Professional Documents

Culture Documents

Gantry Crane Wheel

Uploaded by

spnatuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gantry Crane Wheel

Uploaded by

spnatuCopyright:

Available Formats

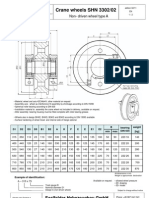

C1-30-EN

SIBRE Crane Wheel Systems

B06 20 224 E-EN page 1 / 12 04.2009

page General Applications Driven- and Non-Driven Assemblies with roller bearing similar to DIN 15090 codification of Wheels Wheel shape codification Shaft Types of driven Wheel Assemblies Selection Parameter Support of Wheel Assemblies Dimensions and Nomenclature of Wheel Assemblies Driven- & Non-Driven Assemblies with spherical roller bearing series 222 approx. Weights of Driven- & Non-Driven Wheel Assemblies Parts List for Driven- & Non-Driven Wheel Assemblies Basics of Wheel Assembly Calculation (extract of DIN 15070) Rectified nominal life time of bearings L10h in hours [h] Example of calculation 2 2 2 3 3 4 4 5 6 7 7 8 9 11 12

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

General

B06 20 224 E-EN page 2 / 12 04.2009

Wheels are machine-components with load bearing function. When selecting wheels and their material quality, a broad variety of options is available. Our production portfolio includes separate wheels of diameter 315 to 1000 mm as well as complete wheel assemblies similar to DIN, as per customer drawing or as design proposal approved by our customer. SIBRE standard wheels are made of forged cylinders of material 42CrMo4V. For particularly high demands the wheels can be deep-hardened for reduced tread-wear.

Applications

Gantry Travel Drives Trolley Travel Drives Slewing Drives etc.

Driven- and Non-Driven Assemblies with roller bearing similar to DIN 15090

pict. 1: Driven Wheel Assembly: T- BHKE 500x90 Z 100x152 222

pict. 2: Non-Driven Wheel Assembly: M- BHKE 500x90 222

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

B06 20 224 E-EN page 3 / 12 04.2009

pict. 3: Driven Wheel Assembly: T- SHKD 500x90 P 90x132

pict. 4: Non-Driven Wheel Assembly: M- SHKD 500x90 222

codification of Wheels

T BHKE 500x90 Z100x152 222 bearing series shaft end as adapter shaft 100x152, series 2 wheel , dimension b1 wheel shape codification

driven wheel assembly

Wheel shape codification

code

meaning narrow wheel wide wheel wheel with flanges wheel without flanges wheel without rim with oil-pressure interference fit assembly without oil-pressure interference fit assembly

S B

H

G K D E

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Shaft Types of driven Wheel Assemblies

We supply driven wheel assemblies with shafts for any type of drive

Ausf hrtype ung " P"

B06 20 224 E-EN page 4 / 12 04.2009

Ausf hrtype ung " Z" Ausf hrtype ung " H"

Ausf hrtype ung " V"

DI N 5480

pict. 5

with connecting shaft resp. coupling hub with key-way acc. DIN 6885 T1 with gearing acc. DIN 5480 with extended shaft for slide on gear box with shrink disc

type Z type P type V type H

Selection Parameter

For an optimum selection, the following parameter must be indicated by the customer wheel load rail profile and material travelling speed, rotation speed life expectiation ambient conditions available assembly dimensions wheel shape B (wide), S (narrow) type of shaft end for drive wheel assemblies

Wheel calculation is made acc. to DIN 15070 and the bearing calculation is made acc. to DIN 15071. Correlation of wheel profile and rail is selected acc. to DIN 15072.

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Support of Wheel Assemblies

B06 20 224 E-EN page 5 / 12 04.2009

In parallel to the wheel assemblies with 45 split support (pict. 6), we can also supply driven- and nondriven wheel assemblies with rectangular split support (pict. 7) similar to TGL 34968.

pict. 6: 45 split support

pict. 7: rectangular split support

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Dimensions and Nomenclature of Wheel Assemblies

b2 b1 9 10 16 11 1 11 16 10 9 15

B06 20 224 E-EN page 6 / 12 04.2009

15

l 5

11

7 12 d2 d1 d5 d4 d3

Area drawn 15 offset Ber ei ch um 15 ver set zt gezei chnet

17 4 2 8 13 3 5 14 l 6 l 1 l 2 l 12 14 6 3 13 6

pict. 8: driven wheel assembly type T-BHKE

9 10 16 11 b2 b1 1 11 16 10 9 15 15 7 n l 5 n

12 d2 d1 d5 d4

Area 15 offset Ber ei drawn ch um 15 ver set zt gezei chnet 12

17 4

d3

17

2 4

13

13 5 14 l 1 14 l 1 6 3

l 6

pict. 9: non-driven wheel type M-BHKE

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

d7

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Driven- & Non-Driven Assemblies with spherical roller bearing series 222

dimensions and shape for wheels d1 h9 315 400 500 630 710 800 900 1000 S B S B S B S B S B S B S B S B 45-55 55-65 55-65 70-90 55-65 70-90 65-75 80-110 75-90 95-160 75-90 95-160 75-90 95-160 75-90 95-160 90 110 350 110 120 110 120 440 140 130 110 130 540 140 140 120 160 680 160 180 140 170 760 210 190 140 180 850 210 200 140 190 950 210 230 140 200 1050 210 250 Form

1)

B06 20 224 E-EN page 7 / 12 04.2009

b1

2)

b2

6)

d2

d3

3)

d4 h7 210 230 230 250 250 265 290 330 310 350 330 370 350 420 370 480

d5

l5

6)

l1 171 173 188 202 202 210 237 245 249 278 255 289 268 315 279 332

l6

n +0,15 +0,05 62 62 72 72 82 94 94 104 94 114 104 134 114 146

Roller bearings acc. DIN 635-2

dims. only for driven wheel assemblies l2 d7

4)

l12

d7

4)

l12

5)

220 240 240 260 260 275 305 345 325 365 345 385 365 435 385 500

110 140 140 150 160 180 210 180 210 190 210 190 210

235 265 280 280 290 325 335 350 395 355 405 375 430 385 450

222 18 222 20 222 20 222 22 222 22 222 24 222 26 222 30 222 28 222 32 222 30 222 34 222 32 222 40 222 34 222 44

185 190 205 215 215 225 250 265 260 300 275 310 290 335 300 355

series1 70 105 70 105 80 120 80 100 100 110 110 130 140 160 120 152 152 152 172 202 202

series 2 70 105 80 120 80 120 90 132 90 132 100 152 100 152 110 110 152 130 172 120 172 140 202 130 172 160 202 140 202 180 252

1) S = narrow wheel B = wide wheel 2) dimension for track gauge b1 when ordering please advise 3) interference fit of wheel and shaft; H7 / u6 4) tolerance for d7 acc. to DIN 15091. 5) series 2 is in accordance with cardan shaft classification acc. to DIN 15450. 6) for wheel shape S dimensions b2 and l5 are not identical

approx. Weights of Driven- & Non-Driven Wheel Assemblies

series 222 Wheel 1) shape d1 h9 S 315 B S 400 B S 500 B S 630 B S 710 B S 800 B S 900 B S 1000 B

weight2)

1) S = narrow wheel = in kgs 3) non-driven HK GK 95 145 150 220 210 205 305 290 345 540 515 460 790 755 560 975 930 675 1260 1220 835 1610 1570

B = wide wheel.

driven HK GK 100 150 155 230 220 215 315 300 360 560 530 475 820 780 580 1010 960 700 1310 1240 865 1680 1590

3)

2) weight calculation is based on series 2 of shaft ends, without connecting flange resp. coupling disc, referring to max. b1. Indicated weights are approx. figures and are supposed to provide an orientation. The actual weight depends on the selected version and the selected manufacturing process. 3) see codification

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Parts List for Driven- & Non-Driven Wheel Assemblies

quantities for wheel- d1 Pos. No. Nomenclature 315 S 1 wheel B 400 S B 500 S B Driven Wheel assy 630 S B 1 710 S B 800 S B 900 S B 1000 S B 315 S B 400 S B 500 S B Non-driven wheel assy 630 S B 1 710 S B 800 S B 900 S B

B06 20 224 E-EN page 8 / 12 04.2009

material / DIN 1000 S B 42CrMo4V

wheel shaft

42CrMo4V

bearing frame

St 52-3

cover

St 52-3

cover

St 52-3

cover

St 52-3

shaft washer

St 52-3

wheel bushing

C 45

nipple adapter

9SMn28K

10

spherical roller bearing

222 SNR premier

11

shaft sealing

NBR

12

hexagon screw

DIN 933-8.8 VZ

13

hexagon screw

16

16

16

16

24

16

24

24

24

24

16

16

16

16

24

16

24

24

24

24

DIN 931-8.8 VZ

14

hexagon nut

16

16

16

16

24

16

24

24

24

24

16

16

16

16

24

16

24

24

24

24

DIN 934-8 VZ

15

grease nipple

DIN 3404 A2

16

grub screw

DIN 913-45H VZ

17

lock washer

B 53070 VZ

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Basics of Wheel Assembly Calculation (extract of DIN 15070)

Calculation of wheels: The wheel force is calculated acc. following formula:

B06 20 224 E-EN page 9 / 12 04.2009

R p zul c 2 c 3 d1 (k 2 r1 )

The result is the wheel diameter:

(1)

d1 =

R p zul c 2 c 3 (k 2 r1 )

R k-2r pzul d1 c2 c3

(2)

= wheel force [N] = ideal usable width of rail head [mm] = allowed compression between wheel and rail [N/mm] = diameter of wheel [mm] = rotation speed factor [chart mating of materials] = operating time factor [chart mating of materials]

The characteristic wheel force R0 is the result of equation (1) if: pzul c2 c3 inserted to: = 5,6 N/mm =1 =1 (3)

R 0 = 5,6 d1 (k 2 r1 )

R0 = characteristic wheel force

By usage of characteristic wheel force the allowed wheel force can be calculated simplified by following formula

R R0 c1 c 2 c 3

(4)

For crane wheels:

R=

R min + 2 R max 3

Rmax Rmin = max wheel force [N] = min. wheel force [N]

(5)

For trolley wheels:

R = R max

(6)

Rmax and Rmin should be found by the frequent operating position of charged trolley.

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Mating of Materials Rail / Wheel

allowed compression pzul and material- factor c1 material pzul tensile strength at least c1 N/mm N/mm rail wheel 590 330 2.8 0.5 410 3.6 0.63 490 4.5 0.8 590 5.6 1.0 690 740 7.0 1.25 operating time- factor c3 Operating time of travel drive c3 (referred to 1 hour) up to 16% 1.25 over 16 25% 1.12 over 25 40% 1 over 40 63% 0.9 over 65% 0.8

B06 20 224 E-EN page 10 / 12 04.2009

wheel - rotation speed - factor n, c2 -1 n min 200 160 125 112 100 90 80 71 63 58 50 45 40 35.5 31.5 c2 0.66 0.7 0.77 0.79 0.82 0.84 0.87 0.89 0.91 0.92 0.94 0.96 0.97 0.99 1.0 wheel - rotation speed - factor n, c2 -1 n min 28 25 22.4 20 18 16 c2 1.02 1.03 1.04 1.06 1.07 1.09

14 1.1

12.5 11.2 10 8 6.3 5.6 5 1.11 1.12 1.13 1.14 1.15 1.16 1.17

Characteristic Wheel Force R0

Chart I wheeldiameter d1 [mm] 315 400 500 630 710 800 900 1000 R0 in N narrow wheel for crane rail: A 45 A 55 A 65 65000 83000 101000 104000 126000 159000 187000 211000 R0 in N wide wheel for crane rail: A 75 A 55 A 65 A 75 A 100 79000 119000 132000 148000 165000 208000 282000 235000 318000 264000 358000 297000 403000 330000 448000

A 120 398000 448000 504000 560000

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Rectified nominal life time of bearings L10h in hours [h]

B06 20 224 E-EN page 11 / 12 04.2009

Nominal characteristic- life time of bearings LKenn in hours [h] (calculatet with characteristic wheel forces R0 and the factors c1 = c2 = c3 = 1,0) for spherical roller bearings, type 222, SNR premium. Chart II wheeldiameter d1 [mm] 315 400 500 630 710 800 900 1000 narrow wheel wide wheel

for crane rail: for crane rail: A 45 A 55 A 65 A 75 A 55 A 65 A 75 A 100 A 120 336000 355000 297000 154000 215000 152000 330000 174000 155000 108000 210000 122000 218000 79000 119000 83000 83000 39000 95000 91000 43000 100000 135000 64000 114000 183000 87000

The figures for bearing lifetime L Kenn as mentioned in chart II are based on characteristic wheel force R0 with factors c1 = c2 = c3 = 1,0 according DIN 15070. Differing wheel forces and factors can be calculated simplified as follows: Nominal life time of bearings:

L10 h

1 = LKenn c Ges

10 / 3

31,5 nvorh

[h]

(7)

L Kenn: according Chart II [h] -1 n vorh: existing rotation speed [min ] C ges: total factor Based on given wheel force R and by usage of characteristic wheel force acc. DIN 15070, the total factor can be calculated simplified with following formula:

R R 0 c 1 c 2 c 3 R 0 c Ges c Ges = R R0

(8)

(9)

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

C1-30-EN

SIBRE Crane Wheel Systems Laufradsysteme

Example of calculation

wheel diameter wheel type existing rail average rotation speed max. wheel force min. wheel force : d1 : B : A : n vorh : R max : R min = 75 = 77 min

-1

B06 20 224 E-EN page 12 / 12 04.2009

= 400 mm

= 145 kN = 45 kN

Wheel force:

R=

R min + 2 R max 3

(5) = 111,7 KN

R=

45 + 2 145 3

Total factor:

c Ges =

R R0

= 132 kN DIN 15070 = 400 mm = A 75

(6)

R0 wheel crane rail

c Ges =

111,7 132

= 0,85

Nominal life time:

L10h

1 = L Kenn c Ges

L Kenn

10 / 3

31,5 n vorh

[h]

(7) [from chart II]

= 152000 h

10 / 3

1 L 10h = 152000 h 0,85

L10h = 106800 h

31,5 = 77

Alterations reserved Siegerland Bremsen Emde GmbH & Co. KG Auf der Stcke 1-5 D-35708 Haiger, Germany Tel.: +49 2773 94000 Fax: +49 2773 9400-10 e-mail: info@sibre.de www.sibre.de

G:\CATALOGUES\DE-EN CATALOGUES\DOC-CATALOGUE\12 Components\C1-30 EN Laufradsystem 2009-04.doc

You might also like

- BevelsDocument15 pagesBevelsJitender Reddy50% (2)

- Gantry Cranes-Design ProcedureDocument29 pagesGantry Cranes-Design ProcedurePoulami Guchhait100% (5)

- Technical Data/component Parts: Demag Pillar and Wall-Mounted Slewing Jib CranesDocument52 pagesTechnical Data/component Parts: Demag Pillar and Wall-Mounted Slewing Jib CranesНиколаЖижовић100% (1)

- Winch DesignDocument132 pagesWinch DesignShreyas Raut100% (2)

- User ManualDocument135 pagesUser ManualRaghuveer Rao Pallepati100% (2)

- Circuit Diagrams P160110 Rev.0Document24 pagesCircuit Diagrams P160110 Rev.0tuyetden613No ratings yet

- Crane Wheel Systems Sra / SRNDocument28 pagesCrane Wheel Systems Sra / SRNKovács Endre100% (1)

- Double Beam Gantry CraneDocument5 pagesDouble Beam Gantry CraneRandy AriaputraNo ratings yet

- Abus Cranes CatalogDocument28 pagesAbus Cranes CatalogGeorge JabbourNo ratings yet

- Crane Rating ChartsDocument48 pagesCrane Rating Chartsjhoward2012npNo ratings yet

- Projectreport ExcavatorArmDocument41 pagesProjectreport ExcavatorArmVinod Yb0% (1)

- 200te Reel Hub DriveDocument3 pages200te Reel Hub Drivejohariak100% (1)

- Crane Wheel Load EccentricityDocument2 pagesCrane Wheel Load Eccentricitypranit_rai0% (1)

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDocument6 pagesFEA and Optimization of Telescopic Boom of Mobiles Hydraulic Cranenpd1986100% (2)

- Thong So Ky ThuatDocument30 pagesThong So Ky ThuatQuang HưngNo ratings yet

- Hoist CapacityDocument10 pagesHoist CapacityDheeraj ThakurNo ratings yet

- Liebherr Winch SystemsDocument8 pagesLiebherr Winch SystemsGuglielmo CancelliNo ratings yet

- Gantry Crane WheelsDocument3 pagesGantry Crane WheelsflasnicugNo ratings yet

- Hitachi Wire Rope HoistDocument50 pagesHitachi Wire Rope HoistVananh Nguyen100% (2)

- 30tonne Transvictory Double Drum Winch PDFDocument1 page30tonne Transvictory Double Drum Winch PDFIvan MaltsevNo ratings yet

- Liebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFDocument8 pagesLiebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFJuan David Cabrera CardonaNo ratings yet

- 30te Hydraulic Winch: Underwater Technology Services (S) Pte LTDDocument5 pages30te Hydraulic Winch: Underwater Technology Services (S) Pte LTDjohariakNo ratings yet

- SPMT and Pump Data PDFDocument5 pagesSPMT and Pump Data PDFlipanzyNo ratings yet

- CraneDocument11 pagesCranesamuelNo ratings yet

- Tutorial Design of Cranes 2017Document2 pagesTutorial Design of Cranes 2017rip11117633% (3)

- Hoisting DesignDocument25 pagesHoisting DesignIshaan00748850% (2)

- Liebherr Crane Summary Specification P131L LCC4740-0 19-12-2014Document8 pagesLiebherr Crane Summary Specification P131L LCC4740-0 19-12-2014CallumWoodwardNo ratings yet

- Offshore Latticed Structures - Analysis of The Lattice Crane BoomDocument1 pageOffshore Latticed Structures - Analysis of The Lattice Crane BoomGogyNo ratings yet

- LIFTECH - Container Crane DesignDocument49 pagesLIFTECH - Container Crane Designaiyubi2100% (1)

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraNo ratings yet

- ABUS Overhead CranesDocument36 pagesABUS Overhead CranesAya AlgalladNo ratings yet

- Cross Travel Motor Power CalculationsDocument1 pageCross Travel Motor Power Calculationssmarika_16No ratings yet

- Syncrolift EngDocument2 pagesSyncrolift EngBahman IraniNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationAbhiNo ratings yet

- Katalog Stahlplus EngDocument254 pagesKatalog Stahlplus EngNilesh MahajanNo ratings yet

- Quay Crane Productivity Paper PDFDocument12 pagesQuay Crane Productivity Paper PDFAdnan BhuttoNo ratings yet

- Catalog CRANEDocument37 pagesCatalog CRANEhipreyashNo ratings yet

- Telescopic Boom Cranes - Lifetime ExcellenceDocument3 pagesTelescopic Boom Cranes - Lifetime ExcellenceAzwar SalehNo ratings yet

- 11 Traction Winch SystemsDocument14 pages11 Traction Winch Systemsimmanueljd100% (1)

- Design and Analysis For CraneDocument10 pagesDesign and Analysis For CraneOmar WardehNo ratings yet

- HaGun Gantry CraneDocument131 pagesHaGun Gantry CraneXwerty BoxNo ratings yet

- Cranes Manual VINCA Ver 01-10 enDocument32 pagesCranes Manual VINCA Ver 01-10 enMarcNo ratings yet

- Atlas 30tonne Waterfall Hyd Transvictory Winch Spec Sheet PDFDocument1 pageAtlas 30tonne Waterfall Hyd Transvictory Winch Spec Sheet PDFIvan MaltsevNo ratings yet

- Gantry Girders - Sections and Design - Construction - Civil Engineering PDFDocument12 pagesGantry Girders - Sections and Design - Construction - Civil Engineering PDFDinesh VermaNo ratings yet

- Wheel Load Data PDFDocument54 pagesWheel Load Data PDFDinesh PatilNo ratings yet

- 科尼起重机 ShipyardDocument16 pages科尼起重机 ShipyardHui ChenNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument10 pagesPveng: Pressure Vessel Engineering LTDseshuNo ratings yet

- Leveling System Controller Electro-HydraulicDocument5 pagesLeveling System Controller Electro-HydraulicCHRISTIAN LOPEZ FLOREZNo ratings yet

- Final of Goliath CraneDocument22 pagesFinal of Goliath CraneKaran Kaul50% (2)

- Crane ManaulDocument18 pagesCrane ManaulfaisalnadimNo ratings yet

- PUSNES Deck Machinery Installation ProcedureDocument18 pagesPUSNES Deck Machinery Installation ProcedurexatzaraNo ratings yet

- Crane HookDocument55 pagesCrane HookEr Prabhakar100% (3)

- Technical Wire RopesDocument17 pagesTechnical Wire RopesAdrian CantaragiuNo ratings yet

- Tractive Force SPMTDocument1 pageTractive Force SPMTBHAUMIK SOLANKI0% (2)

- Gantry Crane Design Calculations - Google SearchDocument2 pagesGantry Crane Design Calculations - Google SearchJebin Abraham100% (1)

- UR A Pdf148 Mooring AnchoringDocument21 pagesUR A Pdf148 Mooring AnchoringMeleti Meleti MeletiouNo ratings yet

- Sibre Crane Wheel SystemsDocument13 pagesSibre Crane Wheel SystemsLeonardo CanditoNo ratings yet

- Sibre Crane Wheel SystemsDocument13 pagesSibre Crane Wheel Systemsdotsy11No ratings yet

- C1 30 - 3 EN Crane Wheel SystemsDocument16 pagesC1 30 - 3 EN Crane Wheel SystemsKovács EndreNo ratings yet

- Non-Driven Wheel DIN15090 Series 223 EN PDFDocument1 pageNon-Driven Wheel DIN15090 Series 223 EN PDFayavuzbvsNo ratings yet

- Non-Driven Wheel DIN15090 Series 223 enDocument1 pageNon-Driven Wheel DIN15090 Series 223 enayavuzbvsNo ratings yet

- Non-Driven Wheel SHN 3302 enDocument1 pageNon-Driven Wheel SHN 3302 enAnonymous Hy5Ir9QXNo ratings yet

- Steel MillsDocument60 pagesSteel MillsJulio CarbonettiNo ratings yet

- Treak Sayhadri2008Document5 pagesTreak Sayhadri2008spnatuNo ratings yet

- Hwe Zero Velocity Valve Rev 1Document1 pageHwe Zero Velocity Valve Rev 1spnatuNo ratings yet

- NayaSaral FormDocument2 pagesNayaSaral FormspnatuNo ratings yet

- 6 - EDMS CompletionDocument60 pages6 - EDMS CompletionspnatuNo ratings yet

- 5 - EDMS StudyDocument4 pages5 - EDMS StudyspnatuNo ratings yet

- Coping With Information Overload: Is Your E-Mail An E-Pile?Document36 pagesCoping With Information Overload: Is Your E-Mail An E-Pile?spnatuNo ratings yet

- 4 - Implementing Electronic Document ManagementDocument19 pages4 - Implementing Electronic Document ManagementspnatuNo ratings yet

- Our Product Range: Single Girder E.O.T. Crane (Up To 10 Tons)Document3 pagesOur Product Range: Single Girder E.O.T. Crane (Up To 10 Tons)spnatuNo ratings yet

- GettingStarted Guide Libre OfficeDocument360 pagesGettingStarted Guide Libre OfficespnatuNo ratings yet

- 3 - Edms-2Document4 pages3 - Edms-2spnatuNo ratings yet

- 1 - Joomla 3 in Ten Easy StepsDocument84 pages1 - Joomla 3 in Ten Easy StepsspnatuNo ratings yet

- 2a - Introduction To Joomla 3Document3 pages2a - Introduction To Joomla 3spnatuNo ratings yet

- 1 - EdmsDocument6 pages1 - Edmsspnatu0% (1)

- 2 - Document ManagementDocument6 pages2 - Document ManagementspnatuNo ratings yet

- Ndian StandardS ListDocument314 pagesNdian StandardS ListspnatuNo ratings yet

- Central Water Commission - Schedule of Rates 2012Document124 pagesCentral Water Commission - Schedule of Rates 2012Moni Sankar Hazra100% (1)

- Manual For The Design of Pipe Systems and Pumps - GEADocument56 pagesManual For The Design of Pipe Systems and Pumps - GEABeomHee LeeNo ratings yet

- Economics of R.C.C. Wate..Document15 pagesEconomics of R.C.C. Wate..spnatuNo ratings yet

- Construction of Concrete RoadDocument2 pagesConstruction of Concrete RoadspnatuNo ratings yet

- Earthquake Tips IITDocument2 pagesEarthquake Tips IITTarun GoelNo ratings yet

- INDIAN Steel TableDocument6 pagesINDIAN Steel TableKingshuk SarkarNo ratings yet

- Pump Sump-Design General PrinciplesDocument14 pagesPump Sump-Design General Principlesspnatu0% (1)

- Seismic Evaluation of Existing BLDGDocument33 pagesSeismic Evaluation of Existing BLDGMunna BhaiNo ratings yet

- Our Product Range: Single Girder E.O.T. Crane (Up To 10 Tons)Document3 pagesOur Product Range: Single Girder E.O.T. Crane (Up To 10 Tons)spnatuNo ratings yet

- Garib Rath of Indian Rai..Document3 pagesGarib Rath of Indian Rai..spnatuNo ratings yet

- Unit 10 Water Tanks: StructureDocument28 pagesUnit 10 Water Tanks: StructureMuhammad FaisalNo ratings yet

- 002-Retaining Wall DesignDocument3 pages002-Retaining Wall DesignBijay Krishna DasNo ratings yet

- HMT16 MarksDocument12 pagesHMT16 MarkstagoreboopathyNo ratings yet

- Solution Stoichiometry 1Document54 pagesSolution Stoichiometry 1Johncy MoradaNo ratings yet

- RulesonEarthquake - AccelerographDocument17 pagesRulesonEarthquake - AccelerographmjfprgcNo ratings yet

- FF7AN - Credit ManagementDocument6 pagesFF7AN - Credit ManagementRoberta FernandesNo ratings yet

- Air-Pollution-Meteorology UNIT IIDocument91 pagesAir-Pollution-Meteorology UNIT IIDR. Ramesh ChandragiriNo ratings yet

- Itp582b-515-01-Ib 2Document12 pagesItp582b-515-01-Ib 2Cara & Drei Amazing JourneyNo ratings yet

- Synthetic Fiber Reinforced ConcreteDocument13 pagesSynthetic Fiber Reinforced ConcreteSahir Abas0% (1)

- Vmware Vsphere 4: The Best Platform For Building Cloud InfrastructuresDocument5 pagesVmware Vsphere 4: The Best Platform For Building Cloud InfrastructuresAshok Reddy AdurintiNo ratings yet

- 7 Maths em 2020-21Document326 pages7 Maths em 2020-21ThNo ratings yet

- Elemental Analysis of Crude OilsDocument8 pagesElemental Analysis of Crude OilsMirzan Alexandra Torres LaraNo ratings yet

- Chapter 4 - Production TheoryDocument10 pagesChapter 4 - Production TheorypkashyNo ratings yet

- Appendix15B - RE Wall Design ChecklistDocument6 pagesAppendix15B - RE Wall Design ChecklistRavi Chandra IvpNo ratings yet

- ch12 칼리스터 재료과학과 공학 답지Document71 pagesch12 칼리스터 재료과학과 공학 답지hayun9999999No ratings yet

- Product Position and Overview: Infoplus.21 Foundation CourseDocument22 pagesProduct Position and Overview: Infoplus.21 Foundation Courseursimmi100% (1)

- LG FlatRon RepairDocument55 pagesLG FlatRon Repairdany89roNo ratings yet

- ISO 10110 Optical Drawing StandardsDocument17 pagesISO 10110 Optical Drawing Standardskalvino314No ratings yet

- Linear Interpolation Equation Formula Calculator PDFDocument3 pagesLinear Interpolation Equation Formula Calculator PDFMatthew HaleNo ratings yet

- Concrete Mix DesignDocument36 pagesConcrete Mix Designamitbd80% (5)

- Ansys ManualDocument124 pagesAnsys ManualUdamanNo ratings yet

- Kathrein 80010430 PDFDocument1 pageKathrein 80010430 PDFRaúl Fernández SánchezNo ratings yet

- Diversity in DNS Performance MeasureDocument13 pagesDiversity in DNS Performance MeasureAllan LeandroNo ratings yet

- Vdot Training TabelDocument7 pagesVdot Training TabelVarto RazvanNo ratings yet

- TERZ 94OMManualRev0107 PDFDocument66 pagesTERZ 94OMManualRev0107 PDFRoberto Andres Vasquez Campusano75% (4)

- Lipid TestDocument4 pagesLipid TestHak KubNo ratings yet

- Statistics Fall2013 - Final Sample Test 01Document7 pagesStatistics Fall2013 - Final Sample Test 01Thanh VyNo ratings yet

- MX60 Manual Rev6 2Document48 pagesMX60 Manual Rev6 2wgenNo ratings yet

- Presupposition: A Short PresentationDocument13 pagesPresupposition: A Short PresentationShaimaa SuleimanNo ratings yet

- Neil - Bernardo@eee - Upd.edu - PH Bernalyn - Decena@eee - Upd.edu - PH Ephraim - Lizardo@eee - Upd.edu - PHDocument3 pagesNeil - Bernardo@eee - Upd.edu - PH Bernalyn - Decena@eee - Upd.edu - PH Ephraim - Lizardo@eee - Upd.edu - PHbdec95No ratings yet