Professional Documents

Culture Documents

Form Work

Uploaded by

jamilhse7759Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Form Work

Uploaded by

jamilhse7759Copyright:

Available Formats

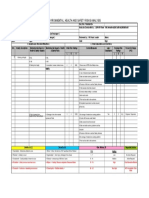

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

Safe Work Method Statement

COMPANY DETAILS Precision Formwork & Constructions Pty Ltd 6/226 The Boulevarde Punchbowl NSW 2196 ABN: 18 120 614 057 Accepted: Yes Job: No ERECTION AND DISMANTLING OF FORMWORK Possible Hazards: Risk Score

Risk Potential *Class 1, 2 or 3

Project Name and Site Address: ______________________________________________ __________________________________________________________________________

Signed off:

Name in Full: ______________________________________________ Signature: _________________________________________________

Date: ________________________

No: ___________________

Area: Safety Controls:

Procedure (in steps):

Break the job down into steps. Each step should accomplish some major task and be in a logical sequence.

Identify the hazards associated with each step. Examine each to find possibilities that could lead to an accident.

Specify what action or procedure will be taken to eliminate or minimise the risk of injury or damage. Include what measures will be taken to ensure that the safety control is maintained.

Responsible Person

1.

Planning & arranging materials

Inadequate access, poor selection of equipment, inadequate employee numbers lead to possible risk of manual handling injuries,

Work site assessment completed and Scope of works completed including listing of equipment requirements, staffing levels, site hazards and difficulties. Arrangements will be made for delivery schedule of materials.

Precision Formwork & Construction Site Forman

2.

Delivery of materials and site set up

Transporting materials to areas of work lead to manual handling risks

Small materials will be palletized and delivered by truck with mounted crane by (less than 10 tonne) for unloading. Larger materials will be delivered by truck with slewing crane with certified operator and dogman for unloading.

truck driver

* Class 1: Death or Permanent Disability

Class 2: Serious Injury/Lost Time

Class 3: Minor Injury resulting in no lost time

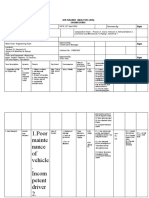

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

Procedure (in steps) continued :

Break the job down into steps. Each step should accomplish some major task and be in a logical sequence.

Possible Hazards:

Identify the hazards associated with each step. Examine each to find possibilities that could lead to an accident.

Risk Score

Risk Potential *Class 1, 2 or 3

Safety Controls:

Specify what action or procedure will be taken to eliminate or minimise the risk of injury or damage. Include what measures will be taken to ensure that the safety control is maintained. Responsible Person

3.

Delivery of materials and site set up

Site unknown to workers lead to possible incidents involving other contractors, and site hazards

1-3

Team to be provided with site induction on arrival by Principal Contractor. Site notices to be posted and barriers put in place as needed. PPE must be worn at all times (include hard hats, safety shoes, fluoro wear All materials and equipment will be transported to work area by crane. See SWMS for Crane Operation All timbers will be visually inspected at commencement of the job. Barbs, nails etc will be removed with pliers, tools. Structurally Defective timbers are removed from use. All timber and equipment will be inspected and serviced as required by manufacturer and recorded on the plant and equipment register Faulty plant and equipment will be tagged out of service and removed from site.

Precision Formwork & Construction Forman and Builder Warehouse caretaker Precision Formwork & Construction Forman

4. 5.

Transport of materials from trucks to floors of building Inspection of Timbers & Equipment

Pedestrians and workers being hit by falling objects and manual handling risks Risk of splinters and cuts to workers. Possible risk of failure of timbers and equipment

2 2

6.

Erection of formwork whilst other work (i.e. demolition or excavation etc.) is being carried out

Risk of being hit by plant such as excavators Risk of being hit by debris from other trades work like brick layers, demolition works, jip rockers and services trades etc.

2 2

Use barrier via tap or other wise to seal off areas were work is being carried out away from any plant machinery operating. PPE must be worn at all times (include hard hats, safety shoes, fluoro wear

Precision Formwork Construction Forman

* Class 1: Death or Permanent Disability

Class 2: Serious Injury/Lost Time

Class 3: Minor Injury resulting in no lost time

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

Procedure (in steps) continued :

Break the job down into steps. Each step should accomplish some major task and be in a logical sequence.

Possible Hazards:

Identify the hazards associated with each step. Examine each to find possibilities that could lead to an accident.

Risk Score

Risk Potential *Class 1, 2 or 3

Safety Controls:

Specify what action or procedure will be taken to eliminate or minimise the risk of injury or damage. Include what measures will be taken to ensure that the safety control is maintained. Responsible Person

7.

Erection of Formwork support & Structure

Defective formwork supports could lead to structural instability of works risk of being hit by falling object. Erection of supports and frames may lead to risk of being hit by attachments and support structures.

All formwork supports, structures and attachments are inspected for defects prior to operations. Defective equipment will not be used. Hardhats and Steel capped boots Engineer to complete hand-over certificate for structure Use structure as per manufacturers recommendations

Precision Formwork & Construction Forman And all workers

Risk of tripping and falling when attaching timbers to framing if no work platform available.

Temporary work platforms to be put in place when attaching framing. Platforms to meet scaffolding standards. Handrails need to be erected on leading edge and post to be screwed down with screws. Harnesses need to be worn and secured to a strong support if a person is to work beyond handrails If platform is in working progress and hand rails are not erected yet, personnel must stay away at least 2 meters from leading edge. PPE must be worn at all times (include hard hats, safety shoes, fluoro wear Workers are not to work in windy or slippery condition on the formwork deck. A platform made up of planks which is to be at least 450mm in total width is to be erected on top of the first set of frames to prevent a fall greater than 2 meters to a hard surface. The same will apply when striping high formwork.

Working on windy or wet days

Working From heights more than 1 frame high can lead to falling in access of 2 meters

* Class 1: Death or Permanent Disability

Class 2: Serious Injury/Lost Time

Class 3: Minor Injury resulting in no lost time

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

Procedure (in steps) continued :

Break the job down into steps. Each step should accomplish some major task and be in a logical sequence.

Possible Hazards:

Identify the hazards associated with each step. Examine each to find possibilities that could lead to an accident.

Risk Score

Risk Potential *Class 1, 2 or 3

Safety Controls:

Specify what action or procedure will be taken to eliminate or minimise the risk of injury or damage. Include what measures will be taken to ensure that the safety control is maintained. Responsible Person

8.

Plying

Inadequate perimeter fencing could lead to risk of fall from height when laying ply when wet or windy conditions are present. Stepping on nail in plywood Woking too close to train line can lead to shock from train power lines or even collision and death with an on passing train . Possible Hazards - Cut to limbs - Electrocution - Many circular saws working in close proximity may cause hearing damage. May damage sight due to flying debris

Erection of fall protection when working at height Scaffolding will be used if in situ. Alternatively hand-rail guarding will be erected. Denial and always work in safe weather conditions Dont go any were near train lines and always keep a safe distance from them. For the purpose out works, there is no work to be carried out any weer near the train lines. Always obtain power from a known power source. Ensure all leads and power tools are tagged monthly. No more than one lead is to be used re joining of a 30m lead is prohibited. Safety glasses and ear plugs are to be worn at all times. Guard must be used when using power saws. A stable platform at waist height must be utilised with the power saw and the timber, lead also should also be well away from water preferably over the shoulder

Precision Formwork & Construction Forman and Builder

9.

Woking next to train line

Power Tools 10.

Precision Formwork & Construction Forman and power tools safety certifier

11. 12.

Delivery and set up of crane on road Stripping

Risk of pedestrian and motor vehicle accident if insufficient planning. Risk of being struck by falling building ceiling, floor if support frames are dropped from under the structure drop stripping. 1 Drop stripping is prohibited for all works. All support jacks will be lowered incrementally with appropriate supports left in situ to minimise risk being hit by falling object. Ply will be removed sheet-by-sheet from the concrete. All timbers will be de-nailed as stripping occurs and stored immediately. No nails will be left on work floor.

Crane contractor Precision Formwork & Construction Forman

Risk of puncture injury if nails are left in timbers when being stripped, all nails should be de-nailed as being stripped.

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

Procedure (in steps) continued :

Break the job down into steps. Each step should accomplish some major task and be in a logical sequence.

Possible Hazards:

Identify the hazards associated with each step. Examine each to find possibilities that could lead to an accident.

Risk Score

Risk Potential *Class 1, 2 or 3

Safety Controls:

Specify what action or procedure will be taken to eliminate or minimise the risk of injury or damage. Include what measures will be taken to ensure that the safety control is maintained. Responsible Person

Risk of being hit by falling object if access to area where stripping is undertaken is not secured.

The work area will be cordoned off by appropriate tape and barriers and signage erected indicating unauthorised access denied. Only 2 workers will be allowed to enter and work in the stripping area at one time. Workers will be appropriately trained. Supervision will be provided. All formwork equipment must be stacked and/or palletised and removed from site immediately after stripping and prior to removal of centralising equipment too ensure adequate access. Area to be cordoned off with tape and barriers to prevent access to non-authorised personnel. Signage to be erected Only 2 competent staff members to remove centralising equipment. Line of site supervision Back propping to be erected prior to dismantling centralising equipment t allow adequate curing time for cement.

Precision Formwork & Construction Forman

13.

Removal of Centralising Equipment

Form work materials left in area could lead to risk of trip/fall risk and inadequate access

Precision Formwork & Construction Forman and Builder

Risk of being hit by falling object when removing centralising equipment

* Class 1: Death or Permanent Disability

Class 2: Serious Injury/Lost Time

Class 3: Minor Injury resulting in no lost time

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

Safe Work Method Statement (Part 2)

Personnel: Site Supervisor Leading Hand Responsibilities: Supervise safe work procedure Safety Inspection Relevant Hand Over Certificate if applicable Follow safe work procedures Store gear in safe isolated area General good housekeeping Wear PPE Competency & Training: General OHS Industry Induction Relevant Competencies Site Specific Induction General OHS Industry Induction Relevant Competencies Site Specific Induction Relevant Tool Box Talk

Workers

Engineering Details/Certificates/WorkCover Approvals: HANDOVER CERTFICATE

Codes of Practice, Legislation: COP Overhead Protection Structures OHS Act 2000, Regulation 2001 COP Manual Handling Regulation 2001 COP Electrical practices for Construction Work Scaffolding: AS/NZS 4576: 1995 AS 1742 Part 3, Traffic Control First Aid Regulation 2001 Certification of Workers Regulation 2001 Work Safety Guide: Rigging Workplace Consultation Regulation 2001 OHS Induction Training Regulation 2001 COP for Formwork 1998 Cat No 009 Work Safety Guide: Moving Plant on Construction sites COP Amenities for Construction Work Regulation 2001 Maintenance Checks: Before use to plant & equipment Random in use to plant & equipment Monthly to electrical equipment On return to plant & equipment

Plant/Equipment/PPE Hard Hats, Steel Capped Shoes, Fluorescent Vests, hearing protection, eye protection U head jacks, Base jacks, Hand tools Frames, Timbers, Ply, Power saws

All workers have been instructed in the SWMS:

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

SAFE WORK INSTRUCTION

TASK OPERATION:

USE OF MOBILE SCAFFOLD

SPECIAL COMMENTS: This procedure is to be used with any operating manuals or training relevant to the tasks.

Platforms or scaffolds should be used for heavy or lengthy work.

N0: SWI009 ACTIVITY STEPS IN ORDER OF PERFORMANCE

Preparation

HAZARDS APPLICABLE TO EACH STEP

Electrocution Falling Falling Tools Strains Abrasions Falling

HOW TO DO IT IDENTIFY EQUIPMENT, SAFETY QUALITY AND PERFORMANCE REQUIREMENTS

Check for overhead Electrical Hazards Check for obvious hazards overhead Tree Branches etc. Scaffold only to be erected on level or near level site Ensure area under scaffold is clear and clean Only erect scaffold on a firm surface Minimum of 4 castors must be provided under the standards (uprights) Every standard not fitted with a castor must be strutted Working load on castors must not be exceeded The maximum height of the scaffold must not exceed 3 times the minimum width All planks must be secured to the scaffold Ensure toe boards are fitted No person shall remain on mobile scaffolding while it is being moved Only one working platform per scaffold When erecting scaffold ensure each joint is locked into place Only use scaffold in accordance with manufacturers instructions All wheel locks must be engaged before entering scaffold Never climb on the outside of the scaffold Two people should always be in attendance when scaffolds are in use Clear area must be maintained around the scaffold using cones, bunting mesh etc. Incomplete and/or unattended scaffold must have appropriate controls to protect against unauthorised access Never drop tools, equipment or materials from the scaffold Safety helmets must be worn when working around or ascending and descending scaffold Materials and tools should be raised and lowered by rope

PERSONAL PROTECTIVE EQUIPMENT REQUIRED

Hard Hats Safety shoes Safety glasses Ear muffs Fluoro shirts All as standard to be worn at all times.

Erection

Falling Tools Strains Abrasions

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

SAFE WORK INSTRUCTION

TASK OPERATION:

USE OF LADDERS

SPECIAL COMMENTS: This procedure is to be used with any operating manuals or training relevant to the tasks.

Platforms or scaffolds should be used for heavy or lengthy work .

N0: SWI008

HOW TO DO IT ACTIVITY STEPS IN ORDER OF PERFORMANCE Safety Precautions HAZARDS APPLICABLE TO EACH STEP Electrocution Falling IDENTIFY EQUIPMENT, SAFETY QUALITY AND PERFORMANCE REQUIREMENTS Check for overhead Electrical Hazards Perform visual check for obvious faults and defects Ensure clean surface for placing ladder Ladders must be used on level Surfaces Do not place a ladder in front of a doorway unless locked or guarded Never use drums, boxes etc., to gain extra height Secure work area around the ladder Clean mud, grass etc, from boots to prevent slippage Use a tool pouch to carry tools Do not leave tools and equipment in ladder rungs Do not over-reach Only one person on a ladder at any one time Face the ladder at all times Ladders should only be used to gain access or for simple operations The top should be lashed into position (by side rails otherwise a person must remain at the bottom to secure the ladders slope of the ladder should not exceed four in one (one meter out for four meters up) The ladders should extend one meter above landing place The Ladders must be placed against a fixed and stable support Do not climb higher than the third rung from the top (WorkCover Safety Guide 4503) Ensure step ladder legs are fully spread Do not climb higher than third step from the top PERSONAL PROTECTIVE EQUIPMENT REQUIRED

Falling Tools Strains

Extension Ladders

Falling Falling tools Strains

Step Ladders

Falling Falling Tools Strains

PRECISION FORMWORK AND CONSTRUCTION PTY LTD

Workers Commitment Forms

Issue: Revision: 1

CLIENT ID: Project: Date:

SWMS/JSA: WC

Company Name:

Precision Formwork & Construction Pty Ltd

I do make an undertaking that I am fully conversant with and comprehend the Job Safety Analysis Statement as submitted by my employer and will act in accordance with the Job Safety Analysis Statement with safe working practices and in a safe manner. JSA Employees Name Signature Date No.

You might also like

- JSA Concrete WorksDocument8 pagesJSA Concrete Worksfrancis_e_tan93% (27)

- JSA Concrete WorksDocument8 pagesJSA Concrete Worksfrancis_e_tan93% (27)

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- Excavation Working in Trenches Swms 10281-6Document17 pagesExcavation Working in Trenches Swms 10281-6JamesNo ratings yet

- Sanesto MG - Risk AssessmentDocument9 pagesSanesto MG - Risk AssessmentReynaldo Taveras SantanaNo ratings yet

- HIRA No. 08 Rev 04 - Adverse WeatherDocument5 pagesHIRA No. 08 Rev 04 - Adverse WeatherVenkadesh PeriathambiNo ratings yet

- Jsa Nitrogen Purging PDFDocument2 pagesJsa Nitrogen Purging PDFBISWA RANJAN SAHOONo ratings yet

- Equipment MobilizationDocument2 pagesEquipment MobilizationSn Ahsan0% (1)

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 pagesJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSNo ratings yet

- Job Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteDocument6 pagesJob Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteNaz ッ Wany100% (1)

- 5.1 ReteachDocument2 pages5.1 ReteachCarlos Pastrana0% (1)

- Certified Quality Director - CQD SYLLABUSDocument3 pagesCertified Quality Director - CQD SYLLABUSAnthony Charles ANo ratings yet

- Neurovascular Holding PointsDocument8 pagesNeurovascular Holding PointsAlexandru Baciu100% (1)

- 06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Document6 pages06 Earthworks, Blinding, Screeding, Water Proofing, Form Work, Reinforcement, Concreting and Cur2Hilbrecht De PedroNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- DemolitionDocument2 pagesDemolitionGanga Daran100% (1)

- Safe Work ProcedureDocument2 pagesSafe Work Proceduresterlin gosineNo ratings yet

- JHA Vessel EntryDocument2 pagesJHA Vessel EntryRiyadh SalehNo ratings yet

- Work Permit ProcedureDocument8 pagesWork Permit ProcedureAmargeet kr RamNo ratings yet

- Hazard Identification FormDocument1 pageHazard Identification Formabdulrazzaq hatem100% (1)

- 2017-7996 Referral-Attach-Indigo 4102 Pep-Part2 Phse Plan TemplateDocument14 pages2017-7996 Referral-Attach-Indigo 4102 Pep-Part2 Phse Plan TemplateOke Adesina GaniyuNo ratings yet

- Job Hazard Analysis Engineering Site Inspection 2Document5 pagesJob Hazard Analysis Engineering Site Inspection 2Nonsoufo ezeNo ratings yet

- 1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002Document3 pages1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002nurul sarahNo ratings yet

- SUMMER WORK PLAN (For Gulf Countries)Document13 pagesSUMMER WORK PLAN (For Gulf Countries)Zubair Khan0% (1)

- MDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - UptdDocument21 pagesMDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - Uptdshamshad ahamedNo ratings yet

- HDPE Plastic PIPE FUSION WELDING WORK METHOD STATEMENT 01 PDFDocument11 pagesHDPE Plastic PIPE FUSION WELDING WORK METHOD STATEMENT 01 PDFSuryakant Suraj100% (1)

- 3.REG001 Training Attendance RegisterDocument81 pages3.REG001 Training Attendance RegisterWelma JohnsonNo ratings yet

- Project HSE Plan KOC - Ge.048Document4 pagesProject HSE Plan KOC - Ge.048Wellfro0% (1)

- Hsse Department: (Solar Alert SDN BHD)Document2 pagesHsse Department: (Solar Alert SDN BHD)syafiq firdausNo ratings yet

- Sample JHADocument5 pagesSample JHAKen100% (1)

- HSE Manual Documentation PDFDocument9 pagesHSE Manual Documentation PDFemeka2012No ratings yet

- Confined Space Entry PermitDocument2 pagesConfined Space Entry PermitradeepNo ratings yet

- SWMS Mobilisation of Blocks For MLT TEST RKDocument14 pagesSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- Confined-Space-Entry ProcedureDocument18 pagesConfined-Space-Entry ProcedureMayur100% (1)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- Permit To Load UnloadDocument2 pagesPermit To Load UnloadSarah HaiderNo ratings yet

- Asphalt and Bitumen Patching PDFDocument1 pageAsphalt and Bitumen Patching PDFcityofdarwingisNo ratings yet

- DM Technical GuidelinesDocument11 pagesDM Technical GuidelinesshyamdameraNo ratings yet

- Excavation & Trenching PlanDocument37 pagesExcavation & Trenching PlanBogdan RaduNo ratings yet

- RA-LE008 For Sheetpiling by Excavator-Mounted Vibro Machine - Upper Changi RoadDocument8 pagesRA-LE008 For Sheetpiling by Excavator-Mounted Vibro Machine - Upper Changi RoadWr ArNo ratings yet

- Batching Plant Project: Initial Environmental Examination (Iee) ReportDocument16 pagesBatching Plant Project: Initial Environmental Examination (Iee) ReportavieNo ratings yet

- Project: Site / Office: Contractor: Date: Time:: Topics To Be Discussed During HSE InductionDocument2 pagesProject: Site / Office: Contractor: Date: Time:: Topics To Be Discussed During HSE InductionBashir ArisarNo ratings yet

- Daily HSE Report 22-12-2018Document117 pagesDaily HSE Report 22-12-2018Moaatazz NouisriNo ratings yet

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- Health, Safety, & Environment Manual: Piling WorksDocument12 pagesHealth, Safety, & Environment Manual: Piling Worksrizal azizanNo ratings yet

- Critical Task Inventory (CTI)Document1 pageCritical Task Inventory (CTI)Salman FareesNo ratings yet

- Heat Stress Management Inspection ChecklistDocument1 pageHeat Stress Management Inspection ChecklistrexivyNo ratings yet

- Absolute Rules DeclarationDocument1 pageAbsolute Rules DeclarationThandabantu MagengeleleNo ratings yet

- Method Statement & Risk Assessment Hydrostatic Leak TestDocument7 pagesMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniNo ratings yet

- WMS Infineon Project Tower ( Lifting Activities)Document14 pagesWMS Infineon Project Tower ( Lifting Activities)tanaNo ratings yet

- Mid West Ports Authority 4.6 Working On, Over or Near WaterDocument9 pagesMid West Ports Authority 4.6 Working On, Over or Near Waterqualiman1No ratings yet

- HSE Weekly Review MOM 11.01.2023Document2 pagesHSE Weekly Review MOM 11.01.2023APEX STRUCTURENo ratings yet

- Pouring PermitDocument1 pagePouring PermitHanz RodriguezNo ratings yet

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- Risk Assessment (2.8) - Ra For Substation - UpdatedDocument234 pagesRisk Assessment (2.8) - Ra For Substation - UpdatedShafie ZubierNo ratings yet

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- Monsoon Safety PlanDocument24 pagesMonsoon Safety Planarka raheemNo ratings yet

- 1 Excavations and TrenchesDocument2 pages1 Excavations and TrenchesAruNo ratings yet

- BargeDocument4 pagesBargeanon_222140886No ratings yet

- Risk Assessment Removal of Walers & StrutsDocument6 pagesRisk Assessment Removal of Walers & StrutsBhargav BbvsNo ratings yet

- JHA For Hill Cutting Activities.R.01Document8 pagesJHA For Hill Cutting Activities.R.01SreekumarNo ratings yet

- Fall Prevention Plan For WAHDocument2 pagesFall Prevention Plan For WAHJimmy LowNo ratings yet

- List of DM TGDocument2 pagesList of DM TGrmsajai0% (2)

- 2640.011SWP - Excavations and TrenchesDocument7 pages2640.011SWP - Excavations and TrenchesHasanuddin HAMIDNo ratings yet

- Section A: Safe Work PlanDocument2 pagesSection A: Safe Work Planjamilhse7759No ratings yet

- Safety NotesDocument14 pagesSafety Notesjamilhse7759No ratings yet

- Risk Assessment 5 Use of Mob Elevating Working Platform (MewDocument1 pageRisk Assessment 5 Use of Mob Elevating Working Platform (Mewjamilhse7759No ratings yet

- Nebosh AnswersDocument6 pagesNebosh AnswersTushar Kanti JhaNo ratings yet

- Safety Alert - EnglishDocument1 pageSafety Alert - Englishjamilhse7759100% (1)

- New Microsoft Office PowerPoint HSE PresentationDocument9 pagesNew Microsoft Office PowerPoint HSE Presentationjamilhse7759No ratings yet

- Chapter 21Document11 pagesChapter 21jamilhse7759No ratings yet

- Translation of Yellow Pages and General Booklet in ArabicDocument11 pagesTranslation of Yellow Pages and General Booklet in Arabicjamilhse7759No ratings yet

- Glossary of HSE TermsDocument20 pagesGlossary of HSE TermsAngel AngeleyeNo ratings yet

- Quran QuizDocument5 pagesQuran QuizWaris HusainNo ratings yet

- Harnesses Insp. RegisterDocument1 pageHarnesses Insp. Registerjamilhse7759No ratings yet

- SKMBT C28012112508060Document8 pagesSKMBT C28012112508060jamilhse7759No ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionsjamilhse7759No ratings yet

- Abrassive Wheel MachineryDocument7 pagesAbrassive Wheel Machineryjamilhse7759No ratings yet

- 8 Welding SymbolsDocument43 pages8 Welding Symbolsjamilhse77590% (1)

- 8 Welding SymbolsDocument43 pages8 Welding Symbolsjamilhse7759No ratings yet

- University of Mumbai: Bachelor of Management Studies (Finance) Semester VIDocument73 pagesUniversity of Mumbai: Bachelor of Management Studies (Finance) Semester VIPranay ShettyNo ratings yet

- Basic English: Unit 14 Guidelines Leisure ActivitiesDocument5 pagesBasic English: Unit 14 Guidelines Leisure ActivitiesDeyan BrenesNo ratings yet

- Sampling TechniquesDocument96 pagesSampling Techniquessixteen liquidoNo ratings yet

- 1.CH 211 IntraductionDocument13 pages1.CH 211 IntraductionCarlos BuchwaNo ratings yet

- 25 - A Hard Days NightDocument2 pages25 - A Hard Days NightBruno GovernatoriNo ratings yet

- Faith Confession SheetDocument5 pagesFaith Confession SheetArjel Jamias100% (1)

- Internetworking Concepts Overview: © 1999, Cisco Systems, IncDocument50 pagesInternetworking Concepts Overview: © 1999, Cisco Systems, IncShashi Kant RaviNo ratings yet

- A Beginner's Guide To Reading Jung - Jungian Center For The Spiritual SciencesDocument6 pagesA Beginner's Guide To Reading Jung - Jungian Center For The Spiritual SciencesRosa ChacónNo ratings yet

- Resume Design 2019Document2 pagesResume Design 2019ezke4pq2100% (2)

- Case Presentation 1Document18 pagesCase Presentation 1api-390677852No ratings yet

- Courtesy Begins at HomeDocument2 pagesCourtesy Begins at Homell Snowitchy llNo ratings yet

- DapusDocument2 pagesDapusIneke PutriNo ratings yet

- The Campanile (Vol 90, Ed 2), Published Oct 22, 2007Document24 pagesThe Campanile (Vol 90, Ed 2), Published Oct 22, 2007The CampanileNo ratings yet

- Microbiology KROK-1 PDFDocument121 pagesMicrobiology KROK-1 PDFHimanshu RanaNo ratings yet

- How Cooking The Books WorksDocument27 pagesHow Cooking The Books WorksShawn PowersNo ratings yet

- Sword Art Online - Unital Ring IV, Vol. 25Document178 pagesSword Art Online - Unital Ring IV, Vol. 257022211485aNo ratings yet

- Safety Awareness TrainingDocument20 pagesSafety Awareness TrainingPl nagappanNo ratings yet

- Thesis Statement For Moral CourageDocument7 pagesThesis Statement For Moral CourageMonica Franklin100% (2)

- Streetcar - A Modern TradegyDocument4 pagesStreetcar - A Modern Tradegyel spasser100% (2)

- 3 - QMT425-T3 Linear Programming (29-74)Document46 pages3 - QMT425-T3 Linear Programming (29-74)Ashraf RadzaliNo ratings yet

- Presentation Management Trainee Batch VII - Mohammad Arian RahmatullahDocument8 pagesPresentation Management Trainee Batch VII - Mohammad Arian RahmatullahMohammad Arian RahmatullahNo ratings yet

- Information Technology SECTORDocument2 pagesInformation Technology SECTORDACLUB IBSbNo ratings yet

- Exercises 2Document7 pagesExercises 2Taseen Junnat SeenNo ratings yet

- Lesson Plan Form Day 2 / 3 (4) Webquest Data GatheringDocument1 pageLesson Plan Form Day 2 / 3 (4) Webquest Data GatheringMarkJLanzaNo ratings yet

- Construction Quality Management 47 PDFDocument47 pagesConstruction Quality Management 47 PDFCarl WilliamsNo ratings yet

- Reflection Chapter 13 and 14Document2 pagesReflection Chapter 13 and 14Vanessa Zevallos HernandezNo ratings yet

- Lemonade by Jeremy Passion: Song Lyrics and Poetry: Student ChoiceDocument2 pagesLemonade by Jeremy Passion: Song Lyrics and Poetry: Student Choiceapi-330744576No ratings yet