Professional Documents

Culture Documents

Set of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th Edition

Uploaded by

Iskandar BellOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Set of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th Edition

Uploaded by

Iskandar BellCopyright:

Available Formats

Problem set #9

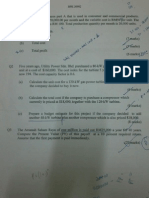

1) A centrifugal pump having the characteristics shown in the figure is used to pump water between two large

open tanks through 100 ft of 8-in.-diameter pipe.

The pipeline contains 4 regular flanged 90 elbows , a check valve, and a fully open globe valve. Other minor

losses are negligible. Assume the friction factor f=0.02 for the 100-ft section of pipe. If the static head

(difference in height of fluid surfaces in the two tanks) is 30 ft, what is the expected flowrate?

Solution

h

p

= 30 + 1.0210

-5

[Q(gal/min)]

2

This curve intersect the pump curve at Q = 1740 gal/min. The efficiency at this flow rate is near peak efficiency

at about 83%. The pump should be satisfactory.

2) In a chemical processing plant a liquid is pumped from an open tank,

through a 0.1-m-diameter vertical pipe, and into another open tank as

shown in fig.a (assume elevation difference h = 30 m instead h = 30 m as

shown). A valve is located in the pipe, and the minor loss coefficient for

the valve as a function of the valve setting is shown in fig. b. The pump

head capacity relationship is given by the equation h

a

= 52.0 - 1.01x10

3

Q

2

with h

a

in meters when Q is in m3/s . Assume the friction factor f = 0.02

for the pipe, and all minor losses, except for the valve, are negligible. The

fluid levels in the two tanks can be assumed to remain constant.

(a) Determine the flowrate with the valve wide open.

(b) Determine the required valve setting (percent open) to reduce the

flowrate by 50%.

Solution

h

p

= 33 + 5.7810

3

[Q(m

3

/s)]

2

Since the pump equation is h

a

= 52.0 - 1.01x10

3

Q

2

h

p

= 33 + 5.7810

3

Q

2

= 52.0 - 1.01x10

3

Q

2

Q = 0.0529 m

3

/s

(b) Determine the required valve setting (percent open) to reduce the flowrate by 50%.

h

a

= 52.0 - 1.01x10

3

Q

2

= 52.0 - 1.01x10

3

(0.0529/2 )

2

= 50.6 m

h

p

= 50.6 m = 33 m + (K

L

+ 6)(826)(0.0529/2)

2

K

L

= 24.3

From Figure 12.29b the valve should be 13% open to obtain this value.

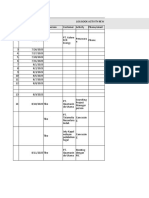

3) A centrifugal pump having an impeller diameter of 1 m is to be constructed so that it will supply a head rise of

200 m at a flowrate of 4.1 m

3

/s of water when operating at a speed of 1200 rpm. To study the characteristics of this

pump, a 1/5 scale, geometrically similar model operated at the same speed is to be tested in the laboratory.

Determine (a) the required model discharge and (b) head rise. Assume that both model and prototype operate with

the same efficiency (and therefore the same flow coefficient).

Solution

For similarity, the model pump must operate at the same flow coefficient so that

3

m

Q

D e

| |

|

\ .

=

3

p

Q

D e

| |

|

\ .

Q

m

=

m

p

e

e

3

m

p

D

D

| |

|

|

|

\ .

Q

p

Q

m

= (1)(1/5)

3

(4.1) = 0.0328 m

3

We also have

2 2

a

m

gh

D e

| |

|

\ .

=

2 2

a

p

gh

D e

| |

|

\ .

h

a,m

=

p

m

g

g

2

m

p

e

e

| |

|

|

|

\ .

2

m

p

D

D

| |

|

|

|

\ .

h

a,p

h

a,m

= (1)(1)

2

(1/5)

2

(200) = 8.0 m

4) A centrifugal pump has the performance characteristics of the pump with the 6-in.-diameter impeller

described in the Figure. Note that the pump in this figure is operating at 3500 rpm. What is the expected head

gained if the speed of this pump is reduced to 2800 rpm while operating at peak efficiency?

Solution

From the figure, for the 6-in diameter impeller operating at 3500 rpm, Q = 170 gpm and h

L

= 230 ft. If the pump

is still operated at peak efficiency with the speed reduced to 2800 rpm then

1

2

Q

Q

=

1

2

e

e

Q

2

=

2

1

e

e

Q

1

= (2,800/3,500)(170) = 136 gpm

We also have

1

2

a

a

h

h

=

2

1

2

2

e

e

h

a2

=

2

2

1

e

e

| |

|

|

|

\ .

h

a1

h

a2

= (2,800/3,500)

2

(230) = 147 ft

5) A centrifugal pump provides a flowrate of 500 gpm when operating at 1750 rpm against a 200-ft head.

Determine (a) the pump's flowrate and (b) developed head if the pump speed is increased to 3500 rpm.

Solution

1

2

Q

Q

=

1

2

e

e

Q

2

=

2

1

e

e

Q

1

= (3,500/1,750)(500) = 100 gpm

We also have

1

2

a

a

h

h

=

2

1

2

2

e

e

h

a2

=

2

2

1

e

e

| |

|

|

|

\ .

h

a1

h

a2

= (3,500/1,750)

2

(200) = 80 ft

6) In a certain application a pump is required to deliver 5000 gpm against a 300-ft head when operating at 1200

rpm. Find a specific speed N

sd

of the pump and recommend an appropriate pump from the given figure.

Solution

N

sd

=

| |

3/ 4

( ) ( )

( )

a

rpm Q gpm

h ft

e

=

3/ 4

1200 5000

(300)

= 1180

From the above figure, at specific speed of 1180, a radial flow pump (centrifugal pump) would be

recommended.

7) A hydraulic turbine operating at 180 rpm with a head of 100 feet develops 20,000 horsepower. Estimate the

power if the same turbine were to operate under a head of 50 ft.

Solution

Head coefficient remains constant:

2 2

1

a

gh

D e

| |

|

\ .

=

2 2

2

a

gh

D e

| |

|

\ .

2

100

180

=

2

2

50

e

since D

1

= D

2

and g

1

= g

2

e

2

= 127 rpm

Power coefficient is the same

3 5

1

shaft

W

D e

| |

|

|

\ .

=

3 5

2

shaft

W

D e

| |

|

|

\ .

3

20,000

100

=

,2

3

127

shaft

W

since D

1

= D

2

and g

1

= g

2

,2 shaft

W = 41,000 hp

8) Water for a Pelton wheel turbine flows from the headwater and through the penstock as shown in the given

Figure. The effective friction factor for the penstock, control valves, and the like is 0.032 and the diameter of

the jet is 0.20 m. Determine the maximum power output.

Solution

Maximum

shaft

W = 23,200 kW

12.70) Turbines are to be designed to develop 30000 horsepower while operating under a head of 70 ft and an

angular velocity of 60 rpm. Estimate the flowrate needed.

Solution

N

sd

=

| |

5/ 4

( ) ( )

( )

shaft

t

rpm W hp

h ft

e

=

5/ 4

60 30,000

(70)

= 1180

shaft

W = Qh

t

Q =

shaft

W /h

t

= (30,000550)/(62.470)

Q = 378 ft

3

/s

You might also like

- Group Asgmt No 2 EEDocument7 pagesGroup Asgmt No 2 EEHafiz Bin HarunNo ratings yet

- 10 May 2020 Before 5 PM at Author - Uthm.edu - My (I Will Create The Folder To Submit)Document2 pages10 May 2020 Before 5 PM at Author - Uthm.edu - My (I Will Create The Folder To Submit)Sky FireNo ratings yet

- Slab DesignDocument45 pagesSlab DesignOkino CharlesNo ratings yet

- Assignment Mathematics 3Document21 pagesAssignment Mathematics 3Najmi AimanNo ratings yet

- Topic 6 OCHydraulicsDocument49 pagesTopic 6 OCHydraulicsSue Ila100% (1)

- HYDRAULIC Cqi QuestionsDocument2 pagesHYDRAULIC Cqi QuestionsJibul temulakNo ratings yet

- Dynamic Lab ReportDocument20 pagesDynamic Lab ReportJohnsheng LeeNo ratings yet

- Tutorial Problem SetDocument5 pagesTutorial Problem SetWK PangNo ratings yet

- Exp 4 FMDocument17 pagesExp 4 FMKhadijah Ulol AzmiNo ratings yet

- 01e Properties of Materials January 2011 s81-85Document5 pages01e Properties of Materials January 2011 s81-85Munir EffendyNo ratings yet

- ECW 231 Tutorial and Answers Buoyancy Sept19Document5 pagesECW 231 Tutorial and Answers Buoyancy Sept19hairinnisaNo ratings yet

- Individual Assignment 5Document3 pagesIndividual Assignment 5Sirak Masresha0% (1)

- Slides 5 Hydraulic MachineryDocument18 pagesSlides 5 Hydraulic MachineryTing Wee KietNo ratings yet

- Literature Review Spur GearDocument3 pagesLiterature Review Spur Gearthai avvaiNo ratings yet

- Analysis of Steady Flow in Pipelines2Document12 pagesAnalysis of Steady Flow in Pipelines2Shafika AliaNo ratings yet

- Assignment No. 4Document7 pagesAssignment No. 4sheikh hafiziNo ratings yet

- Lab 12Document4 pagesLab 12Samuel RodgersNo ratings yet

- Tutorial 3Document2 pagesTutorial 3Anonymous Vx9KTkM8nNo ratings yet

- Discussion of Ultrafiltration and UV Sterilization ProcessDocument5 pagesDiscussion of Ultrafiltration and UV Sterilization ProcessTan Wee YekNo ratings yet

- Assignment FluidDocument16 pagesAssignment FluidHaiqal RafiqNo ratings yet

- Final Exam Hydraulic Jan2012Document9 pagesFinal Exam Hydraulic Jan2012Anni SuhanaNo ratings yet

- Eng MathDocument13 pagesEng MathZaKy ZubaidiNo ratings yet

- Experiment: Torsion of A Spiral Spring: Vibrations LabDocument4 pagesExperiment: Torsion of A Spiral Spring: Vibrations LabVenkata DineshNo ratings yet

- Hydraulics Sniper ReportDocument8 pagesHydraulics Sniper ReportKhumo Ezekiel MoraNo ratings yet

- Measure of Pump Efficiency, Head and DischargeDocument15 pagesMeasure of Pump Efficiency, Head and DischargeHaikal HarithNo ratings yet

- Tutorial 1Document4 pagesTutorial 1Unta Di PadAng PaSirNo ratings yet

- VRVTEWUPIG FootbridgeDocument2 pagesVRVTEWUPIG FootbridgeVeenoyNo ratings yet

- Student Code of Ethic (SCE) : Department of Civil Engineering Centre For Diploma Studies UthmDocument13 pagesStudent Code of Ethic (SCE) : Department of Civil Engineering Centre For Diploma Studies UthmKerol Kerol Kerol0% (1)

- BFC21103 Chapter2Document74 pagesBFC21103 Chapter2badrulNo ratings yet

- Universiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringDocument11 pagesUniversiti Tun Hussein Onn Malaysia Department of Mechanical EngineeringAriff ShasteraNo ratings yet

- Aaaaaayidddddd287190871 Thermofluids Lab Fluid MixingDocument21 pagesAaaaaayidddddd287190871 Thermofluids Lab Fluid Mixingezzat0% (1)

- Tie Brick Lab ReportDocument7 pagesTie Brick Lab ReportRose ShazilahNo ratings yet

- Francis TurbineDocument8 pagesFrancis TurbineMohamad HamimyuddinNo ratings yet

- 1045 Deannamuhidi (Contract Ass1)Document7 pages1045 Deannamuhidi (Contract Ass1)Deanna MuhidiNo ratings yet

- Ecw568 Test Question 5 Feb 2021Document4 pagesEcw568 Test Question 5 Feb 2021Syalmira LovetobelovedNo ratings yet

- Bernoulli's TheoremDocument12 pagesBernoulli's TheoremNur Falini Mohd Sukkri100% (3)

- Fluid Mechanics - 01 Problem - CIVE2400-2007 PDFDocument4 pagesFluid Mechanics - 01 Problem - CIVE2400-2007 PDFTania Edna Bhakty SoetjiptoNo ratings yet

- EESB15 Sedimentary Rock Classification Chart Used (Guide)Document1 pageEESB15 Sedimentary Rock Classification Chart Used (Guide)Kristika RaguthasNo ratings yet

- Full As Contoh Member AkashahDocument29 pagesFull As Contoh Member AkashahWayen Bulat100% (1)

- BFC 32202 Engineers & Society Chapter 4 (Student Copy)Document36 pagesBFC 32202 Engineers & Society Chapter 4 (Student Copy)mhdbad aminNo ratings yet

- All Three Labs 2Document22 pagesAll Three Labs 2JaeNo ratings yet

- LAB REPORT ECS238 3 Pin ArchDocument6 pagesLAB REPORT ECS238 3 Pin Archmarina zamriNo ratings yet

- Fluid Mixing IntroDocument7 pagesFluid Mixing IntroMaizatul Akma HashimNo ratings yet

- Structure Lab-Strut BucklingDocument7 pagesStructure Lab-Strut BucklingFendi RoonNo ratings yet

- NR-310304 - Dynamics of MachineryDocument8 pagesNR-310304 - Dynamics of MachinerySrinivasa Rao GNo ratings yet

- Student Code of Ethic (SCE)Document10 pagesStudent Code of Ethic (SCE)Rahim GenesisNo ratings yet

- 8 Pipe Note 3 PDFDocument13 pages8 Pipe Note 3 PDFHENDRIK2011No ratings yet

- Lab Centre of Pressure Ecw341Document4 pagesLab Centre of Pressure Ecw341danialNo ratings yet

- Fluid Lab2Document11 pagesFluid Lab2邱瑞香No ratings yet

- Progress Report IIDocument19 pagesProgress Report IIAkashahZakariaNo ratings yet

- Softening Point TestDocument6 pagesSoftening Point Testarif50% (2)

- EXP 3 Packed Absorption Column Raschig RingDocument14 pagesEXP 3 Packed Absorption Column Raschig RingHaiqal AzizNo ratings yet

- CV1012 Tutorial 10 SolutionsDocument4 pagesCV1012 Tutorial 10 SolutionsleemariosanNo ratings yet

- 345s02p2 PDFDocument10 pages345s02p2 PDFAdrian Antonio TorresNo ratings yet

- Lecture On Affinity LawsDocument10 pagesLecture On Affinity LawsCyduck GuevarraNo ratings yet

- Addi Examples Pipe3Document10 pagesAddi Examples Pipe3Diego MorenoNo ratings yet

- QuizesDocument13 pagesQuizesahmadNo ratings yet

- Ej Vol Control Pelu oDocument8 pagesEj Vol Control Pelu oPablo Martínez CavieresNo ratings yet

- TiO2 Thin Films Prepared by Spin Coating TechniqueDocument6 pagesTiO2 Thin Films Prepared by Spin Coating TechniqueIskandar BellNo ratings yet

- Summary of NDT StudiesDocument2 pagesSummary of NDT StudiesIskandar BellNo ratings yet

- BDA 40502 - Engineers & Society - v5Document4 pagesBDA 40502 - Engineers & Society - v5Iskandar BellNo ratings yet

- Topic - 1 Basic Injection MouldingDocument67 pagesTopic - 1 Basic Injection MouldingIskandar BellNo ratings yet

- Slide 8 BDA 40303-Heat Transfer IZDocument10 pagesSlide 8 BDA 40303-Heat Transfer IZEl JulaibibNo ratings yet

- Sem 2 1213 Final ExamDocument8 pagesSem 2 1213 Final ExamIskandar BellNo ratings yet

- Bda 30502 Sem 2 1213Document5 pagesBda 30502 Sem 2 1213Iskandar BellNo ratings yet

- All Batch - Pre RegistrationDocument415 pagesAll Batch - Pre RegistrationIskandar BellNo ratings yet

- 4 T, Yrg: LNTVQL - .-CMP D CLH' WL (.H FWDocument1 page4 T, Yrg: LNTVQL - .-CMP D CLH' WL (.H FWIskandar BellNo ratings yet

- Modelling of Rotational Mechanical SystemDocument63 pagesModelling of Rotational Mechanical SystemIskandar BellNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- EGR 334 Lecture 36 Gas Reheat and IntercoolingDocument19 pagesEGR 334 Lecture 36 Gas Reheat and IntercoolingIskandar Bell100% (1)

- Universiti Tun Hussein Onn MalaysiaDocument2 pagesUniversiti Tun Hussein Onn MalaysiaIskandar BellNo ratings yet

- BDA 30203 Review ProblemsDocument2 pagesBDA 30203 Review ProblemsBryon DeanNo ratings yet

- Hint For The Subject Taken by Mechanical UTHM StudentDocument2 pagesHint For The Subject Taken by Mechanical UTHM StudentIskandar BellNo ratings yet

- Set of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionDocument6 pagesSet of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionIskandar BellNo ratings yet

- Upload 7c1bfqqh5hk32kip5doq1l7pu6946986 FinalDocument1 pageUpload 7c1bfqqh5hk32kip5doq1l7pu6946986 FinalIskandar BellNo ratings yet

- Cara Menulis Rujukan-Apa StyleDocument18 pagesCara Menulis Rujukan-Apa StyleWan AqilahNo ratings yet

- Upload 7c1bfqqh5hk32kip5doq1l7pu6214742 FinalDocument1 pageUpload 7c1bfqqh5hk32kip5doq1l7pu6214742 FinalIskandar BellNo ratings yet

- Format Penulisan PSM UtemDocument35 pagesFormat Penulisan PSM UtemAbdulHalimNo ratings yet

- Vapor Sensor: Installation GuideDocument12 pagesVapor Sensor: Installation GuideShalvaTavdgiridzeNo ratings yet

- 5000m3 LPG Tank FarmDocument2 pages5000m3 LPG Tank FarmLpgTankFarmNo ratings yet

- SERVERON - Duval DGA Seminar - July 2016 (Summary)Document33 pagesSERVERON - Duval DGA Seminar - July 2016 (Summary)Cristian Méndez100% (1)

- Kul-24.3200 Lecture PropII 01aDocument27 pagesKul-24.3200 Lecture PropII 01aLong NguyenNo ratings yet

- BLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsDocument12 pagesBLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsHamza TikkaNo ratings yet

- JCI-GENCAT-2008Document203 pagesJCI-GENCAT-2008Susan LamNo ratings yet

- Tropospheric Ducting TDMMDocument16 pagesTropospheric Ducting TDMMMuhammad JunaidNo ratings yet

- Lbs 405 - 5e Lesson Plan 3Document11 pagesLbs 405 - 5e Lesson Plan 3api-406656032No ratings yet

- Lab 5 - Sync GeneratorDocument4 pagesLab 5 - Sync GeneratorzawirNo ratings yet

- A Review of Probabilistic Approaches For Available Transfer Capability CalculationDocument12 pagesA Review of Probabilistic Approaches For Available Transfer Capability CalculationAZOJETE UNIMAIDNo ratings yet

- Corrosion Manual (2015) PDFDocument164 pagesCorrosion Manual (2015) PDFRitu Raj Raman100% (1)

- Log Book ActivityDocument15 pagesLog Book ActivityGus BisantikoNo ratings yet

- VRV - ADocument48 pagesVRV - Amuzakir ludinNo ratings yet

- Product Catalog: Lighting The Led Revolution™Document76 pagesProduct Catalog: Lighting The Led Revolution™Fernando MolinaNo ratings yet

- Operating Procedure ERLDCDocument154 pagesOperating Procedure ERLDCbramhanand vermaNo ratings yet

- Green HydrogenDocument20 pagesGreen HydrogenBhavana CNo ratings yet

- Matlab CodeDocument3 pagesMatlab CodeAbdallAh ALi SmaDi50% (2)

- CDCCL PresentationDocument41 pagesCDCCL Presentationrizcst9759100% (5)

- Financial Reports March 2012Document246 pagesFinancial Reports March 2012adil1983adilNo ratings yet

- Labphys 6Document4 pagesLabphys 6Edyson CitraNo ratings yet

- Handbook of Coil Winding: Jürgen Hagedorn Florian Sell-Le Blanc Jürgen FleischerDocument30 pagesHandbook of Coil Winding: Jürgen Hagedorn Florian Sell-Le Blanc Jürgen FleischerAdeebaShaheenNo ratings yet

- CBIP Protection Guide 2016Document342 pagesCBIP Protection Guide 2016Sushant Yadav100% (5)

- 06 FEED Development - Onshore and OffshoreDocument2 pages06 FEED Development - Onshore and Offshorezdq02No ratings yet

- Enhancement of Hydrotreating Process Evaluation: Correlation Between Feedstock Properties, In-Line Monitoring and Catalyst DeactivationDocument13 pagesEnhancement of Hydrotreating Process Evaluation: Correlation Between Feedstock Properties, In-Line Monitoring and Catalyst Deactivationleilasalimleal_27406No ratings yet

- PDF DC Address by BeeDocument1 pagePDF DC Address by BeePranabesh MallickNo ratings yet

- PPP Baramsagar LIS (17-12-2019) - 1Document17 pagesPPP Baramsagar LIS (17-12-2019) - 1Yathiraj R100% (1)

- I 210 DatasheetDocument8 pagesI 210 DatasheetMichael WilkinNo ratings yet

- Graduation ProjectDocument97 pagesGraduation Projectvenuskurd49No ratings yet

- Energy Technology SolutionsDocument94 pagesEnergy Technology SolutionsAlper KoçerNo ratings yet

- Physics Class Xii Sample Paper Test 01 For Board Exam 2023 AnswersDocument18 pagesPhysics Class Xii Sample Paper Test 01 For Board Exam 2023 AnswersGyan BardeNo ratings yet

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (10)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsFrom EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNo ratings yet

- A Mind at Play: How Claude Shannon Invented the Information AgeFrom EverandA Mind at Play: How Claude Shannon Invented the Information AgeRating: 4 out of 5 stars4/5 (53)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)