Professional Documents

Culture Documents

Hybrid 06

Uploaded by

Jorge Eduardo Diaz Valenzuela0 ratings0% found this document useful (0 votes)

138 views0 pagesHybrid vehicles use three types of multiplex communication: CAN, BEAN and AVC-LAN. The '04 and later Prius includes an electric compressor that is powered by the inverter. The hybrid vehicle's gasoline engine is small, thermally efficient, and runs only when needed.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHybrid vehicles use three types of multiplex communication: CAN, BEAN and AVC-LAN. The '04 and later Prius includes an electric compressor that is powered by the inverter. The hybrid vehicle's gasoline engine is small, thermally efficient, and runs only when needed.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

138 views0 pagesHybrid 06

Uploaded by

Jorge Eduardo Diaz ValenzuelaHybrid vehicles use three types of multiplex communication: CAN, BEAN and AVC-LAN. The '04 and later Prius includes an electric compressor that is powered by the inverter. The hybrid vehicle's gasoline engine is small, thermally efficient, and runs only when needed.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

TOYOTA Hybrid System - Course 071 6-1

The body electrical system includes special technology to increase fuel

efficiency and accommodate the special requirements of a hybrid

powertrain. For instance, the 2004 & later Prius uses an electric

compressor so that A/C operation is not dependent on the engine. It

also uses a humidity sensor to make cabin dehumidification more

efficient.

To maintain communication between the vehicles many electronic

control components, hybrid vehicles use three types of multiplex

communication: CAN, BEAN and AVCLAN. A Gateway ECU is used

to link the three circuits.

The Prius A/C unit provides 2way flow so it can recirculate warm

internal air in the foot well while simultaneously introducing fresh, dry

external air to the upper part of the cabin. This allows it to effectively

heat the vehicle and demist the windshield at the same time.

The 0103 Prius air conditioning is controlled from the air

conditioning control panel.

The 04 & later Prius air conditioning system can be controlled

either from the air conditioning screen on the multi display or from

switches on the steering pad.

The system includes several components to meet the special

requirements of a hybrid vehicle.

The 04 & later Prius includes an electric compressor that is

powered by the inverter and does not draw any power unless it is

needed to run the A/C.

The hybrid vehicle A/C system also uses two Positive Temperature

Coefficient (PTC) heaters embedded in the heater core to

supplement the heat provided by the engine.

The A/C control circuits include special logic tailored to support the

hybrid powertrain. If the HV battery becomes too warm with

recirculation ON, the HV battery ECU will switch to FRESH in order

to increase the flow of air across the battery.

Section 6

Body Electrical

Overview

Air Conditioning

System

Section 6

6-2 TOYOTA Technical Training

A/C Main Components

(04 later Prius)

Figure 6.1 T071f601c

Body Electrical

TOYOTA Hybrid System - Course 071 6-3

The hybrid vehicles gasoline engine is small, thermally efficient, and

runs only when needed. Therefore, engine coolant may not always be

hot enough to heat the cabin to a comfortable temperature. To address

this, two 165Watt PTC heater elements are embedded in the heater

core and used to supplement engine heat when warming the vehicle.

Heater Core

Figure 6.2 T071f602

PTC Heater

Figure 6.3 T071f603

Heater Core and

PTC Heater

Section 6

6-4 TOYOTA Technical Training

The Prius A/C condenser includes a subcooler that improves heat

exchange efficiency. After the refrigerant passes through the

condensing portion of the condenser, both the liquid refrigerant and

any gaseous refrigerant that was not liquefied during condensation are

cooled again in the supercooling portion of the condenser. Because of

this twostep approach the refrigerant sent to the evaporator is almost

completely liquefied.

When recharging most cooling systems, air bubbles disappear from the

refrigerant when the system is full. With this system, however, air

bubbles will disappear from the refrigerant before the system is full.

See the Prius Repair Manual for the proper method of recharging this

system.

Sub-Cool Cycle

Figure 6.4 T072f052c

The 0103 Prius uses a scroll compressor with an oil separator that

reduces the circulation of compressor oil in the system.

When diagnosing the A/C, you may need to force the A/C system to

remain on. Setting the controls to the MAX A/C position will cause the

engine to remain on, maintaining A/C compressor operation.

Condenser and

Sub-Cool Cycle

NOTE

Compressor

(01-03 Prius)

NOTE

Body Electrical

TOYOTA Hybrid System - Course 071 6-5

A/C Compressor

Selecting MAX A/C on the

01-03 Prius will cause the

engine to run continuously

Figure 6.5 T071f605p

The 04 & later Prius uses an electric compressor driven by an

integrated motor. The motor runs on 201.6V AC supplied by the A/C

inverter so compressor operation does not depend on the engine.

The electric compressor consists of a spirally wound fixed scroll and

variable scroll, a brushless motor, and an oil separator. The oil

separator reclaims most of the compressor oil that is intermixed with

the refrigerant. To insure proper insulation between the compressor

housing and the highvoltage components inside the compressor, the

04 Prius uses a special high insulation value ND11 compressor oil.

NEVER use any compressor oil other than ND11.

The A/C compressor is powered by 201.6V AC. So when servicing the

A/C compressor you should use the same high voltage safety

procedures you would use for the vehicles other high voltage circuits.

Electric A/C

Compressor

(04 & later Prius)

Figure 6.6 T071f606p

Electric Compressor

(04 & later Prius)

NOTE

Section 6

6-6 TOYOTA Technical Training

The room temperature sensor includes a humidity sensor to help make

the A/C systems dehumidification process more effective. As a result,

compressor power consumption has been reduced while still

maintaining a comfortable humidity level within the cabin.

The humiditysensing resistance film contains small carbon particles.

As humidity in the cabin changes the hydroscopic film expands and

contracts, changing the distance between the carbon particles. This

changes the resistance of the film and sensor output voltage.

Humidity Sensor

(04 & later Prius)

Figure 6.7 T071f607c

Room Temperature

Sensor and

Humidity Sensor

(04 & later Prius)

Body Electrical

TOYOTA Hybrid System - Course 071 6-7

The electric water pump provides stable heater performance even when

the engine is stopped. When the engine is running the engines water

pump is forcing coolant through the system so the electric water pump

does not operate.

On the 0103 Prius, when the engines water pump is operating a

bypass valve opens to minimize flow resistance. The bypass valve has

been discontinued on the 04 & later Prius because a new pump design

minimizes water flow resistance.

Water Pump

Coolant Flow

(01-03 Prius)

Figure 6.8 T072f053c

Water Pump

Section 6

6-8 TOYOTA Technical Training

The Prius uses the following communication systems to coordinate

vehicle activities:

The Controller Area Network (CAN) links vehicle control systems

that require highspeed communication, such as the ECM, HV

ECU, Skid Control ECU and others.

The Body Electronics Area Network (BEAN) connects the body

control systems.

The Audio Visual Communication Local Area Network

(AVCLAN) links the audiovisual system ECUs and devices.

The Gateway ECU contains communication circuits that allow the

CAN, BEAN and AVCLAN systems to connect with each other.

Multiplex

Communication

(04 & later Prius)

Figure 6.9 T071f609c

Multiplex

Communication

System

Body Electrical

TOYOTA Hybrid System - Course 071 6-9

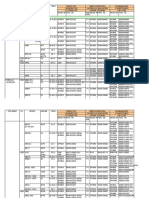

CAN System Diagram

CAN communication

speed is 500 k bps

(04 & later Prius)

Figure 6.10 T071f610c

Control

Chassis Electrical

System Control

Body Electrical

System Control

Protocol

CAN

(ISO Standard)

BEAN

(TOYOTA Original)

AVC-LAN

(TOYOTA Original)

Communication Speed

500 k bps

(Max. 1 M bps)

Max. 10 k bps Max. 17.8 k bps

Communication Wire Twisted-pair Wire AV Single Wire Twisted-pair Wire

Drive Type

Differential

Voltage Drive

Single Wire

Voltage Drive

Differential

Voltage Drive

Data Length 1-8 Byte (Variable) 1-11 Byte (Variable) 0-32 Byte (Variable)

Figure 6.11 T071f611

CAN, BEAN &

AVC-LAN Chart

(04 & later Prius)

Section 6

6-10 TOYOTA Technical Training

The SULEV 20012003 Prius warranty offers:

Basic 3 years / 36,000 miles

Powertrain (Engine, Transaxle with motors) 5 years /

60,000 miles

Hybrid System (HV Battery, HV Battery ECU, Hybrid ECU,

Inverter and Converter) 8 years / 100,000 miles

The ATPZEV 2004 & later Prius, the warranty offers:

Basic 3 years / 36,000 miles

Powertrain (Engine, Transaxle with motors) 5 years / 60,000

miles

Hybrid System 8 years / 100,000 miles

Emission Performance, Emission Defects, and Hybrid Battery Pack

150,000 miles

Warranty

Body Electrical

TOYOTA Hybrid System - Course 071 6-11

WORKSHEET 6-1

Electric Air Conditioning System

Vehicle Year/Prod. Date Engine Transmission

Worksheet Objectives

This worksheet will familiarize you with the operation of the high voltage A/C compressor on the 2004 and later

Prius using Active Tests and viewing the high and low pressures. You will also become familiar with the

customize modes on the Diagnostic Tester, which allow A/C functions to be modified to suit customer needs.

Tools and Equipment

Vehicle

Pressure Gauges

Diagnostic Tester

Repair Manual

New Car Features

Section 1: A/C Compressor

1. Describe the A/C compressor. What drives the compressor? What type of compressor is it?

2. What type of compressor oil is used and why is it unique to this system?

3. List the safety precautions that should be followed when servicing the A/C System.

Section 6

6-12 TOYOTA Technical Training

Section 2: Refrigerant Pressure

1. Turn the A/C OFF and then turn the vehicle OFF.

2. Connect the pressure gauges to the high and low-pressure service ports.

3. Restart the vehicle, verifying it is in READY mode.

4. Connect the Diagnostic Tester to DLC3.

5. Select Active Test and COMPRS TARG SPD. Start at zero and note the refrigerant pressure. Increase the

RPM to 4000 and note the pressure. Increase the RPM to 6000 and note the pressure.

Compressor Speed: Low Side Pressure: High Side Pressure:

Compressor Speed: Low Side Pressure: High Side Pressure:

Compressor Speed: Low Side Pressure: High Side Pressure:

Section 3: Humidity Sensor

1. What is the purpose of the humidity sensor?

2. Where is the humidity sensor located?

3. Is the humidity sensor located on the A/C Data List?

Body Electrical

TOYOTA Hybrid System - Course 071 6-13

Section 4: A/C Data List

1. Select the A/C Data List using the Diagnostic Tester. Under User Data select EVAPORATOR TEMP, ROOM

TEMP, HUMIDITY SENSOR, COMPRESSOR SPEED, and COMPRESSOR TARGET SPEED.

2. What is the relationship of the room temperature to the evaporator temperature when the A/C is OFF and

then with the A/C ON?

3. What happens to the humidity sensor reading when the A/C is turned ON?

4. What happens to the compressor target speed when the humidity sensor and evaporator temperature

sensor values drop?

Section 5: Customize Mode

1. The Customize Mode allows air conditioning functions to be modified to suit the customers needs. Modes

are changed using the Diagnostic Tester.

2. With the Diagnostic Tester connected to DLC3, enter the Customize Mode located on the second screen

after you turn the tester ON.

3. Select Individual Change. List at least three A/C climate control modes that can be customized.

Note: Return all cars to the original state and return to the classroom.

Section 6

6-14 TOYOTA Technical Training

Body Electrical

TOYOTA Hybrid System - Course 071 6-15

SELF-ASSESSMENT 6-1

Electric Air Conditioning System

Name: Date:

Self-assessment Objectives

Review this sheet as you are doing the Electric Air Conditioning worksheet. Check off either category after

completing the worksheet and instructor presentation. Ask the instructor if you have questions. The Comments

section is for you to write notes on where to find the information, questions, etc.

I have questions I know I can

Topic Comment

Describe the electric A/C compressor.

Describe the safety precautions of why ND11 oil

must be used.

List the safety precautions to be followed when

servicing the A/C system.

Access Active Test and select compressor

speed.

Locate the humidity sensor using TIS or the

repair manual.

View the A/C Data List.

Locate and use Customize Mode for A/C.

TOYOTA HYBRID SYSTEM

Section 6

6-16 TOYOTA Technical Training

You might also like

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- 22 - Hybrid TransaxleDocument75 pages22 - Hybrid Transaxlepejopo100% (1)

- Brake Control PDFDocument410 pagesBrake Control PDFClod HopperNo ratings yet

- If Your Vehicle Needs To Be Towed: 5-1. Essential InformationDocument7 pagesIf Your Vehicle Needs To Be Towed: 5-1. Essential InformationxsmartieNo ratings yet

- Toyota Prius 2010 Cruise ControlDocument9 pagesToyota Prius 2010 Cruise ControlBrais Diaz SanchezNo ratings yet

- 2uztrd PDFDocument33 pages2uztrd PDFbob loblawNo ratings yet

- Brake System - HMCDocument69 pagesBrake System - HMCDani HidayatulohNo ratings yet

- Hybrid2009 SKBDocument6 pagesHybrid2009 SKBsovon adhikaryNo ratings yet

- Plug-In Hybrid: PriusDocument6 pagesPlug-In Hybrid: Priusahmed199705No ratings yet

- Mazda 5 EngineDocument143 pagesMazda 5 EngineAngel CastNo ratings yet

- 1Nz-Fe Engine Mechanical: Service DataDocument3 pages1Nz-Fe Engine Mechanical: Service Dataalbert phiriNo ratings yet

- BYD G3-Owner's Manual20110610-EN PDFDocument160 pagesBYD G3-Owner's Manual20110610-EN PDFamer100% (1)

- Transmission Fluid PDFDocument5 pagesTransmission Fluid PDFLv2mackNo ratings yet

- 2azfe 12 PDFDocument20 pages2azfe 12 PDFmasakpNo ratings yet

- TIS - Lexus 2013 LX570 Repair Manual (RM19F0U)Document18 pagesTIS - Lexus 2013 LX570 Repair Manual (RM19F0U)Celis TabaresNo ratings yet

- M800 OEM WRX78 Installation DocumentDocument10 pagesM800 OEM WRX78 Installation DocumentRaheel FaroukNo ratings yet

- Alphard Chassis Ind PDFDocument70 pagesAlphard Chassis Ind PDFDikyNo ratings yet

- EMISSION CONTROL SYSTEM (2AZ FE) CamryDocument30 pagesEMISSION CONTROL SYSTEM (2AZ FE) CamryRahmat HidayatNo ratings yet

- Automatic Transmission PDFDocument334 pagesAutomatic Transmission PDFAriel MercochaNo ratings yet

- G Electrical Wiring Routing: Position of Parts in Engine CompartmentDocument8 pagesG Electrical Wiring Routing: Position of Parts in Engine CompartmentTec RomeroNo ratings yet

- Electronically Controlled Transmission Communication CircuitDocument3 pagesElectronically Controlled Transmission Communication CircuitErln Lima100% (1)

- Eee 1Document3 pagesEee 1Gordo FragosoNo ratings yet

- A32 GiDocument49 pagesA32 GiLevin Tan HtNo ratings yet

- DTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)Document4 pagesDTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)williamNo ratings yet

- Instrument Panel Yaris 2008Document89 pagesInstrument Panel Yaris 2008Pat NeenanNo ratings yet

- MIL ON DTC P2820 2014 - 2017 Corolla Transmission(s) CVT 2017 Im Transmission(s) CVTDocument10 pagesMIL ON DTC P2820 2014 - 2017 Corolla Transmission(s) CVT 2017 Im Transmission(s) CVTSajjad HussainNo ratings yet

- Harrop Lc200-1ur InstallDocument22 pagesHarrop Lc200-1ur InstallArtur ElectroMecânicoNo ratings yet

- 2014-16 Transmission CVT Fluid Change - Corolla (k313)Document16 pages2014-16 Transmission CVT Fluid Change - Corolla (k313)Repuestos Maceira100% (2)

- Terminals of Ecu: DiagnosticsDocument4 pagesTerminals of Ecu: DiagnosticsDaniel Mamani ParedezNo ratings yet

- Air Mass Sensor With Frequency OutputDocument2 pagesAir Mass Sensor With Frequency OutputXaockaNo ratings yet

- Electrically Controlled Shift Lock SystemDocument3 pagesElectrically Controlled Shift Lock SystemMayobanex Moya MartinezNo ratings yet

- Toyota Rav4 Ecu Recall Euc Problem PDFDocument4 pagesToyota Rav4 Ecu Recall Euc Problem PDFرشيد الحربيNo ratings yet

- 2008 Chevrolet HHR DTCDocument6 pages2008 Chevrolet HHR DTCTal Benyamin100% (1)

- Audi A6 No. 71 / 2: Current Flow DiagramDocument8 pagesAudi A6 No. 71 / 2: Current Flow DiagramDascaliuc Daniel100% (1)

- Terminals of Ecm: E17 E16 E15 E14Document5 pagesTerminals of Ecm: E17 E16 E15 E14Martin ChilbetNo ratings yet

- CVT FWD & 4WD (Electronic Control With Converter) (Toyota Auris, Corolla, Porte, Ractis, Rumion)Document3 pagesCVT FWD & 4WD (Electronic Control With Converter) (Toyota Auris, Corolla, Porte, Ractis, Rumion)Gardenia AndradeNo ratings yet

- ECM/PCM Input and Output TestsDocument2 pagesECM/PCM Input and Output TestsDhami NongNo ratings yet

- P1271 1272 PDFDocument11 pagesP1271 1272 PDFHasnain Diesel100% (2)

- VSC Warning LightDocument3 pagesVSC Warning Lightbob loblawNo ratings yet

- Z18XE SCHDocument3 pagesZ18XE SCHJan WolnyNo ratings yet

- Cooling System (2Az-Fe) : On-Vehicle InspectionDocument27 pagesCooling System (2Az-Fe) : On-Vehicle InspectionTung NguyenNo ratings yet

- Evo X ECUDocument2 pagesEvo X ECUJustin StarkNo ratings yet

- Engine 2JZ-GEDocument108 pagesEngine 2JZ-GEroy.cheong900% (1)

- Greddy E Manage Instalcion en MitsubishiDocument11 pagesGreddy E Manage Instalcion en MitsubishiFelipe Cortes0% (1)

- Biante SKYACTIV: Dimension & Weight Seating & TrimDocument4 pagesBiante SKYACTIV: Dimension & Weight Seating & Trimyusransyah100% (1)

- 1 ZzfeDocument8 pages1 ZzfeScuderia Redin100% (1)

- Toyota Yaris IIIDocument2 pagesToyota Yaris IIIIoniță Sorin CristianNo ratings yet

- LS600hL - LS600h (Hybrid System)Document62 pagesLS600hL - LS600h (Hybrid System)Nguyễn Hoài Nam100% (1)

- DI102Document6 pagesDI102Erln LimaNo ratings yet

- '02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinDocument5 pages'02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinElvin Domingo100% (1)

- Steering Column Switch PDFDocument26 pagesSteering Column Switch PDFDaniel OlariNo ratings yet

- BeltsDocument89 pagesBeltszul100% (2)

- Tomihawk Tools CatalogueDocument60 pagesTomihawk Tools CatalogueRosília DomingosNo ratings yet

- ESP Torque Sensor: Resetting A CorollaDocument1 pageESP Torque Sensor: Resetting A CorolladoudzoNo ratings yet

- Attn 0205 AjDocument35 pagesAttn 0205 AjRheezal DanuNo ratings yet

- P1656 PDFDocument3 pagesP1656 PDFTalleban TalNo ratings yet

- 10-Automatic Transmission PDFDocument192 pages10-Automatic Transmission PDFLakzana Budhy100% (2)

- A760E Auto Trans - InstallationDocument7 pagesA760E Auto Trans - InstallationJohn Locke100% (1)

- Aie R Conditioning Sysatem TeierDocument72 pagesAie R Conditioning Sysatem TeierDinsosnakertrans KudusNo ratings yet

- Passo 2010-2015 PDFDocument32 pagesPasso 2010-2015 PDFWaqar KhattakNo ratings yet

- Tlt830wa User's ManualDocument13 pagesTlt830wa User's ManualJorge Eduardo Diaz ValenzuelaNo ratings yet

- TLT440W IntroductionDocument1 pageTLT440W IntroductionJorge Eduardo Diaz ValenzuelaNo ratings yet

- KWA-300 3D Wheel Aligner User's Manual enDocument34 pagesKWA-300 3D Wheel Aligner User's Manual enJorge Eduardo Diaz ValenzuelaNo ratings yet

- Installation & Activation Guide (Dongle) : ZwsoftDocument45 pagesInstallation & Activation Guide (Dongle) : ZwsoftJorge Eduardo Diaz ValenzuelaNo ratings yet

- RAC Questions NewDocument2 pagesRAC Questions NewChary100% (1)

- AGA Export NSW Schedule2Document480 pagesAGA Export NSW Schedule2Kopi BrisbaneNo ratings yet

- Cooling Coil Spec ###Document2 pagesCooling Coil Spec ###PeterWangNo ratings yet

- Provision System ZDocument36 pagesProvision System ZDaud Antony BonteNo ratings yet

- Product Specifications: Model EZSTL8LCDocument2 pagesProduct Specifications: Model EZSTL8LCJames LoewenNo ratings yet

- Preturi Daikin 2010Document36 pagesPreturi Daikin 2010GigieseNo ratings yet

- Name 5 Types of Compressors and Describe Their Operation ReciprocatingDocument4 pagesName 5 Types of Compressors and Describe Their Operation ReciprocatingAj Ax100% (1)

- Build-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACDocument18 pagesBuild-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACchristianNo ratings yet

- R & AC SyllabusDocument2 pagesR & AC SyllabusviveksujNo ratings yet

- Dibujo - Chller 300 TR - IDocument1 pageDibujo - Chller 300 TR - Ijuan yenqueNo ratings yet

- Lusail Palaces Design and Build Project Shop Drawings TrasmittalsDocument7 pagesLusail Palaces Design and Build Project Shop Drawings TrasmittalsMohamedHanyNo ratings yet

- Installation Manual: Air To Water Heat PumpDocument186 pagesInstallation Manual: Air To Water Heat PumpbernardNo ratings yet

- Dimplex Bwp30hlw - Manual TécnicoDocument21 pagesDimplex Bwp30hlw - Manual Técnicohmgp1975No ratings yet

- Principles of Air ConditioningDocument23 pagesPrinciples of Air ConditioningGeorgios Roumpies100% (2)

- SoluçãoDocument16 pagesSoluçãoFrancisco Rafael CerónNo ratings yet

- Pulse Tube RefrigeratorDocument6 pagesPulse Tube Refrigeratormuna222No ratings yet

- A4351S09 12 Cooling LoadsDocument49 pagesA4351S09 12 Cooling LoadsFarid SedekyNo ratings yet

- Displacement Design GuideDocument52 pagesDisplacement Design GuideNoushad P HamsaNo ratings yet

- Manual B1012 EDocument24 pagesManual B1012 ERPNo ratings yet

- DHW Systems Water Heaters Catalog Nov14Document52 pagesDHW Systems Water Heaters Catalog Nov14Vin BdsNo ratings yet

- Water Cooled Screw Chiller Service ManualDocument90 pagesWater Cooled Screw Chiller Service Manualshajil100% (1)

- Freezeco TrifoldDocument6 pagesFreezeco Trifoldjpdavila205No ratings yet

- Direct Expansion & Tempered Water: Specification Sheets ForDocument84 pagesDirect Expansion & Tempered Water: Specification Sheets ForgregmNo ratings yet

- 03 Rhoss Tcaey-Thaey-Txaey 115-238 Compact-Y en NTDocument60 pages03 Rhoss Tcaey-Thaey-Txaey 115-238 Compact-Y en NTJosé MacedoNo ratings yet

- Tg-Bec 2015Document210 pagesTg-Bec 2015Simoncarter LawNo ratings yet

- SolarDocument12 pagesSolarabdulwadi84No ratings yet

- Split System Air ConditionersDocument124 pagesSplit System Air ConditionersLubyanka100% (1)

- Boiler EuroDocument2 pagesBoiler EuroCristi SoareceNo ratings yet

- Amonia Energy PDFDocument10 pagesAmonia Energy PDFLeonardo PachecoNo ratings yet

- Heat Exchanger DesignDocument2 pagesHeat Exchanger DesignAmit Sharma ParasharNo ratings yet