (Pitch)

Asphalt DAO

*SRK -Mod Panag. -Reid

**PR -Mod Panag. -Reid

The SRK Modified Panagiotopoulos -Reid method gives the best fit to the practical results !

EDL Anlagenbau

21EDL_SDA_PRO/II_Fill-Options

Study of thermodynamic models

EDL Anlagenbau

22EDL_SDA_PRO/II_Fill-Options

Solvent impact

The choise of the solvent or solvent mixture is very important !

Asphaltenes

Resins

Oils

C

r

u

d

e

O

i

l

A

m

o

s

p

h

e

r

i

c

R

e

s

i

d

u

e

V

a

c

u

u

m

R

e

s

i

d

u

e

P

r

o

p

a

n

e

P

r

e

c

i

p

i

t

a

t

e

P

e

n

t

a

n

e

P

r

e

c

i

p

i

t

a

t

e

H

e

p

t

a

n

e

P

r

e

c

i

p

i

t

a

t

e

EDL Anlagenbau

23EDL_SDA_PRO/II_Fill-Options

Simulation studies of Solvent mixtures

EDL Anlagenbau

24EDL_SDA_PRO/II_Fill-Options

Ternary plots -Temperature influence-

Ternary plot from literature:

1

2

3

Solvent to Feed ratio

(tie lines):

10,5

23,0

38,0

Binodal curves

EDL Anlagenbau

25EDL_SDA_PRO/II_Fill-Options

Ternary plot Pressure influence -

Binodal curves

Solvent to Feed ratio

(tie lines):

10,5

23,0

38,0

1

2

3

EDL Anlagenbau

26EDL_SDA_PRO/II_Fill-Options

PRO/II simulation of multiple stage extraction

Heater on stage 1 to precipitate Asphalt

Controller for precipitation

EDL Anlagenbau

27EDL_SDA_PRO/II_Fill-Options

Ternary plot Pressure influence -

The number of trays are not so important !

For the design the

HTU, NTU concept

must be applied !

HTUHeight of Transfer Unit

NTUNumber of Transfer Unit

EDL Anlagenbau

28EDL_SDA_PRO/II_Fill-Options

The Solvent Deasphalting (SDA) is a key technology processing heavy

residues to valuable oils (DAO, Deasphalted Oil) and asphalt (Pitch) for the

Bitumen production. The process will be more and more interesting also in

fuel oil refineries as a Bottom to Barrel technology with low costs.

The calculation of the extraction process with NPB components is difficult

because of the lack of BIPs between the components. Other ways to build

up the data from the UNIFAC model are not applicable.

The model from CHUEH and PAUSNITZ, published in the AIChE Houston

Meeting in 1967 is applicable to estimate the BIPs between the NBP

components and the solvents, finally to calculate the extraction of the SDA

for high pressure.

Summary

EDL Anlagenbau

29EDL_SDA_PRO/II_Fill-Options

Summary

The model application in the PRO/II simulation program under the

Equation of State (EOS) with the VLE K values Fill Option is the basis

for the complete process simulation of the whole SDA process.

Experimental results have shown that the model can be applied to design

the SDA process with different solvents (Propane, Butane etc.) and

solvent mixtures for the sub- and supercritical extraction processes.

Further investigation should be done to apply the model also to other

extraction technologies e.g. solvent extraction with furfural or NMP.

Thank you for your attention !

You might also like

- Diesel Fuels & Diesel Fuel Systems: Application and Installation GuideDocument58 pagesDiesel Fuels & Diesel Fuel Systems: Application and Installation Guidedimaomar100% (1)

- Rigorously Size Relief Valves For Critical FluidsDocument10 pagesRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Solvent Deasphalting PPT Final - 1Document30 pagesSolvent Deasphalting PPT Final - 1studyendless100% (4)

- EDL SDA Pilot Plant PDFDocument8 pagesEDL SDA Pilot Plant PDFProcess EngineerNo ratings yet

- (MEA) CO2 Capture PFDsDocument95 pages(MEA) CO2 Capture PFDsfNo ratings yet

- Febuary 01, 2000 05:25:41 Information Handling Services, 2000Document128 pagesFebuary 01, 2000 05:25:41 Information Handling Services, 2000Rajvachan ManiNo ratings yet

- Inside Your Carbs PDFDocument29 pagesInside Your Carbs PDFTamara GarciaNo ratings yet

- 2014 PTQ q4Document156 pages2014 PTQ q4digeca100% (1)

- Aromatics Upgrading Technologies: Ihs ChemicalDocument9 pagesAromatics Upgrading Technologies: Ihs ChemicalLêĐứcTiếnNo ratings yet

- Fuels Liq Manufacture of Metallurgical Coke: Beehive Oven Otto Hoffmann OvenDocument51 pagesFuels Liq Manufacture of Metallurgical Coke: Beehive Oven Otto Hoffmann OvenAgnivesh Sharma0% (3)

- GBH Enterprises, LTD.: SMR Pre-Reformer Design Case Study #0618416GB/HDocument17 pagesGBH Enterprises, LTD.: SMR Pre-Reformer Design Case Study #0618416GB/HAnonymous qPt2MHzXTNo ratings yet

- Uop Benfield DatasheetDocument2 pagesUop Benfield DatasheetSusan Monteza GrandezNo ratings yet

- Select NGL Recovery and Optimization Technologies Using Simulation and AlgorithmDocument8 pagesSelect NGL Recovery and Optimization Technologies Using Simulation and AlgorithmNoirchevalNo ratings yet

- Reducing Pressure - Increasing Efficiency: PanoramaDocument4 pagesReducing Pressure - Increasing Efficiency: PanoramapsshnkrNo ratings yet

- Control Valves Tuning PDFDocument13 pagesControl Valves Tuning PDFsteam100deg1658No ratings yet

- What A Low Delta Coke Catalyst Means To The Refiner2Document4 pagesWhat A Low Delta Coke Catalyst Means To The Refiner2Nagaphani Kumar RavuriNo ratings yet

- Aspen Utilities - Refinery EngineersDocument72 pagesAspen Utilities - Refinery EngineersUrcan GeorgianaNo ratings yet

- E PR 440Document44 pagesE PR 440studyendless100% (2)

- A Financial Analysis For The Production of HQ Propylene-MustangDocument19 pagesA Financial Analysis For The Production of HQ Propylene-Mustangandrei12320003181No ratings yet

- Debottlenecking - FractionatorDocument5 pagesDebottlenecking - Fractionatorsuprateem100% (1)

- TATA Ammonia Plant: Design Features and Operating ExperienceDocument17 pagesTATA Ammonia Plant: Design Features and Operating Experiencevaratharajan g rNo ratings yet

- Critical Variable in Catalytic Reforming and Unit Monitoring Best PracticesDocument18 pagesCritical Variable in Catalytic Reforming and Unit Monitoring Best Practicesbakhtyar21No ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Achieve Success in Gasoline HydrotreatingDocument6 pagesAchieve Success in Gasoline Hydrotreatingdonald55555No ratings yet

- Fractionation and Absorption For The Process Man PDFDocument70 pagesFractionation and Absorption For The Process Man PDFWilliam SandersNo ratings yet

- Distillation Part 1 Experimental Validation of Column Simulations PDFDocument9 pagesDistillation Part 1 Experimental Validation of Column Simulations PDFRajendraNo ratings yet

- Section-IV Shutdown Rev4Document12 pagesSection-IV Shutdown Rev4Balasubramanian CNo ratings yet

- 142 Yer HS PSM 0001Document75 pages142 Yer HS PSM 0001Janakiraman MalligaNo ratings yet

- AGR OptimizationDocument43 pagesAGR Optimizationinara amatullahNo ratings yet

- Diesel HydrotreatingDocument21 pagesDiesel HydrotreatingIzack Silva S100% (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- 943025-806 Strainers Rev01Document3 pages943025-806 Strainers Rev01studyendlessNo ratings yet

- Rate-Based Modeling For CO2 AbsorptionDocument10 pagesRate-Based Modeling For CO2 AbsorptiongoingtohellwithmeNo ratings yet

- 2009-03 CleanDieselHydroPTQ MustangDocument7 pages2009-03 CleanDieselHydroPTQ Mustanganhchangleloi100% (2)

- Pims Model Solution ReportDocument19 pagesPims Model Solution ReportAsad RazaNo ratings yet

- Process Simulation of Ammonia PlantDocument9 pagesProcess Simulation of Ammonia Planthamidrezaee008No ratings yet

- Biofuel: From Wikipedia, The Free EncyclopediaDocument18 pagesBiofuel: From Wikipedia, The Free Encyclopediabekku100% (1)

- Optimize Sour Water Stripper Feed Preheating For Low Capital PDFDocument6 pagesOptimize Sour Water Stripper Feed Preheating For Low Capital PDFDaniel Gonzalez RodriguezNo ratings yet

- 03 Refinery Overview - r0Document42 pages03 Refinery Overview - r0Satrio Agung WijonarkoNo ratings yet

- Methyldiethanolamine As A Solvent For Gas DesulfurizationDocument66 pagesMethyldiethanolamine As A Solvent For Gas DesulfurizationAnime MtNo ratings yet

- Dynamic Model of A Scrubber Using Aspen PlusDocument11 pagesDynamic Model of A Scrubber Using Aspen PluschetanNo ratings yet

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Cyril Cromier, Frost & SullivanDocument24 pagesCyril Cromier, Frost & SullivanGaurav SahuNo ratings yet

- Modeling and Simulation of Steam CrackersDocument6 pagesModeling and Simulation of Steam CrackersFathan FathullahNo ratings yet

- Understanding Gas Treatment FundamentalsDocument8 pagesUnderstanding Gas Treatment Fundamentalsazotik1985No ratings yet

- Integration of Petrochemical and Refinery Plants As An Approach To Compete in Hydrocarbon MarketDocument31 pagesIntegration of Petrochemical and Refinery Plants As An Approach To Compete in Hydrocarbon MarketHuiJooHweeNo ratings yet

- POWER Magazine - May 2023-1Document43 pagesPOWER Magazine - May 2023-1MarcialgonzalezpNo ratings yet

- The Future of Hydrogen-Opportunities and Challenge PDFDocument14 pagesThe Future of Hydrogen-Opportunities and Challenge PDFDavid Fernando Otalvaro ZuletaNo ratings yet

- 4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev ClaesDocument8 pages4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev Claesvaratharajan g rNo ratings yet

- Topsoe Claus Tail Aug09 Low Res - AshxDocument8 pagesTopsoe Claus Tail Aug09 Low Res - AshxJustin DeVitoNo ratings yet

- Process Design - Some Practical TipsDocument102 pagesProcess Design - Some Practical Tipsstudyendless100% (3)

- CDU Enhance Energy EfficiencyDocument5 pagesCDU Enhance Energy Efficiencyrvkumar61100% (2)

- Enrtl-Rk Rate Based Dea ModelDocument31 pagesEnrtl-Rk Rate Based Dea ModelsamandondonNo ratings yet

- Enhanced NGL Recovery ProcessDocument5 pagesEnhanced NGL Recovery ProcessEdgar HuancaNo ratings yet

- Hydro Treating CompleteDocument19 pagesHydro Treating CompleteFaiq Ahmad Khan100% (3)

- A Guideline For Design Pressure - Part 1Document4 pagesA Guideline For Design Pressure - Part 1Said Ahmed SalemNo ratings yet

- Gasification Process ModelingDocument6 pagesGasification Process ModelingRebeca Santamaria MedelNo ratings yet

- Sweetening LPG With AminesDocument8 pagesSweetening LPG With AminessizwehNo ratings yet

- Dehydration of Ethanol To EthyleneDocument10 pagesDehydration of Ethanol To EthylenewiboonwiNo ratings yet

- Simulation and Performance Analysis of Propane Propylene SplitterDocument4 pagesSimulation and Performance Analysis of Propane Propylene SplitterAnonymous UY9QffNo ratings yet

- Filling The Propylene Gap On Purpose TechnologiesDocument12 pagesFilling The Propylene Gap On Purpose Technologiesvajidqc100% (1)

- Nicholas Oligomerization PDFDocument16 pagesNicholas Oligomerization PDFTanase DianaNo ratings yet

- Junín Upgrader Hydrocracking Unit (14) Overall Material BalanceDocument11 pagesJunín Upgrader Hydrocracking Unit (14) Overall Material BalancegarciahoNo ratings yet

- KBCDocument15 pagesKBCMauricio Huerta JaraNo ratings yet

- Fluid Catalytic Cracking Unit (FCCU)Document1 pageFluid Catalytic Cracking Unit (FCCU)Billy BlinksNo ratings yet

- Oxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery UnitDocument22 pagesOxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery Unitsara25dec689288No ratings yet

- Pinch Spreadsheet NOV06 FINALDocument194 pagesPinch Spreadsheet NOV06 FINALSzelee KuekNo ratings yet

- The Rose Process: Tayseer Abdel-Halim and Raymond FloydDocument14 pagesThe Rose Process: Tayseer Abdel-Halim and Raymond FloydBharavi K SNo ratings yet

- CoMo PDFDocument4 pagesCoMo PDFNeniitha SánchezNo ratings yet

- 3 3 MR Robert PardemannDocument47 pages3 3 MR Robert Pardemannhoremheb1No ratings yet

- Liquefaction Process EvaluationDocument15 pagesLiquefaction Process Evaluationapi-3715370100% (1)

- Fluid Package EOSDocument12 pagesFluid Package EOSdani2611No ratings yet

- Acid Gas Sweetening Case StudyDocument16 pagesAcid Gas Sweetening Case Studyome solNo ratings yet

- Oil Benchmarks - What NextDocument6 pagesOil Benchmarks - What NextstudyendlessNo ratings yet

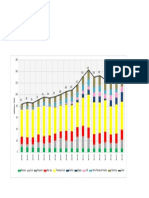

- OPEC Annual Statistical Bulletin - 50th Edition - 2015Document120 pagesOPEC Annual Statistical Bulletin - 50th Edition - 2015studyendlessNo ratings yet

- Europia - Whitepaper v16 LR External Use-2010-03068-01-EDocument72 pagesEuropia - Whitepaper v16 LR External Use-2010-03068-01-EstudyendlessNo ratings yet

- API Separators - SolutionsDocument8 pagesAPI Separators - SolutionsnorthstarleoNo ratings yet

- Estimating The Viscosity of Mixtures - NeutriumDocument4 pagesEstimating The Viscosity of Mixtures - NeutriumstudyendlessNo ratings yet

- Discussion Document - Effect of Ethanol Blending On Gasoline RVPDocument10 pagesDiscussion Document - Effect of Ethanol Blending On Gasoline RVPstudyendlessNo ratings yet

- 卡西欧 fx-6300G 用户手册Document99 pages卡西欧 fx-6300G 用户手册studyendlessNo ratings yet

- Regulation of Properties of Oxidized Asphalt From Heavy CrudeDocument2 pagesRegulation of Properties of Oxidized Asphalt From Heavy CrudestudyendlessNo ratings yet

- Experimental Study of A Pilot Plant Deasphalting Process in Supercritical ConditionsDocument6 pagesExperimental Study of A Pilot Plant Deasphalting Process in Supercritical ConditionsstudyendlessNo ratings yet

- Asphalt Oxidation Studies at Elevated TemperaturesDocument4 pagesAsphalt Oxidation Studies at Elevated TemperaturesstudyendlessNo ratings yet

- Motor Gasolines Technical ReviewDocument124 pagesMotor Gasolines Technical Reviewpurple_onionNo ratings yet

- Production of High-Quality Paraffinic Distillates and Vacuum Resid. Revamping of The AVT-2 Unit Vacuum BlockDocument4 pagesProduction of High-Quality Paraffinic Distillates and Vacuum Resid. Revamping of The AVT-2 Unit Vacuum BlockstudyendlessNo ratings yet

- Discussion Document - Effect of Ethanol Blending On Gasoline RVPDocument10 pagesDiscussion Document - Effect of Ethanol Blending On Gasoline RVPstudyendlessNo ratings yet

- Consider New Analysis For FlaresDocument5 pagesConsider New Analysis For FlaresstudyendlessNo ratings yet

- Understanding Fines in Coking More Important NowDocument5 pagesUnderstanding Fines in Coking More Important NowstudyendlessNo ratings yet

- Basic Petroleum EngineeringDocument3 pagesBasic Petroleum EngineeringbejoraharjokuNo ratings yet

- Topham: Swimming Pools For M Kun I. CarburettorDocument2 pagesTopham: Swimming Pools For M Kun I. CarburettorMihai DucaNo ratings yet

- Hydrodesulfurization - Wikipedia, The Free EncyclopediaDocument7 pagesHydrodesulfurization - Wikipedia, The Free EncyclopediaLammie Sing Yew LamNo ratings yet

- American Renewable Fuel Suppliers (ARFS) Ethanol Dehydration Method 2B PathwayDocument3 pagesAmerican Renewable Fuel Suppliers (ARFS) Ethanol Dehydration Method 2B PathwayBlog da Engenharia de ProduçãoNo ratings yet

- BPDocument1 pageBPEce KıtaybahadırNo ratings yet

- HPCL Visahk Refinery, Vizag: An Application of Linear Programming ConceptsDocument8 pagesHPCL Visahk Refinery, Vizag: An Application of Linear Programming ConceptsRaasam SiddharthNo ratings yet

- Expartment No. 1: Smoke Point TestDocument5 pagesExpartment No. 1: Smoke Point Testshivbham chaurasiyaNo ratings yet

- Laporan Housebank 2019Document2 pagesLaporan Housebank 2019girsaNo ratings yet

- Experiment No-3 To Study Biogas PlantDocument4 pagesExperiment No-3 To Study Biogas PlantANUP KUMARNo ratings yet

- Cracking Hydrocarbon Feedstock With A Heavy TailDocument4 pagesCracking Hydrocarbon Feedstock With A Heavy TailGhasem BashiriNo ratings yet

- Mineral Fuels, Mineral Oils and Products of Their Distillation Bituminous Substances Mineral WaxesDocument3 pagesMineral Fuels, Mineral Oils and Products of Their Distillation Bituminous Substances Mineral WaxesSakib Ex-rccNo ratings yet

- Biobased Energy in Flanders, Belgium: Rslag Biobased Economie PDFDocument7 pagesBiobased Energy in Flanders, Belgium: Rslag Biobased Economie PDFTiinaKoolNo ratings yet

- Unisource Series 2215 HoseDocument1 pageUnisource Series 2215 HosejoeNo ratings yet

- IntroductionDocument18 pagesIntroductiondonyaNo ratings yet

- 2Document1 page2Gissa SevieNo ratings yet

- LPG in Ic EnginesDocument23 pagesLPG in Ic EnginesSwapnil Patil100% (1)

- Fuel PricesDocument1 pageFuel PricesTiso Blackstar GroupNo ratings yet

- HdsDocument4 pagesHdsbac_nobita76570% (1)

- Biodiesel Plant Lists PDFDocument1 pageBiodiesel Plant Lists PDFRaju GummaNo ratings yet

- Future PPT SDocument44 pagesFuture PPT SvisutsiNo ratings yet

- Demand Forecasting of LPGDocument91 pagesDemand Forecasting of LPGNawab RaghuNo ratings yet

- 3.internal Combustion Engine-21-30Document10 pages3.internal Combustion Engine-21-30Aqsa KanwalNo ratings yet

- Indian Oil CorporationDocument5 pagesIndian Oil CorporationNarendra PatilNo ratings yet