Professional Documents

Culture Documents

Burnt Oil Pit-R1

Uploaded by

Irshad KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Burnt Oil Pit-R1

Uploaded by

Irshad KhanCopyright:

Available Formats

PROJECT:

110/33kv SUBSTATION AT IXORA, PANVEL

THE TATA POWER COMPANY LTD.

Godrej & Boyce Mfg. Co.Ltd.

Vikhroli , Mumbai

MUMBAI

PROJECT:

110/33kv SUBSTATION AT IXORA, PANVEL DRN.

PRPD CHKD APPD

NAME

A.K. S.A S.A

SIGN

DATE

02.07.13 02.07.13 02.07.13

TITLE :-

BURNT OIL PIT

DOC NO: G&B-TPC-PNL-IXORA-AEP-CAL - 88

REV. NO. 1

DOC.NO:

ALIF ENGINEERS AND PLANNERS

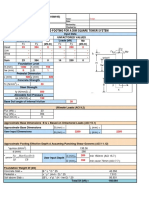

Design calculation For Burnt Oil pit

G&B-TPC-PNL-IXORA-AEP-CAL - 88 REV R1

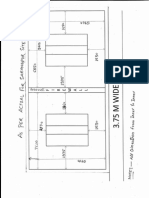

Design as a uncracked section as per IS 3370 Oil capacity = 25000 Litres. Taking 30% more = 32500 Litres Volume of tank required = 32.5 CuM 2.3 Cap. of tank Volume Density of oil = 3.8 x 3.8 x 2.3 3.75 1.20

= 33.2 CuM OK = 1.0 T/m3 4.30

Data:

For M25 and Fe 500 9 N/mm2 ( IS 456 Table 21) For M25 concrete 130 N/mm2 ( IS 3370 Part II - Table 2)

Perm Stress in concrete (c) = Perm Stress in steel (t) m = 280/3c mc/t = 10.4 =

= nc / (d-nc)

therefore nc =

0.58 d 0.81 2.11

a = d - nc/3

= 0.81 d

therefore j =

MR = b nc c/2 a = 2.11 bd2 Density of soil = 1.70 T/m3

therefore Q =

Angle of repose = 10 deg

Ka =

0.7

Case I - When tank is full. (Neglecting earth pressure) Using design charts of IS 3370 Part IV - considering top and bottom hinged. As per Table 1 IS 3370 (Part IV) - 1967 a = height of wall = b = Width of wall = c = Width of wall = c/a = 1.1 b/a = 3.8 m 4.3 m 4.3 m 1.1 1.25 Density of liquid w = 1.0 Depth of wall below ground = 3.5 m

Moment coefficients (Taking Maxm values) for b/a = Mx = 0.019 -0.009 My = 0.019 -0.045

Table 1 - IS 3370 Part IV

Godrej and Boyce

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

G&B-TPC-PNL-IXORA-AEP-CAL - 88 REV R1

Maximum Horizontal moment = My w a ^3 = 0.019 x 1 x 2.3 ^3 = 0.23 TM (Inside face) Maximum Horizontal moment = My w a ^3 = 0.045 x 1 x 2.3 ^3 = 0.55 TM (Outside face) Maximum Vertical moment = Mx w a ^3 1 x 2.3 ^3 = 0.009 x = 0.11 TM (Outside face) Maximum Vertical moment = Mx w a ^3 = 0.019 x 1 x 2.3 ^3 = 0.23 TM (Inside face) Oil press. Oil Press. Horzt. Moment

Vert. Moment Case II - When tank is empty (Full earth pressure) Soil pressure Ka = 0.70 x 1.70 = 1.2 T/m2

Using design charts of IS 3370 Part IV - considering top and bottom hinged. As per Table 1 IS 3370 (Part IV) - 1967 Moment coefficients (Taking Maxm values) for b/a = Mx = 0.019 -0.009 My = 0.019 -0.045 1.25 Soil Press.

Table 1 - IS 3370 Part IV

Maximum Horizontal moment = My w a ^3 = 0.019 x 1.2 x 3.2 ^3 = 0.75 TM (Outside face) Maximum Horizontal moment = My w a ^3 = 0.045 x 1.2 x 3.2 ^3 = 1.77 TM (Inside face) Maximum Vertical moment = Mx w a ^3 = 0.009 x 1.2 x 3.2 ^3 = 0.35 TM (Inside face) Maximum Vertical moment = Mx w a ^3 = 0.019 x 1.2 x 3.2 ^3 = 0.75 TM (Outside face)

Horzt. Moment

Soil Press.

Vert. Moment

Godrej and Boyce

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

G&B-TPC-PNL-IXORA-AEP-CAL - 88 REV R1

Depth of wall required = Sqrt ( M/Q b) c d = 1.77 x 10 2.11 x 1000 = = 91 Provide overall depth = 12 = 250 mm

7

c c c c 0.125 x

c c c

Required Provided d

250 - 40 -

198 mm

Shear due to oil pressure will cause tension in walls and slab. Shear coefficients (Taking Maxm values) for b/a = Sx = 0.500 = = = Table 7 - IS 3370 Part IV Coefficient x w x a^2 0.500 x 1.00 x 2.645 1.10

Tension in wall

2.3

^2

(depth of oil considered)

Area of horzt. steel required = M-Tx / t j d + T/t (For Maxm Values of BM) Horizontal steel outside face Ast1 Ast1 = Ast1 + Ast2

= M-Tx / t j d = = 0.75 x 10 ^7 - 2.65 x 10^4 x 125 130 x 10 0.81 ^7 x 186 212.76 mm2 `

Ast2

= T/t = 2.65 x 10 ^4 130 = 200 mm2 = = Ast1 + Ast2 213 + 199.6

Total Ast

412 mm2

Horizontal steel inside face = Ast1 + Ast2 Ast1 1.77 x 10 ^7 = 130 x 10 ^7 x 186 0.81 = Ast2 = = = = Provide Y 12 @ 906 mm2 3 x 10 ^4 130 203 mm2 Ast1 + Ast2 906 + 203.5 = 1109.2 mm2 `

Total Ast

100 c/c

Ast provided =

1131 mm2 > 1109.2 mm2 OK

Godrej and Boyce

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

G&B-TPC-PNL-IXORA-AEP-CAL - 88 REV R1

Area of Vertical steel required = M / t j d (For Maxm values of BM) Vertical steel (Outside face) Vertical steel (Inside face) Provide Y Provide Y 12 @ 12 @ = 0.75 x 10 ^7 130 x 10 0.81 ^7 x 0.35 x 10 ^7 0.81 ^7 x 130 x 10 = 198 = 198 646 mm2 (Inside face) 646 mm2 (Outside face) (Cl. 7.1 IS 3370 part IV) (10% reduction for HYSD steel) < 4.30 646 OK 161 mm2 359 mm2

175 c/c 175 c/c

Ast provided = Ast provided =

Mimimum steel required 0.3 for 100mm to 0.2% for 450mm For thickness of 250 mm mimimum steel shall be = 0.231 % 0.231 x 250 x 1000 = 100

Minm Area of steel required = Design of top slab. Thick = 150 Loads Span = 4.05 m Self weight Live Load Total Load

2 579 mm

d = 115 mm

= 0.150 x 2.5 = 0.38 T/m2 = 0.5 T/m2 = 0.88 T/m2 1.0 = x = 0.056 Table 26 IS 456

2

Designing as a two way slab for Ly/Lx = Maximum BM

0.056 x 0.88 x 4.05

0.8

TM

Area of steel required = M-Tx / t j d (For Maxm Values of BM) Ast1 required = = x 10 ^7 130 x 10 0.81 ^7 x 667.03 mm2 0.8

115

Total Ast

= =

Ast1 667

= Ast provided =

667.0

mm2 667.0 mm2 OK p= 0.257 %

Provide Y

10 @

100 c/c

785 mm2 > For 150 mm

Provide minm reinforcement in bottom of slab Ast = 0.25 x 1000 x 150 = 386 mm2 100 Provide Y 10 @ 200 c/c Ast provided =

393 mm2 >

386 mm2 OK

Godrej and Boyce

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

G&B-TPC-PNL-IXORA-AEP-CAL - 88 REV R1

Design of base slab. Critical - when tank is full Weight of Roof slab Weight of wall Weight of oil Weight of base slab Total Load Upward pressure Net pressure

250 Thick

d=

205

= 0.15 x 4.30 x = 4 x 4.30 x = 2.3 x 3.80 x = 0.25 x 4.80 x = = = 87.24 T 87.24 / 3.786 4.80 -0.9 x 1.0 =

2

4.30 0.25 3.80 4.80

x 2.5 = x 2.5 3.35 x 0.9 = x 2.5 =

6.93 x 2.5 29.9 14.40

T = 36.01 T T T

= 3.79 T/m2 2.3 0.25 x

(250mm projection on each side) 2.5 = 1.09 T/m2

Designing as a two way slab for Ly/Lx =

x =

0.056

Table 26 IS 456

2

Maximum BM causing tension on liquid side

0.056 x 1.09 x 4.30

= 1.13 TM

Area of steel required = M-Tx / t j d + T/t (For Maxm Values of BM) Ast1 required = = Ast2 1.13 x 10 ^7 - 2.65 x 10^4 x 125 ^7 x 205 0.81 130 x 10 372.17 mm2 = = Total Ast = = Provide Y 10 @ 2.65 x 10 ^4 130 203 mm2 Ast1 + Ast2 203.5 = 575.6 mm2 575.6 mm2 OK p= 0.231 %

372 +

125 c/c

Ast provided =

628 mm2 > For 250 mm

Provide minm reinforcement in bottom of slab Ast = 0.231x 1000 x 100 Provide Y 10 @ 250 = 578 mm2

125 c/c

Ast provided =

628 mm2 >

578 mm2 OK

Godrej and Boyce

You might also like

- Design calculation for a burnt oil pitDocument5 pagesDesign calculation for a burnt oil pitIrshad KhanNo ratings yet

- Burnt Oil Pit r1Document6 pagesBurnt Oil Pit r1Rupesh KhandekarNo ratings yet

- For Detail of Section TB 0 332 316 004Document43 pagesFor Detail of Section TB 0 332 316 004MUKESH KUMARNo ratings yet

- 9m Pole CalculationDocument6 pages9m Pole CalculationPankaj SherwalNo ratings yet

- RCC Bund Wall With Shear KeyDocument27 pagesRCC Bund Wall With Shear Keynhulugalla100% (1)

- SubstationDocument73 pagesSubstationShubham MittalNo ratings yet

- Cable Trench MainDocument17 pagesCable Trench MainAchin Achena100% (6)

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- Transformer Foundation Along With Blast WallDocument11 pagesTransformer Foundation Along With Blast Wallkrmurali2000No ratings yet

- Title: Document/Drawing Approval/Comment Transmital ProjectDocument2 pagesTitle: Document/Drawing Approval/Comment Transmital ProjectPritom AhmedNo ratings yet

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFDocument1 pageRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilNo ratings yet

- Fire Pipe Trench-Doc TemplateDocument63 pagesFire Pipe Trench-Doc TemplateSivaAgathamudiNo ratings yet

- Transformer Soak Pit Design PDFDocument2 pagesTransformer Soak Pit Design PDFevonik123456100% (3)

- DG FoundationDocument4 pagesDG Foundationbollasudarshan100% (2)

- Checklist For Transformer Burnt Oil Tank Design & DrawingDocument3 pagesChecklist For Transformer Burnt Oil Tank Design & DrawingRupesh KhandekarNo ratings yet

- FOUNDATION Blow Down Tank Design CalculationsDocument30 pagesFOUNDATION Blow Down Tank Design CalculationsvasudhaNo ratings yet

- DGS 1482-004 REV 2 - Geotechnical InvestigationDocument13 pagesDGS 1482-004 REV 2 - Geotechnical InvestigationcarloNo ratings yet

- Calculation Sheet For Gantry CPF & Cluster Rev.0 (8015-0151-82-Po-45-0009-9784-S03-12054)Document36 pagesCalculation Sheet For Gantry CPF & Cluster Rev.0 (8015-0151-82-Po-45-0009-9784-S03-12054)tanujaayerNo ratings yet

- 160MVA TRFRFDNDocument23 pages160MVA TRFRFDNSohan Lal JainNo ratings yet

- 8829 SubstationDocument87 pages8829 SubstationUttam Kumar Ghosh100% (3)

- Street Light Poles Indian Standard 2713Document4 pagesStreet Light Poles Indian Standard 2713uddinnadeem100% (1)

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- Car Parking Shade Design ReportDocument28 pagesCar Parking Shade Design Reportsiso hegoNo ratings yet

- Load calculations for EOT crane framesDocument4 pagesLoad calculations for EOT crane framesknight1729No ratings yet

- Cable Trench Design Calculation for 50 MW Solar PlantDocument4 pagesCable Trench Design Calculation for 50 MW Solar PlantAmol ChavanNo ratings yet

- 21-20-21-E Gantry Foundations Calculation & Basic DesignDocument12 pages21-20-21-E Gantry Foundations Calculation & Basic DesignOscar AlcasNo ratings yet

- Transformer Foundation DesignDocument13 pagesTransformer Foundation Designengage4u202067% (3)

- Electrical Cable Trench Structural Design Calculations and AnalysisDocument13 pagesElectrical Cable Trench Structural Design Calculations and AnalysisNimantha Chamil LakmalNo ratings yet

- IDT FoundationDocument15 pagesIDT FoundationARUN RAWATNo ratings yet

- 1.60m Deep-35m Tower Foundation Design 9nov 2019-11.14Document3 pages1.60m Deep-35m Tower Foundation Design 9nov 2019-11.14Harold Jackson MtyanaNo ratings yet

- Trench DesignDocument8 pagesTrench Designprasadnn2001No ratings yet

- 132kv Building - Calculations (R1)Document42 pages132kv Building - Calculations (R1)Vijith29No ratings yet

- Design of Transformer FoundationDocument6 pagesDesign of Transformer FoundationManan MansoorNo ratings yet

- Design of Light Pole FoundationDocument2 pagesDesign of Light Pole Foundationabhinav100% (2)

- Design Calculation of Oc+15 MTR TowerDocument14 pagesDesign Calculation of Oc+15 MTR TowerGuru MishraNo ratings yet

- Transmission Tower DesignDocument48 pagesTransmission Tower DesignTarun SaiNo ratings yet

- Culvert Design Using Staad As Per IrsDocument171 pagesCulvert Design Using Staad As Per IrsTanvir Shahrier MahmudNo ratings yet

- Construction of 33kV Substation at NTPC LaraDocument5 pagesConstruction of 33kV Substation at NTPC LaraIrshad KhanNo ratings yet

- Lighting SLDDocument1 pageLighting SLDParthasarathy SarathyNo ratings yet

- Cable Trench Sections Icb 29 (All Locations)Document1 pageCable Trench Sections Icb 29 (All Locations)Anoop DikshitNo ratings yet

- Design of The PoleDocument7 pagesDesign of The Polevirous08No ratings yet

- 66kv Ha & de Type Tower Foundation DrawidngDocument2 pages66kv Ha & de Type Tower Foundation DrawidngBAWA ALEXNo ratings yet

- QES PEVC-ENG260 - Checklist For Gantry Foundation Design & DrawingDocument2 pagesQES PEVC-ENG260 - Checklist For Gantry Foundation Design & DrawingRupesh KhandekarNo ratings yet

- Load Calculation For LT TransformerDocument6 pagesLoad Calculation For LT TransformerTarun BhatejaNo ratings yet

- 33KV LineDocument138 pages33KV LineSekharmantri SitapatiNo ratings yet

- Foundation plan and section detailsDocument1 pageFoundation plan and section detailssathishNo ratings yet

- 30 MVA Transformer Foundation DesignDocument19 pages30 MVA Transformer Foundation DesignSagun KatuwalNo ratings yet

- Design of Drain Box FoundationDocument16 pagesDesign of Drain Box FoundationGOMASH RCPNo ratings yet

- CABLE TRENCH PadgheDocument25 pagesCABLE TRENCH PadgheAnindit MajumderNo ratings yet

- Transformer Pile Calculations PDFDocument1 pageTransformer Pile Calculations PDFMaienAhasanNo ratings yet

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- Design of Conical Storage TankDocument17 pagesDesign of Conical Storage TankvijaypatelnewtonNo ratings yet

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- RCC design of major bridge abutmentsDocument26 pagesRCC design of major bridge abutmentsshashibhushan singhNo ratings yet

- Design of Grade SlabDocument7 pagesDesign of Grade SlabMUTHUKKUMARAM100% (1)

- Column Wall DesignDocument42 pagesColumn Wall DesignCivilax.comNo ratings yet

- CIS EVA (SideWall) 6320 SDWL 01Document29 pagesCIS EVA (SideWall) 6320 SDWL 01Nasrul AdliNo ratings yet

- Are 12 PDFDocument105 pagesAre 12 PDFIrshad KhanNo ratings yet

- Is 13920 1993Document24 pagesIs 13920 1993structuralengineersNo ratings yet

- Drawings of GIS, SEC-4, GurgaonDocument62 pagesDrawings of GIS, SEC-4, GurgaonIrshad Khan100% (1)

- The Code Corner No. 15Document3 pagesThe Code Corner No. 15Irshad KhanNo ratings yet

- Scanned Docs by CamScanner AppDocument5 pagesScanned Docs by CamScanner AppIrshad KhanNo ratings yet

- Vendor Contact & Bank Details for Alif Engineers and PlannersDocument1 pageVendor Contact & Bank Details for Alif Engineers and PlannersIrshad KhanNo ratings yet

- Code of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsDocument2 pagesCode of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsIrshad KhanNo ratings yet

- Steel ConnectionDocument18 pagesSteel ConnectionIrshad KhanNo ratings yet

- 1367 6 PDFDocument20 pages1367 6 PDFIrshad Khan100% (1)

- Retaining Wall ProposalDocument2 pagesRetaining Wall ProposalIrshad KhanNo ratings yet

- Baseplate t3p 18 07Document3 pagesBaseplate t3p 18 07Irshad KhanNo ratings yet

- M.Raje Structural Consultants Pvt. LTDDocument2 pagesM.Raje Structural Consultants Pvt. LTDIrshad KhanNo ratings yet

- Is 2502 1963Document31 pagesIs 2502 1963Lokesh SharmaNo ratings yet

- Fire Retardant Paint RequirementsDocument2 pagesFire Retardant Paint RequirementsIrshad Khan100% (1)

- Wasim CVDocument2 pagesWasim CVIrshad KhanNo ratings yet

- Revised Foundation For 315 Mva Transformer. 28-10-09 - ModelDocument1 pageRevised Foundation For 315 Mva Transformer. 28-10-09 - ModelIrshad KhanNo ratings yet

- D 800 Cover 40 Bar Dia FCK 50 Fy 500 SDocument2 pagesD 800 Cover 40 Bar Dia FCK 50 Fy 500 SIrshad KhanNo ratings yet

- PortalDocument1 pagePortalIrshad KhanNo ratings yet

- Typical Plinth Protection DetailDocument1 pageTypical Plinth Protection DetailIrshad KhanNo ratings yet

- PortalDocument1 pagePortalIrshad KhanNo ratings yet

- Typical Plinth Protection DetailDocument1 pageTypical Plinth Protection DetailIrshad KhanNo ratings yet

- Civil Specification Vol-IIIDocument266 pagesCivil Specification Vol-IIIIrshad KhanNo ratings yet

- Bot 0001Document1 pageBot 0001Irshad KhanNo ratings yet

- Axially Loaded ColumnsDocument33 pagesAxially Loaded Columnsyunuswsa0% (2)

- Car LiftDocument4 pagesCar LiftIrshad KhanNo ratings yet

- Alif Engineers and Planners ProfileDocument5 pagesAlif Engineers and Planners ProfileIrshad KhanNo ratings yet

- Mixdesign M25Document9 pagesMixdesign M25Irshad KhanNo ratings yet

- COVER Burnt Oil PitDocument1 pageCOVER Burnt Oil PitIrshad KhanNo ratings yet

- Base Plate For Thickness CalculationsDocument7 pagesBase Plate For Thickness CalculationsyunuswsaNo ratings yet

- Dimention of TraffoDocument1 pageDimention of TraffoIrshad KhanNo ratings yet

- 09931372A Clarus 590 User's GuideDocument284 pages09931372A Clarus 590 User's GuideLuz Idalia Ibarra RodriguezNo ratings yet

- TMS320C64xx VLIW DSPDocument23 pagesTMS320C64xx VLIW DSPbibiameenaNo ratings yet

- Architectural Analysis of The National Assembly Building of Bangladesh (Louis Kahn 1961)Document2 pagesArchitectural Analysis of The National Assembly Building of Bangladesh (Louis Kahn 1961)Jenna Bailey86% (7)

- Isotope TutorialDocument6 pagesIsotope Tutorialask4imadeosas9393No ratings yet

- TSIO-550 Operation ManualDocument8 pagesTSIO-550 Operation ManualoscarNo ratings yet

- ElectronicsDocument264 pagesElectronicszamalahmed132No ratings yet

- How-To Guide - A Quick Guide To B2B XCM ConfigurationDocument45 pagesHow-To Guide - A Quick Guide To B2B XCM Configurationrobi_kren0No ratings yet

- Sanitec Intelligent Toilets & E-Bidet FeaturesDocument5 pagesSanitec Intelligent Toilets & E-Bidet FeaturesCHOTIENo ratings yet

- Innovations in Semiochemical FormulationDocument20 pagesInnovations in Semiochemical FormulationgfermatuNo ratings yet

- Hibernate Tutorial 12 Caching ObjectsDocument8 pagesHibernate Tutorial 12 Caching ObjectskantiprasadNo ratings yet

- 5 Antenna Relay Switch Iss 2 Ea5avlDocument2 pages5 Antenna Relay Switch Iss 2 Ea5avlJack RodriguezNo ratings yet

- The Best of PupungDocument3 pagesThe Best of PupungPeter ParkerNo ratings yet

- Charging 5L-EDocument3 pagesCharging 5L-ETedros BelaynehNo ratings yet

- Role of The Quantity SurveyorDocument13 pagesRole of The Quantity SurveyorLokuliyanaNNo ratings yet

- Indian Standard: Mild Steel Wire For General Engineering PurposesDocument7 pagesIndian Standard: Mild Steel Wire For General Engineering PurposesDevendrasinh PadhiyarNo ratings yet

- Steam Turbine Overspeed-Protection Woodward Protech-GIIDocument4 pagesSteam Turbine Overspeed-Protection Woodward Protech-GIIMarioEnriqueAlcocerÁvilaNo ratings yet

- OTC-25163-MS Subsea Wellhead Validation Testing (Dril-Quip)Document21 pagesOTC-25163-MS Subsea Wellhead Validation Testing (Dril-Quip)joNo ratings yet

- KITZ ProductDocument44 pagesKITZ Productkingathur26681No ratings yet

- Chapter 3-PIC IO Port ProgrammingDocument36 pagesChapter 3-PIC IO Port Programmingouterrace67% (3)

- LPG Chapter 09-18Document12 pagesLPG Chapter 09-18DINESH SIVANo ratings yet

- Pin-Fuse Joint FinalDocument10 pagesPin-Fuse Joint FinalShubham BeraNo ratings yet

- Engine Protection Requirements BulletinDocument3 pagesEngine Protection Requirements BulletinjoaoNo ratings yet

- Radiolysis of WaterDocument7 pagesRadiolysis of WaterMoh'd Riyas Rahmaniya0% (1)

- Catalog 201506 PDFDocument75 pagesCatalog 201506 PDFDairo OvalleNo ratings yet

- Watertight Bulkheads Protect Passenger ShipsDocument6 pagesWatertight Bulkheads Protect Passenger Shipsoussama achouriNo ratings yet

- Gama de Perfiles Europeos 1 European SecDocument251 pagesGama de Perfiles Europeos 1 European SecHolman Josue Reyes MoralesNo ratings yet

- En LV Power Supplies For High Altitude Applications Application NoteDocument7 pagesEn LV Power Supplies For High Altitude Applications Application Notejoe blowNo ratings yet

- Sheet MetalDocument75 pagesSheet MetalMalik Shahid SultanNo ratings yet

- Rosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & MunicipalitiesDocument12 pagesRosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & Municipalitiesdiegoh_silvaNo ratings yet

- Economics of Power GenerationDocument22 pagesEconomics of Power Generationbhaskar123321No ratings yet