Professional Documents

Culture Documents

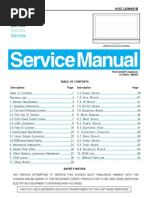

Sony CRT 01 CRTV

Uploaded by

Daniboy1994Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sony CRT 01 CRTV

Uploaded by

Daniboy1994Copyright:

Available Formats

Training Manual

Course: CRT-01

CRT

Troubleshooting

Diagnostics and Troubleshooting

Recommended Troubleshooting & Repairing Guide:

V3.0 LED & LCD TV

Repair Tips ebook

More information on

T-con Board & Mainboard

Secret Repair Tips!

V2.0- LCD TV Repair

Tips & Case Histories

V1.0- Collection of LCD

TV Repair Tips

Vol-3 LCD/LED

Monitor Repair Case

Histories by Jestine

Yong

LCD/LED & 3D TV

Repair Membership Site

Plasma & 3D TV

Repair Membership

Site

Projection TV &

DLP/LCD Projector

Repair Membership Site

Troubleshooting &

Repairing LCD TV

Guide

Plasma TV Repair Guide-

Display Fault

Troubleshooting Basic

LCD TV Repair

Secrets Revealed

LCD Monitor Repair Guide

Vol .1- 10 Trus Repair

Case Histories of LCD

Monitor

SMPS-Switch Mode

Power Supply Repair

Guide

Testing Electronic

Components like a Pro-

For Beginner

Please visit: http://lcd-television-repair.com/newsletter/Recommend.html

Table of Contents

1. Inside the CRT ..................................1

2. Repair Analysis Flowchart .............2

3. CRT Related Symptoms .................4

Spots (black, white, burn, dust); color mixing;

shadows; line kinks................................................ 4

Arcing - popping noise fro the CRT gun; raster

noise; intermittent focus; intermittent

brightness changes ............................................... 4

No picture; sound is present; heater filaments

are on ...................................................................... 4

No color in picture .................................................. 4

Poor convergence; color distortion...................... 5

Geometric distortion.............................................. 5

Entire screen is out of focus ................................. 5

Raster with retrace lines (normal or low

brightness), no video ............................................. 5

Dark or no picture; sound is present, limited

brightness level adjustment ................................... 5

Color contamination or incorrect colors, typically

at the corners.......................................................... 6

No picture, no sound, HV will not turn ON............ 6

4. DEAD Unit Troubleshooting (DEAD

or PIXX) ..................................................7

CRT Causes........................................................... 7

Broken CRT............................................................ 7

5. No Picture or Dark Picture

Troubleshooting (NPIX or PIXS) .......9

Poor Emission, Vacuum ....................................... 9

Short, Hot Short ...................................................... 9

No Heaters ............................................................. 9

6. Arcing, No Color, Intermittent

Picture, Jiter, Raster Only or Retrace

Lines (ARCS, PIXC, PIXI, PICJ,

PIXL) ......................................................11

PIXL, PIXI, PIXK PICC OR ARCS - CRT

Causes................................................................... 11

Collateral Damage Caused by Arcing ................ 12

7. Convergence / Beam Landing

Troubleshooting (PIXD, PIXW) .........14

Overview................................................................ 14

Identifying Convergence / Beam Landing

Problems ............................................................... 14

CRT Caused ......................................................... 14

Non CRT Caused ................................................. 15

Fine Convergence Adjustments .......................... 17

8. Geometric Distortion

(PIXD, PIXW) .........................................25

Overview................................................................ 25

Adjustments ........................................................... 25

Fine Geometric Adjustments ............................... 25

9. Focus Troubleshooting (PIXF).....30

Overview................................................................ 30

CRT Causes.......................................................... 30

Non CRT Causes.................................................. 31

10. Convergence Supplemental

Information ...........................................32

Process.................................................................. 32

Center Adjustments .............................................. 32

H-Stat Adjustment ................................................. 33

Y Axis Adjustments................................................ 34

X Axis Adjustments ............................................... 35

Corner Adjustments .............................................. 37

Appendix

Geometry Adjustment ............................................. i

1

1. AX-1 Chasis PCB I nterconnections and Functional Descriptions

Chapter 1 - Inside the CRT

FIGURE 1-1 - EXPLODED VIEW

SOCKET BASE

APERTURE GRILL

ELECTRON GUN

PHOSPHOR &

CARBON STRIPES

12/5/03 CTR01.1-1

STEM

ECR

FOCUS

IBR R2

R1

G5 G4 G3

RED

CATHODE

GREEN

CATHODE

BLUE

CATHODE

G2 G1

HV

ANODE

FIGURE 1-2 - TOP VIEW OF ELECTRON GUN

CRT01.1-2 12/5/03

2

2. Repair Analysis Flowchart

Chapter 2 - Repair Analysis Flowchart

Repair damaged

part of loose

connections.

At this point,

check for DEAD

set.

Check for visible

damaged parts

or loose

connections

OK

= Set returned to Customer

Yes

No

NG

NG

Age unit

FIGURE 2-1 - ANALYSIS FLOWCHART

12/3/03 CTR01.2-1

TV sent to repair

technician.

Technician to

check the reported

fault

Check for

physical

damage

It is likely to have

caused the

problem

Test TV

Repair using

service bulletin

Age set &

monitor

Yes

No

NG

OK

No

Yes

OK

No

Check for

service

bulletins

Age unit

No

Repair Damage

Yes

Go to next page

Turn set ON to

observe fault or

test set.

NG

3

2. Repair Analysis Flowchart

FIGURE 2-2 - ANALYSIS FLOW (CONTINUED)

12/3/03 CTR01.2-2

No

Yes

CHECK

Heaters

Board voltages

Board connections

Fuses

*Refer to information

sheet

DEAD

No Picture

No Sound

(PIXX)

EIA Code

No Picture

Dark Raster

(NPIX, PIXS)

EIA Code

Will set turn on?

Step 1

Is bright Raster

visible?

Step 2

CHECK

Heaters

Board voltages

Board connections

*Refer to information

sheet

No

CHECK

Board voltages

Board connections

Ground connections

*Refer to information

sheet

Picture Condition:

Noisy

Intermittently turns off

Black & white only

No video

Step 3

Raster only

Intermittent picture

Jitter - Jumping

No color

Arcing

EIA Code

Yes

Yes

CHECK

Focus

Landing

Convergence

Geometry

*Refer to information

sheet

CHECK

Spots, scatches

Color spots

Shadows, lines, etc.

*Refer to information

sheet

Is picture quality

poor?

Step 4

Yes

No

Is there a flaw on

outside surface of

inside of the screen?

Step 5

CRT blemish,

Physical

damage

(APPR)

(DAMG)

EIA Code

Picture distorted

Picture noisy

Out of focus

Poor color

Wrong color

(PIXD) (PIXF)

(PIXW)

EIA Code

No

4

3. CRT Related Symptoms

Chapter 3 - CRT Related Symptoms

Spots (black, white, burn, dust); color mixing; shadows; line kinks

Cause:

Flaw on or behind phosphor affecting the overall appearance of the picture.

EIA Code: APPR

EIA Description: Appearance defect

CTV Description: Visual defect

Arcing - popping noise from the CRT gun; raster noise; intermittent focus;

intermittent brightness changes

Cause:

Current leak, stray electrons. Particles in the electron gun cause intermittent current leakage between

elements.

EIA Code: ARCS; PIXI; PIXJ

EIA Description: Arcing; Intermittent picture; Jittery/unstable picture

CTV Description: Arcing; Short

No picture; sound is present, heater filaments are ON

Cause:

Cathode emission; short; low vacuum. The cathode emission may be weak; grids may be shorted; may be

intermittent or consistent.

EIA Code: NPIX

EIA Description: No picture

CTV Description: White balance, short

No color in picture

Cause:

CRT short at cathode or grids causing a defect in B board (video drive).

EIA Code: PIXC

EIA Description: No color in picture

CTV Description: Short

5

3. CRT Related Symptoms

Poor convergence; color distortion

Cause:

CRT gun is not perpendicular to the CRT face - physical damage; internal IBR resistor is damaged. Color

distortion may consist of colored shadows in the picture.

EIA Code: PIXD

EIA Description: Picture distorted/noisy

CTV Description: Convergence

Geometric distortion

Cause:

CRT gun is not perpendicular to the CRT face - physical damage; internal IBR resistor is damaged.

EIA Code: PIXD

EIA Description: Picture distorted/noisy

CTV Description: Geometric

Entire screen is out of focus

Cause:

Leak current between G-3 and G-4. This may be constant or intermittent.

EIA Code: PIXF

EIA Description: Picture out of focus

CTV Description: Focus

Raster with retrace lines (normal or low brightness), no video

Cause:

Short between grids (typically G1 and G2). G2 drive circuit may become damaged.

EIA Code: PIXL

EIA Description: Raster is present, but no picture

CTV Description: Short

Dark or no picture, sound is present, limited brightness level adjustment

Cause:

Poor emission due to shorted grids or vacuum leak. Sound is present, but the picture is weak or cannot be

seen.

EIA Code: PIXS

EIA Description: Dark picture

CTV Description: White balance

6

3. CRT Related Symptoms

Color contamination or incorrect colors, typically at the corners.

Cause:

Purity beam landing; DY ring magnets; CRT magnets; degauss defective

EIA Code: PIXW

EIA Description: Poor or incorrect color

CTV Description: Landing

Symptom/Cause: Mislanding, purity shift

No picture, no sound. HV will not turn ON.

Cause:

Vacuum leak; broken neck; frit leak; open filament heaters. Main fuse may be blown.

EIA Code: PIXX, DEAD

EIA Description: No picture, no sound

CTV Description: Broken CRT, open heaters

7

4. DEAD Unit Troubleshooting (DEAD or PI XX)

Chapter 4 - DEAD Unit Troubleshooting (DEAD or PIXX)

CRT Causes

No Heaters

Turn the power ON and visually check the heaters.

FIGURE 4-1

FIGURE 4-2

Broken CRT

Look for damage to the neck of body of the CRT.

FIGURE 4-3 - BROKEN CRT

8

4. DEAD Unit Troubleshooting (DEAD or PI XX)

Table 4-1 DEAD Unit (DEAD, PIXX)

Possible causes other than the CRT

Symptom CHECK ITEMS COUNTER MEASURE

Power cord plugged in /

Power on ?

Plug in / Turn power on

Fuse Change fuse

Anode cap position Connect anode cap securely if off

Check G2 level If too high (2 flash OCP), lower H-

out may be defective. If too low (5

flash AKB) will occur. Adjust for

correct level.

Check B+ voltage Check for short circuit to GND.

AE-5A may be low H-out (2 flash

OCP). Power IC problem. The

fuse may be broken replace

fuse.

Check FBT soldering

connection

Re-solder bad connection.

Check for crack board near

FBT

Replace board

Check M board connection Secure M board, insert correctly.

Check service bulletin

information

Implement fix as per bulletin.

No Picture / No

Power

Check DY connection Check if DY connector is inserted

into the board correctly.

9

5. No Picture or Dark Picture Troubleshooting (NPI X or PI XS)

Chapter 5 - No Picture or Dark Picture

Troubleshooting (NPIX or PIXS)

Poor Emission, Vacuum

Adjust the Cathode drive and G-2 level and check for brightness changes.

Short, Hot Short

With CRT socket off, check each CRT pin for a short with another pin. (Note: G-1 and heaters have multiple

pins.)

Heat expansion may cause hot shorts. For hot shorts, turn the set on, wait until problem occurs, then quickly

shut down and check for shorts.

No Heaters

Turn the power ON and visually check the filament heaters for glow

FIGURE 5-1

HEATER NO

GOOD

FIGURE 5-2

12/5/03 CTR01.5-2

HEATER OK

10

5. No Picture or Dark Picture Troubleshooting (NPI X or PI XS)

Table 5-1 No Picture or Dark Picture (NPIX or PIXS)

Possible causes other than the CRT

Symptom CHECK ITEMS COUNTER MEASURE

No Picture Voltages to each electron gun. Trace back to power source for

the cause.

Video drive circuit. Replace IC.

Check if anode cap is on. Connect the anode cap securely.

C board: may be loose or off.

(Normally a 5 flash AKB error)

Attach the C board properly.

Filament heater. Heater voltage

should be about 6.3 Vrms (Sound

should work).

Trace cause of missing heater

voltage and repair.

G2 voltage. (2 flash OCP or 5

flash AKB error)

If too high, lower H-out may be

broken (2 flash OCP error). If too

low, 5 flash AKB error will occur.

Readjust.

B+ voltage Repair short circuit to GND. AE-

5A may be low H-out (2 flash

OCP). Power IC problem. Broken

/ blown fuse. Repair

FBT mounting Repair / re-solder bad connection.

FBT circuit - cracked board Replace board.

M board connection Secure M board, insert properly.

DY connector insertion Reconnect DY properly

Check service bulletin information Implement fix as per bulletin.

11

6. Arcing, No Color, I ntermittent Picture, J itter, Raster Only or Retrace Lines

Chapter 6 - Arcing, No Color, Intermittent Picture,

Jitter, Raster Only or Retrace Lines

(ARCS, PIXC, PIXI, PIXJ, PIXL)

PIXL, PIXI, PIXJ, PICC or ARCS CRT Causes

Four causes may produce above symptoms and all are related to current flow between electron gun elements.

1. Internal Arcing (Popping sound)

Cause:

Current discharge from a high voltage potential to ground or to low voltage potential.

Arcing can occur when foreign particles as small as 2mm are present in the CRT gun. Factors for arcing are:

voltage potential differences between the electrodes; distances between the electrodes; shape, size and

location of the particles.

High

Low

Space between Electrode ~2mm

Dust, burr ~2mm in height

(+)

(-)

Neck Glass

FIGURE 6-1

12/5/03 CTR01.6-1

Round-shaped dust

Pin-shaped dust

High

Low

12/5/03 CTR01.6-2 FIGURE 6-2

Occasionally, arcing occurs between the cathodes, causing emission problems.

2. Stray Electrons

Cause:

As a result of cold emissions, electrons flow from

a lower electric potential of the gun to a higher

potential of the gun in areas that they would not

otherwise normally flow.

Cold Emission occurs when an electron flow is

induced by a strong electric field between two

parallel electrodes.

Voltage : V

d

Electric Field : F

FIGURE 6-3

12

6. Arcing, No Color, I ntermittent Picture, J itter, Raster Only or Retrace Lines

3. External Leaks

Cause:

These leaks occur between the CRT pins on the CRT socket and are caused by external contamination on

the socket between the pins or by insufficient RTV.

Solution:

Clean socket and apply RTV compound in areas shown.

4. Shorts

Cause:

A complete short between two grids. It may be internal, usually caused by physical damage or mishandling;

or external, caused by contamination or shorted wires.

Collateral Damage Caused by Arcing

Semiconductor Damage

Arcing can damage semiconductors.

Surface Burn Spots

When stray electrons occur in the neck area, areas of the screen can remain illuminated after deflection has

ceased and cause CRT burn marks.

Focus Shift

A resistor divider normally supplies G4 voltage. When stray current flow occurs, the excessive current flow

through the resistor can change its value, causing focus changes.

Brightness and White Balance Changes

On some units a resistor divider supplies G2 voltage. When stray current flows from G2, the excessive current

flow through resistor can change its value, causing brightness level changes on direct view units and white

balance changes on projection units.

On some units, this can also occur from G1, with similar results.

Horizontal Static Misconvergence (HME)

Stray current from G1, G2 and G4 or from the internal CRT wall may hit the C plate and flow through the IBRs C

terminal, causing a potential change on this terminal and horizontal static misconvergence.

IBR Resistance Change

Stray electrons flowing through the IBR and ions bombarding the IBR directly can cause a temperature

rise in the IBR, changing its value. This causes the horizontal static convergence to gradually shift with

use.

13

6. Arcing, No Color, I ntermittent Picture, J itter, Raster Only or Retrace Lines

Table 6-1 Causes other than the CRT

PROBLEM CHECK ITEMS COUNTER MEASURE

Open ground connections Reconnect if loose.

HV leaks around anode cap. Clean anode / area. Apply sealer

(if required).

Arcing

Arcing / leakage at socket pins. Apply RTV G4 and IBR pins.

No color in

picture

Check video drive circuit. Repair IC.

Check connections on the boards. Reconnect loose connections.

Check for cracked circuit boards. May be intermittent contact.

Replace board.

Intermittent or

jittery picture

Check for cold soldering Resolder the bad connection.

Check G-2 drive circuit. Overdriving will produce retrace

Replace the defective part /

readjust

Raster only, no

picture.

Retrace lines

Check Video drive circuit. Repair IC

14

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

Chapter 7 - Convergence / Beam Landing

Troubleshooting (PIXD, PIXW)

Overview

Incorrect colors can be caused either by 1) incorrect beam landing (purity) that is one or more beams do land

on their respective color phosphor stripe, or by 2) incorrect convergence that is the R, G, B beams are not

superimposed over each other.

Identifying Convergence / Beam Landing Problems

Beam Landing

Poor beam landing is visible as a discoloration whenever there

is a raster on the screen. In can be of any size and in any location

on the screen. An example is shown in figure 7-1.

FIGURE 7-1

Convergence

The three beams produced by the CRT electron gun must be

superimposed and converge on the same spot on the CRT face.

A poorly converged unit will have discolorations at either

horizontal or vertical areas of the picture. It will not occur in solid parts of the picture. An example of poor

horizontal and vertical convergence is shown in Figure 7-2.

FIGURE 7-2

12/5/03 CTR01.7-2

CRT Caused

H-static Drift

The most common cause of color convergence problems attributable to the CRT is h-static drift caused by a

change of the IBR resistor value. This occurs after a unit has been placed in service.

Stray current inside the electron gun, or arcing, can change the IBR resistor value. If this occurred, H-static in the

center of the CRT will still be adjustable. The drift may stabilize after a period and further adjustment or CRT

replacement may not be necessary.

15

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

Aging

Slight convergence drifts due to aging if the CRT may cause slight convergence drifts. The drift may be small and

within tolerances, or may be large.

Magnetization

External environmental magnetization can magnetize the CRT over time so and create a purity problem.

Customer Dissatisfaction

The unit may be within acceptable limits but the customer may not be satisfied. This issue is more subjective

than an actual problem and may require customer counseling, circuit touchups, or Sony Customer Service

intervention.

Solutions

1. In all instances, fine adjustments to the CRT and circuits are the first steps to take to satisfy the

customer.

When appropriate, steps should include, external degaussing, circuit adjustments, DY ring adjustments,

CRT magnet replacements, and permalloy strip replacements.

2. Replace the deflection yoke if step 1 does not yield satisfactory results. It usually has the same effect

as replacing the CRT.

3. Replace the CRT if steps 1 and 2 do not yield satisfactory results. Consult with your Sony Technical

representative before replacing a CRT if the unit is within acceptable limits and the customer is still

dissatisfied.

CRT Aperture Grill

An aperture grill that has shifted off its frame causes the symptom shown

in Figure 7-3. The unit being dropped usually causes this. Check for

other physical damage to unit or packaging to confirm. Replace the CRT.

FIGURE 7-3

12/5/03 CTR01.7-3

Non CRT Caused

Beam Landing (Purity M/L)

The beam landing discolorations are usually caused by either a

magnetized CRT aperture grill or by external magnetic forces near

the CRT that affects the CRT beam. The most common external items

are:

Set Stand

If the set is on an iron or steel stand, take it off the stand. Discoloration

will usually occur on the bottom of the screen. See Figure 7-4.

If M/L disappears, inform customer of the need to change stand. If

home service, add B/L magnet.

If still M/L still exists, take off existing landing magnets on the

effected corner and add new magnets to improve landing. Check

landing, see Note 2.

Set Location

Check If set is on the floor or near building beams/posts. Move set to

different location and recheck.

If M/L disappears, inform customer to change location of set. If

home service, add magnet.

FIGURE 7-4

FIGURE 7-5

16

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

If M/L still exists, take off existing landing magnets on the effected

corner. Add new magnets to improve landing.

DY Adjustment

Adjust 2-pole purity ring magnets on DY slightly.

DY Position

Check for loose DY, especially If M/L is extreme and concentrated on

the right/left sides rather than at corners. See Figure 7-6. If DY is

loose, slide DY forward or backward to improve landing and tighten.

see Note 2.

Degauss Circuit

See Figures 7-7 and 7-8.

Switch unit off for 15 minutes (minimum). Turn on again and check if

degauss is working by sound and vibration. If not working, repair

degauss circuit (Check connector).

Weak L/D Magnets

These can occur in any screen edge or corner. See Figure 7-8.

Remove L/D magnets and replace with new one on the effected corner.

Readjust.

FIGURE 7-6

FIGURE 7-7

FIGURE 7-8

17

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

Fine Convergence Adjustments

The following tables show the fine convergence adjustments, by model number

MODEL

H STAT

V STAT H-AMP = APH

KV29S90, KV 21SE43C H-STAT

knob RV-

701

4 pole

VSTAT

MAGNET

6 pole BMC

MAGNET &

NECK ASSY

KV13FS100, KV13FS110, KV14FV300,

KV20FS100, KV20FV300, KV21FM100,

KV21FS100, KV21FV300, KV24FV300,

KV25FV300, KV24FS100, KV25FS100

H-STATE

knob RV-

1750

4 pole

VSTAT

MAGNET

6 pole BMC

MAGNET &

NECK ASSY

KV25FS12, KV25FS12C, KV27FS100,

KV27FS13, KV27FS17, KV27FS200,

KV27FV17, KV27FV300, KV29FV300,

KV32FS13, KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C, KV34FS17,

KV32FS100, KV32FS200, KV32FV300,

KV34FS100, KV36FS100, KV36FS200,

KV36FV300, KV38FS200

H-STAT

knob RV-

701

4 pole

VSTAT

MAGNET

6 pole BMC

MAGNET &

NECK ASSY

KV32FV27, KV36FS13, KV36FS17,

KV36FV27, KV38FS17

H-STAT

knob RV-

1761

4 pole

VSTAT

MAGNET

6 pole BMC

MAGNET &

NECK ASSY

KV34XBR2, KV32HS20, KV32XBR450,

KV36HS20, KV36HS20H, KV36XBR450,

KV36XBR450H

H-STAT

knob

(RV9001)

4 pole

VSTAT

MAGNET

6 pole BMC

MAGNET,

NECK ASSY &

BUS RSAP,

LSAP

KV34XBR800, KV34DRC500, KV32HS500,

KV32HV600, KV36HS500, KV35XBR800,

KV38DRC500, KV40XBR800,

KV42DRC800

H-STAT

knob

(RV9001)

4 pole

VSTAT

MAGNET

6 pole BMC

MAGNET,

NECK ASSY &

BUS RSAP,

LSAP

Table 7-1A Convergence Adjustments

18

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

HCR

V-AMP =

APV

VCR

KV29S90, KV 21SE43C 6 pole BMC

MAGNET

4 pole

VSTAT

MAGNET

6 pole

BMC

MAGNET

KV13FS100, KV13FS110, KV14FV300,

KV20FS100, KV20FV300, KV21FM100,

KV21FS100, KV21FV300, KV24FV300,

KV25FV300, KV24FS100, KV25FS100

6 pole BMC

MAGNET

4 pole

VSTAT

MAGNET

6 pole

BMC

MAGNET

KV25FS12, KV25FS12C, KV27FS100,

KV27FS13, KV27FS17, KV27FS200,

KV27FV17, KV27FV300, KV29FV300,

KV32FS13, KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C, KV34FS17,

KV32FS100, KV32FS200, KV32FV300,

KV34FS100, KV36FS100, KV36FS200,

KV36FV300, KV38FS200

6 pole BMC

MAGNET

4 pole

VSTAT

MAGNET

6 pole

BMC

MAGNET

KV32FV27, KV36FS13, KV36FS17,

KV36FV27, KV38FS17

6 pole BMC

MAGNET

4 pole

VSTAT

MAGNET

6 pole

BMC

MAGNET

KV34XBR2, KV32HS20, KV32XBR450,

KV36HS20, KV36HS20H, KV36XBR450,

KV36XBR450H

6 pole BMC

MAGNET,

NECK ASSY &

BUS RSAP,

LSAP

4 pole

VSTAT

MAGNET

6 pole

BMC

MAGNET

KV34XBR800, KV34DRC500, KV32HS500,

KV32HV600, KV36HS500, KV35XBR800,

KV38DRC500, KV40XBR800,

KV42DRC800

6 pole BMC

MAGNET,

NECK ASSY &

BUS RSAP,

LSAP

4 pole

VSTAT

MAGNET

6 pole

BMC

MAGNET

Table 7-1B Convergence Adjustments

MODEL

19

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

MODEL

H-TILT = TLH

V-TILT = TLV X CROSS - = XCV

KV29S90, KV 21SE43C DY tilt DY tilt No Adjustment

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300,

KV24FS100, KV25FS100

TLH PLATE TLV VR DY & XCV CORE

KV25FS12, KV25FS12C,

KV27FS100, KV27FS13,

KV27FS17, KV27FS200,

KV27FV17, KV27FV300,

KV29FV300, KV32FS13,

KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C,

KV34FS17, KV32FS100,

KV32FS200, KV32FV300,

KV34FS100, KV36FS100,

KV36FS200, KV36FV300,

KV38FS200

TLH PLATE TLV VR DY & XCV CORE

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS17

TLH PLATE TLV VR DY & XCV CORE

KV34XBR2, KV32HS20,

KV32XBR450, KV36HS20,

KV36HS20H, KV36XBR450,

KV36XBR450H

TLH PLATE &

BUS RSAP,

LSAP

TLV VR DY & XCV CORE

KV34XBR800, KV34DRC500,

KV32HS500, KV32HV600,

KV36HS500, KV35XBR800,

KV38DRC500, KV40XBR800,

KV42DRC800

TLH PLATE &

BUS RSAP,

LSAP

TLV VR DY & XCV CORE

Table 7-1C Convergence Adjustments

20

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

MODEL

C CROSS = CCV

CQV M CROSS = MVC

KV29S90, KV 21SE43C No adjustment 6 pole & 4 pole

balance

4 pole balance

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300,

KV24FS100, KV25FS100

DY & XCV

CORE

6 pole & 4 pole

balance

XCV CORE & 4 pole

balance

KV25FS12, KV25FS12C,

KV27FS100, KV27FS13,

KV27FS17, KV27FS200,

KV27FV17, KV27FV300,

KV29FV300, KV32FS13,

KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C,

KV34FS17, KV32FS100,

KV32FS200, KV32FV300,

KV34FS100, KV36FS100,

KV36FS200, KV36FV300,

KV38FS200

DY & XCV

CORE

6 pole & 4 pole

balance

XCV CORE & 4 pole

balance

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS17

DY & XCV

CORE

6 pole & 4 pole

balance

XCV CORE & 4 pole

balance

KV34XBR2, KV32HS20,

KV32XBR450, KV36HS20,

KV36HS20H, KV36XBR450,

KV36XBR450H

DY & XCV

CORE

6 pole & 4 pole

balance

XCV CORE & 4 pole

balance

KV34XBR800,

KV34DRC500, KV32HS500,

KV32HV600, KV36HS500,

KV35XBR800,

KV38DRC500,

KV40XBR800,

KV42DRC800

DY & XCV

CORE

6 pole & 4 pole

balance

XCV CORE & 4 pole

balance

Table 7-1D Convergence Adjustments

21

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

MODEL Y CROSS =

YCH

C CROSS =

CCH

CHH

KV29S90, KV 21SE43C DY tilt DY tilt No adjustment

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300,

KV24FS100, KV25FS100

DY & YCH

reactor

DY & YCH

reactor

No adjustment

KV25FS12, KV25FS12C,

KV27FS100, KV27FS13,

KV27FS17, KV27FS200,

KV27FV17, KV27FV300,

KV29FV300, KV32FS13,

KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C,

KV34FS17, KV32FS100,

KV32FS200, KV32FV300,

KV34FS100, KV36FS100,

KV36FS200, KV36FV300,

KV38FS200

DY & YCH

reactor

DY & YCH

reactor

No adjustment

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS17

DY & YCH

reactor

DY & YCH

reactor

No adjustment

KV34XBR2, KV32HS20,

KV32XBR450, KV36HS20,

KV36HS20H, KV36XBR450,

KV36XBR450H

Bus YBWU,

YBWL

Bus RUBW,

RLBW, LUBW,

LLBW

Bus RUBW, RLBW,

LUBW, LLBW

KV34XBR800,

KV34DRC500, KV32HS500,

KV32HV600, KV36HS500,

KV35XBR800,

KV38DRC500,

KV40XBR800,

KV42DRC800

Bus YBWU,

YBWL

Bus RUBW,

RUMB, RLBW,

RLMB, LUBW,

LUMB, LLBW,

LLMB

Bus RUBW, RUMB,

RLBW, LUBW,

LUMB, LLBW, LLMB

Table 7-1E Convergence Adjustments

22

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

MODEL

Y BOW = YBH

C BOW = CBH X BOW XBV

KV29S90, KV 21SE43C H-Static

balance

H-Static

balance

4 pole balance

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300,

KV24FS100, KV25FS100

H-Static

balance

H-Static

balance

4 pole balance

KV25FS12, KV25FS12C,

KV27FS100, KV27FS13,

KV27FS17, KV27FS200,

KV27FV17, KV27FV300,

KV29FV300, KV32FS13,

KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C,

KV34FS17, KV32FS100,

KV32FS200, KV32FV300,

KV34FS100, KV36FS100,

KV36FS200, KV36FV300,

KV38FS200

H-Static

balance

H-Static

balance

4 pole balance

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS17

H-Static

balance

H-Static

balance

4 pole balance

KV34XBR2, KV32HS20,

KV32XBR450, KV36HS20,

KV36HS20H, KV36XBR450,

KV36XBR450H

Bus YBWU,

YBWL

Bus RUBW,

RLBW, LUBW,

LLBW

4 pole balance

KV34XBR800,

KV34DRC500, KV32HS500,

KV32HV600, KV36HS500,

KV35XBR800,

KV38DRC500,

KV40XBR800, KV42DRC800

Bus YBWU,

YBWL

Bus RUBW,

RUMB, RLBW,

RLMB, LUBW,

LUMB, LLBW,

LLMB

4 pole balance

Table 7-1F Convergence Adjustments

23

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

MODEL

C BOW = CBV

CHCR MBH

KV29S90, KV 21SE43C 4 pole balance 4 pole & 6 pole

balance

4 pole & 6 pole

balance

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300,

KV24FS100, KV25FS100

4 pole & TLV

balance

4 pole & 6 pole

balance

4 pole & 6 pole

balance & TLH &

APH

KV25FS12, KV25FS12C,

KV27FS100, KV27FS13,

KV27FS17, KV27FS200,

KV27FV17, KV27FV300,

KV29FV300, KV32FS13,

KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C,

KV34FS17, KV32FS100,

KV32FS200, KV32FV300,

KV34FS100, KV36FS100,

KV36FS200, KV36FV300,

KV38FS200

4 pole & TLV

balance

4 pole & 6 pole

balance

4 pole & 6 pole

balance & TLH &

APH

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS17

4 pole & TLV

balance

4 pole & 6 pole

balance

4 pole & 6 pole

balance & TLH &

APH

KV34XBR2, KV32HS20,

KV32XBR450, KV36HS20,

KV36HS20H, KV36XBR450,

KV36XBR450H

4 pole & TLV

balance

Bus RUBW,

RLBW, LUBW,

LLBW

4 pole & 6 pole

balance & TLH &

APH

KV34XBR800,

KV34DRC500, KV32HS500,

KV32HV600, KV36HS500,

KV35XBR800,

KV38DRC500,

KV40XBR800,

KV42DRC800

4 pole & TLV

balance

Bus RUBW,

RUMB, RLBW,

RLMB, LUBW,

LUMB, LLBW,

LLMB

4 pole & 6 pole

balance & TLH &

APH & Bus RUMB,

RLMB, LUMB LLMB

Table 7-1G Convergence Adjustments

24

7. Convergence / Beam Landing Troubleshooting (PI XD, PI XW)

MODEL

CVCR

CSV MSV

KV29S90, KV 21SE43C 4 pole & 6 pole

balance

4 pole balance 4 pole balance

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300,

KV24FS100, KV25FS100

4 pole & 6 pole

balance

4 pole & TLV

balance

4 pole & TLV

balance

KV25FS12, KV25FS12C,

KV27FS100, KV27FS13,

KV27FS17, KV27FS200,

KV27FV17, KV27FV300,

KV29FV300, KV32FS13,

KV32FS17, KV29FV17,

KV29FV17C, KV34FS13C,

KV34FS17, KV32FS100,

KV32FS200, KV32FV300,

KV34FS100, KV36FS100,

KV36FS200, KV36FV300,

KV38FS200

4 pole & 6 pole

balance

4 pole & TLV

balance

4 pole & TLV

balance

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS17

4 pole & 6 pole

balance

4 pole & TLV

balance

4 pole & TLV

balance

KV34XBR2, KV32HS20,

KV32XBR450, KV36HS20,

KV36HS20H, KV36XBR450,

KV36XBR450H

4 pole & 6 pole

balance

4 pole & TLV

balance

4 pole & TLV

balance

KV34XBR800,

KV34DRC500, KV32HS500,

KV32HV600, KV36HS500,

KV35XBR800,

KV38DRC500,

KV40XBR800, KV42DRC800

4 pole & 6 pole

balance

4 pole & TLV

balance

4 pole & TLV

balance

Table 7-1H Convergence Adjustments

Note 1: CRT Beam Landing adjustment tool (9-948-310-60) works effectively for Landing adjustment.

Note 2: Landing adjustment and inspection direction

Adjustment Direction: Face unit in an east or west direction (this creates a stronger geo-magnetic effect on the

CRT)

Check Unit Direction: Set should turn to North and South, then degauss and check landing.

A minimum check of three directions is needed (east or west, and north and south).

25

8. Geometric Distortion (PI XD, PI XW)

Chapter 8 - Geometric Distortion (PIXD, PIXW)

Overview

In simple terms, geometric distortion causes straight lines appear angled, crooked, bent, too short, or too long

The most common causes geometric distortion are slight drifts caused by aging, fine circuit adjustment drift and

customer dissatisfaction with acceptable limits.

1. In both instances, fine adjustments to the geometric control circuits are the first steps to take to satisfy the

customer.

2. Readjust the DY tilt slightly

3. Replace the deflection yoke if step 1 does not yield satisfactory results. It usually has the same effect as

replacing the CRT.

4. Replace the CRT if steps 1, 2 and 3 do not yield satisfactory results. But note: geometric distortion is not

likely to be caused by a CRT.

Adjustments

Table 8-1 shows the most common generic geometric distortions and what to adjust to correct the distortion.

PROBLEM CHECK ITEMS COUNTERMEASURE

CORNER BEND

L/D magnet position is too

close to DY.

Take the magnet off, then readjust. The best position is around DY on the CRT carbon

coating edge. Check visual L/D.

DY DY

If the corner still bends, adjust the data register for Corner Pin.

Check Permalloy Quantity

Take off Permally and readjust. Check the Convergence again.

PATTERN KINK

Check Bus data

Adjust DY up and down to improve. Touch up Y Axis magnet to share top, middle and

bottom.

V-PIN

Check if DY is down. Pull up DY to improve

Y Axis Correction Magnet

Adjust data register for Trapezoid. V-TRAPEZOID

Bus Data

Adjust data register for Corner Bend.

Bus Data

DY Swing

Adjust data register for H-Trapezoid. Move DY left and right, then fix the DY wedge.

H-TRAPEZOID

TLV VR on the DY (H-Trap) Adjust the TLV VR a little bit. Last option.

TILT

Picture Tilt

Adjust Manual Picture Rotation Menu (Circuit).

If it is still tilted, readjust DY the tilt. (Before adjustment, the rotation menu should be

set to 0.)

Table 8-1 Geometric Adjustments

26

8. Geometric Distortion (PI XD, PI XW)

Fine Geometric adjustments

The following four tables show the geometric circuits to adjust, by model number.

MODEL

GROUP

V

CENTER

V SIZE

H

CENTER

H SIZE

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300

DEF Bus

VPOS

Bus

VSIZ

Bus

HPOS

Bus

HSIZ

KV20S90, KV21SE43C DEF Bus

VPOS

Bus

VSIZ

Bus

HPOS

Bus

HSIZ

KV24FS100, KV25FS100 DEF Bus

VPOS

Bus

VSIZ

Bus

HPOS

Bus

HSIZ

KV25FS12, KV25FS12C DEF Bus

VPOS

Bus

VSIZ

Bus

HPOS

Bus

HSIZ

KV27FS12, KV27FS17, KV27FV17,

KV29FS13, KV29FV17,

KV29FS13C, KV29FV17C,

KV32FS13, KV32FS17,

KV24FS13C, KV24FS17

DEF Bus

VPOS

Bus

VSIZ

Bus

HPOS

Bus

HSIZ

KV32FV27, KV36FS13, KV36FS17,

KV36FV27, KV38FS16

VP Bus

VPOS

Bus

VSIZ

Bus

HPOS

Bus

HSIZ

KV27FS100, KV27FS200,

VK29FS100, KV32FS100,

KV32FS200, KV34FS100,

KV27FV300, KV29FV300,

KV32FV300, KV36FV300,

KV36FS100, KV36FS200,

KV38FS200

VP1 Bus

VPOS

Bus

VSIZ

Bus

HPOS

Bus

HSIZ

KD34XBR2, KV32HS20,

KV36HS20, KV36HS20H,

KV32XBR450, KV36XBR450,

KV36XXBR450H, KV32HS500,

KV32HV600, KV34DRC500,

KV34XBR800, KV36HS500,

KV36XBR800, KV38DRC500,

KV40XBR800, KV40DRC800

CXA2150D-

1 & 2

2170D-1 &

2

Bus

VPOS

Bus

VSIZ

Bus

HPOS,

HCNT

Bus

HSIZ

Table 8-2 A Geometric Adjustments

27

8. Geometric Distortion (PI XD, PI XW)

Table 8-2 B Geometric Adjustments

MODEL GROUP ROTATION V-

CENTER

V-PIN V

ANGLE

V BOW

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300

DEF DY & User

control

DY TILT No

adjustmen

t

Bus

VANG

Bus

VBOW

KV20S90, KV21SE43C DEF DY ROTATION DY TITLE

& Y

magnet

No

adjustmen

t

Bus

VANG

Bus

VBOW

KV24FS100, KV25FS100 DEF DY & User

control

DY & Y

magnet

No

adjustmen

t

Bus

VANG

Bus

VBOW

KV25FS12, KV25FS12C DEF DY & User

control

DY & Y

magnet

No

adjustmen

t

Bus

VANG

Bus

VBOW

KV27FS12, KV27FS17,

KV27FV17, KV29FS13,

KV29FV17, KV29FS13C,

KV29FV17C, KV32FS13,

KV32FS17, KV24FS13C,

KV24FS17

DEFL DY & User

control

DY & Y

magnet

No

adjustmen

t

Bus

VANG

Bus

VBOW

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS16

VP DY Rotation &

TILT

CORRECTION

MENU

DY & Y

magnet

No

adjustmen

t

Bus

VANG

Bus

VBOW &

Y-

MAGNET

KV27FS100, KV27FS200,

VK29FS100, KV32FS100,

KV32FS200, KV34FS100,

KV27FV300, KV29FV300,

KV32FV300, KV36FV300,

KV36FS100, KV36FS200,

KV38FS200

VP1 DY Rotation &

TILT

CORRECTION

MENU

DY & Y

magnet

No

adjustmen

t

Bus

VANG

Bus

VBOW &

Y-

MAGNET

KD34XBR2, KV32HS20,

KV36HS20, KV36HS20H,

KV32XBR450,

KV36XBR450,

KV36XXBR450H,

KV32HS500, KV32HV600,

KV34DRC500,

KV34XBR800, KV36HS500,

KV36XBR800,

KV38DRC500,

KV40XBR800,

KV40DRC800

CXA2150D-

1 & 2

2170D-1 &

2

DY Rotation &

TILT

CORRECTION

MENU, Bus

NSCO

DY & Bus

VCEN

Bus VPIN Bus

VANG,

LANG

Bus

VBOW,

LANG

28

8. Geometric Distortion (PI XD, PI XW)

MODEL

GROUP

PIN

AMP

KEYSTONE

S

CORRECTION

V LINEARITY

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300

DEF Bus

PAMP

Bus TRAP Bus SCOR Bus VLIN

KV20S90, KV21SE43C DEF Bus

PAMP,

CPIN

Bus TRAP Bus SCOR Bus VLIN

KV24FS100, KV25FS100 DEF Bus

PAMP

Bus TRAP Bus SCOR Bus VLIN

KV25FS12, KV25FS12C DEF Bus

PAMP

Bus TRAP Bus SCOR Bus VLIN

KV27FS12, KV27FS17,

KV27FV17, KV29FS13,

KV29FV17, KV29FS13C,

KV29FV17C, KV32FS13,

KV32FS17, KV24FS13C,

KV24FS17

DEFL Bus

PAMP

Bus HTRP Bus SCOR Bus VLIN

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS16

VP Bus

PAMP

Bus HTRP

& DY VR

Bus VSCO Bus VLIN

KV27FS100, KV27FS200,

VK29FS100, KV32FS100,

KV32FS200, KV34FS100,

KV27FV300, KV29FV300,

KV32FV300, KV36FV300,

KV36FS100, KV36FS200,

KV38FS200

VP1 Bus

PAMP

Bus HTRP

& DY VR

Bus SCOR Bus VLIN

KD34XBR2, KV32HS20,

KV36HS20, KV36HS20H,

KV32XBR450,

KV36XBR450,

KV36XXBR450H,

KV32HS500, KV32HV600,

KV34DRC500,

KV34XBR800,

KV36HS500,

KV36XBR800,

KV38DRC500,

KV40XBR800,

KV40DRC800

CXA2150D-

1 & 2

2170D-1 &

2

Bus

PIN,

MPIN

Bus PPHA Bus VSCO Bus VLIN

Table 8-2 C Geometric Adjustments

29

8. Geometric Distortion (PI XD, PI XW)

MODEL

GROUP

UPPER

CORNER

PIN

LOWER

CORNER

PIN

V TRAP

HOR. S

CORRECTION

KV13FS100, KV13FS110,

KV14FV300, KV20FS100,

KV20FV300, KV21FM100,

KV21FS100, KV21FV300,

KV24FV300, KV25FV300

DEF Bus UPIN Bus LPIN No

adjustment

No adjustment

KV20S90, KV21SE43C DEF No

Adjustment

No

Adjustment

No

adjustment

No adjustment

KV24FS100, KV25FS100 DEF Bus UPIN Bus LPIN No

adjustment

No adjustment

KV25FS12, KV25FS12C DEF Bus UPIN Bus LPIN No

adjustment

No adjustment

KV27FS12, KV27FS17,

KV27FV17, KV29FS13,

KV29FV17, KV29FS13C,

KV29FV17C, KV32FS13,

KV32FS17, KV24FS13C,

KV24FS17

DEFL Bus UPIN Bus LPIN Bus VTRP No adjustment

KV32FV27, KV36FS13,

KV36FS17, KV36FV27,

KV38FS16

VP Bus UPIN Bus LPIN No

adjustment

No adjustment

KV27FS100, KV27FS200,

VK29FS100, KV32FS100,

KV32FS200, KV34FS100,

KV27FV300, KV29FV300,

KV32FV300, KV36FV300,

KV36FS100, KV36FS200,

KV38FS200

VP1 Bus UPIN Bus LPIN Bus VTRP No adjustment

KD34XBR2, KV32HS20,

KV36HS20, KV36HS20H,

KV32XBR450, KV36XBR450,

KV36XXBR450H, KV32HS500,

KV32HV600, KV34DRC500,

KV34XBR800, KV36HS500,

KV36XBR800, KV38DRC500,

KV40XBR800, KV40DRC800

CXA2150D-

1 & 2

2170D-1 &

2

Bus UCP,

UXCG,

UXCP,

XCPP

Bus LCP,

LXCG,

LXCP,

XCPP

Bus HTPZ SLIN

Table 8-2 D Geometric Adjustments

30

9. Focus Troubleshooting (PI XF)

Chapter 9 - Focus Troubleshooting (PIXF)

Overview

Figure 9-1 shows two examples of a focused CRT and two of an unfocused CRT. The focused examples are on

the left and the unfocused ones are on the right.

FIGURE 9-1

CRT Causes

Internal Current leakage

Check for a blue glow in the CRT neck assy. If present, it indicates a current leak within the CRT gun. See figure

9-2.

If a blue glow is not present initially, allow the unit to warm up for about 6 hours then recheck. Current leakage

can develop with time.

FIGURE 9-2

31

9. Focus Troubleshooting (PI XF)

External Current leakage

Leakage between the CRT pins on the socket

base due to dirt or insufficient RTV material.

Remove the C board, clean the CRT base and

the CRT socket, and reapply RTV material to

the area shown in Figure 9-3.

Non CRT Causes

Focus control

The focus control on FBT affects the entire screen.

Adjust for best center focus with the focus control of the FBT; then correct the side focus with the focus

phase control (next paragraph).

Focus Phase Control

The focus phase control (data bus) has a greater effect on the sides of the screen than on the center.

Adjust for best focus on both sides of the screen with the focus phase control; then compensate at the

center of the screen with the focus control (previous paragraph).

G2 and RGB Drive Levels

Excessive G2/drive levels will cause red beam flare at peak saturation

which appears as poor focus.

FIGURE 9-3

FIGURE 9-4

G4 Level

Poor focus can be caused by an incorrect G4 voltage level. G4 voltage

is normally supplied by a resistor divider and this divider may change in

value; either spontaneously, or due to overheating caused by stray

current flow inside the CRT.

Set-up Levels (data bus)

Incorrect level setups can cause peak overdrive levels and blooming which can give the appearance of an out of

focus CRT.

32

10. Convergence Supplemental I nformation

Chapter 10 - Convergence Supplemental Information

Process

A three-step process is used to adjust convergence:

1. Center adjustments

2. X and Y axis adjustments

3. Corner adjustments

The locations of these steps are shown in Figure 10-1.

1

2

2

2 2

3

3

3

3

Adjustment Steps

FIGURE 10-1 - CONVERGENCE STEPS

Note: To minimize interactions with each other, set all VRs and magnets to zero or null positions before starting.

Center Adjustments

V-Stat Adjustment

With H-Stat separated, adjust the 4-pole ring magnet to align the blue and red spots in the horizontal axis. This

is done by either spreading apart or bringing together the two handles on the magnet.

FIGURES 10-2 A & B

33

10. Convergence Supplemental I nformation

Rotate both 6-pole magnet rings together as a unit to align the red and blue (together) to the green in the

horizontal axis.

FIGURES 10-3 A & B

H-Stat Adjustment

Separate or bring together the 6-pole magnet rings so that the blue and red spots are equal distance from the

green.

FIGURES 10-4 A & B

Adjust the H-Stat control on the C board to bring the red and blue spots in line with the green.

FIGURES 10-5 A & B

34

10. Convergence Supplemental I nformation

Y Axis Adjustments

These adjustments converge the center part of the screen,

vertically, from top to bottom. See Figure 10-6.

TLV Reactor Adjustment

Separate the dots (again) with the TLV reactor control on the DY, and adjust the LTV reactor to converge the red

and blue dots at the top and the bottom of the screen. See Figure 10-7a. The location of the reactors is shown

in Figure 10-7b.

FIGURE 10-6 - Y-AXIS

FIGURES 10-6 A & B = LTV REACTOR FUNCTION & LOCATION

APV or VCR Adjustment

Ideally, all three color dots should line up in the horizontal axis from the top

to the bottom of the screen. If the screen looks like Figure 10-8, make

corrections by rotating both 6-pole magnet rings together as a unit. Touch

ups with the 4-pole ring magnets may be necessary as the rings interact

with each other. Priority must be given to the center areas.

FIGURE 10-8

35

10. Convergence Supplemental I nformation

Y-Bow Adjustment

There are two adjustment methods when the red or blue are bowed

but line up on the same side of the green in the vertical plane.

See Figure 10-9.

Use the YBWU and YBWL bus service mode registers on

units that have these registers. Many units do not have

these registers.

On models without the YBWU and YBWL registers, make

corrections with the H-STAT control.

FIGURE 10-10

Y-Cross Adjustment

There are three adjustment methods when the red or blue shift their positions from

the green as you go from the top towards the bottom of the screen. See Figure 10-

10.

Use the YBWU and YBWL bus service mode registers on units that have

these registers. Many units do not have these registers.

Tilt the DY up and down.

YCH Reactor.

X Axis Adjustments

These adjustments converge the center horizontal part of the

screen, from the left to the right of the screen. See Figure

10-11.

FIGURE 10-9

FIGURE 10-11 - Y-AXIS

36

10. Convergence Supplemental I nformation

APH adjustment

There are three adjustment methods when the red and

green misconverge but are on the same side of the green

at both sides of the screen. See Figure 10-12.

Use the RSAP and LSAP bus service mode

registers on units that have these registers.

Use the 6-pole magnets.

Move the neck assembly slightly forward or back.

FIGURE 10-12

TLH adjustment

There are two adjustment methods in cases where the red and green misconverge in opposite directions on both

sides of the screen:

TLH plate on the side of the DY (slide TLH plate in or out to make changes). Inserting the TLH plate in an

opposite side will make it move the red and blue in an opposite direction.

Some models have bus service mode registers RSAP and LSAP.

FIGURES 10-13A & B - TLH PLATE FUNCTION & LOCATION

XCV Adjustment

For models with reactor controls, turn the control wheel to

correct convergence keystone. Figure 10-7b shows the

XCV reactor location. In convergence keystone, the red

and blue dots cross vertical positions from side to side.

See Figure 10-14

FIGURE 10-14

37

10. Convergence Supplemental I nformation

XBV Adjustment

Convergence bowing can only be corrected with the

with the 4-pole ring magnets. In convergence bowing,

the red and blue dots vary in their vertical position with

respect to each other when scanned across the screen,

but are always on the same side of each other. See

Figure 10-15.

FIGURE 10-15

Corner Adjustments

Identify the corner with the convergence problem and insert permalloy strips behind the DY in the area

corresponding to the convergence problem.

Vary the position and depth of the strip until the mis-convergence is minimized.

Several permalloy strips may be required in the same location.

FIGURES 10-16A & B - CORNER ADJUSTMENT & PERMALLOY LOCATIONS

i

Appendix

Appendix

Geometry Adjustment

1) Adjust V position and V size by using Bus service mode VPOS and VSIZ.

Bus: VPOS

Vertical Position

Bus: VSIZ

Vertical Size

2) Adjust H position and H size by using Bus service HPOS and HSIZ.

Bus: HPOS

Horizontal Position

Bus: HSIZ

Horizontal Size

ii

Appendix

3) Adjust Rotation by rotating the DY. Note: Some models have adjustment in the users menu. Be sure to adjust

the menu to Zero value prior to the adjustment on the DY and H size by using Bus service mode HPOS and

HSIZ.

DY Rotation

Rotation

4) There are three methods to adjust V-Center depending on the chassis. One is DY tilt up and down. Note: This

will effect convergence and landing. The second method is Y-Magnet on the neck assy. The third is Bus service

mode VCEN.

DY Tilt, Y-Magnet, VCEN

Vertical Center

5) Most models do have have an adjustment for V-PIN. The models which do are located in the Bus service mode

VPIN.

VPIN

Vertical Pin Cushion

6) Adjust V-Bow by Bus service mode VBOW. In the event that the center is straight but the sides are bowed,

then use LBOW for adjustment.

VBOW or LBOW

Vertical Bow

iii

Appendix

7) Adjust Pin Amp by Bus service mode PAMP.

PAMP

Pin Amplitude

8) Adjust Pin Phase by Bus service mode PPHA.

PPHA

Pin Phase

9)

VANG or LANG

AFC Angle, Linear Angle

10)

HTPZ

H-Trapezoid

iv

Appendix

11) Adjust vertical S-Correction and V Linearity so that the height of the squares is the same at the top, center and

bottom of the screen using the Bus service mode VSCO and VLIN.

VSCO

S CORRECTION

VLIN

V LINEARITY

12) Adjust Upper Corner Pin and Lower Corner Pin using the Bus service mode UCP and LCP.

UPC

Upper Corner Pin

LCP

Lower Corner Pin

CRT010104 01/05/04

is a trademarks of Sony Electronics

2004 Sony Electronics Inc.

EMCS - A Service Company

1 Sony Drive

Park Ridge, New Jersey 07656

Reproduction in whole or part without written permission is prohibited. All rights reserved

You might also like

- 7 Most Common Problems With CRT TV and Their Possible DiagnosisDocument5 pages7 Most Common Problems With CRT TV and Their Possible DiagnosisLouieGonzales100% (1)

- TCON Troubleshooting and Replacement GuideDocument44 pagesTCON Troubleshooting and Replacement GuideDaniel Ignacio Castillo RosasNo ratings yet

- Flyback Transformer ABL PinDocument2 pagesFlyback Transformer ABL PinisosicaNo ratings yet

- Computer Monitor RepairDocument53 pagesComputer Monitor RepairraveensanjeewaNo ratings yet

- LCD TV Repair Guide Handbook 140211 v1Document45 pagesLCD TV Repair Guide Handbook 140211 v1devender kumar100% (2)

- Led Repairing MultitechDocument2 pagesLed Repairing MultitechKrishna TiwariNo ratings yet

- 2013 LED/LCD TV Engineering GuideDocument72 pages2013 LED/LCD TV Engineering GuideRivaldoNo ratings yet

- Toshiba 20AS24 CRT RepairDocument4 pagesToshiba 20AS24 CRT RepairJorge G. ManzaneroNo ratings yet

- Freereportlcd PDFDocument10 pagesFreereportlcd PDFAnthony GonzalesNo ratings yet

- SONY T-CON - Training - Manual PDFDocument12 pagesSONY T-CON - Training - Manual PDFJose Barroso GuerraNo ratings yet

- LCD TV Repair Guide Handbook 140211 v1Document45 pagesLCD TV Repair Guide Handbook 140211 v1Jonatan Didier Sinkpon100% (1)

- How To Completely Check The High Voltage Circuit in CRT Monitor/TelevisionDocument12 pagesHow To Completely Check The High Voltage Circuit in CRT Monitor/TelevisionspencerNo ratings yet

- LG 60ps11 Training Manual PDFDocument157 pagesLG 60ps11 Training Manual PDFNsb El-kathiriNo ratings yet

- LG 50PV450 Training ManualDocument160 pagesLG 50PV450 Training ManualDrew DumasNo ratings yet

- Repair InterviewDocument16 pagesRepair InterviewFaried RijalulhaqNo ratings yet

- Samsung LCD TV Repair PowerDocument3 pagesSamsung LCD TV Repair Powerhenry200867% (3)

- Bob's Blue2 Ring Tester Checks InductorsDocument4 pagesBob's Blue2 Ring Tester Checks InductorsAsher Duane Clairet AzeleaNo ratings yet

- T - Con Module Fault - Google SearchDocument2 pagesT - Con Module Fault - Google SearchRaja Pathamuthu.G100% (1)

- Laptop Power Sequence Final by IntersotDocument15 pagesLaptop Power Sequence Final by IntersotHas BiansyahNo ratings yet

- Test Flyback TransformerDocument8 pagesTest Flyback TransformerKailash RaoNo ratings yet

- LCD TV Display Failure Symptoms and Possible CausesDocument4 pagesLCD TV Display Failure Symptoms and Possible Causeskachappilly2012No ratings yet

- LED LCD TV Repair Guide: WWW - Television-Magazine - Co.ukDocument47 pagesLED LCD TV Repair Guide: WWW - Television-Magazine - Co.ukShauna WhelanNo ratings yet

- Samsung OLED TV Repair Training: Organic Light Emitting Diode Technology and Troubleshooting ProceduresDocument113 pagesSamsung OLED TV Repair Training: Organic Light Emitting Diode Technology and Troubleshooting ProceduresPaulo Henrique SNo ratings yet

- Replacing burnt SMD capacitor and T-con board fixes TV image issuesDocument4 pagesReplacing burnt SMD capacitor and T-con board fixes TV image issuesElmir Grabcanovic100% (1)

- TFT-LCD Modules " Improving Video Performance/ Reducing CostDocument7 pagesTFT-LCD Modules " Improving Video Performance/ Reducing CostAnonymous O5WK6kiLiV100% (1)

- Service Manual: ChassisDocument43 pagesService Manual: ChassisSokol Kadare50% (2)

- Collection of LG LCD/LED/OLED TV Interconnect Diagrams Under 40 CharactersDocument364 pagesCollection of LG LCD/LED/OLED TV Interconnect Diagrams Under 40 CharactersMantención FastpackNo ratings yet

- Led TV Vartical LineDocument9 pagesLed TV Vartical LinetusharNo ratings yet

- AC-DC LCD TV Poower Architecture and LED Backlight PDFDocument53 pagesAC-DC LCD TV Poower Architecture and LED Backlight PDFRun Mouth100% (3)

- LG 42LH90 LED LCD TV Training JCRL PDFDocument97 pagesLG 42LH90 LED LCD TV Training JCRL PDFs mNo ratings yet

- LG 50PV450 Training Manual PDFDocument160 pagesLG 50PV450 Training Manual PDFeliasNo ratings yet

- Sony - KDL 22 26 32ex420 - 22 26ex423 - 32 40 46ex520 - 32 40 46ex523 - CH - Az2gDocument126 pagesSony - KDL 22 26 32ex420 - 22 26ex423 - 32 40 46ex520 - 32 40 46ex523 - CH - Az2gMalay K GhoshNo ratings yet

- Panasonic 10th Gen PDP TV Training ManualDocument100 pagesPanasonic 10th Gen PDP TV Training Manualenforcer2008No ratings yet

- How To Troubleshoot and Repair DVD With The SymptomDocument6 pagesHow To Troubleshoot and Repair DVD With The SymptomJojit AquinoNo ratings yet

- Intersoft Basic Notes For Pci Pinout DetailDocument63 pagesIntersoft Basic Notes For Pci Pinout DetailZulfiqar AliNo ratings yet

- TV TheoryDocument199 pagesTV Theorynelson/igan100% (1)

- TV Repair InstructionsDocument24 pagesTV Repair InstructionsAnthonyChanNo ratings yet

- TVDocument21 pagesTVOpena JcNo ratings yet

- LG Fallas TV PLASMA TrainingDocument74 pagesLG Fallas TV PLASMA Trainingdesonline86% (7)

- Daewoo Sl-150t, Sl-150pDocument74 pagesDaewoo Sl-150t, Sl-150plachiondoNo ratings yet

- 7-Inch LCD Monitor & DVD Player Specs and TroubleshootingDocument42 pages7-Inch LCD Monitor & DVD Player Specs and TroubleshootingЕвгений СафоновNo ratings yet

- Amoi Lc26t1e 32t1e 37t1e 42t1e (ET)Document120 pagesAmoi Lc26t1e 32t1e 37t1e 42t1e (ET)Dimitris ApostolouNo ratings yet

- Dpc-7200n Daewoo DVD Portable PlayerDocument42 pagesDpc-7200n Daewoo DVD Portable PlayermaurorzhzNo ratings yet

- D26W931 D32W931 LC32W053 LC42H053Document188 pagesD26W931 D32W931 LC32W053 LC42H053FABIO TECNo ratings yet

- Chassis PT 90 NEAT Service ManualDocument64 pagesChassis PT 90 NEAT Service ManualZoltan OlahNo ratings yet

- Applecolor Highres RGB Mon PDFDocument129 pagesApplecolor Highres RGB Mon PDFifilesbackupNo ratings yet

- Sp20so - La20s51b - Samsung - TFT-LCD TVDocument28 pagesSp20so - La20s51b - Samsung - TFT-LCD TVmiguel197234100% (1)

- Aoc Le32h158iDocument165 pagesAoc Le32h158iValmir BarbosaNo ratings yet

- LTW32/42DV-SERVICE MANUAL TROUBLESHOOTING GUIDEDocument44 pagesLTW32/42DV-SERVICE MANUAL TROUBLESHOOTING GUIDEMaria de GuerreroNo ratings yet

- 09060616135056Document160 pages09060616135056Segundo Francisco Jauregui ValenciaNo ratings yet

- Optimize the LCD TV Repair GuideDocument99 pagesOptimize the LCD TV Repair GuideivanbeneNo ratings yet

- LTW32/42DV Service ManualDocument44 pagesLTW32/42DV Service ManualSantiago VentoNo ratings yet

- MIC DatasheetDocument16 pagesMIC DatasheetArosh Thiwanka LiveraNo ratings yet

- PHILIPS LC04 LCD TV Technical Training ManualDocument44 pagesPHILIPS LC04 LCD TV Technical Training Manualcentauro2013No ratings yet

- Sony Ctv-65 Az1k Chassis Training Manual (ET)Document45 pagesSony Ctv-65 Az1k Chassis Training Manual (ET)deac1234No ratings yet

- Aoc Le23h037Document71 pagesAoc Le23h037Evanier Souza de AlencarNo ratings yet

- Another 6 Pin SMD IC in LED & LCD TV:MonitorDocument1 pageAnother 6 Pin SMD IC in LED & LCD TV:MonitorAllamNo ratings yet

- Aoc Lc32k0d3d Lc42k0d3dDocument116 pagesAoc Lc32k0d3d Lc42k0d3dmarcellobbNo ratings yet

- ITC222 Focus InstructionsDocument3 pagesITC222 Focus Instructionsrodbuilder3No ratings yet

- ITC222 Advanced Convergence InstructionsDocument4 pagesITC222 Advanced Convergence InstructionsEvelyn NaranjoNo ratings yet

- Service Manual LG LED 32LE5500.Document51 pagesService Manual LG LED 32LE5500.Mihai TanaseNo ratings yet

- LG 32LN5300 PDFDocument43 pagesLG 32LN5300 PDFAldo TonatoNo ratings yet

- Acer TFT LCD Color Monitor AL1713 Parts and ServiceDocument46 pagesAcer TFT LCD Color Monitor AL1713 Parts and ServiceВадим НефедовNo ratings yet

- ITC222align PDFDocument7 pagesITC222align PDFDaniboy1994No ratings yet

- Manual de Servicio KDL-26L5000Document55 pagesManual de Servicio KDL-26L5000ca_otiNo ratings yet

- Sharp Service ManualDocument74 pagesSharp Service ManualTurlough MakubikaNo ratings yet

- LG 32LN5300 PDFDocument43 pagesLG 32LN5300 PDFAldo TonatoNo ratings yet

- Service Manual LG LED 32LE5500.Document51 pagesService Manual LG LED 32LE5500.Mihai TanaseNo ratings yet

- DVR I3dvr ManualDocument66 pagesDVR I3dvr ManualDaniboy1994No ratings yet

- Pro Psb322 enDocument11 pagesPro Psb322 enDaniboy1994No ratings yet

- Acer x193wDocument50 pagesAcer x193wdaoud70No ratings yet

- Samsung Hlr4264wx Xac Chassis l62bDocument81 pagesSamsung Hlr4264wx Xac Chassis l62bDaniboy1994No ratings yet

- Sharp LC 42d65uDocument114 pagesSharp LC 42d65uDaniboy1994No ratings yet

- Cur Dvd1084 enDocument26 pagesCur Dvd1084 enDaniboy1994No ratings yet

- Manualuserssharplc 46d64ulcdscreenDocument0 pagesManualuserssharplc 46d64ulcdscreenDaniboy1994No ratings yet

- Emerson Lc320em8Document66 pagesEmerson Lc320em8Edilberto Avila100% (1)

- KDL40Z4100 PDFDocument111 pagesKDL40Z4100 PDFDaniboy1994No ratings yet

- NCTL09109 0-284388 PDFDocument36 pagesNCTL09109 0-284388 PDFDaniboy1994No ratings yet

- Service Manual: LCD Color TelevisionDocument18 pagesService Manual: LCD Color Televisionsil885No ratings yet

- V43 Service ManualDocument91 pagesV43 Service Manualplasmapete100% (2)

- Pan DLP 61lcx65Document81 pagesPan DLP 61lcx65Terry SeymourNo ratings yet

- Drc6379t RcaDocument28 pagesDrc6379t RcaDaniboy1994No ratings yet

- DX WC100 ManualDocument9 pagesDX WC100 ManualDaniboy1994No ratings yet

- LCD TV: Service ManualDocument28 pagesLCD TV: Service ManualDaniboy1994No ratings yet

- PC Power Supply Repair GuideDocument4 pagesPC Power Supply Repair GuideAntonio ChavezNo ratings yet

- Electrical Power Line Theft DetectionDocument5 pagesElectrical Power Line Theft DetectionEditor IJRITCC100% (1)

- Question Bank: E1153 - Basic Electrical & Electronics EngineeringDocument18 pagesQuestion Bank: E1153 - Basic Electrical & Electronics EngineeringAnanthilakaNo ratings yet

- Schneider Short Circuit CalculationDocument36 pagesSchneider Short Circuit Calculationincobar100% (2)

- Guia Electricidad MarcelaDocument8 pagesGuia Electricidad MarcelaMARCELA MORENO ROJASNo ratings yet

- Bangalore Sahodaya School Complex Association Preboard Examination - (Set-2) Subject: PhysicsDocument8 pagesBangalore Sahodaya School Complex Association Preboard Examination - (Set-2) Subject: PhysicsMohd AdilNo ratings yet

- Electrical Machines I: Efficiency and All Day Efficiency of TransformersDocument9 pagesElectrical Machines I: Efficiency and All Day Efficiency of TransformersShraddha RautNo ratings yet

- Multimeter VIMPDocument61 pagesMultimeter VIMPSysu KumarNo ratings yet

- WAssce Physics SyllabusDocument24 pagesWAssce Physics SyllabusIkedi UcheNo ratings yet

- Preview: Comptia Pdi+ Certification Instructor's EditionDocument104 pagesPreview: Comptia Pdi+ Certification Instructor's Editionpierre_pouliotNo ratings yet

- Ultra ConductorsDocument28 pagesUltra ConductorsAnu Kp50% (8)

- 30 TOP MOST MAGNETIC CIRCUIT - Electrical Engineering Multiple Choice Questions and Answers Electrical Engineering Multiple Choice QuestionsDocument10 pages30 TOP MOST MAGNETIC CIRCUIT - Electrical Engineering Multiple Choice Questions and Answers Electrical Engineering Multiple Choice QuestionsDineshKanawat100% (1)

- Vacuum TubesDocument30 pagesVacuum TubesAira Mae CrespoNo ratings yet

- Resistivity by Four Probe Method (Theory) - Solid State Physics Virtual Lab - Physical Sciences - Amrita Vishwa Vidyapeetham Virtual LabDocument3 pagesResistivity by Four Probe Method (Theory) - Solid State Physics Virtual Lab - Physical Sciences - Amrita Vishwa Vidyapeetham Virtual Labupanith100% (1)

- IECDocument52 pagesIECM.r. Munish100% (2)

- Engineering Economics by J Tiong PDFDocument31 pagesEngineering Economics by J Tiong PDFRainier RamosNo ratings yet

- Datasheet GRL18S-F2336 1059533 enDocument8 pagesDatasheet GRL18S-F2336 1059533 enbertelheNo ratings yet

- Mi - 7 - Phy Lesson Plan 14.5 - Electric Current-RevDocument1 pageMi - 7 - Phy Lesson Plan 14.5 - Electric Current-RevLAKSHAY BEDINo ratings yet

- Neher Mcgrath1 PDFDocument13 pagesNeher Mcgrath1 PDFelmodeer9841No ratings yet

- Basic Electrical Concepts OverviewDocument3 pagesBasic Electrical Concepts OverviewManuel Philip ZamoraNo ratings yet

- ZMS Cable CatalogDocument28 pagesZMS Cable Catalogenghassanain6486No ratings yet

- Brief History of Classical ElectrodynamicsDocument15 pagesBrief History of Classical ElectrodynamicsHernán H.No ratings yet

- Domestic Electrical Installation PDFDocument90 pagesDomestic Electrical Installation PDFHenok Ayele93% (28)

- Electrochemical CellDocument2 pagesElectrochemical CellHee Ting WongNo ratings yet

- Chapter5 Conductorand DielectricsDocument21 pagesChapter5 Conductorand Dielectricsspong1ertzNo ratings yet

- Distance and Differential RelayDocument15 pagesDistance and Differential RelayHimanshu Tiwari100% (1)

- FIZ102E SuggestedProblemsDocument26 pagesFIZ102E SuggestedProblemsSelin PınarNo ratings yet

- Theory 1: in EE 311Document13 pagesTheory 1: in EE 311Ad PlusNo ratings yet

- Curapuls670 PulsedShortwaveTherapy 1419762-42Document53 pagesCurapuls670 PulsedShortwaveTherapy 1419762-42Aswathy KumarNo ratings yet

- Lesson 3 HW Questions - Mark SchemeDocument6 pagesLesson 3 HW Questions - Mark SchemeVinodKumarTummalurNo ratings yet

- Electrical Interview QuestionDocument118 pagesElectrical Interview QuestionMumtaj Khan0% (1)